Non-ferrous metal Rolled aluminum Sheet

Aluminum sheets are produced in accordance with GOST 21631-76 from aluminum and its alloys of grades A0-A7, AD0, AD1, AD, AMg2, AMg3, AMg5, AMg6B, AMts, VD1, D16A, D1, etc. The thickness of aluminum sheet is within 0. 3-10.5mm, aluminum sheet length - 2000-7200mm. The weight of an aluminum sheet is determined according to the tables of GOST 21631-76, which show the theoretical weights of one linear meter of sheet.

Possessing fire-resistant qualities, as well as incomparable resistance to atmospheric and mechanical influences, aluminum sheet is increasingly used by many designers.

Weight of aluminum sheet according to GOST 21631-76

Sheet thickness, mm

Theoretical weight of 1 m of sheet, kg, normal manufacturing accuracy in thickness and increased accuracy in width

Aluminum sheet weight

For the convenience of preliminary calculations of various designs, we bring to your attention the weight of aluminum sheets per piece and square meter in the table below. These sheets are widely used in industry. The weight of sheets made of other alloys can be calculated using conversion factors. To calculate the weight of AMg2 aluminum sheets, this weight must be multiplied by a factor of 0.992; Amg3 – 0.988; AMg5 – 0.981; AMg6 – 0.977; D16 – 1.03. Please note that the indicated weight of aluminum sheet is approximate and calculated using theoretical formulas. The weight of real sheets can fluctuate both up and down by several percent; this is due to technological variation during production. If the required sheet size is not in the table, you can use our non-ferrous rolled metal weight calculator

You may also need other calculation tables for other types of rolled aluminum

Pipe weight: how to calculate it yourself?

Pipe weight is one of the main characteristics of pipe parameters. In addition to characteristics such as dimensions and strength characteristics, the weight of a meter of pipe is a value that allows certain calculations of the load on supporting structures to be made when designing and installing pipelines.

In addition, the weight of the pipe is important when transporting pipes, especially large ones, for calculating the load capacity and the number of transported pipes. The weight of a meter of pipe is most often measured in kilograms.

It is especially important to be able to calculate the weight of stainless steel pipes when installing a water supply or gas pipeline in order to calculate the load on supports or fastenings when installing pipes on a supporting structure.

Science and technology have again come to the aid of the average consumer, and not only him. To determine the specific gravity of steel, polypropylene, cast iron and copper pipes, there are special tables and so-called. calculators for calculating the weight or mass of pipes.

But this applies to standard pipe parameters. What if you need non-standard pipes? It is for calculating the specific gravity of pipes that there are formulas that allow you to calculate the weight of pipes made of any material.

To calculate a round stainless steel pipe, the formula is as follows: Vmp = ((Dn - T)/40.55)*T. The decoding of the meanings is as follows:

- WMP is the weight of a linear meter, which is calculated in kilograms.

- Dn – pipe diameter in mm.

- T – pipe wall thickness in mm.

For each pipeline system, the appropriate pipes should be selected, taking into account their operational characteristics and overall weight parameters.

It is recommended to select plastic or metal-plastic pipes for the heating system or water supply system in the house. In addition to their high qualities, they are light in weight. The weight of a PVC pipe or the weight of a polypropylene pipe is much lower than the weight of steel pipes.

Polymer pipes are a molded product, and the weight of the pipe is determined for one linear meter. There are two types of weight: real and calculated. The real (actual) weight of a polyethylene pipe is the actual weight of one linear meter of pipe.

Advice

There is a formula for the calculated (theoretical) weight of the pipe: M=R*S. R is the density of the pipe in kg/m3, S is the cross-sectional area in sq.m. The density value for polyethylene pipes is taken at 950 kg/m3.

To organize sewer pipelines, a cast iron sewer pipe is still used, the weight of which significantly exceeds the weight of polyethylene pipes. Therefore, if you are planning to install a sewer or drainage system in your house, then PVC pipes are successfully used for these purposes, the weight and performance characteristics of which make the installation of the pipeline more convenient and practical.

