When constructing reinforced concrete structures, to increase the strength of concrete, it is always necessary to assemble a reinforcing frame from reinforcement. To connect it, welding of reinforcement can be used, which produces a reliable and durable connection that is not inferior in characteristics to a solid metal rod of the same diameter, if the welded connection of the reinforcement is made using technology.

What reinforcement should be used for welding frames?

For welding in the manufacture of reinforced frames, hot-rolled rods of the grades Ap600S, A800S, At1000S, A600S, A500S, A400S and A240 are used, as well as cold-deformed reinforcement of class B500S and BP-1. Welding is carried out using the electric arc method with the formation of a pool or overlap, since the joints have an optimal ratio of strength and ductility, and do not deform or burst under load, provided that the welding work is carried out according to the technology.

All classes of reinforcement listed above have a periodic profile, except for A240, which is smooth.

Rods of suitable diameter for arc welding - 10 to 40 mm - are selected individually for each project depending on the requirements for structural strength and other mechanical characteristics. Resistance welding can be used for rods with a diameter of 3 to 40 mm, depending on the class of reinforcement used.

When creating reinforcement frames, transverse and longitudinal elements are used. They are selected so that the cross-section of the transverse rods is smaller than that of the longitudinal ones.

What does GOST 14098-2014 establish, and what is the scope of its application?

GOST 14098-2014 “Welded connections of reinforcement and embedded products of reinforced concrete structures. Types, designs and sizes" was put into effect in July 2015. It replaced the previously existing GOST regarding welding of reinforcement, number 14098-91.

The provisions of this document apply to:

- For welded joints of rod reinforcement.

- For connections of reinforcing wire that has a diameter of 3 mm or more.

- For connections between reinforcement and rolled products with a thickness of 4 to 30 mm.

These works can be performed during the production of reinforcement and embedded reinforced concrete structures, as well as during their installation and construction.

The standard establishes the types, design features and dimensions of the weld. Here are the requirements for performing work using resistance and arc welding.

The standard excludes welded connections of embedded parts without anchors made of reinforcing steel.

Methods for connecting reinforcement by welding

Reinforcement for creating frames during concreting can be connected in the following ways:

- overlap;

- end-to-end;

- in a cross-shaped way.

Overlapping

An example of an overlap weld.

Overlapping reinforcement connections are permissible in areas where high loads are not expected. The method is suitable for connecting rods of the same diameter. The rods must be horizontal.

The diagram below shows how to properly weld reinforcement; a table of weld seam sizes depending on the class of reinforcement used is also attached.

Also, an overlap connection by welding can be made using paired overlays from reinforcement whose diameter is equal to that being welded, with or without offset. See the diagram and table of reinforcement overlap dimensions below.

The minimum diameter of the reinforcement for manual arc welding with an overlap connection is 10 mm, and for contact relief welding it is 6 mm.

Butt-butt

The reinforcement is butt-joined when its diameter is from 10 to 40 mm. Before joining, the rods are placed so that there is a small gap between them. Overlays or a U-shaped bracket are installed in the joint area. This is required so that a metal bath with the specified characteristics is formed and carbon does not enter the melt from the air. After completing the welding work, the overlays are removed. This method is called bath welding of reinforcement; it can be performed directly at a construction site; it is most often used when reinforcing columns, for joining vertical rods.

This method is one of the most reliable and allows you to work at any angle. The disadvantage is the increased consumption of electrodes. Also, these works require certain knowledge and skill from the welder.

Currently, U-shaped baths are most often used in which the fittings are welded, see the photo below.

An example of welding reinforcement using the bath-seam method on a steel bracket-plate.

Cross spot welding

For the cross-shaped method, contact spot welding and arc flank welds (tack welds) are used, implemented in a vertical or horizontal position.

An example of cross-shaped welding of reinforcement using a manual arc method (tack welding).

Contact type welding is mainly used in factory conditions to create reinforcing mesh. To implement it, automatic welding machines are required. Spot welding is a highly productive method, but it requires the use of large equipment and also incurs significant energy costs.

The process of connecting reinforcement by resistance welding.

To weld steel rods, their surface is cleaned, then clamped with special pliers and a short electric pulse is applied. There are several welding points for reliable fixation of the parts to be joined.

Recommendations for work

Operations such as welding of masonry mesh and reinforcement frames are carried out using special equipment. Rods with a diameter of no more than 26 mm are connected using spot welding machines. For larger thicknesses, the work is carried out using manual electric welding.

When welding meshes and frames made of cold-rolled steel, the mode is selected with a high welding current, but welding occurs in small sections. The joined ends must be cleaned of rust, grease and dirt.

When working on resistance welding, you should periodically clean the contact surfaces of the electrodes, the diameter of which must be at least 12 mm.

Foundation reinforcement is one of the main works when laying the foundation of a building. The service life of the house depends on the quality and reliability of the joints . Therefore, welding of frames and enlarged assembly must be carried out by a qualified specialist.

How to choose electrodes?

When carrying out welding work, the following types of electrodes are often used:

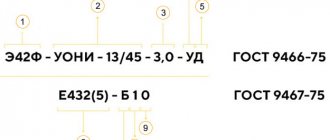

- UONI-13/55U. Suitable for welding with the formation of a pool of molten metal. The electrodes ensure high quality welds.

- ANO-21. Used with inverters for welding reinforcement directly over rust without stripping. Allows you to position the electrode at any angle to the surface to be welded.

