0 0

Read Time:1 Minute, 40 Second

Electric rivet welding is widely used in industry for joining structures made of thin sheet metal. For household purposes, it is often easier to weld using a regular seam, but there are exceptions. Spot welding may be needed when doing car body repairs yourself, when covering vans, pavilions, etc. with steel sheets. However, given the low popularity of this welding method, few people are familiar with it, so it is worth considering it in more detail.

How to install rivets using semi-automatic welding - Metalworker's Handbook

Electric rivets are spot welds that are made with a welding arc using a consumable or non-consumable electrode. Welding in this way is widely used in industry; it is highly productive and convenient in assembling large-sized structures, for example, when covering passenger cars.

Application

Electric rivet welding is used to:

- connect thin-sheet sheathing to frames made of rolled profiles. Since, due to the large dimensions of the structure, it is impossible to use the contact method of spot welding.

- a connection was formed from a package of elements.

- weld the studs.

How is welding done?

Developed by S.A. Egorov , welding with electric rivets is usually organized using a consumable steel electrode under a layer of flux. It is done in two ways.

- In the first case, the upper part is melted by a welding arc. Used when the metal sheet is thin (less than 2 mm).

- The second method is based on a pre-prepared hole, made by drilling or piercing.

The first method turned out to be more economical, when welding metal with electric rivets occurs without a hole in the upper part .

Also, welding with electric rivets can be carried out using a submerged steel electrode without pre-drilling a hole in the top sheet up to 12 mm thick. This becomes possible thanks to the use of a welding current of 4590 - 5000 A and the use of electrode wire with a diameter of 14 - 16 mm.

But still, welding parts with a thickness of more than 2 mm without a prepared hole is usually impractical. After all, then large welding currents and electrodes of large diameters are used, which ends in the formation of a very large electric rivet head, while the diameter of its rod is small.

If the elements

are more than 2 mm thick , then the need to drill or pierce a hole leads to a limitation in the scope of application of electric riveted seams.

The use of a non-consumable electrode when welding with electric rivets allows you to create seams without reinforcement, which results in a greater depth of metal penetration compared to the use of a consumable electrode.

Sheets with a thickness of 6 mm or more can be welded with a non-consumable graphite electrode using direct current, which is used in the range from 400 - 700 A. Graphite mass of grade A, produced by the Moscow Electrode Plant, is used as an electrode material.

To protect the seam during welding, you can use flux or a variety of shielding gases.

Welding technique and modes

Electric rivets are placed with or without welding wire feeding. In the first case, the wire is directed into the welding zone, the process is completed after a given amount of wire has melted.

This occurs using a time relay or mechanical interrupter. Without wire, the process is carried out as follows: during the burning of the arc, it is not supplied, since it is fixed in the current-carrying mouthpiece.

The arc continues to burn until it naturally breaks, because its length and voltage change.

The holes are melted using an electric riveter without flux, when the current is 1800 - 2000 A.

To start the process, you need to install the electric riveter in such a way that the welding wire forms an angle of 15-20 degrees , and the end of the welding wire corresponds to the center of the future point.

The result of a short burning of the arc will be the splashing of molten metal by its blow onto the edge of the hole. Excess metal is removed using a chisel and hammer.

Engineer I.I. Kakhovsky made the connection using electric rivets with manual wire feeding. In order for the wire to fall smoothly as it melts, you need to guide it and at the same time quickly turn it in both directions, making movements around its axis. Its diameter can be the same and does not depend on the diameter of the hole in the upper part.

To choose a welding mode and technique, you need to consider the following points:

- Depending on the brand of flux used, its consumption and penetration depth are determined.

- Electric rivets can come in different sizes, which is affected by the wire feed speed.

- If the flux layer is small, the electric rivets swell.

- Porosity forms in electric rivets, which can be caused by rust, scale or wet flux.

Hose semi-automatic machines are useful for efficient work , because then to penetrate the top layer you will need a significantly lower amount of welding current.

When they are used, the most important parameter of the welding mode is the arc burning time, which determines the quality of electric rivets.

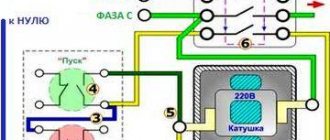

Therefore, the electrical circuit of a semi-automatic device must be based on a relay in order to dose the current flow time.

If the welding mode and technique are not followed, this can lead to defects in electric riveted joints.

