A screw jack is a mechanism whose main task is to lift a load and fix it at a height. A screw lift differs from other similar mechanisms in that the mechanism is installed directly under the load, which eliminates the need to use additional tools - chains and ropes. The load is lifted manually by means of a screw.

Many people believe that a mechanical screw jack is used only when changing car wheels, although bridge spans are also moved with the help of similar mechanisms; the bodies of large machines are held in the desired position, powerful springs are compressed, and steel pipes are moved through the soil. The design of the screw device is simple and reliable.

Types of screw mechanical jacks

There are many types of lifting devices for cars, the most popular is the diamond screw jack. A screw jack, the price of which is at an average level, is the most stable and compact.

Car jack

The main advantages are:

- The car is lifted along a vertical plane, without pushing in different directions.

- If the maximum permissible loads are observed, it is durable and does not break.

- It is characterized by increased stability.

- Repairable, folds compactly.

Repair of this type of mechanism occurs without difficulty; the screw part often fails, which can be replaced with a screw-type construction pin. If you have the necessary plumbing skills, it is enough to cut the stud in accordance with the size of the jack and weld a nut on the fastening side. It is possible to make the device yourself, but the time spent is not worth the savings, because the price of a screw mechanical jack starts from 400 rubles.

Mechanical jack

The mechanical jack of the lever-screw type is reliable during operation, thanks to the smallest number of moving elements. The price of such a device on the market is not high, but there are a number of disadvantages. The stability of the device is not at a high level; when lifted, it pushes the car body away from itself. Increased effort is required to lift equipment with such a device, which is not very convenient for women, as well as for long-term work.

In the domestic automobile industry, vertical screw jacks have been used for a long time. The design features a long stroke and smooth force applied to the handle. The lifting height, sufficient for any type of work, made the unit attractive to car enthusiasts.

Vertical screw jacks

Rack-mount screw mechanisms are used less and less due to the high cost and specific purpose of the work. They require the object to be lifted to have special holes for guides. If installed incorrectly, it is easy to damage the car's paintwork.

Bottle devices differ from competitors in having a greater load capacity. There are varieties that can lift up to 5 tons; this solution will help owners of SUVs or minibuses. The design consists of persistent threads with impressive internal elements, which allows you to not worry about durability. The price of the device is high, which makes it difficult to choose between a conventional design; such jacks will help for construction purposes and other purposes.

Bottle jacks

In households, special screw construction jacks are used, which allow you to hold the load at a certain height. Under conditions of frequent use and a larger mass of objects, an electric jack, also of a screw configuration, is used.

Reviews from car owners

“The DVB-20 Hi model (the highest) is perfect for a duster, I think you can even take the DVB-20 Mi, if you suddenly need to jack it up out of the mud - it’s a little lower. To my joy, the DVB-20 Hi also fit under the VAZ-2114, with a gap of only 1 cm, but it fit under the standard seats - very successfully!” — review source

“To change the wheels and use them in minor garage repairs, we purchased a new mechanical telescopic jack AUTOPROFI 2 tons (DVB-20 Lo) with a price tag of 985 rubles. After purchasing, I tested the jack for ease of use:

- The jack is not high and easily fits into a car with a lowering of -30

- the long knob allows you to be located further away from the car body, eliminating human contact with the car body

- the effort to raise and lower the jack is very small, even a child can handle it

- The jack’s lifting capacity of 2 tons will allow it to be used not only for passenger cars but also for minibuses and SUVs” - source of review

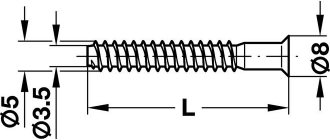

Screw jack device

Screw jacks are a simple design capable of lifting large masses of loads. The operating principle consists of converting torque into translational movement; the main structure consists of a screw, nut and gearbox.

A device with a loose nut must be used with extreme caution and monitor the level and quantity of its lubricant. Failure to comply with the maximum loads can damage the screw mechanism.

Increased safety during work is achieved by the presence of a self-braking function.

The device of a car screw jack

The gearbox transmits torque to the support nut, where it lifts the load. There is a more modified screw jack device, where lifting rollers are added to the screws and nuts. Modernization is carried out to improve service life, reduce the coefficient of friction for easier lifting of the car.

