Basic manufacturing methods

Blanks for the products in question are obtained by forging or casting, in some cases using cutting technology. The technological process of manufacturing a gear is quite complicated, since it is necessary to obtain a working surface of complex shape with certain geometric parameters. Helical wheels and other products are cut using two main technologies:

- The copying method involves milling, in which a cut between the cavities of the teeth is formed by using disk, modular or end mills. After each cavity is formed, the workpiece is rotated exactly one tooth. Among the features of this technology, it can be noted that the shape of the cutting tool used follows the shape of the cavity.

- The break-in method is much more common today. In this case, machining involves simulating the engagement of a gear pair, one element of which is a hob cutter. In the manufacture of the tool, high-strength metal is used, due to which cutting occurs. Processing by the copying method involves the use of not only a hob cutter, but also a cutter and a comb.

Hob cutters have become quite widespread. A similar tool is represented by a rack; at the time of operation, the workpiece rotates around its axis. The tool is used to produce exclusively gears with external teeth.

Rolling technology is used to produce large gears as well as large quantities. In this case, hot rolling is carried out; due to heating, the degree of workability of the material increases. The crown is obtained by extrusion. To significantly improve accuracy, mechanical processing can be carried out.

The manufacture of shaft gears must also be carried out taking into account operating conditions. There is a high load on this element, so a workpiece made of high-strength hardened steel is used as a base. The toothed gear, the manufacture of which is carried out taking into account the diameter of the shaft, is mounted using the pressing method, fixation is ensured by a key.

Production of non-standard hardware

Our bolt production is focused on producing not only standard, but also non-standard (special) products. For example, stainless steel bolts: their processing by cold deformation is quite complex and requires special knowledge. Or high-strength bolts, which, in addition to professional stamping, must also undergo complex heat treatment. We also suggest that you make self-locking bolts, under the head of which an additional toothed plane is “hidden” to prevent the fastener from self-unscrewing.

Thread rolling in bolt production

In the production of bolts for critical connections, thread production is most often carried out by rolling. Responsible, for example, are flange connections for the energy, oil and gas and chemical industries.

Rolling - Stages and schemes of rolling

Thread rolling of bolts and studs is a technological process of forming threads on a workpiece by means of its elastic-plastic deformation with a special tool (rollers, dies, etc.). Thread rolling is a type of metal forming.

Thread rolling temperature in bolt production

Depending on the

- mechanical characteristics of workpiece materials,

- tools,

- energy capabilities of thread rolling equipment

Bolt thread rolling can be carried out:

- at normal temperature or

- elevated temperature, under conditions of superplasticity

- and in other modes.

Under the influence of external forces, deformation of the bolt workpiece material occurs; therefore, it is worth taking into account the dependence of the movement of the workpiece material on time.

Main characteristics of thread rolling on fasteners:

- physical parameter for the manufacture of bolt threads - radial elastoplastic or residual movement of the tool turns in the body of the workpiece (or the corresponding radial load on the workpiece during rolling),

- The technological parameter of thread rolling in the production of bolts is the duration of the rolling process.

Rolling process

The process of rolling bolt threads with rollers occurs in two stages:

- extrusion (section AB in Figure 1);

- calibration (section BC in Figure 1).

Figure 1. Making bolts. Curves of changes in the radial displacement of the movable thread rolling roller (1), rolling force 2), torque on the roller 3) and temperature in the contact zone of the tool with the workpiece during rolling 4)

The speed of tool penetration during extrusion can be determined by the radial feed - the amount of radial movement per one revolution of the threaded fastener workpiece:

Sr = dδ/dn.

Figure 2. Thread profiles during rolling with small (a) and large (b) radial feed a) Sr = 0.01 mm/rev; b) Sr = 0.60 mm/rev

Experiments show that with a small radial feed when rolling threads onto bolts or studs, grooves are formed at the tops of the thread turns (Figure 2, a), which gradually disappear or roll up, forming radial folds.