The reasons for their formation are:

- When welding without wire direction, unwelded edges are obtained if the hole diameter is 1-3 mm larger than the wire diameter.

- If the lower element is not welded, then this is possible at low current, if the diameter of the wire is small, with insufficient compression of the elements being connected, or weakening of the circuit contacts.

- The upper part is burned through in the event of strong compression of the welding elements or when the current is increased.

- If the welded surfaces are poorly compressed, then cracks appear in the core of the electric rivet.

- Pores form on the surface and in the cross-section of the electric rivet from the connection of elements that are not cleaned of rust, moisture, dirt, and also if wet or contaminated flux is used.

- A splash of metal on the surface or on the edges of the electric rivet occurs when flux clogged with slag crust is used or when the end of the wire or the current-carrying nozzle is clogged.

- If an insufficient amount of flux is poured into the welding zone, then swelling of the head of the electric rivet occurs.

- An electric rivet in which insufficient head height is formed is the result of a gap between the surfaces being connected.

- An electric rivet height that is too high occurs when the flux contains many small particles, as well as when the current is insufficient for a particular wire diameter.

High performance of electric riveted joints is observed under shock and alternating loads , compared to continuous seams. On thin metal, quality control can be carried out by appearance on both sides.

- Fedor Ilyich Artyomov

How to cook a semi-automatic machine correctly

- Date: 07/30/2015

- 795

- : 41

Welding with a semi-automatic welding machine is a good way to connect machine parts.

Scheme of an inverter semi-automatic welding machine.

Its advantage is that this equipment can weld both parts up to 1 mm and more than 4 mm.

How to weld a semi-automatic machine, welding methods

There are several methods:

- butt method

- overlap welding

- "electric rivet".

“Butt” technology is a type of welding in which the parts used (pipes, metal plates, etc.) are welded at all points of contact. Work occurs at high temperatures. This technology is used when only part of a part needs to be welded, for example, part of a wing.

The method has a big disadvantage for a beginner. Its essence lies in the fact that the parts must be adjusted very precisely when welding, that is, if possible, do not leave any gaps or leave only very small ones.

If the gaps are large enough, a large hole can be found at the seam site.

Among the advantages of this method are the strength of the seam (sometimes it is even stronger than the part itself) and the presence of simplifying materials (wire, electrodes). However, it will be better if the work is carried out by an experienced professional. If you need to gain experience in this type of welding, then it is better to take metal with a thickness of 2 mm. It forgives most errors and poor fit.

Semi-automatic welding panel.

In auto mechanics, it is better to use this method for working with external parts or in cases where high professional training is needed.

If you do not have enough professionalism for butt welding, then you can use the simplest method - overlap welding. In this case, the metals are completely and partially superimposed on each other and welded. The method should not cause problems for a beginner. This method is used when working with power elements or when soldering boards.

The technique of the “Electro-rivet” method is similar to spot welding, which is used in factories. The method is a variation of overlap welding, and therefore welding is also understandable to beginners.

This welding method is used in various situations - when welding sills, wings, etc.

Types of welding seams

There are several types of welding seams:

- continuous interrupted seam;

- continuous seam;

- spot stitch.

A continuous intermittent seam consists of alternating seams of the same (sometimes different) lengths and spaces between them. The length of the seams and gaps can be chosen arbitrarily (depending on the task at hand).

Arc welding method with electric rivets

Electric rivet welding is used to:

- connect thin-sheet sheathing to frames made of rolled profiles. Since, due to the large dimensions of the structure, it is impossible to use the contact method of spot welding.

- a connection was formed from a package of elements.

- weld the studs.

How to cook with a semi-automatic machine

- Taking into account the thickness of the parts, select the strength of the welding current and the characteristic feed speed of the welding wire. To do this, use the table that is displayed in the instructions for this device.

- Selecting and installing replacement gears will help you adjust the welding wire feed speed required for welding.

Use a table or a special gearbox. - Using adjusting devices, adjust the power source (DC machine or welding transformer) to the required current and voltage.

This will allow for stable arc burning, high-quality bead formation and the required amount of molten flux. - The welding wire flows through a special hose into or out of the mouthpiece itself, depending on the position of the switch located on the hardware box.

Set the switch to the “Forward” position and the wire will begin to flow towards the holder to the designated welding location. By setting the “Back” position, you will direct the wire towards the coil. Therefore, set the required mode. - Fill the funnel with flux, set the switch to the “Forward” position.