How much does a square meter of aluminum sheet weigh?

| Sheet size | Weight of 1 square meter, kg |

| Weight of 1 sq.m of aluminum sheet 0.5 mm thick | 1,4 |

| Weight of 1 sq.m of aluminum sheet 1 mm thick | 2,7 |

| Weight of 1 sq.m of aluminum sheet 1.5 mm thick | 4,1 |

| Weight of 1 sq.m of aluminum sheet 2 mm thick | 5,4 |

| Weight of 1 sq.m of aluminum sheet 2.5 mm thick | 6,8 |

| Weight of 1 sq.m of aluminum sheet 3 mm thick | 8,2 |

| Weight of 1 sq.m of aluminum sheet 4 mm thick | 10,9 |

| Weight of 1 sq.m of aluminum sheet 5 mm thick | 13,6 |

| Weight of 1 sq.m of aluminum sheet 6 mm thick | 16,3 |

| Weight of 1 sq.m of aluminum sheet 8 mm thick | 21,8 |

| Weight of 1 sq.m of aluminum sheet 10 mm thick | 27,2 |

How to find out the weight by the diameter and wall thickness of a pipe - formulas and calculation examples

Everyone has their own reasons for determining the mass of one pipe or an entire batch. For example, it is necessary to resolve the issue of laying communications and the carrying capacity of the vehicle. But mainly this is required to verify the correctness of monetary calculations.

The specificity of pipe products is that their cost is more “tied” not to the length of the products, but to their weight, and the price mainly depends on the raw material component, that is, on the amount of metal per 1 running meter, so the weight of the pipe can be calculated in diameter and wall thickness - they are the most important indicators in this case.

How to find out the weight of a pipe

According to tables posted in specialized directories or on thematic sites. In many of them, the calculated weight of 1 linear meter is indicated in the right column. pipes for each sample, depending on its steel pipe diameter and its wall thickness.

How much does an aluminum sheet weigh?

