06.12.2021 Author: VT-METALL

From this material you will learn:

- Advantages and disadvantages of submerged arc welding

- Submerged Arc Welding Applications

- Required equipment for submerged arc welding

- Types of fluxes for welding

- Submerged Arc Welding Technology

- Selecting the appropriate submerged arc welding mode

- Problems encountered during submerged arc welding

Submerged arc welding is a technology for joining metal parts/workpieces. There are different welding methods: manual, semi-automatic, automatic. Accordingly, various equipment is used and certain modes are selected.

Due to its undeniable advantages: accuracy, speed, seam protection from corrosion, submerged arc welding is used in almost all areas of metalworking: from mechanical engineering to the manufacture of large-diameter pipes and use in small industrial enterprises. How everything happens according to technology and what problems often arise during the work is described in detail in the article below.

Advantages and disadvantages of submerged arc welding

Welders are aware of the negative effects of oxygen in welding and its impact on product durability and weld quality. Oxidation processes cause cracks in metal welded joints. Compliance with the technological process helps to avoid such negative aspects. One of them is submerged arc welding. This is one of the most effective methods of welding metals, providing a strong and even welded joint. But to make such a seam, you need special equipment and an appropriate level of qualification of the welder.

It is often simply impossible to connect parts made of stainless steel, aluminum and copper without using automatic arc welding under a layer of flux, which serves as protection against oxygen. The same applies to the classic method using manual or semi-automatic welding. Melting of the metal and joining of workpieces can only occur when the electric arc reaches a high temperature.

Arc welding is often accompanied by sparks and spatter, as well as increased smoke and intense ultraviolet radiation. When using submerged arc welding technology, such factors are eliminated, since the entire molten pool is completely located under its thick layer, which makes this process safe.

In addition, the neutralization of smoke and radiation makes submerged arc welding safer than other welding methods. Operators supervising welding do not need to wear protective clothing; standard work uniform will do.

Since submerged arc welding uses electricity, it does not need to be applied under pressure. In addition, the increased level of heat generated during the welding process allows thick-walled workpieces to be joined.

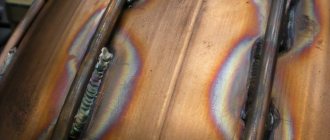

A special feature of submerged arc welding is its high rate of metal deposition. It is this property that can provide a deep weld pool. Welding using submerged cored wires can accelerate deposition compared to using solid wires.

In addition, a high concentration of heat speeds up welding, the speed can reach 5 m/min. As a result, the structure of the completed seam becomes more viscous, durable, homogeneous and acquires increased corrosion resistance. In addition, the welded joint looks smoother and neater.

VT-metall offers services:

The most difficult task in welding is to avoid deformation of the weld. The reason is the expansion and contraction of the metal, as well as non-uniform non-ferrous metals. Since when welding under a layer of flux, accelerated welding with an increased thermal concentration is used, this allows one to avoid such violations.

This welding technology is performed not only indoors, but also outdoors. Even in light wind conditions, submerged arc welding can be performed without violating the requirements for such types of work.

There are also a number of disadvantages:

- Increased difficulty in setting up equipment.

- Impossibility of welding work in ceiling and vertical positions.

- Uneven edges of the surfaces of the parts being welded, which do not allow for a high-quality welded connection.

In addition, it is difficult to control the quality of welding, since the welded joint is under a layer of flux.

Materials used

The quality of welding depends on the correct choice of electrode wire. The chemical composition of the wire determines the suture characteristics. It is advisable to use steel wire that complies with GOST 2246-70. It is made from alloy, high-alloy, low-carbon steel. The dimensions of the finished wire correspond to the standard (diameter is 0.3-12 millimeters).

Wire is usually supplied in eighty-meter coils. Sometimes, with the buyer's permission, cassettes and reels are used. Before using wire that has been stored in a warehouse for a certain period, experts recommend cleaning it and treating it with gasoline/kerosene. This makes it possible to remove rust and dirt from it.

To connect aluminum parts, wire is used that complies with GOST 7871-75. Copper-coated wire is often used. It does not need to be pre-processed. The quality of welding performed with flux-cored wire without gas directly depends on the characteristics of the flux. The characteristics of the gaseous medium and liquid slag depend on the composition of the flux. Interacting with the part, the slag determines the structure of the weld metal. The resistance of the product to cracking depends on its structure.

Flux is used to:

- alloy seam metal;

- isolate the weld pool from external influences;

- create a suture surface;

- stabilize the arc discharge.

Submerged Arc Welding Applications

However, this technology is justified on an industrial scale, as it increases labor productivity, improves the quality of the welded joint and the reliability of the metal structure as a whole.

Submerged arc welding has found wide application in the following industrial sectors:

- Shipbuilding. The hull of the vessel consists of pre-welded sections, manufactured using automatic or semi-automatic welding. Using sectional assembly technology, production times are significantly reduced. On an industrial scale, carrying out welding work in compliance with the technology ensures high quality of the welded joint.