Orient the holder so that the tip of the mouthpiece is directly above the welding area. Having opened the flap of the flux funnel, press “Start” and at the same time make a slight movement of the device holder towards the welding site. This movement will initiate the arc and begin the welding process.

Now you know how to prepare the device for cooking and how to cook semi-automatically. will perfectly complement the acquired knowledge and will help you clearly see that cooking with a semi-automatic device is not at all difficult. It is much more difficult to make beautiful, reliable (if for pipes) and durable seams.

Also, semi-automatic welding can take place in a protective gas environment - carbon dioxide.

Anyone can learn how to weld semi-automatically, the main thing is to understand the principle of operation, which is that copper-plated wire is automatically fed to the holder with a nozzle and, at the same time, carbon dioxide is released from the nozzle.

The carbon dioxide and wire feed rates can be adjusted. The result and quality of welding depend mainly on the correctly selected wire and gas feed speed.

You can weld with a semi-automatic machine in various positions, and, unlike arc welding, the welding seam has a smooth surface without slag and practically without “snot”.

Aluminum welding

20.05.2013 Features of aluminum affecting the nature of welding

The properties of aluminum and its alloys differ from the properties of steel, so their welding has a number of features. Aluminum has high thermal conductivity (about 5 times higher than that of ordinary steels), so heat from the welding site is intensively transferred to the parts being welded.

This dictates the need for increased heat input compared to welding steels. Because of this, preheating of massive aluminum parts is recommended.

Aluminum is characterized by a low melting point - about 640°C, that is, it is significantly lower than the melting point of steel (about 1500°C), and its strength decreases sharply when heated.

In addition, it does not change color when heated (which is typical for most metals) and, as a result, does not “tell” the welder that it is heated almost to the melting point.

Thus, due to the specific properties of aluminum (high thermal conductivity and low melting point combined with a significant decrease in strength when heated), the likelihood of “burning through” or even melting a part when welding aluminum is much higher than when welding steel. Aluminum has significant casting shrinkage (2 times more than steel), therefore, when the metal of the weld pool solidifies, significant internal stresses and deformations develop in it, leading to the formation of so-called “hot cracks”.

Seam welding

Welded metal joints are among the main methods of fastening structures used in everyday life and production. This is a very reliable method of obtaining a single design, which is also relatively cheap.

Bonds of this type are formed by melting the metal in the joint area and then crystallizing it as it cools. Their quality depends on the correct choice of operating mode of the electric welding machine, electrode, and seam penetration. This is regulated by current regulations and standards. They indicate all types of welds, as well as types of joints and their characteristics.

Numerous metals have their own welding characteristics, different work conditions, and requirements for fastening. For them, appropriate types of electric welded connections are used. When welding metal elements, the main types of electric welding fasteners are used, which are discussed below.

Classification

Welding joints are divided into several varieties, depending on their characteristics. The classification of welds covers the entire range of their uses. According to external parameters they are:

- convex type (with reinforcement);

- concave (weakened design);

- flat type (normal).

According to the type of execution, they are found in one-sided, as well as double-sided, according to the number of passes with the electrode: single-pass, double-pass. In addition, there are single-layer and double-layer welding methods.

According to their length, suture fastenings are:

- unilateral with intermittent pitch;

- solid one-sided;

- spot (with contact electric welding);

- chain double-sided;

- double-sided checkerboard pattern.

Separation by spatial location:

- horizontal, lower;

- vertical, ceiling;

- into a boat;

- semi-horizontal design;

- semi-ceiling type;

- semi-vertical.

According to the force vector:

- longitudinal (flank) – the force has a vector parallel to the penetration;

- transverse - the force acts perpendicularly;

- combined - a type of frontal, as well as flank;

- oblique - the impact occurs at an angle.

According to their purpose and function, electric welding penetrations can be durable, as well as durable and tight, hermetically sealed. Based on their width, they are distinguished into thread type, which does not exceed the diameter of the electric welding electrode rod, and widened, performed using oscillatory movements when welding in the transverse direction.

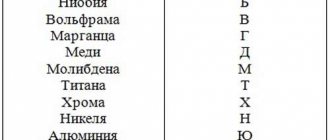

To simplify the understanding of the classification and application of certain varieties, a special table has been compiled.

All types of seams have strict designations according to GOST. The drawings use special icons that contain complete information about the type of fastening and its method of execution. For those who are thinking of seriously engaging in welding work at a professional level, they should additionally study the drawing symbols of welded fasteners.