| Aluminum sheet weight | Weight of 1 sheet, kg |

| Weight of aluminum sheet 1x1200x3000 | 9,9 |

| Weight of aluminum sheet 1x1500x3000 | 12,4 |

| Weight of aluminum sheet 1x1500x4000 | 16,5 |

| Weight of aluminum sheet 1x1500x6000 | 24,8 |

| Weight of aluminum sheet 1.5x1200x3000 | 14,9 |

| Weight of aluminum sheet 1.5x1500x3000 | 18,6 |

| Weight of aluminum sheet 1.5x1500x4000 | 24,8 |

| Weight of aluminum sheet 1.5x1500x6000 | 37,1 |

| Weight of aluminum sheet 2x1200x3000 | 19,8 |

| Weight of aluminum sheet 2x1500x3000 | 24,8 |

| Weight of aluminum sheet 2x1500x4000 | 33 |

| Weight of aluminum sheet 2x1500x6000 | 49,5 |

| Weight of aluminum sheet 2.5x1200x3000 | 24,8 |

| Weight of aluminum sheet 2.5x1500x3000 | 30,9 |

| Weight of aluminum sheet 2.5x1500x4000 | 41,3 |

| Weight of aluminum sheet 2.5x1500x6000 | 61,9 |

| Weight of aluminum sheet 3x1200x3000 | 29,7 |

| Weight of aluminum sheet 3x1500x3000 | 37,1 |

| Weight of aluminum sheet 3x1500x4000 | 49,5 |

| Weight of aluminum sheet 3x1500x6000 | 74,3 |

| Weight of aluminum sheet 4x1200x3000 | 39,6 |

| Weight of aluminum sheet 4x1500x3000 | 49,5 |

| Weight of aluminum sheet 4x1500x4000 | 66 |

| Weight of aluminum sheet 4x1500x6000 | 99 |

| Weight of aluminum sheet 5x1200x3000 | 49,5 |

| Weight of aluminum sheet 5x1500x3000 | 61,9 |

| Weight of aluminum sheet 5x1500x4000 | 82,5 |

| Weight of aluminum sheet 5x1500x6000 | 123,8 |

| Weight of aluminum sheet 6x1200x3000 | 59,4 |

| Weight of aluminum sheet 6x1500x3000 | 74,3 |

| Weight of aluminum sheet 6x1500x4000 | 99 |

| Weight of aluminum sheet 6x1500x6000 | 148,5 |

| Weight of aluminum sheet 8x1200x3000 | 79,2 |

| Weight of aluminum sheet 8x1500x3000 | 99 |

| Weight of aluminum sheet 8x1500x4000 | 132 |

| Weight of aluminum sheet 8x1500x6000 | 198 |

| Weight of aluminum sheet 10x1200x3000 | 99 |

| Weight of aluminum sheet 10x1500x3000 | 123,8 |

| Weight of aluminum sheet 10x1500x4000 | 165 |

| Weight of aluminum sheet 10x1500x6000 | 247,5 |

Read also: What to make a wedge for an ax from

You can also study the materials

At Nevskaya Aluminum Company you can buy various types of rolled aluminum from a warehouse in St. Petersburg:

Send your applications for the purchase of rolled aluminum and copper to our email This email address is being protected from spambots. You must have JavaScript enabled to view it.

St. Petersburg, Ligovsky, 266 © Nevskaya Aluminum Company, 2019

Aluminum sheets are resistant to corrosion and acids of organic origin, high ductility, good electrical and thermal conductivity. Upon contact with oxygen, an Al2O3 oxide film is formed on the surface of the material, protecting products from aggressive environments and rust formation. To enhance the original properties of the metal and its alloys, cladding is used - a thermomechanical coating based on aluminum with the addition of alloying elements and impurities (zinc, magnesium, copper, silicon, manganese, iron, titanium).

The scope of application of aluminum sheets is determined by the initial characteristics of the material:

- acid-resistant

- used for the production of fuel tanks, welded containers, rivets, radiators and vehicle frames. - technical

- economical insulating and finishing material. - food grade

- suitable for the manufacture of freezers, canisters, tanks, sinks, and kitchen equipment.

Perforated blanks are in demand in the construction industry. Textured (corrugated) sheets are used for arranging technical platforms and stairs, floors in workshops and truck bodies. Corrugated material with different wave heights is intended for the construction of roofing coverings.

Aluminum sheet is produced from flat ingots by cold and hot rolling. The first method is only suitable for producing layers up to 6 mm thick.

Classification according to GOST 21631-76

The main document regulating the production of smooth, corrugated and perforated aluminum sheets is GOST 21631-76.

| Categories, classes, groups | Letters, indices | Notes | |

| By type of manufacture | Unclad (without protective coating) | Without designation | |

| Technological cladding | B | The layer thickness is 1.5% of the actual sheet thickness. Facilitates the rolling process and improves the appearance of semi-finished products. | |

| Plating is normal | A | The layer thickness is 2% for sheet thickness from 1.9 mm, 4% for sheet thickness less than 1.9 mm. Performs the function of anti-corrosion protection. | |

| Thickened plating | U | The layer thickness is 4% with a sheet thickness of 0.5-1.9 mm, 8% with a sheet thickness of 1.9 mm. Gives decorative properties to the surface. | |

| Material composition | No heat treatment | Without designation | Sheets can be annealed, with the exception of products made from VD1 alloy |

| Annealed | M | It is possible to manufacture without heat treatment - in cases where the mechanical properties, surface quality and non-flatness are within normal limits. | |

| Hardened, artificially aged | T1 | ||

| Cold-hardened | N | Cold working increases strength, tensile strength and hardness. | |

| Tempered, naturally aged | T | ||

| Semi-hardened | H2 | ||

| Hard-worked, hardened and naturally aged | TN | ||

| Quality finish | Normal | Without designation | Manufactured from all grades of aluminum and aluminum-based alloys regulated by GOST 21631-76. |

| Increased | P | ||

| High | IN | The maximum sheet thickness is 4 mm. They are made of aluminum under the brands A7, A6, A5, A0, AD00, AD0, AD1, AD and aluminum alloys under the brands AMts, AMg2. | |

| Precision manufacturing | Normal | Without designation | |

| Increased | P | According to one or more parameters - length, width, thickness. |

Read also: Tool for sanding wood at home

Domestic producers of rolled aluminum meet 80% of the needs of the Russian market, while the production of sheets accounts for about 70% of the total production volume. Imported materials are marked according to ISO 209-1 (international standard) and EN 573 (European standard).

Transcription examples

- Sheet AMg2.M 07P×1200×2000P GOST 21631-76.