Comparative review of popular models

The choice of a quality tool largely depends on its basic characteristics, manufacturer and demand for a particular model. The models presented below have gained strong popularity among consumers today.

Hydraulic rolling jack 2t TORIN Big Red TA820012S

Appearance TORIN Big Red TA820012S

Characteristics:

- Load capacity - 2 tons.

- Pickup height (min.) - 135 mm.

- Lifting height (max.) - 330 mm.

- Weight - 8.5 kg.

- There is a case for storing the device.

The jack is of excellent quality, has a reinforced structure and is quite maneuverable.

The plastic case helps protect the device from damage during transportation.

Low profile hydraulic rolling jack 2t Stels 51131

Appearance of Stels 51131

Characteristics:

- Load capacity - 2 tons.

- Pickup height (min.) - 100 mm.

- Lifting height (max.) - 350 mm.

- Weight - 12 kg.

This jack model is designed for lifting cars with low ground clearance.

To make the work process more convenient, the device was equipped with a rotating rubberized handle. In addition, the model has a rubber lining on the support platform and there is a tray for storing and transporting spool valves, nuts and other necessary parts. Thanks to the increased comfort in use, Stels 51131 is sought after by car owners who are accustomed to servicing their cars themselves.

Hydraulic rolling jack 3t Ombra OHT 203

Appearance of Ombra OHT 203

Characteristics:

- Load capacity - 3 tons.

- Pickup height (min.) - 192 mm.

- Lifting height (max.) - 533 mm.

- Weight - 19 kg.

On a note. The Ombra OHT 203 model is popular among motorists who drive a crossover or SUV. The jack allows you to easily pick up a vehicle and lift it more than half a meter.

Main features of a rack and pinion jack

The list of works performed by jacks can be listed endlessly. The rack and pinion design mechanism stands out from its competitors, which is useful in conditions remote from service when repairing a car.

Rack jack

Rack jack device

The design of the mechanism has increased dimensions; it can hardly fit into the trunk of a passenger vehicle. The technical characteristics and features of the rack jack correspond to the dimensions; the design allows you to lift a load weighing up to two tons to a height of more than 70 centimeters. The mechanism is also used in the form of a winch in rural areas; if you correctly adapt the device, it will help rescue the car from difficult conditions.

Bottom line

A jack is a necessary element of a car, which is selected as a useful thing. More than once he will save the owner on the road or help another person in trouble. Don't spare money on your purchase. A correctly selected jack will definitely please the owner.

- Next How to choose a DVR for a car: types of devices and their features

- Back Do-it-yourself heated mirrors: step-by-step instructions and installation

- Aug 6, 2019

- Aug 5, 2019

- Hyundai crossovers / News

Aug 5, 2019

- Aug 3, 2019

- Legislation / Taxes and fines

Aug 2, 2019

- Aug 1, 2019

- April 13, 2019

- March 12, 2019

- Feb 17, 2019

- April 11, 2019

- July 27, 2017

Hydraulic jacks

A common type of hydraulic jacks are bottle jacks. The main differences are in dimensions and working load capacity. The larger the jack body, the higher its characteristics and ability to lift loads, and, accordingly, the price. Durability and stability make this type of lifting equipment the most used in car repair shops. The design provides a safety valve that does not allow work to continue if the object weight exceeds 25% of the declared one.

Hydraulic jack and its structure

Repairing hydraulic devices is a simple process in which the main thing is to replace the seals and replenish the fluid level. The disadvantage is the increased initial height, heavy weight, and the ability to work only in a vertical position. A type of hydraulic device is a rolling one, which can often be found in auto repair shops.

The best companies

Encyclopedia of Mechanical Engineering XXL SEARCH

AE&T. This is one of the Russian companies that specialize in the production of car accessories. The Automotive Equipment & Tools brand was founded in 2005. Today its products can be purchased in almost all regions of Russia. It is almost impossible to find fault with the quality of this company’s products, since customer reviews are only good.

AIRLINE. This brand produces a huge number of different products intended for motorists: tool sets, luggage systems and, of course, jacks with a lifting capacity from 1 to 16 tons. All AIRLINE products are painted in the signature orange color.

Forsage. Mainly hydraulic jacks are produced under this brand. Their body is painted blue-gray. These products are manufactured in China, but this in no way affects their quality. Products can serve customers well for many years.