- Oil industry. The technique allows for the assembly of tanks from blanks on site by welding steel sheets into roll-type panels.

- Manufacturing of large diameter pipes for water communications, oil and gas industries.

- In the engineering industry for mass production of metal structures: trolleys, carriages, automobile wheels and similar products.

There are technologies for welding non-ferrous metals, aluminum, titanium and its alloys, which makes it possible to use submerged arc welding in the production of highly reliable structures, aircraft, household and industrial equipment.

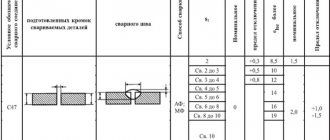

Welded joints - as defined by the state standard

According to GOST 8713-79, welds are classified as:

- butt;

- corner;

- T-bar;

- overlap.

In turn, they are divided into compounds:

- with flanged edge;

- without bevel;

- with bevel of one edge;

- with a curved bevel of one edge;

- with a broken bevel of one edge;

- with two symmetrical bevels on one edge.

Required equipment for submerged arc welding

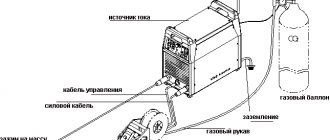

To perform automatic submerged arc welding, it is necessary to provide a workplace:

- Welding plate. It should be installed on a concrete platform because it is made of materials that are resistant not only to high temperatures, but also to sudden temperature changes.

- Fused wire. Its thickness usually ranges from 0.3 to 12 mm, and consists of the same material as the product being welded.

- A non-consumable electrode that includes a metal core and a ceramic shell.

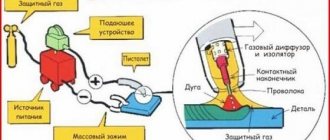

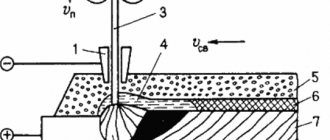

- A system that supplies flux particles, consisting of a hose of the required diameter and a reservoir.

- Control system. In automatic installations it is more modernized than in semi-automatic ones.

For large-scale production, a special automatic assembly stand is usually used, which allows not only to weld any structures, but also ensures reliable fixation of the workpieces in the position in which they should remain in the finished product. Such equipment provides increased reliability of fastening the workpieces and eliminates any deviations in the shape and connection of the entire structure, despite the fact that the welder does not see the seam during work.

This technology is ideal for making corner and butt welded joints; the process occurs quickly, ensuring the required parameters of quality and reliability of the connection. The design is controlled automatically, so it is quite expensive. In some cases, as an alternative, the stand can be equipped with mobile heads.

The price of a semi-automatic machine is much lower, but such equipment requires much more participation of the welder in the process. The operator must constantly monitor the extension of the electrode and the direction of the wire, despite the fact that the latter is fed automatically. The master independently selects the angle of inclination of the electrode, varies the speed when applying the seam and the voltage power according to the specifics of the workpiece.

Manual equipment is most often used by amateur welders in private workshops, although there are special cases of application if it is the most convenient of all options for welding products. Manual welding can be used from any position and even in awkward, hard-to-reach places.

Modes

The choice of welding mode depends on various indicators, for example, the method of cutting the edges, their thickness, the planned number of passes along the future seam and the method of holding the weld pool. Current strength and voltage, wire cross-section diameter, welding speed, position of the product itself and electrode extension also influence the choice of workpiece processing tactics. Parameters for each workpiece are always calculated individually.

For example, for the most common welding of butt seams, one one-sided pass under submerged arc is enough, provided that the thickness of the workpiece does not exceed 3 cm. If the parts are thicker, the seam is welded on both sides and additional passes can be added. One-sided welding is relevant only in cases where the material is not afraid of overheating, and the seams should not give welding cracks.

If the sheets being welded are very thin (no thicker than 6 mm), cutting the edges as a stage of preparation for further processing is not performed, and the parts to be joined are placed as close to each other as possible, trying to minimize the gap to the limit. When the thickness of the workpiece is about 1-1.2 cm, on the contrary, a gap is left - this will help achieve improved quality of the seam and at the same time reduce the excess of molten metal. In any of the described cases, special fixation of the parts is required - either with a lining, or a welding seam, or preliminary assembly “into a lock.”

The lining is the most popular solution for welding metal sheets no more than 1 cm thick. As a rule, it is steel, 3-6 mm thick and 3-5 cm wide. Lock welding is used to connect important parts where burning through the material is unacceptable. It is also the best method for joining large and heavy structures. As for the back weld, this is a relatively rare welding mode, which is appropriate only if re-edging of the product is not realistic.

Types of fluxes for welding

According to the manufacturing method, fluxes can be:

- fused;

- unfused (ceramic).

