21.07.2020

Let's consider one of the traditionally popular methods of restoring the original geometry of worn parts. The focus is on manual welding and arc surfacing: what technology is used to carry it out, what nuances arise, are there any pros, cons, features - we will try to answer every question.

Let us immediately emphasize that these methods remain relevant and continue to be used in industry, even despite the general tendency towards automation. They are used in hard-to-reach places that cannot be reached with the help of equipment, as well as for spot and/or complex work. But the main thing is that they make it possible to apply layers of metal with the required physical and mechanical properties onto the surface with sufficient uniformity and thereby perform repairs on the required product.

Features of surfacing technology using manual arc welding

The basic conditions for its implementation are the same as in the standard case.

- • Before performing the procedure, the surface of the part must be thoroughly cleaned so that there is not the slightest trace of rust or a single greasy stain left on it.

- • The selection of electrodes is carried out depending on the conditions under which the element being restored is operated; the most common options are for alloy steels, or special flux-cored wires for wear-resistant coatings.

- • Power sources are transformers and serial rectifiers.

The work process is accompanied by the application of rollers. They should be used alternately - so that the previous one overlaps the next one by a third of the width; you can apply them using the so-called transverse vibration method - exactly the same as when enlarging a welding seam. It is also acceptable to create gaps and then fill them (after removing slag and cleaning). The main thing is that in the end the entire worn surface is evenly covered with a layer that restores its original geometry.

If we compare the technology with classical connection welding, manual metal surfacing has one important difference: in its case, the applied material can seriously differ from the base one in its chemical composition. Therefore, it is so important to choose the right electrodes so that they help provide a suitable structure (uniform and durable). When this cannot be achieved, it is worth giving preference to other solutions, for example, applying alloying powders, pastes, briquettes or immersion in a protective gas environment.

In this case, various techniques can be used, including automatic ones. But in all situations it is necessary to minimize residual stresses, deformations and tolerances.

Surfacing of rail ends

Photo source: specserver.com

The operation of high-speed trains requires good condition of the rails. Wheel impacts lead to deformation, crushing and bending of the ends of the rails. Restoration by surfacing is a standard technique.

Before starting work, all flattened and peeled metal is removed from the rail. To do this, it is recommended to use a chisel, emery wheel or other tool. To increase the deposition rate, it is necessary to preheat the ends of the rails.

The following surfacing technologies are used on Russian railways to restore rail ends:

1. Manual arc surfacing is performed with a piece electrode of the K-2-55, OZN-300, OZN-350 brands. The rollers are applied in three ways: along, across the rail and diagonally. The best results are obtained when working with the second method. The average width of the roller is 24-30 mm. This value may vary depending on the diameter of the rod, current strength and other factors.

There is also the possibility of fusing a bunch of electrodes: 2-3 rods arranged in a comb. This method improves productivity. Surfacing should begin at the end of the rail by applying a bead. The arc is excited on the inside, making a small indent from the end. The deposition of the first bead is also completed by moving slightly away from the end of the rail. The ends of each of these rollers are brought to the end of the previous roller and the crater is sealed there. The overlap of adjacent rollers should be 1/5-1/6 of the width of the previous roller. The work ends with grinding the ends of the rails along the rail.

2.

as a filler material when performing semi-automatic electric arc surfacing . This method has several advantages compared to the manual arc method: high quality of work, significant labor productivity.

The work is carried out in stages:

- defect measurement;

- preparation of equipment for surfacing;

- removal of defects by grinding;

- installation of surfacing apparatus on rails and setting work boundaries;

- heating the working area;

- performing the main process - deposition;

- mechanical processing with an abrasive tool after natural cooling.

Surfacing is carried out in one or several words, depending on the depth of the defect.

What types of surfacing exist?

The variety we are considering is far from the only one of the current technologies. Therefore, we will pay attention to other options - also deserving the right to popularity - and then return to ours.

Submerged - carried out using wires - one or more, powder or solid, strip or round in cross-section.

In a protective gas - with immersion in a medium of hydrogen, nitrogen, argon; in this case, there is some overestimation of labor productivity - it is measured by the size, area or mass of the applied material.

Vibro-arc - the electrode is affected by vibrations with an amplitude of 0.75-1 of its diameter; this allows you to speed up the process and achieve a more uniform distribution of the restoration layer.

Electroslag - the coating is formed forcibly and strictly per pass, with convenient adjustment, due to which its total mass can reach hundreds of kilograms per hour (on dimensional parts); The performance of the method is impressive.

Plasma - with a compressed high-temperature jet as a heat source; The most common option today is a direct burner, although combined burners are also in demand. As an additive, you can take tape, wire, fine-grained powder, and the latter is especially convenient - it is easy to supply with gas and simply blow in, it quickly becomes liquid and spreads evenly over the surface.