When rolling with rolling with a larger radial feed, the deformation spreads over the entire thickness of the coil, causing a uniform rise in the metal of each compressed section (Figure 2, b). The rise of the metal is proportional to the radial load on the workpiece and, as a consequence, to the depth of penetration of the tool turns into the workpiece. Extrusion ends after implementation:

- predetermined radial penetration (movement) of tool turns into the body of the bolt workpiece or

- achieving the set value of the radial load on the bolt workpiece (rolling force).

With further movement (rolling or rotation) of the bolt workpiece, the resulting thread is calibrated (section BC on curve 1, see Figure 1) with insignificant radial penetration of the tools into the body of the workpiece.

The duration of extrusion during the manufacture of threads for bolts and studs is determined:

- design parameters (for example, thread profile height) and

- physical parameters (elastic-plastic characteristics of the workpiece material, strain rate).

The calibration duration, which directly determines the thread accuracy of bolts and studs, can be freely set by the bolt manufacturer.

To prevent rolling of threads in a filled contour and to prevent crushing of the workpiece under high forces, a stop is used that limits the maximum movement of the movable roller and absorbs excess load.

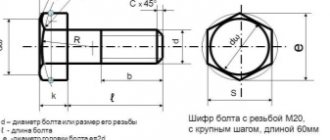

Types and characteristics of bolts

Bolts are cylindrical rods with a helical groove at one end and a head at the other, designed to create detachable connections. According to the shape of the head, bolts are of the following types:

- Hexagonal;

- Round;

- Oval;

- Square.

The head profile can have a semicircular or countersunk shape, depending on the purpose and area of application of the hardware.

The most widely used are bolts with hexagonal heads, which are used in connections experiencing loads of various types - static, cyclic and dynamic. Such products are actively used in the automotive industry for connecting parts operating in difficult conditions - fastening connecting rods, crankshaft covers, connecting cylinder heads, as well as chassis elements.

Universal steel bolts are distinguished by the following characteristics:

- Diameter of thread and smooth part of the rod;

- Thread length and total rod length;

- Head diameter – normal or reduced.

There are three classes of bolt manufacturing accuracy - rough, normal and increased. According to this indicator, hardware is distinguished by the accuracy of its geometric dimensions, the amount of deviation from the nominal shape, as well as appearance defects, which are regulated by the provisions of the interstate standard GOST 1759.0-87.

The most common bolts have metric screw threads, which are applied to the outer part of the rod. The shape of the grooves and protrusions forms an isosceles triangle. The unit of measurement is millimeters. Hardware with pipe, trapezoidal, thrust or rectangular threads are much less common.

Technical conditions and types of coatings

The technical conditions specified in the GOST 1759.0-87 standard apply to bolts, screws, studs and nuts with metric threads with a diameter of up to 48 mm. According to the provisions of the document, hardware products may have a decorative or protective coating, the type and thickness of which corresponds to GOST 9.303. The most popular types of coatings are:

- Zinc is the most common anti-corrosion coating, which provides anodic protection of steel from atmospheric influences at normal and low temperatures;

- Cadmium is rare in modern industry due to the toxicity of this chemical element and its compounds. At the same time, the performance properties are comparable to zinc coating.

- Nickel is cathodic in relation to steel, so the coating is used to improve the visual quality of hardware. The main area of application is furniture production;

- Phosphating is a chemical treatment of the surface with special compounds, resulting in the formation of a phosphate film with high protective properties. The type of crystal structure depends on the quality of the base preparation;

- Oxidation – the formation of an oxide film on the surface of bolts, the protective properties of which are close to those of a phosphate coating.

The best characteristics are provided by zinc lamellar coating, which does not contain hexavalent chromium. Protective properties are provided by aluminum and zinc lamellas.

During the batch acceptance process, control samples of products are checked for compliance with the following mechanical characteristics:

- Tensile strength is the ratio of the maximum load to the initial cross-section.

- The yield strength is the lowest stress at which deformation of the material occurs without a noticeable increase in tensile load.

- Relative elongation is the ratio of the length of the sample after rupture to the initial value.

- Brinell hardness is the ratio of force to indentation area left by the identifier.

- Impact strength is the total work expended on the deformation and destruction of a previously prepared sample.