B - sheet of aluminum alloy grade AMg2 in an annealed state, 0.7 mm thick, 1200 mm wide, 2000 mm long, increased manufacturing accuracy, high surface finish. - Sheet AD1 5x1000x2000 GOST 21631-76

- sheet of aluminum grade AD1, without heat treatment, 5 mm thick, 1000 mm wide, 2000 mm long, normal manufacturing accuracy, normal surface finish. - Sheet AD1.M 5×1200×2000 GOST 21631-76.

P - the same, annealed, increased surface finish. - Sheet AD1.N2 5P×1000P×2000 GOST 21631-76.

P - the same, semi-hardened, with increased manufacturing precision in thickness and width. - Sheet D16.B.TN 2×1200×2000 GOST 21631-76.

P - sheet of aluminum alloy grade D16 with technological cladding, cold-hardened after hardening and natural aging, 2 mm thick, 1200 mm wide, 2000 mm long, normal manufacturing accuracy, increased surface finish. - Sheet D16.B.TN 2P×1200×2000 GOST 21631-76.

P - the same, with increased manufacturing accuracy in thickness.

Aluminum sheet weight

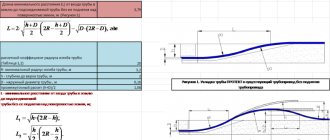

To calculate the theoretical mass of aluminum sheets (kg/linear meter), the following formula is used:

- Nmax - the largest thickness indicator (in mm);

- Nmin - the smallest thickness indicator (in mm);

- Vmax - the largest width (in mm);

- Vmin - the smallest width (in mm);

- γ—alloy density (in g/m³).

According to GOST 21631-76, the weight is calculated at a declared density of 2.85 g/m³, which corresponds to grades B95, B95-1, B95-2. For other aluminum alloys, conversion factors are used.

Data for sheet 1000 mm wide:

| Declared thickness, mm | Theoretical weight in m² with normal manufacturing accuracy in terms of width and thickness, kg | Theoretical weight in m² with increased manufacturing accuracy in thickness and normal precision in width, kg | Theoretical weight in m² with increased manufacturing precision in terms of width and thickness, kg | Theoretical weight in m² with normal manufacturing accuracy in thickness and increased precision in width, kg | Theoretical weight in m² of sheets made of AMg3, AMg5, AMg6 alloys - without heat treatment and annealed, kg |