Open arc - performed mechanically, without the use of a gaseous medium or flux. The method is quite universal and therefore makes it possible to restore even complex, concave or convex surfaces, small diameters and much more. Another area in which it is involved is the strengthening of products subject to consistently high loads.

Briefly about copper welding

Several types of copper welding process are used:

- manual welding with metal electrodes;

- manual welding with carbon electrodes;

- argon-arc welding.

Some features of the welding process with copper electrodes

- Welding non-ferrous metals can differ significantly from welding steel, which is caused by a sharp difference in physical and chemical properties. The main factors that determine the weldability of non-ferrous metals include melting and boiling points, as well as thermal conductivity and affinity for gases contained in the air (nitrogen, oxygen, water vapor).

- Copper has increased fluidity in molten form, high electrical and thermal conductivity. It is also characterized by activity when interacting with certain gases and, especially with hydrogen and oxygen, which during welding can cause the formation of microcracks and pores in the weld metal. To prevent the formation of such defects in the joints being welded, it is necessary to use only well-deoxidized copper.

- Welding on copper must be carried out with carefully calcined electrodes, the parts to be welded must be well prepared in the places where the seams are applied - cleaned to a metallic shine and oxides, contaminants, fats, etc. removed.

Manual arc surfacing: GOST and technical conditions

As a result of its implementation, the applied material may have the same properties as the base one, or others, thus changing the performance characteristics of the part. It all depends on the electrodes, and if in the first case they correspond to the interstate standard 9467-60, then in the second they correspond to 10051-62.

In standard situations, preference is given to “E” and “F” type rods. Particularly interesting are the options with calcium fluoride coating from the U and UONI series. Because they produce a fine-grained material characterized by high impact strength, and this is the key to the absence of cracks.

Please note that the technology of manual arc surfacing of steel depends on the chemical composition of the part. If the proportion of carbon in it is no more than 0.25%, work can be done at any temperature. But the higher the percentage of carbon, the more likely it is that hardening structures will appear at points of thermal impact. Therefore, products containing 0.25-0.5% C must be heated to 120-350 0C.

How many layers should I do? It depends on the overall thickness that needs to be maintained. It is important to ensure that their distribution is correct - so that the new one goes along the upper third of the previous one. Why? Because it is in this section that there are the fewest pores and foreign inclusions, which means it is best suited for creating a strong seam.

At what current is manual welding and surfacing of parts carried out? This is influenced by a number of factors, in particular, the brand and diameter of the selected electrode, the quantity, weight and height of the final coating. The smaller the product, the lower the amperage should be, and vice versa.

Deformations that arise during labor can be reduced; to do this, it is enough to make one or more (depending on the situation) of the following rational decisions:

- • heat the part to 200-400 0C;

- • bend the product in the opposite direction;

- • immerse the object in water, but do not wet the work surface;

- • arrange the rollers symmetrically (thereby balancing the force effects);

- • rigidly fix the workpiece in a jig or similar device - so that it can be removed only after cooling is complete;

- • correctly distribute the additive over problem areas, for example, in a spiral, with application on the reverse side, with a breakdown of large planes;

- • relieve internal stresses using high-temperature tempering - with heat treatment at 650 0C.

Surfacing of manganese steel crosspieces.

To repair manganese steel crosspieces, electric arc surfacing is used, which must be carried out by a qualified welder using appropriate electrodes

It is very important that the temperature of the manganese casting of the cross does not exceed 260 ° C, since otherwise the metal can become brittle and brittle. The electrodes should be of a type that would produce 12 to 14% metal deposition while maintaining an austenitic structure. Before surfacing, all damaged and hardened metal must be removed from the surface of the cross using a grinding stone.

The weld beads must be no wider than 19 mm and no longer than 76 mm; To relieve stress and prevent cracking, the metal of the roller is compacted with hammer blows. Temperature measurements are made frequently enough to prevent the casting temperature from increasing above 260° C. After the thickness of the deposited metal reaches the desired value, its surface is ground.

How does the process work?

Manual arc surfacing is performed using consumable or non-consumable (graphite, carbon, tungsten, hafnium) electrodes. The formation of a seam in the first case occurs due to the interaction of the applied material and the base metal (surface of the part), in the second - due to the additive. Option 1 is more popular, since it can be implemented in any spatial position, and it is suitable for workpieces and elements of any shape.

Attention, the coating of the rods can be very different, but in practice three are the most common. The specifics of performing the work for each of them are somewhat different, so we will consider everything.

Acidic substances are aluminosilicates, oxides and deoxidizing agents. When its components begin to melt, a protective gas is released. The nuances are as follows:

- • Welding can be carried out under both direct and alternating current. In both cases, the surface of the part is actively exposed to carbon, which causes the bath to boil (but this has a very positive effect on the quality of the joint). The seam turns out smooth and tight, even if the work was carried out on rust or scale.