Current standards

The nature of the technological process for producing bolts depends on the type of product and current standards. Let's consider the main regulatory documents.

| Product accuracy | Standard | Application area |

| Hex Bolts | ||

| A | GOST 7805-70 | Versatile fastener for a wide range of applications in a variety of construction materials, including stainless steel bolts, titanium bolts, and brass fasteners |

| IN | GOST 7798-70 | |

| WITH | GOST 15589-70 | |

| High strength bolts | ||

| IN | GOST 22353-77 | Used to connect critical structures that are subject to additional reliability requirements |

| Oversized Carriage Bolts | ||

| WITH | GOST 7802-81 | Furniture bolts, which are used in assembly plants. Alternative application – joining hardwood and softwood structures |

| Hex head reduced bolts | ||

| A | GOST 7817-80 | Precision fit bolts designed to fit into reamed holes without clearance |

| Self-anchoring expansion bolts | ||

| – | GOST 28778-90 | BSR bolts are steel self-anchoring spacer bolts with a jamming element, designed for fastening pipelines, technological structures and equipment to monolithic foundations made of various building materials |

| Hinged bolts | ||

| B/C | GOST 3033-79 | Fastening element with a spherical head, designed for creating detachable quick-release threaded connections |

| Foundation bolts | ||

| – | GOST 24379.1-2012 | A relatively modern standard that regulates the process of manufacturing anchor foundation bolts, which are used for fastening building structures, as well as technological equipment in industry |

Equipment used for hot die forging

Special equipment is used to process metal parts using hot die stamping:

- hammer dies;

- hot stamping crank presses;

- horizontal forging machines.

The most common are double-action steam-air hammers and single-action driven friction hammers. The essence of their work lies in the shock nature of the deforming effect on the workpiece.

High-quality redistribution of metal is achieved by simultaneous regulation of the stroke of moving parts and impact force together with tilting of the workpiece. Hammers are relatively inexpensive equipment.

In the GOSH process, crank hot stamping presses are most often used.

Crank Hot Forging Press

The distinctive features of the stamping press design include a rigid drive, which does not allow changing the direction of the slide, and the absence of shock loads.

Forgings produced on presses have higher accuracy due to their rigid motion, especially in height. This reduces the appearance of machining allowances (the main advantage of a press over a hammer).

However, there are also disadvantages. In the absence of preliminary cleaning of the workpiece from scale, it is pressed into the body of the forging. When the heated metal comes into contact with the walls of the press, the workpiece cools due to the large amount of time spent on the deformation process.

Upsetting of metal blanks

Metal upsetting

To manufacture a rod-type part, such as a bolt, a forging that is thickened at one end is required and is produced by upsetting. The upsetting end of the billet of the required length is heated in a forge or slot furnace to forging temperature. The blacksmith places the workpiece on the anvil with the heated end up (Fig. 6.4, a) and uses a handbrake to show the hammer the places of impacts and their force. If it is necessary to plant a small area of the workpiece, but most of it has heated up, then the area not subject to planting is cooled by dipping it in water. Under the blows of a sledgehammer, the heated part of the workpiece is deformed, increasing in diameter and decreasing in length. The cold part of the workpiece, which has tens of times greater resistance to deformation, retains its original shape. Since the flow of the metal of the heated part of the workpiece along the perimeter is not limited by anything, under the influence of impacts the end of the workpiece takes on a barrel-shaped shape, smoothly turning into the lower cylindrical undeformed part.

If the workpiece is placed with the heated end on the anvil and blows are applied to the cold end, then the upset part will be higher and the diameter will be smaller than in the first case. It is obvious that it will not be possible to carry out the upset of the end of a long rod workpiece using the considered method, since the workpiece will lose stability and bend under the influence of impacts. Therefore, end upset on relatively long workpieces is performed using a flat nailer. Nail 2 is installed above the hole in the tail part of the anvil (Fig. 6.4, b), and workpiece 1 is passed through the hole in the nail. Under the influence of the sledgehammer, the protruding part of the workpiece is subject to upset. In the manufacture, for example, of bolts with square heads, a nailer with a corresponding recess is used (Fig. 6.4, c).