Types of welds

Depending on the material used, thickness, and design features, different types of welds are used. To do this, you need to undergo the necessary theoretical training.

This will allow you to better understand the specifics of welding parts and avoid defects in work.

Novice welders often do not sufficiently weld the joint areas, which affects the weak mechanical resistance of the joints.

By choosing the right operating modes and types of welding, you can obtain welding seams of sufficient strength and quality. Welder training consists not only of practical training, but also of theoretical training with the study of requirements, norms and rules, as well as including the types of welding joints and equipment used.

Knowledge of the principles of using certain electric welding fasteners, the techniques for producing them, the joints will be very strong and durable.

Butt

This connection option is the most used among other types of welding seams. This butt welding is used on end sections, pipes or sheet metal structures.

To obtain it, a minimum amount of time, material and effort is spent. These butt joints have some seam features. On thin sheet metal, welding is carried out without bevel of edges.

Products with large thickness of joint sections require preliminary preparation of joints, which consists of bevelling them to increase the depth of welding penetration.

This is necessary when the thickness of metal products is over 8 mm and up to 12 mm. Thicker sections must be joined by double-sided welding with preliminary bevel of the edges.

Butt welding is most often performed on products in a horizontal plane.

T-bar

These types of electric welding connections are made like a regular letter “T”. They connect objects of the same or different thickness, which determines the width of the weld seam. In addition, these types are used single- or double-sided, which is influenced by the characteristics of the fastening.

When working with metal elements of varying thickness, the electrode is held in an inclined position at an angle of about 60 degrees. The welding process can be greatly simplified by using tacks, as well as boat welding. This method significantly reduces the occurrence of undercuts. The T-weld is applied in one welding pass.

In addition to manual arc welding, automatic electric welding machines are widely used for this type.

Overlapping

This method is used for welding sheet metal with a thickness of up to 12 mm. The areas to be joined are overlapped and welded along the joints on both sides. Do not allow moisture to enter the interior of the structure being welded. To strengthen the bond, full welding is performed around the perimeter.

With this welding, the formation of a connecting joint occurs between the end of one product and the surface of another. With this type of welding seams and connections, the consumption of materials increases, which must be taken into account in advance. Before starting work, you should align the sheet structures and ensure that they are pressed well together.

Corner

These connections include fastenings of elements made at a certain angle to each other. They are characterized by the use of preliminary bevels to ensure the best weld penetration.

This will increase the depth of the welding joint, which will increase the reliability of the structure. To enhance strength, double-sided welding of metal products is used, while gaps in the joined edges are not allowed.

Welding with preliminary hole preparation

To gain the necessary experience, a novice welder should start making electric rivets by first drilling a hole in the top sheet metal. When welding steel 3 mm thick, its diameter should be 6-9 mm.

The electrode is applied to the bottom workpiece through a hole in the top sheet. If thin steel is used, then it should start igniting from the center, then slowly move and continue fusing the metal at the edge, moving upward in a circle. On thick metal with a large hole, you need to ignite the electrode at the edge, and when moving in a circle, sometimes move towards the center.

To get a reliable rivet, you need to follow several rules:

- To quickly heat up the lower workpiece, it is better to set the current to 110A on the welding machine.

- Place at least 2 rivets to prevent the parts being connected from being twisted out.

- Press thin workpieces tightly together to prevent burning of the top metal;

- The higher the cross-section of the metal, the larger the diameter of the hole for installing the rivet is needed.

- The rivet is installed in one go without pause. Thanks to this, all the slag will collect on top and it can be knocked down, creating a neat fungus.

Electric rivet or through-hole welding

Electric rivets are spot welds that are made with a welding arc using a consumable or non-consumable electrode. Welding in this way is widely used in industry; it is highly productive and convenient in assembling large-sized structures, for example, when covering passenger cars.

Welding body metal (part 2)

In the previous article, in which we described the choice of welding equipment and its configuration for carrying out body work, we promised that after that we would look at the methods of the main methods of welding bodywork and talk about the most popular options for joining metal by welding in this process. And this will be discussed in our article today.

Types of welds

To begin with, let's define some types of welds that are formed during welding, regardless of the method of joining the metal.

- Solid

- Continuous intermittent

- Spot

So, a continuous welding seam is here; it will be immediately clear from the name that this seam will be performed without gaps along the length. Therefore, continuous welds are not used in the car body.

This can be explained by the fact that the car body must have some "elasticity" in order to reduce the likelihood of fatigue cavities and cracks forming during its operation.