| 0,3 | 0,715 | 0,758 | 0,758 | 0,715 | – |

| 0,4 | 1,001 | 1,03 | 1,029 | 1 | – |

| 0,5 | 1,288 | 1,316 | 1,315 | 1,286 | – |

| 0,6 | 1,545 | 1,574 | 1,572 | 1,544 | – |

| 0,7 | 1,831 | 1,86 | 1,858 | 1,829 | – |

| 0,8 | 2,117 | 2,146 | 2,144 | 2,115 | – |

| 0,9 | 2,404 | 2,432 | 2,43 | 2,401 | – |

| 1 | 2,647 | 2,69 | 2,687 | 2,644 | – |

| 1,2 | 3,219 | 3,262 | 3,259 | 3,216 | – |

| 1,5 | 4,006 | 4,092 | 4,088 | 4,002 | – |

| 1,6 | 4,292 | 4,378 | 4,374 | 4,288 | – |

| 1,8 | 4,864 | 4,922 | 4,917 | 4,86 | – |

| 1,9 | 5,151 | 5,208 | 5,203 | 5,145 | – |

| 2 | 5,437 | 5,494 | 5,488 | 5,431 | – |

| 2,5 | 6,796 | 6,896 | 6,889 | 6,789 | – |

| 3 | 8,155 | 8,298 | 8,29 | 8,147 | – |

| 3,5 | 9,586 | 9,7 | 9,69 | 9,576 | – |

| 4 | 11,016 | 11,102 | 11,091 | 11,005 | – |

| 4,5 | 11,447 | 12,504 | 12,492 | 12,435 | – |

| 5 | 13,806 | 13,878 | 13,864 | 13,793 | 14,307 |

| 5,5 | 15,267 | 15,31 | 15,295 | 15,252 | 15,769 |

| 6 | 16,629 | 16,658 | 16,641 | 16,613 | 17,203 |

| 6,5 | 18,063 | 18,091 | 18,073 | 18,045 | 18,636 |

| 7 | 19,496 | 19,525 | 19,506 | 19,477 | 20,07 |

| 7,5 | 20,93 | 20,959 | 20,938 | 20,909 | 21,503 |

| 8 | 22,292 | 22,335 | 22,313 | 22,27 | 22,937 |

| 8,5 | 23,725 | 23,768 | 23,745 | 23,702 | 24,37 |

| 9 | 21,159 | 25,202 | 25,177 | 25,134 | 25,804 |

| 9,5 | 26,592 | 26,635 | 26,609 | 26,566 | 22,237 |

| 10 | 27,954 | 27,983 | 27,955 | 27,926 | 28,671 |

| 10,5 | 29,388 | 29,416 | 29,387 | 29,359 | 30,105 |

Read also: Repair of a Chinese soldering iron with temperature controller

Table - calculation of the weight of an aluminum pipe. Dimensions and thicknesses of aluminum pipe. Millimeters.

Are you interested in calculating the weight of an aluminum pipe in millimeters? The supplier Evek GmbH offers to buy aluminum pipes at an affordable price in a wide range. We will ensure delivery of products to any point on the continent. The price is optimal.

Weight per linear meter of aluminum pipes

It is necessary to determine the volume of the order of pipe metal products. The difficulty lies in the fact that each deformable aluminum alloy differs in its density values, so an accurate calculation of the total pipe length is possible only for products made from the same grade of rolled aluminum pipe. According to the order card, the range of aluminum alloys that are included in the application is determined; The density of each type of aluminum alloy is established. For most brands of deformable aluminum, you can use the table:

| Alloy grade | AD1, AB | AMts | AMg | D1 | D16 | VD17, D19 | B93…B96 |

| Density, kg/m3 | 2710 | 2730 | 2650…2680 | 2790 | 2770 | 2755 | 2840…2890 |

- Using the formula V = 3.14 (R2-r2)L, the volume of a tubular element with length L is determined (R is the outer radius of the tube, r is the inner radius of the tube);

- According to the dependence M = ρV (where ρ is the density of the aluminum material or its alloy), the mass of a certain section of the tube is determined.

The supplier Evek GmbH offers to buy aluminum pipes at an affordable price in a wide range. We will ensure delivery of products to any point on the continent. The price is optimal.

Approximate weight of aluminum pipes

In many cases, there is no need to accurately calculate the mass of rolled aluminum pipes or its alloys. Then, taking into account a certain reserve (5...10%, depending on the cross-section of the pipes and the type of technological processes used for its processing), the mass of a linear meter can be calculated using the proposed table:

| Outer diameter, mm | Approximate mass of one linear meter of rolled pipe with the average thickness of its machine, mm | ||||

| 0,05…0,1 | 0,1…0,75 | 0,14…1,5 | 0,2…2,5 | 0,4…5,0 | |

| 6 | 0,023 | 0,034 | 0,043 | — | — |

| 10 | 0,04 | 0,059 | 0,11 | 0,163 | — |

| 15 | 0,062 | 0,091 | 0,174 | 0,271 | — |

| 20 | 0,083 | 0,123 | 0,238 | 0,378 | — |

| 25 | 0,104 | 0,154 | 0,302 | 0,485 | 0,868 |

| 32 | — | 0,199 | 0,391 | 0,636 | 1,168 |

| 38 | — | 0,237 | 0,468 | 0,765 | 1,426 |

Buy. Supplier, price

Are you interested in calculating the weight of an aluminum pipe in millimeters? The supplier Evek GmbH offers to buy aluminum pipes at the manufacturer's price. We will ensure delivery of products to any point on the continent. The price is optimal. We invite you to partner cooperation.