Rice. 6.4. Upsetting the end of the workpiece: a - in the usual way, b, c - using a nailer, d - direction of the fibers in the workpiece after upsetting; 1 - blank, 2 - nail, 3 - anvil

As the workpiece settles, the cross-section of its end part increases, and the metal fills the cavity of the nail house. It is obvious that the fibrous structure of the undeformed part of the workpiece remains unchanged after upsetting, while the fibers of the upsetting part will seem to follow the shape of the head (Fig. 6.4, d).

Upsetting the middle of the workpiece is also a type of upsetting. The middle upsetting part of the workpiece is heated to forging temperature in the forge, the workpiece is placed vertically on the anvil and, holding it in this position with pliers, blows are applied to the end with a sledgehammer (Fig. 6.5). These impacts are transmitted through the cold part of the workpiece to its middle part and it, being the hottest part, is deformed, acquiring a barrel-shaped shape. If the ends of the workpiece also become heated during heating, then before upsetting they are cooled with water to the required length.

What are bolts made of or everything about steel!

Articles » What are bolts made of or everything about steel! Steel is an alloy of iron and carbon (up to 2% C). According to the chemical composition, steel is divided into carbon and alloy, and according to quality - into ordinary quality steel, high quality steel, high quality steel and high quality steel. Carbon steel of ordinary quality is divided into 3 groups: A - supplied according to mechanical properties and used in most cases when the product made from it is subjected to hot processing (welding, forging, etc.), which can correct the regulated mechanical properties (St0, St1, etc. .); B - supplied by chemical composition and used for parts subjected to such processing in which the mechanical properties change, and their level, in addition to the processing conditions, is determined by the chemical composition (BSt0, BSt1, etc.); B - supplied according to mechanical properties and chemical composition for parts subject to welding (VSt1, VSt2, etc.). Carbon steel of ordinary quality is produced in the following grades: St0, St1kp, St1ps, St1sp, St2kp, St2ps, St2sp, StZkp, StZps, StZsp, StZGps, StZGsp, St4kp, St4ps, St4sp, St5ps, St5sp, St5Gps, Stbps, Stbsp. The letters St stand for “Steel”, the values are the conventional number of the brand as follows from the chemical composition, the letters “kp”, “ps”, “sp” are the degree of deoxidation (“kp” - boiling, “ps” - semi-calm, “sp” - calm). High-quality structural carbon steel, according to the type of processing upon delivery, is divided into hot-rolled and forged, calibrated, round with a distinctive surface finish - silver. According to the requirements for testing mechanical merits, steel is divided into 5 categories.

Category 1 Without tensile and impact strength testing of mechanical properties Hot rolled, forged, calibrated, silver

Category 2 With testing of mechanical properties for tensile and impact strength on samples made from normalized blanks measuring 25 mm (diameter or square side) Hot rolled, forged, calibrated, silver

Category 3 With tensile testing of mechanical merits on samples made from normalized workpieces of the size specified in the order, although a maximum of 100 mm Hot rolled, forged, calibrated

Category 4 With testing of mechanical properties for tensile and impact strength on samples made from thermally treated (hardening + tempering) workpieces of the size specified in the order, although a maximum of 100 mm Hot rolled, forged, calibrated

Category 5 With tensile testing of mechanical properties on samples made of steels in a cold-worked or heat-treated state (annealed or highly tempered) Calibrated

Alloy steel according to the degree of alloying is divided into low-alloy (alloying elements up to 2.5%), medium-alloy (from 2.5 to 10%), high-alloy (from 10 to 50%). As follows from the main alloying elements, steel is divided into 14 groups. High-alloy steels include: corrosion-resistant (stainless) steels and alloys that are resistant to electrochemical and chemical corrosion; intergranular corrosion, stress corrosion, etc.; heat-resistant (scale-resistant) steels and alloys that are resistant to chemical destruction in gas environments at temperatures above 50 ° C, operating in an unloaded and lightly loaded state; heat-resistant steels and alloys that operate under load at high temperatures for a certain time and, at the same time, have the required heat resistance.

Where to begin?

