In industry, construction and repair, various methods of joining structural parts are used. The most widespread are various types of welding, which are used to fasten not only similar and dissimilar metals, but also glass, plastic, and ceramics. The popularity of the technology is explained by the high strength and reliability of the connections.

Definition of the welding process

Regardless of the type, welding is the technology for creating permanent joints by heating, deformation, or a combination of both methods. The essence of welding is that under the influence of an external energy source (heat, pressure) strong bonds are formed between the materials being joined at the interatomic level. After crystallization, a weld seam is formed at the joint during the cooling process. Depending on the type of material and working conditions, this is local or general heating and deformation of the joining surfaces.

Pressure welding joint

The joining of metal surfaces by means of mechanical deformation is most often carried out in industrial production conditions, since this technology requires expensive equipment.

Pressure welding includes:

- Ultrasonic joining of metal parts. It is carried out thanks to ultrasonic frequency fluctuations.

- Cold welding. It is carried out on the basis of the interatomic connection of two parts by creating high pressure.

- Forge-forge method. Known since ancient times. The material is heated in a forge and then welded by mechanical or manual forging.

- Gas welding with pressing. It is very similar to the blacksmith method, only gas equipment is used for heating.

- Contact electrical connection. It is considered one of the most popular species. In this type of welding, the metal is heated by passing an electric current through it.

- When diffusion welding, the pressure on the metal is low, but a high heating temperature of the joint is required.

Classification of welding types

Depending on the criteria, the classification of welding methods is carried out according to the type of protection of the molten metal from atmospheric oxygen, the method of controlling the process, the material, etc. The technological features of the welding work are also taken into account. According to the method of influencing parts, three main types of welding are distinguished:

- Mechanical is carried out by external pressure, under the influence of which the surfaces are deformed, which leads to a tight connection.

- Thermal is performed using additional materials that are melted by heat from an energy source. Liquid metal fills the gap between the workpieces, and after cooling, a strong connection is formed.

- In thermomechanical (combined) types of welding, parts are exposed to the combined effects of heat and pressure. To increase ductility, parts are preheated and then compressed.

Arc connection methods

Electric arc welding is carried out in three ways:

- Manual method. In this case, all connection stages are performed manually, using simple electric arc welding.

- Semi-automatic metal welding is more productive. With this method, the weld is made manually, and the filler wire is fed automatically.

- Automatic welding is carried out under the supervision of an operator, and all work is done by a welding machine.

Thermal class of welding

These welding methods are performed with the formation of a weld pool from the molten metal of the parts and an electrode or filler material.

Dugovaya

Heat for local melting of the metal of the workpieces is released when an electric arc burns between the electrode and the workpieces. To ignite, briefly touch the surface with the electrode, then move it away to a distance of 2 - 5 mm. The shorter the arc, the higher its temperature.

Arc welding diagram

The following welding methods are used to connect parts:

- manual, when all manipulations with the electrode are performed by the welder;

- semi-automatic with electrode wire feeding by a mechanism installed in the device;

- automatic, when the process is performed according to a given algorithm without human intervention.

The arc type is performed using consumable and non-consumable carbon or tungsten electrodes with the introduction of filler wire into the working area. To protect the molten metal from contact with air, mechanized methods are carried out under flux or in an inert gas environment.

Gas

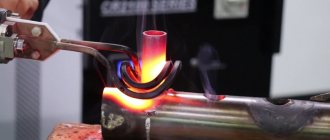

Unlike the arc welding, heating and cooling of the material occurs more slowly in gas welding. Therefore, this method is easier to weld thin-walled steel, non-ferrous metals, and carry out surfacing. Independence from electricity allows you to work in field conditions.

Gas welding diagram

The joint is heated by a burner torch, which is formed by the combustion of acetylene, propane, hydrogen, gasoline vapor or kerosene in pure oxygen. The weld is formed by melting the filler material. For welding work, acetylene is most often used, the flame temperature of which reaches 3100⁰C. Plasma welding, similar in operating principle, is performed with a jet of ionized gas with a temperature of more than 10,000⁰C.

Radial

The technology is based on melting the material of parts with a laser light beam or a stream of electrons created by an electron gun. Both methods are used primarily in the electronics industry for connecting and fastening microelements. To prevent the beam from scattering, electron beam welding is carried out in a vacuum chamber.

Gas welding technology

This type of welding work allows you to connect various metal structures not only in industrial enterprises, but also in domestic conditions. The technology of metal welding is not very complicated; during combustion, the gas mixture melts the edges of the surface, which are filled with filler wire. When cooled, the seam crystallizes and creates a strong and reliable connection of materials.

Gas welding has many positive aspects:

- Ability to connect different parts offline. Moreover, this work does not require a powerful source of energy.

- Simple and reliable gas welding equipment is easy to transport.

- The ability to carry out an adjustable welding process, as it is easy to manually change the angle of the fire and the speed of heating the surface.

But there are also disadvantages to using such equipment:

- The heating area has a large area, which negatively affects neighboring elements of the part.

- Lack of ability to automate the welding process.