- • The material is often heavily splashed, in the process harmful manganese compounds are released into the atmosphere, and there is a tendency for crystallization cracks to quickly appear. These shortcomings somewhat limit the use of electrodes OMM-5, OMA-2, TsM-7 and others from the same group.

The main ones are fluorspar, deoxidizers, marble, alloying additives like ferromanganese. When heated, carbonates dissociate and thus provide gas protection.

The use of manual arc surfacing using rods from the UONI, OZS, VN, VSOR series is quite convenient, since it allows you to obtain a restoring layer with a small amount of harmful impurities, but with high impact strength and ductility (even at sub-zero temperatures), resistant to aging and formation of cracks. This is an option for connecting rigid structures made of low-alloy, carbon, cast steels.

The downside is that pore formation increases significantly if:

- • increase the length of the arc;

- • moisten the contact surface;

- • oil, rust, and scale will appear on the edge of the product.

Work should usually be carried out with direct current, and its polarity should be reversed. The variable can only be connected when lightly ionizing elements are introduced into the coating (that is, soda ash, potassium liquid glass, potash and other additives).

Rutile is aluminosilicates, concentrate, ferromanganese, with gas protection due to cellulose. The rods used (from the OZS, ANO, MR series) help to form an even seam - with little spattering and formation of pores, with good slag separation - but require preliminary calcination for 2-2.5 hours at a temperature of 80-120, 200 -250 or even 300-350 0C.

Attention, the technique and technology of manual arc surfacing with coated electrodes involves the participation of the base metal in the creation of the restoring layer. Its share usually varies in the range of 0.3-0.45 m - this is enough to maintain a stable arc. This value can be reduced (thus minimizing the loss of the original geometry of the part) due to transverse vibrations - use them and bring m to 0.25. But remember that further reduction is undesirable, since along with it the likelihood of lack of penetration will proportionally increase.

When using graphite or carbon rods, it is recommended to work at direct current with straight polarity and make one restoration layer: to make it 2-3 mm thick, 6-8 mm of additive should be applied.

Surfacing of parts exposed to abrasion with impact loads and without impact loads

Products operating under conditions of intense surface wear and high shock loads must be overlaid with electrodes of the following brands:

Welding electrodes for surfacing OZN-400M

Advantages of OMG-N: they comply with state standards, deposition can be carried out with direct and alternating current of reverse polarity.

TsNIIN-4 is one of the most popular and popular brands.

Metal deposited with OZN-7M rods during multilayer deposition has increased resistance to cracking.

Advantages of OZN-400M: high productivity, deposited metal is characterized by increased hardness.

Advantages of OZN-300M: the deposited metal has increased stability of wear resistance and hardness; surfacing is performed with direct and alternating current of reverse polarity.

An example of such parts is elements of construction and earth-moving equipment.

For surfacing parts exposed to abrasion and without shock loads, the following grades of electrodes are used.

To obtain a deposited layer of special hardness, it is necessary to use surfacing electrodes T-590 and T-620. These brands are intended for repairing parts subject to intense abrasion. Thanks to a special coating, which includes ferrochrome, ferrotitanium, ferroboron, boron carbide and graphite, the hardness of the deposited metal can reach 62-64 HRC. Metal deposited with T-590 and T-620 materials is brittle and prone to cracking, and is therefore not intended to withstand significant shock loads. Fusing is carried out in 1-2 layers.

Repair of products made of various metals and alloys also has its own specific characteristics.

Equipment for manual arc surfacing

The power source can be a step-down transformer: at a low output voltage it will give a large amperage, which is convenient. Rectifiers are also often chosen: by converting them, instead of the standard “mains” 220 V and 50 A, it is quite possible to get 600 A at 17-45 V. Inverter machines are also quite popular - due to their relatively small weight and size. Electric generators are becoming portable connection points, but they are quite expensive to operate, which limits their relevance.

The specialist performing the work must protect himself from accidental injuries - wear gloves and a mask with a “chameleon” light filter, which protects the eyes from the harmful effects of UV radiation.

Materials for manual arc surfacing deserve special attention. These are either electrodes, or wires and tapes, or hard alloys. We have already considered the first two options, let's take a look at the third.

Most often these are boride- and carbide-forming metals such as manganese, chromium, titanium, tungsten, combined with iron, nickel, boron, cobalt, both in powder and cast form. A typical representative of the first category is stalinite, the second is rod sormite.

Cases in which they are relevant:

- • restoration of machine tools and production mechanisms;

- • creation of stamps;

- • repair of parts used under severe wear conditions.