I started doing turning work using a regular hand drill with a manual drive (with a handle on the side;-), this was about 20 years ago). The drill shank was clamped in a vice, a workpiece was inserted into the chuck (a polystyrene or wooden rod, sometimes aluminum, as well as brass and steel - but this is very rare) and ground to the required shape. Later I switched to an electric drill, and then to a laboratory mechanical stirrer. All this equipment has disadvantages. Hand drill - you do all the work with only one, right (left-handed-left), hand, and the left (right) pumps up well (;-)). The revolutions of the workpiece are also determined by your capabilities, as is the duration of the “approaches” of work.

Electric drill - the length of the workpiece is limited, up to a maximum of 10 cm, and then with difficulties (I will explain why below), mechanical stirrer - the maximum clamping diameter is 7.5 mm, but the shaft is hollow, you can easily process workpieces of 20-25 cm, and sometimes more, if the rear end of the workpiece is secured against beating. Replacing the cartridge will not help, since 7.5mm is the internal diameter of the hollow shaft. Now I have completed an installation consisting of a hollow shaft with an internal diameter of 15 mm, mounted on 3 bearings, and a cartridge with a maximum clamping diameter of 13 mm, driven through a belt drive by a 220V selsyn motor with a speed control module. The latter is very useful, as is the use of a synchronizer - it is easy to control the speed (from 10 to 2500 on my engine), and change the direction of rotation using one toggle switch. The big “+” of the synchronizer is that it does not lose power when the speed decreases. Unfortunately, I can’t provide a photo yet; everything at the factory is being modified to fit a steel plate-frame. According to experience, for processing wood and polystyrene, 1000-1200 rpm is optimal (if more, the wood burns and the polystyrene melts); duralumin, brass, steel – 1800-2200. The main requirement for such drives (let's call them that) is the maximum possible absence of backlash, both axial and, especially, transverse.

By the way, regarding machines, purchased ones do not always give the best results, especially if they are made in the Middle Kingdom. Plastic structural elements (especially the bed and frame, see the Unimat advertisement in M-Hobby) allow you to safely refuse to buy one; the rigidity is insufficient. And not all aluminum alloys provide the necessary structural rigidity (especially if they save on production in order to reduce the cost). I have seen quite good machines made in Germany (the same Proxxon PD230 and PD400) and the Czech Republic, as well as quite normal products from the Middle Kingdom (there are a lot of them there, but they are brought to us extremely rarely) at prices ranging from $1,500 and above, which Not accessible to all modelers, not even beginners. Buying at foreign auctions and online stores is also not always good and convenient - delivery can cost 50 (it’s still very cheap!) or more dollars. And then it is necessary to deliver not by mail, but by carriers such as UPS, DHL, FedEx, and this is even more expensive.

Technological production of bolts

There are two fundamentally different methods for manufacturing this type of fastener:

The bolt manufacturing process, regardless of the method, consists of the following steps:

Quality control is carried out at all stages of production. When manufacturing hardware according to an individual drawing, the first manufactured part is checked with the most careful control. If deviations from the technical specifications are detected, the bolt manufacturing process should be reviewed and the cause of the discrepancy should be found.

Manufacturing on a screw-cutting lathe

The stages and methods of processing a workpiece depend on the type of source material (hexagonal or cylindrical rod, characteristics of the metal), as well as on the degree of accuracy of the workpiece. Hot-rolled blanks have less accuracy, which eliminates the possibility of precise centering of the future part on a turret lathe or on a CNC machine.

The technological process of manufacturing a bolt part on a lathe from a cold-drawn hexagonal rod is divided into several stages:

If there are special requirements for the hexagon of the head of the part, the technical process of manufacturing the bolt on a lathe becomes more complicated. To prevent displacement of the head axis relative to the cylinder axis, the workpiece is subjected to additional processing.

Manufacturing of bolts by cold stamping

The first stage of the technical process is preparing the metal for the stamping process:

Scale from the surface of metal workpieces is usually removed by etching. To do this, the rod is immersed in a solution of sulfuric or hydrochloric acid of a certain concentration for a period of 5 minutes to half an hour. To eliminate pickling sludge, the workpieces are washed in hot water. If the etching was carried out using a sulfuric acid solution, the residues are washed off and neutralized by liming the rod.