Alloys used in the production of aluminum sheets

For the production of sheets, aluminum grades A0, A5, A6, A7 are used (the chemical composition is regulated by GOST 11069-74), as well as AD, AD0, AD00, AD1 (according to GOST 4784-74). The range also includes products made from heat-strengthened and non-heat-strengthened alloys of the following types:

- high strength;

- weldable, standard strength;

- normal strength (duralumin);

- highly plastic, medium strength (magnalia);

- highly plastic, low strength - with and without alloying.

| Aluminum/alloy grade | No heat treatment | M | H2 | N | T | T1 | TN |

| A0 | + | + | + | + | |||

| A5 | + | + | + | + | |||

| A6 | + | + | + | + | |||

| A7 | + | + | + | + | |||

| HELL | + | + | + | + | |||

| AD0 | + | + | + | + | |||

| AD1 | + | + | + | + | |||

| AD00 | + | + | + | + | |||

| AMts | + | + | + | + | |||

| AMtsS | + | + | + | + | |||

| AMg2 | + | + | + | + | |||

| AMg3 | + | + | + | ||||

| AMg5 | + | + | |||||

| AMg6 | + | + | |||||

| AMg6B | + | + | |||||

| AMg6U | + | ||||||

| AB | + | + | + | + | |||

| D1A | + | + | + | ||||

| D16A | + | + | + | + | |||

| D16B | + | + | + | ||||

| D16 | + | + | + | ||||

| D16U | + | + | |||||

| B95-1A | + | + | + | ||||

| B95-1 | + | ||||||

| B95-2A | + | + | + | ||||

| V95-2B | + | ||||||

| VD1A | + | + | + | ||||

| VD1B | + | + | + | + | |||

| VD1 | + | + | + | + | |||

| AKMA | + | + | + | + | |||

| AKMB | + | ||||||

| AKM | + | ||||||

| B95A | + | + | + | ||||

| 1915 | + | + | + | ||||

| D12 | + | + | |||||

| MM | + |

Dimensions of aluminum sheet according to GOST 21631-76

The dimensions of the sheet depend on the brand of material used and the type of processing:

- The width varies between 600-2000 mm.

- The minimum length is 2000 mm, the maximum is 7000 m.

- Sheet thickness according to GOST 21631-76 - from 0.3 to 10.5 mm.

Rolled aluminum is supplied in sheets of measured, multiple-measured or unmeasured lengths. In the second case, the step is 500 mm.

Maximum deviations in width, in mm:

| Thickness | Length | Increased accuracy | Accuracy is normal |

| 0,3-5 | Up to 1000 | +6 | +8 |

| More than 1000 | +10 | ||

| 5-10,5 | Up to 1000 | +10 | +12 |

| More than 1000 | By agreement | +15 |

Maximum deviations along the length, in mm:

| Thickness | Length | Increased accuracy | Accuracy is normal |

| 0,3-3,5 | 2000-7200 | +8 | +20 |

| 3,5-10,5 | By agreement | +25 |

On one side of the aluminum sheet, the grade and condition of the material, the presence and type of plating, overall dimensions, batch number and quality control stamp are indicated. The data is applied at a distance of no more than 3 cm from the edge. When the thickness of rolled aluminum is less than 1 mm, marking only the top sheet of the bundle is allowed.

You can also:

Atlant-Metal LLC © 1994–2011 All rights reserved.

Pipe weight

Profile pipes are used throughout the construction of systems for transporting liquids and gases as a structural element.

The weight of a meter of round pipe is a necessary parameter when choosing products for installing a plumbing system. The parameter is important for carrying out load calculations in the finished structure, ensuring a level of safety, and eliminating the risk of deformation. Calculating the weight of a rectangular pipe can be important for calculating the cost of transportation. The parameter is influenced by the width, wall thickness, density and shape of the product.

Calculating the mass allows you to determine the future performance characteristics of the finished structure.

Pipe weight table

A common type of structural products are pipes. They are manufactured in Belgorod by winding, molding, pultrusion or extrusion and sold in St. Petersburg and other cities. The profile is used in the field of construction, housing and communal services, and industry. Production standards are established by GOST 10740. For the pipe weight parameter, the table is as follows:

| Nominal diameter, mm | Hardness class | |||

| 2500 | 5000 | 10000 | coupling | |

| 300 | 7 kg | 9 kg | 10 kg | 11 kg |

| 500 | 18 kg | 22 kg | 27 kg | 19 kg |

| 700 | 33 kg | 41 kg | 50 kg | 30 kg |

| 1000 | 66 kg | 82 kg | 103 kg | 63 kg |

| 1200 | 94 kg | 117 kg | 146 kg | 83 kg |

| 1400 | 127 kg | 158 kg | 198 kg | 113 kg |

| 2200 | 305 kg | 384 kg | 482 kg | 232 kg |

The table shows the weight of 1 m of seamless fiberglass pipe with pressure class PN16. The weight of pipes 25, 32, 40, 150 mm in diameter will depend on the material of manufacture.