Manual arc surfacing modes

You need to choose one of them based on a number of parameters - additional and basic, which ultimately determine the size and quality of the seam.

The main characteristics are:

- • current strength - in general, it should be higher, the thicker the diameter of the electrode and the base metal;

- • arc voltage (length), defined as the distance from the end of the rod to the surface of the workpiece - it is important to keep it short and stable;

- • speed – the faster the work is done, the less spreading of the material, but the higher the risk of lack of penetration, so it is necessary that the process occurs evenly;

- • type and polarity of the current – reverse is relevant for thin-sheet and high-alloy items (so as not to burn or overheat them), direct – for massive parts.

Additional parameters include the number of passes, the thickness and chemical composition of the applied layer, and the location of the joint.

Consumption of materials

To determine the cost of the finished product, it is important to correctly calculate the consumption of surfacing materials. Calculations are carried out in accordance with accepted standards for each specific type of work and materials. Also, knowing the exact quantity of necessary consumables can ensure process continuity and create reserves of materials.

Calculation of deposited metal during welding is one of the main indicators. There is a special formula to determine the value of this coefficient. The mass is calculated per 1 meter of weld. How to determine the mass of deposited metal during welding will be analyzed further:

G = F * y * L, where: F – cross-sectional area of the weld (in mm2) y – specific gravity of the metal (g/cm3) L – length of the weld is 1 meter.

Thanks to this formula, any performer will be able to calculate the mass of deposited metal during welding.

Calculation of electrodes for surfacing is also a significant quantitative parameter. The performer does not need to perform calculations to determine this value. Each brand of welding materials has its own indicator - electrode consumption during surfacing of 1 kg. metal varies from 1.4 to 1.8 kg.

to calculate the mass of deposited weld metal per linear meter. According to GOST, each form of weld made of carbon and low-alloy steels, performed by manual electric arc welding with a metal consumable electrode and welding in carbon dioxide, has an average value of this parameter.

Types of manual welding and surfacing

There are several parameters by which they are classified.

For example, there is a common division:

- • by the nature of the arc – compressed (short) and free (long);

- • according to the type of electrode used – with a melting rod (coated) and not;

- • according to the effect on the base metal of the part - direct, three-phase, indirect.

They are also grouped according to the result, that is, according to the restored layer - into:

- M – thin;

- C – average;

- D – thick;

- G – especially thick.

They are classified separately by purpose - options for connection are distinguished:

- • low-alloy and carbon steels;

- • alloyed and heat-resistant;

- • alloys with special properties;

- • layers with non-standard characteristics.

Now we will schematically consider the main methods of manual arc welding and surfacing:

They use:

A – carbon electrode (1) and bulk alloy (2);

B – coated (1) and alloying layer (2);

B – tungsten conductor (1) and filler rod (2) in inert gas;

G – rod (1) in a protective environment;

D – wire (1) and flux (2);

E – tape (1);

G – plasmatron jet (1) and powder (2), already sintered or applied;

Z – conductor (1), copper slider (2), workpiece (3), restoring coating (4).

The choice of a specific option depends on the specific conditions in which the work is carried out, on the planned result and on the required productivity. But each of them can be implemented quite simply and quickly.

Application

Cellulose-coated electrodes are used for welding carbon and low-alloy steels. Their small thickness allows them to be used when working with hard-to-reach structures. Often used for welding main pipelines.

The cellulose coating ensures stable burning of the welding arc both at alternating and direct current. But for better welding, it is recommended to use a current of direct polarity. This way the arc will melt the metal more powerfully, eliminating the possibility of undercuts and pores forming.

When using cellulose electrodes, several nuances should also be taken into account:

- You cannot weld structures made of hardening steels that contain a lot of carbon and alloying elements;

- When preparing electrodes for work, they must be calcined strictly at the temperature specified by the manufacturer. In addition, some (for example, Bohler) strongly do not recommend calcining the electrodes at all. Therefore, it is recommended to clarify the need to prepare rods and the necessary parameters for this in each case.

IMPORTANT! The electrodes must not be overheated during calcination, since they must maintain a humidity level of 1.5 to 5.0%.

If the electrodes are heated at temperatures above 170 °C, they become significantly overdried. As a result, the deposited metal will be more saturated with carbon.

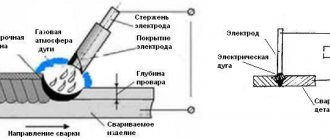

Manual arc surfacing of metal: diagram

It looks like this:

And in it:

1 – part with base metal;

2 – bath in which operations are carried out;

3 – electric arc of a certain length (preferably stable);

4 – fused layer;

5 – restorative coating;

6 and 7 – solidified and liquid slag, respectively;

8 and 9 – rod, already melted (8) and not yet (9);

10 – holder.