The production of bolts from a metal rod occurs without heating the metal. The deformation of the workpiece during cold stamping is accompanied by cold hardening—an increase in the mechanical strength of the metal. The finished part is obtained by filling a standard die of a given configuration with the workpiece material. Next, the part is upset—the finished metal hardware is removed from the die.

Advantages of the cold stamping method in the production of bolts:

When choosing a cold stamping method, you should take into account the ratio of the size of the head and the diameter of the rod of the part, as well as the ratio of the diameter of the head to its height and indicators of relative and true deformation. If the ratios for the listed quantities are higher than the critical values, the possibility of manufacturing the part by hot stamping should be considered.

Blank for making fasteners - what should it be?

Before starting the bolt manufacturing process, it is necessary to determine its main parameters:

- Thread diameter (varies from 1.6 to 160 mm).

- The diameter of the area of the stud where there is no thread.

- Wrench fastener size (usually 1.3-1.4 stud diameters for hex hardware).

- Stud length, thread length.

- The presence of holes, slots, recesses in the head.

- Level of manufacturing accuracy (high, normal, rough, classes A, B and C, respectively).

A steel billet is used as the material for the future bolt. Depending on the purpose and strength class of the hardware, different types of steel are used:

- Alloy steel grades A2 and A4.

- Steels are hardened and tempered, with additives of boron, manganese or chromium.

- Corrosion-resistant steels (grades 20Х13, 20Х18Н10Т).

Bolts are made from non-ferrous metal alloys (copper, brass, bronze). Blanks for further threading on the machine can be purchased at fastener stores. In production conditions, blanks are made on an industrial scale by stamping. When making a bolt on a lathe, a steel rod having a hexagonal or cylindrical shape is used as the starting material.

Higher demands are placed on the quality of blanks for factory stamping. When assessing the quality of raw materials, the following parameters are checked:

- Steel ductility, strength and anti-corrosion characteristics.

- Presence of structural defects (gas bubbles, inclusions of non-metals, surface irregularities).

Blanks for cold stamping are preliminarily cleaned of external defects mechanically or by calcination. To remove rust and grease, the workpieces are kept in a solution of sulfuric acid or concentrated hydrochloric acid. The cleaned workpieces are subjected to liming, then a lubricant is applied. Only after all of the above manipulations are the raw materials supplied for stamping. For hot stamping, blanks are cut using band saws. The raw materials are checked just as carefully as in the case of cold stamping.

Cold stamping production

The production of bolts using this method requires certain parameters of the raw materials. These include plasticity, uniform composition, mechanical characteristics, absence of external and internal defects (non-metallic inclusions, porosity, scratches and captivity on the surface, gas bubbles).

Surface defects are removed mechanically or by fire. Next, contaminants such as scale and grease deposits are cleaned. The latter is removed by etching, which involves immersing the material in a 10–20% mixture of sulfuric acid or concentrated hydrochloric acid. In the first case, the procedure lasts 15–110 minutes, in the second – 10–30 minutes. Next, they are washed to remove sludge and acid successively with hot and cold water.

Afterwards liming is carried out. In some cases, a lubricating layer is created. Next, for workpieces made of low-alloy steels, phosphating is carried out by using usually a 3% mixture of zinc phosphate salt for 10–15 minutes.

Finally, a lubricant is applied, represented by a mixture of machine oil and molybdenum sulfide or paraffin liquid and ukrinol. Instead, you can use soap emulsion. The final operation is drawing.

Cold stamping involves turning a blank into a product with planned geometric parameters. The name of the technical process reflects that in this case heating of the metal is not used. This reduces elongation and contraction of the material, as well as increases hardness, strength and fluidity. In addition, during the considered stamping of blanks, the material is mechanically strengthened.

This technique has some advantages. Firstly, with its use it is possible to create products of various sizes (up to 5.2 cm in cross-section). Secondly, cold forging provides high productivity. Thirdly, this manufacturing technology uses little material. Fourthly, it ensures final dimensional accuracy, surface finish and part strength.

For cold stamping there are several defining parameters:

- Workpiece deformation. This is the main parameter that determines the technological map.