The first type of fluxes (fused) is made from a mixture of quartz sand and slag-forming manganese ores. First they are ground, mixed, and then melted and granulated. This type of flux is relatively economical and is mainly used for welding workpieces made of low-alloy steels.

The composition of the unfused type of flux includes salts of amphoteric metals and oxidizing agents, which are first crushed, mixed with liquid glass until a homogeneous mass is formed, and then granulated and calcined.

The ceramic type has a fine powder structure and is used for submerged arc welding of high-alloy steels and alloys based on them, and a specific flux composition is selected for the specific grade of steel being welded.

Based on their chemical composition, fluxes are divided into:

- oxide;

- saline;

- mixed.

The composition of oxide fluxes used for welding low-carbon steels includes silicon and oxides of active metals. The salt type of fluxes contains chloride and fluoride salts and is used for electric welding of steel alloyed with chromium and nickel, as well as titanium. Mixed fluxes, intended for welding parts made of different metals or multicomponent alloys, use different proportions of a combination of salts and metal oxides.

Submerged Arc Welding Technology

In automatic submerged arc welding, the speed and trajectory of the electrode, as well as the wire feed, are regulated by the control processor; the operator’s function is to monitor the state of the process controllers in case of an emergency shutdown of the welding equipment.

In semi-automatic submerged arc welding, the welding current, the angle of inclination of the electrode relative to the welding line and the wire feed speed are automatically adjusted, and the arc is controlled manually by the welder himself using a remote control or a handle. When using a semi-automatic welding machine, it becomes possible to change some current parameters manually directly while making a welded joint.

The method of manual welding under a layer of flux is used in the presence of small welding installations in which the flux supply system is built into a non-consumable electrode. The welder is responsible for manually adjusting, using special buttons, the speed of movement of the electrode and its angle of inclination, the supply of flux and the strength of the welding current, as well as monitoring the correct trajectory of movement.

There is a general sequence of operations for submerged arc welding:

- Removing oxide film from the surface of workpieces.

- Fastening the part to the welding plate.

- Selecting welding equipment setup modes.

- Filling the tank with flux.

- Installing a coil with a fused wire, connecting the free end to the electrode.

- Direct welding of parts.

- Collecting unused flux after the workpieces have cooled and cleaning the weld seam from slag.

To avoid idle operation of the electrode and damage to parts, special attention should be paid to the consumption of flux and wire.

What it is?

Most metals, when interacting with atmospheric oxygen, are quickly covered with a thin layer of oxide. On the one hand, it even provides some protective function, preventing corrosion of the internal layers of the metal, but for welding, the oxide poses a big problem because it does not allow direct access to the metal product.

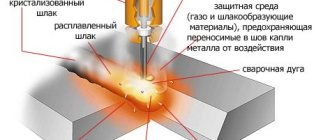

The oxide layer re-forms quite quickly, so welding metal without any protection of the surface from oxygen is unproductive. This or that composition that coats the working surface is called welding flux - it can consist of various components and can often destroy the already formed oxide.

At least fifty types of fluxes are known, however, such diversity does not mean that you can take any of them - each has specific features. All existing brands have clear requirements specified in GOST 9087-81. The essence of submerged arc welding as a process is that the electric arc burns under the flux mixture, and not just where we see it. Arc burning is possible due to the supply of high voltage to the electrode wire. A cloud of gases forms around the arc, formed during the melting of both the flux and the metal itself.

The welding itself and the connections created with its help are described by another GOST - 8713-19.

This is interesting: Features of galvanizing steel using the Sendzimir method

Problems encountered during submerged arc welding

A novice welder who strictly follows instructions may still encounter problems that he does not understand. The most imaginative example is the pores on the weld, which indicate that there is gas under the flux layer. Most often, porosity appears due to the presence of carbon dioxide or hydrogen, in rare cases due to nitrogen, the pores of which appear only when processing micro-alloyed steels, if such materials have nitride hardening.

The same problem can be encountered if the metal was cut with a plasma cutter. If the weld pool has a low percentage of deoxidizers, then carbon dioxide can penetrate under the flux layer. To prevent the formation of pores, the liquid bath is enriched with at least 0.2% silicon. In addition, deoxidation can occur when the temperature decreases and, conversely, the concentration of carbon dioxide will increase with its increase.

The most common reason for the appearance of pores when welding under a layer of flux is the presence of hydrogen, which appears due to insufficient cleaning of edge surfaces from rust and other contaminants, as well as due to wet flux.

Recommended articles

- Types of welds: we understand the classification and features

- Production of metal products: technologies, advantages, step-by-step control

- Fusion welding: where it is used and how it is produced

Finally, it is worth saying that the fusible material that is used in submerged arc welding is in a solid granular state throughout the entire welding process, which allows 50–90% of it to be reused in subsequent welding.