- The need to strictly adhere to safety measures. Working with a gas mixture has a high degree of explosion hazard.

- The thickness of the metal for a high-quality connection should be no more than 5 mm.

Thermo-mechanical welding class

Combined types are used to connect small parts if it is impossible to create a high-quality seam by other means. The thermomechanical class includes the following types of welding:

- blacksmith's;

- contact;

- diffusion

Kuznechnaya

This method was used to connect iron workpieces long before the invention of modern welding classes. The blanks are heated in a forge, placed one on top of the other, and secured with hammer blows. A mechanized subtype, when workpieces are compressed by a press, is called press welding.

Forge welding principle

The quality of the connection depends on the experience of the technician. The list of metals that can be welded by this method is limited to types with good ductility. Due to low productivity and low reliability of the connection, the forge type of welding is rarely used.

Contact

The metal is heated by a current passing through the place of contact of the workpieces, then compressed or upset. This type is easily automated, therefore it is widely used at enterprises in the mechanical engineering industry as part of robotic complexes.

Depending on the tasks to be solved, contact welding is performed as follows:

- Point, clamping parts between the electrodes. After applying current, a point connection is formed at the point of compression.

- Butt joint with heating of the entire contact area.

- Relief with preliminary application of protrusions (reliefs) on the connecting planes. After applying current, the reliefs are deformed and the surface is leveled.

- Suture, when the parts are overlapped with roller electrodes.

Diffusion

The technology is based on the mutual penetration (diffusion) of atoms of materials if they are pressed tightly against one another. When heated, the rate of particle exchange increases. Welding is carried out in a vacuum chamber or an inert gas environment. The parts are compressed with a force of at least 20 MPa, the surface layers are heated by electric current to a temperature close to the melting point. For reliable adhesion, the workpieces are left in this position for some time without turning off the current.

Safety precautions

Working with welding equipment involves many factors hazardous to the health of the operator. High temperatures, explosive atmospheres and harmful chemical fumes require a person to strictly adhere to safety measures:

- All electrical units and devices must be reliably grounded and insulated.

- It is necessary to work in dry overalls and gloves. To protect the skin of the face and eyes, be sure to use a mask with dark glass.

- A first aid kit and a fire extinguisher must be available at the welder’s workplace.

- The room where welding work is carried out must have good ventilation.

- Work is prohibited from being carried out in close proximity to flammable objects.

- It is prohibited to leave gas cylinders unattended.

There are a large number of types of metal welding; the welder himself decides which one to choose, based on the availability of equipment and the ability to achieve the required work result. The welder must know the structure and principles of operation of certain equipment.

Mechanical welding class

These types of welding are performed using the energy of friction, explosion, pressure, and ultrasound. When exposed to them, heat is released sufficient to melt the material.

Friction

The technology is included in the list of promising developments. One of the workpieces to be joined is fixed motionless, the other, pressed against it, rotates. A detailed classification of friction welding includes the following subtypes:

- Stirring is performed on equipment equipped with a rotation tool with two elements - a base (collar) and a tip (pin). The compound is created by extrusion followed by mixing.

- The pipes are joined radially, placing a rotating ring between the ends.

- The pin seals small through damage. In place of the hole, a round hole is drilled into which a rotating pin made of the same metal as the main one is inserted.

- Linear is performed without rotation. The workpieces are rubbed against each other until the mating surfaces begin to melt, then the compression force is increased.

- In inertial welding, the workpieces are moved using the energy of a pre-spun flywheel.

Friction stir welding method

Cold

The technology is based on the principle of compressing parts with punches with a force of 1 - 3 GPa. Spot welding is carried out with rods, seam welding with rollers. The punch is pressed into the workpiece until plastic deformation occurs, which contributes to the appearance of interatomic bonds and the creation of a connection between the parts. Welding is performed by simple compression or by shifting parts after compression. The strength of the connection depends on the quality of preparation of the joint, the degree of compression, and the nature of the impact (vibration or static).

Types of cold welding of metals

When connecting butts, the amount of deformation is limited by the size of the parts of the workpieces protruding from the clamps. To prevent the sheets from warping when overlapped, they are secured with clamps. After plastic deformation, the metal becomes harder, so the strength of the weld is higher than that of the workpieces.

Features of surface welding

The entire process of welding metals occurs in two stages. First, the surfaces of the materials must be brought closer to each other at a distance of interatomic adhesion forces. At room temperature, standard metals are unable to bond even when compressed with significant force. The reason for this is their physical hardness, so contact when such materials come together occurs only at some points, regardless of the quality of surface treatment. It is surface contamination that significantly affects the possibility of adhesion of materials, because films, oxides, as well as layers of impurity atoms are always present in natural conditions.

Therefore, the creation of contact between the edges of parts can be achieved either due to plastic deformations that arise as a result of applied pressure, or in the event of melting of the material.

At the next stage of metal welding, electron diffusion occurs between the atoms of the surfaces being joined. Therefore, the interface between the edges disappears and either a metallic atomic bond or an ionic and covalent bond (in the case of semiconductors or dielectrics) is obtained.