- The ratio of the height of the head to the cross-section of the final product. Determines the complexity of production.

- The ratio of the cross-section to the length of the upsetting workpiece fragment.

The technological process for manufacturing a bolt according to the above method includes several stages. At the first stage, the initial shape of the head is created. This is done by rolling wire through different molds. The first rolling is aimed at straightening and lengthening it. After rolling, the source material is divided into blanks with a reserve for heads. Next, a core is formed for each fragment by passing it through a press, and the heads are also formed using a number of presses.

The final stage consists of applying the chamfer using roller processing at high speed and under high pressure. Finally, the threaded edge is beveled using a sharpening machine.

The last two operations are carried out by plastic deformation or cutting. Most often, the second technology for producing bolts is used using devices integrated into cold heading mechanisms.

The most commonly used option is single reduction. It is used in the production of alloyed low- and medium-carbon alloys. In addition, this method produces bolts with equal rod diameter and thread section. Reduction is avoided in the manufacture of short products with small heads and threads with a strength of 4.8–6.8. In this case, additional heat treatment is usually not carried out. This manufacturing technology is rarely used, since in this way it is difficult to produce bolts with standard heads, and this often leads to the formation of cracks and other defects on them.

Double reduction technology is relevant for bolts with strength from 4.6 to 10.9 made of alloy steels and medium-carbon alloys. At the initial stage, the rod is compressed by 30%, at the second stage the fragment is processed for threading.

The technology with extrusion before reduction is suitable for the production of high-strength bolts with a resistance of about 100 kg/mm2 without subsequent heat treatment, which reduces the cost of production.

Technology and features of bolt production

In the mass production of bolts, cold stamping technology is used, which makes it possible to obtain products of proper quality in large volumes.

The stability of the technological process largely depends on the quality of the workpieces. Surface defects can lead to cracks and tears during the stamping process. To reduce the rejection rate, the workpieces are pre-cleaned mechanically or by fire.

Preliminary heat treatment of the workpiece allows for the least decarburization, which reduces the likelihood of the formation of deep marks and scratches. To remove an oxide film that can cause premature wear of technological equipment, they resort to etching the surface with acid solutions, followed by washing under pressure with cold or hot water. To neutralize acid residues, it is permissible to use liming at elevated temperatures. This procedure also helps reduce the coefficient of friction during sizing or cold forming.

Small-scale production of bolts using turning, milling, drilling and grinding machines begins with the development of a technological map with the calculation of workpieces, allowances and cutting conditions.

The production of non-standard bolts is a sought-after service for many manufacturing enterprises that are improving technological processes. To produce a new type of product, hardware of an original shape or increased strength is sometimes required. Construction organizations often order the production of foundation bolts and anchor bolts of non-standard design, in accordance with the characteristics of the production site and the conditions of the work.

To obtain high-precision parts, it is recommended to use CNC machines that can accurately maintain specified dimensions. It should be taken into account that for each type of bolt it is necessary to configure a new program, which reduces work productivity.

Recently, the range of turning equipment suppliers has expanded significantly. Now you can easily order a small-sized bolt production machine and do the work yourself. It is also possible to purchase a compact automatic line, the overall dimensions of which are selected based on the area and characteristics of the production site.

Prices for different types of bolts

The main factor influencing the final cost of the product is the scale of production. With an increase in output, due to cost optimization, the cost of production decreases. The mass production of bolts and nuts is carried out by large domestic and foreign enterprises equipped with automated production lines. They cover the needs of various sectors of the national economy for standard products.

Small manufacturing enterprises equipped with universal turning equipment are focused on the production of hardware in batches of up to 1000 units. The technological process requires significant labor costs compared to mass and serial production, which leads to higher prices for products. The advantages of single production include a wide range of products - if necessary, small companies are able to quickly satisfy any customer need regarding the production of non-standard grade hardware.

Other factors influencing pricing include the type of material used, accuracy class, and type of protective anti-corrosion coating.

Benefits of custom fasteners

If you require high strength fasteners, then you have come to the right place. All our products are manufactured in accordance with GOST, which is a guarantee of quality and allows them to be used for fastening the most critical parts and assemblies.