How to install rivets using semi-automatic welding - Machine tools, welding, metalworking

Electric rivets are spot welds that are made with a welding arc using a consumable or non-consumable electrode. Welding in this way is widely used in industry; it is highly productive and convenient in assembling large-sized structures, for example, when covering passenger cars.

How to cook semi-automatically - video, features

Semi-automatic welding (MIG) is a kind of evolution of manual arc welding (MMA). Even despite the availability of MMA inverters, it is better to use MIG welding for home use. But to fully appreciate its advantages, you need to know how to cook with a semi-automatic device. In fact, there is nothing complicated about it.

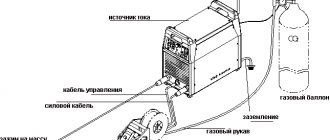

Semi-automatic welding

For semi-automatic welding of metal, special wire and shielding gas are used. Gas is supplied to the torch through the welding sleeve along with the wire, protecting the weld pool from the external environment.

Electrode wire is produced in reels. Its thickness:

- 0.6 mm;

- 0.8 mm;

- 1 mm;

- 1.2 mm.

For metals thinner than 4 mm, wire 0.6-0.8 mm is used, thicker - 1-1.2 mm.

The shielding gas is carbon dioxide or a mixture of CO2 and argon. Pure carbon dioxide is cheaper - but the weld is worse and welding produces more splashes than when using a mixture with argon.

Features of semi-automatic welding:

- automatic feeding of welding wire – increases the speed and quality of welding;

- welds thin metal - the thickness of the workpiece starts from 0.5 mm;

- versatility - a semi-automatic machine welds steel, stainless steel, cast iron and non-ferrous metals;

- there is no slag on the finished welding joint;

- There is virtually no smoke during welding.

On the other hand, the semi-automatic is bulky due to the gas cylinder. In addition, in a strong wind it will not be possible to cook in a gas environment - the wind will blow carbon dioxide out from under the burner.

What you need to know about semi-automatic welding

Before cooking, you need to take into account the intricacies of the welding machine.

How to cook with a semi-automatic machine:

- the positive terminal is connected to the burner, the negative terminal to the workpiece;

- For each type of metal, a special wire is used (for aluminum, stainless steel).

- Amperage and wire feed speed are mutually related settings. The higher the current, the higher the speed and vice versa;

- The current collecting tip used on the torch must match the diameter of the wire. This part is a consumable item and therefore requires periodic replacement;

- the quality of the seam depends on the settings of the wire feeding mechanism;

- the hose feeding the wire must be rigid - otherwise it may bend and the wire feeding will stop;

- It is better to weld metal thinner than 1 mm in spots if you do not need to get a sealed seam. This way the workpiece will not overheat and burn out;

- if the network voltage is lower than rated, for example 190 rather than 220 volts, it is better to use wire of a smaller diameter. For example, instead of 0.8, take 0.6 - the machine will cope with it much easier, and the seam will turn out to be of high quality.

- For semi-automatic welding without gas, a special wire is used, and the positive terminal is connected to the workpiece.

Installing an electric rivet by burning without a hole

Having some experience in seam welding, you can immediately try installing electric rivets without drilling the top sheet. This method is suitable for spot welding thin sheets. The electrode is placed at the junction and held until the characteristic sound of burning the upper part appears. As soon as the sheet burns out, you need to slowly raise the electrode, fusing the metal, to close the resulting hole.

When placing electric rivets on thin metal, you can use rutile electrodes. On more serious workpieces, a base coating is better. If at least 2 rivets are made, then the connected parts will be impossible to break in any direction of impact. Cooking with rivets is faster and more economical in terms of electrode consumption, so the method is really useful.

Welding body metal (part 2). Welding methods | Tiberis

In the previous article, in which we described the choice of welding equipment and its configuration for carrying out body work, we promised that after that we would look at the methods of the main methods of welding bodywork and talk about the most popular options for joining metal by welding in this process. And this will be discussed in our article today.

Overlap welding

This type of welding is one of the most common and simplest methods of joining metal. In lap welding, one layer (piece) of metal is placed on top of another. It is best to use this type of welding when replacing or repairing power elements of the body - amplifiers, sills, side members.

Electric rivet or through-hole welding

This method is one of the varieties of overlap joint. It is very reminiscent of the well-known spot welding, which is used (most often) in factories or at service stations when assembling a body. This method is the easiest way to connect wings, new sills and various types of power elements.