Standard pipe weights by material

Profile elements of round and square cross-section are widely used in various industrial and construction fields. The cost of the material is significantly influenced by the specific gravity of a meter of profile pipe. It depends on the shape of the profile, the width of the walls, the thickness of the walls, as well as the density of the metal for manufacturing.

To calculate the specific mass of a seamless or electric welded element made of aluminum, copper, cast iron, steel, it is necessary to use the formula. One meter of profile is equal to: S*2*(A+B)*p. Designations in the formula:

- S – thickness of one profile wall, measured in meters;

- A, B – length of the sides of the element, measured in meters;

- p is the density of the metal used for manufacturing.

The presented formula allows you to independently determine the weight of an element in the absence of a ready-made table.

Fiberglass pipe weight

Fiberglass pipes are made from polyester and reinforced with fiberglass. The material is durable, reliable, and meets quality standards. Light weight makes it easy to install the structure. The parameter depends on the nominal diameter, wall thickness and rigidity.

The minimum length of the product is 3 meters, the maximum is 18 meters. Products with a length of 12 meters are mainly used. Size also affects the weight of the finished element and its cost. The material is suitable for transporting waste, drinking and industrial water.

The products are used in the construction of water supply and sewerage systems.

Steel pipe weight

The weight of one linear meter of steel pipe needs to be known to carry out load calculations for metal structures. The service life and reliability of the building depend on this. To determine the weight you need to know the following data:

- a – cross-section width;

- b – cross-sectional height;

- S – element wall thickness;

- L is the length of the product itself.

The indicator also depends on the outer diameter of the product, expressed in millimeters. The type of profile plays a big role: square or round. Steel pipes are used as an element for creating a highway and sewer construction.

Stainless pipe weight

A distinctive feature of the product is its resistance to corrosion. The low weight of the stainless pipe allows installation in hard-to-reach places and in narrow spaces. When selling, manufacturers set the cost of the material per kilogram.

The weight of a stainless steel pipe is influenced by the diameter and wall thickness. If you pick up two profiles of the same length, made of the same material, having different wall thicknesses, then their mass will differ.

For example, with a section size of 5 mm and a thickness of 1 mm, the mass of one element will be 0.100 kg, and with a size of 20 mm and a wall thickness of 1 mm - 0.425 kg. The cost of the product also depends on this parameter.

Galvanized pipe weight

Galvanized pipe is made from different grades of steel and is used in the housing and communal services sector. Suitable for the construction of water, gas, heat supply systems, fire or plumbing pipelines. The weight of the drainpipe varies from two to thirty kilograms depending on the following parameters:

- cross-sectional and longitudinal dimensions;

- length expressed in meters;

- the grade of steel used.

The standard weight of galvanized pipe is about 5 kilograms per linear meter. Coated elements are protected from corrosion for many years; their service life is more than 25-30 years. The treated surface does not require additional painting and is aesthetically pleasing.

PVC pipe weight

PVC pipes are successfully used for transporting cold water and working in harsh conditions. They are not subject to corrosion, deformation, mechanical damage, or soil pressure.

The weight of the products depends on the standard dimensional ratio, which is calculated by dividing the outer diameter by the specified wall thickness.

The weight is also affected by the nominal outer section size.

When choosing the profile weight, the maximum operating pressure of the working medium and the density of the polymer material are taken into account. The weight of one linear meter of the product ranges from 2 to 25 kilograms. This allows it to be installed at great depths and provides pressure resistance.

Weight of plastic pipes

In accordance with the state quality standard GOST 18599-2001, the classification of plastic pipes is carried out in relation to the material from which they are made.

The calculated weight of products is influenced by the nominal outer diameter, expressed in millimeters.

note

Manufacturers mainly manufacture plastic structures ranging in size from 10 to 1600 mm, ensuring easy installation and operation.