- TMU-21U. Used for arc welding of critical structures. A special coating guarantees no spattering of molten metal, as well as stable arc burning. The slag is separated without problems.

- UONI-13/45. Used exclusively for reinforcing bars made of low-alloy or carbon steel. The seam has an optimal ratio of strength and ductility, so it does not burst or crack under load.

- OZS-12. The best choice if you want to create a weld with a uniform structure without pores, slag and oxidation.

Experienced welders of the 5th category can independently choose the optimal electrode for creating a weld, which will fully comply with the requirements for the operation of the structure. But most often the project contains instructions with requirements for the weld and the type of electrode used.

The diameter of the rods is selected as follows:

- For fittings with diameters of 5-8 mm, electrodes with a cross section of up to 3 mm are used.

- For rods with a diameter of 8-10 mm, it is recommended to use electrodes whose cross-section is 3-4 mm.

- For thick reinforcement with a diameter of 10 mm or more, electrodes with a diameter of 4 mm or more are used.

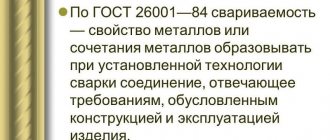

You can select according to labeling as follows:

- “N” – for metal surfacing;

- “U” – for alloys with low carbon content;

- “T” – for alloy steels with increased heat resistance;

- “E” – universal electrodes designed for creating plastic seams.

Knitting with special wire

To reinforce the foundations of private households, it is recommended to tie the reinforcement with a special binding wire. This is a fairly simple and affordable method for small construction.

In this case, it is necessary to lay the lashes and join them with a slight overlap. Then, using mild steel wire, these places must be tied and tightened using a special tool.

Such a frame made of wire and reinforcement has high strength and does not violate the strength of the base metal. The joint turns out to be movable and will not collapse when the structure subsides.

But the low productivity does not allow this method to be used in multi-story construction, so reinforcement is knitted on small foundations.

Welding technology

Welding of reinforcement is performed in the following sequence:

- The rods are cut with a grinder or guillotine to the required length.

- Dirt is removed from the surface, the ends are cleaned to a distance of approximately 30-40 mm with sandpaper or a special metal brush attachment for an angle grinder.

- The reinforcement is installed in its main position, which is determined by the project. The maximum deviation from calculations should not exceed 5%. The gap between the ends should be from 1.5 to 2 cross-sectional diameters of the rods.

- Overlays or staples are put on the rods at the junction. They are designed to prevent spillage of molten metal. Typically these are graphite or ceramic reusable pads. Fixation is carried out with a clamp or using a binding wire.

- If metal plates are used, they are first secured to the reinforcement.

- An electrode is struck along one of the reinforcing bars, melting it a little. Then pass quickly between the two connecting rods until a molten pool is formed. If the electrodes stick, then you need to increase the current, and if they burn through, use a thinner rod or reduce the current.

- Wait until the seam cools to ambient temperature.

After completion of welding work, it is mandatory to check the quality of the seam. To do this, an external inspection is carried out and defects are visually identified: cracks, cavities, chips, undercuts, lack of penetration, etc. After this, by carefully tapping the seam with a hammer, they check its strength. For critical structures, gamma flaw detection is used - the most effective and accurate method for detecting flaws in welded joints.

Knitting or welding - the methods used for connecting rods

To increase the strength of building foundations, various techniques are used. When constructing household buildings, country houses and light buildings, private developers add pieces of metal, glass fragments and various construction waste to the concrete solution. For light ancillary buildings this is acceptable. However, a durable residential building requires reliable reinforcement of the foundation using reinforcing bars or steel mesh. They are cut into pieces of the required size and placed in trenches.

There is no consensus on whether it is possible to weld foundation reinforcing bars together

To ensure increased strength of the base, the rods are combined into a power circuit using various methods:

- by tying together reinforcing bars or lattice pieces using tying wire. To increase flexibility, it is fired and allows you to quickly fix the frame elements using a crochet hook;

- using electric welding. In the manufacture of frames at industrial enterprises, resistance spot welding can be used. In domestic conditions, reinforcing bars are welded using the usual method.

Each method of fixing rods has certain advantages and weaknesses. Let's analyze each mounting option in detail.

What precautions should you take?

When carrying out welding work, it is mandatory to use personal protective equipment: leggings, a mask, and special clothing. When using electric welding, the equipment must be reliably grounded, especially if welding is carried out at high air humidity.

When welding reinforcement at height, it is recommended to follow a number of safety rules:

- For ease of access to the structure, use scaffolding, scaffolding, cradles, ladders, fenced areas with flooring made of non-combustible materials.

- If the installation of the listed structures is impossible, then in this case you can use the fixed elements as a support, but with insurance if the height is more than 1.5 from the ground surface.

- When welding tiered objects, it is necessary to have fencing: shields and decking.

- The equipment must protect against metal splashing.

- Work at height should be stopped in case of strong winds of more than 6 points and in case of ice formation, as well as if the air temperature drops below -30°C.

In addition, the welder must have permission to work at height, confirmed by the appropriate certificate.

Welding reinforcement allows you to create reliable and durable frames for concrete reinforcement that can withstand the necessary loads. Implementation is carried out on the basis of choosing a suitable method that meets the requirements. In terms of the strength of the reinforcing frame, welding is superior to the knitting of reinforcement, however, this technology requires the involvement of a certified specialist and tools.