In addition, TC “Dogma-Krep” can produce fasteners of non-standard shapes and sizes according to customer drawings! We work with each client individually, calculating the cost of manufactured products depending on the complexity of the order and its size. We work quickly, efficiently and in the interests of the client! Contact us, we are always glad to see you!

Bolts and nuts were still used by the Romans during the heyday of their unique civilization. Today it is impossible to imagine how many bolts and nuts in the form of fastening material are used every day in the world. According to experts, 275 of them are required for just one refrigerator. A forklift contains 940, a railroad car contains 1,200, a regular passenger car contains 3,500, and the average jet contains 1.5 million. It is also estimated that 40 percent of all costs fall on the production of hardware.

Making bolts

was put on an industrial basis thanks to the discovery of a thread cutting method. And now in small workshops they use these lathes to turn a bolt and cut threads on it for a car or tractor. But you can't do much with this method. At the end of the 19th century, the American Ward.W made a machine that ensured the production of nuts and bolts in a continuous manner. A metal rod of the required diameter heated to 900 degrees was supplied to special dies. Rolling dies extruded threads in the hot metal. This was the beginning of the continuous production of hardware.

However, this method did not promise high precision thread cutting. To eliminate the shortcoming, the ubiquitous Ward came up with a machine on which threads were cut using the method of cold plastic extrusion of the relief. He significantly strengthened the dies. and made the machine more massive. It should be noted that this method has been preserved to this day with some changes and innovations. That is, cold rolling is the basic principle of bolt production. The production of nuts occurs using approximately the same method. The technology includes a simple but productive scheme. Wire of the required diameter is continuously fed into the bolt cutting machine. The blanks cut to the required length are then passed through a system of stamps, which give them the required shape. And the thread of the required pitch is rolled onto the bolt, ready with a head. There is no provision for preheating the metal, and the fastener is formed by extruding the required parameters.

Modern technologies for the production of hardware ensure a high level of production and profitability. And most importantly, high quality bolts and nuts are produced. Automation of hardware production reduces their cost and marketable price.

Making nails

The production of nails is an area of activity where in order to build a successful enterprise, you do not need to invest large sums in purchasing high-tech equipment. Such a business does not require significant labor and material costs.

The nails are made from low carbon steel wire. For each type of product, raw materials of a certain size (diameter) and cross-section are used. The production technology is simple and consists of only three stages:

- preparation of raw materials - at this stage, the wire is unwound and straightened using special rollers and fed into a nailing machine;

- cutting, forming the head and point - the wire enters the impact mechanism, is clamped and cut off;

- finished products are dumped into a storage tank.

The following machines for the production of hardware are involved in the technological process: a hoist (a manual or electric drive device used for unwinding wire) and a nailing machine. The productivity of the latter can range from 100 to 600 units of finished products per minute. It depends on the model.

The total cost of these two machines is about 500 thousand rubles. You can start by purchasing used equipment. Such a purchase will cost 1.5-2 times cheaper.

Hiring staff

The production of hardware is carried out on automated lines, which eliminates the need to hire a large number of workers. To work in production and warehouse areas, the following employees may be required: turners, mechanics, line operators, loaders and technologists.

Room

It is not necessary to build new buildings to accommodate production facilities. You can rent and restore old abandoned objects, of which there are many in our country. This option will be much cheaper.

It is advisable to run the line in an industrial area or in the countryside, since hardening furnaces used in the manufacture of certain types of hardware produce emissions of pollutants into the atmosphere. But if only cold heading and thread rolling machines are used in production, then a workshop can be organized within the city limits. Making nails, for example, can generally be used as a garage production idea.

Material of manufacture

What the nuts are made of depends on the application. For the manufacture of the vast majority of this type of fasteners, steel is used. In order for the connection to withstand the loads encountered, high or low temperatures, exposure to acids and alkalis, it is necessary to choose the right brand. However, steel is not always applicable. Often there is a need to use a material that is not subject to the aggressive action of certain substances, to make the structure lighter or cheaper. In these cases, plastic, brass, magnesium, titanium and other substances and alloys can be used.