Pneumatic jacks

Pneumatic jacks are also considered a common type of rolling jacks, often used in large auto repair shops. The device consists of a pneumatic cushion that is inflated with compressed air. Inflatable lifting devices are made independently using a tube from a truck, together with a ball valve to gradually release the air.

Pneumatic jack device

For ordinary car owners, a type of pneumatic design is used that can be inflated from a hand pump or exhaust pipe. Such a mechanism will easily lift even the heaviest car to a height of more than half a meter and allow you to replace a wheel or diagnose the chassis.

Recommendations for use

After finishing use, the jack must be freed from loads. The device should be stored in a warm and dry place. Due to excess moisture, the mechanism may rust, and cold will negatively affect the quality of the oil. It is recommended not to work with a jack in severe frost. Loads on the device should not exceed those for which it is designed.

It is necessary to monitor the quality of the working fluid - some workshops may use recycled or low-quality industrial oil. This will lead to rapid breakdown and contamination of the jack. With constant use, pumping (oil change) should be carried out every 2-3 months. For rare use - once every six months. Thus, in the event of a hydraulic jack failure, it is necessary to check 3 components:

- Quality and quantity of liquid.

- Presence of air bubbles in the system.

- Contamination, loose valve fit.

In most situations, to solve all problems with the device, it is enough to clean it and change the oil.

This is interesting: Military oath

Application of screw type jacks

The scope of application of screw-type mechanisms may vary depending on the type of work and purpose. A varied selection of mechanisms according to their characteristics allows the design to be used in various processes:

- Installation and dismantling of car wheels.

- Maintenance and diagnostics of machines.

- Compression of springs and related mechanisms.

- Laying pipes.

- Lifting loads to the required height and moving them.

Lifting system based on jacks

Screw jack as an adjustable shrinkage compensator

Screw-type lifting devices began to be used for lifting loads about two thousand years ago. At that time, the device featured a minimal number of parts in its design, but worked more efficiently than a lever. The main purpose of screw devices is to replace a broken wheel and provide car service. A screw jack is included in every motorist's kit.

Description

The design and structure of a hydraulic jack is relatively simple. These devices have a universal purpose and can be used in a variety of fields, for various jobs and manipulations. The overall simplicity of the system increases its reliability. The body of any model is made of a strong, reliable alloy of a special recipe. An important property of this alloy is its resistance to corrosion.

The working chamber of the hydraulic jack has a mirror surface. The piston is assembled from several components. To limit the movement of liquid, a special valve is used.

A manual or automatic mechanism helps to start moving the oil. Models with a paw differ from regular ones in that they are designed for low pick-up.

This is interesting: Fire ladder (AL): purpose, types, design

How to choose a screw jack

The choice of jack is made for each type of specific work. It is necessary to accurately determine whether it is possible to use a manual mechanism, or whether it is necessary to use an electric drive. Manual devices do not require preliminary calculations; when working with electromechanical devices, the mass of loads lifted by a jack is accurately measured. The calculation is made to calculate the power of the structure, taking into account the factors of maximum lifting height, working stroke and initial height. Hydraulic mechanisms will require calculation of the force exerted on the handle and the power of the electric motor.

Basic requirements for mechanisms:

- The load capacity is selected according to the type of car; if the design is used as a universal device, it is important to pay attention to more powerful models.

- The lifting height varies, so it’s worth looking at the numbers; the higher, the better.

- The presence of special grooves or cells for lifting on a car requires the use of a device of the appropriate type, otherwise stability is lost.

The most popular type of lifting equipment is mechanical screw designs, which are characterized by low cost and ease of operation. The rhombic type of mechanisms comes complete with almost every modern car, but there are times when you have to select a device for certain jobs.

When purchasing a jack, you should refer to the technical documentation of the car, where the curb weight is precisely indicated. A power reserve is necessary, but you should not be overly insured, because... more lifting devices have increased weight and dimensions.

Air or dirt entering the working cavity

During prolonged use of a hydraulic jack, air may accumulate in its working cavity, which negatively affects the efficiency of the device. Usually the reason for this lies in the lack of fluid in the hydraulic system, which is why air gets into it.

To do this, the bypass valve and oil reservoir are opened. After this, the mechanism pump is quickly pumped several times. In this way, you can quickly and effectively remove all the air that got inside the working cavity of the device during operation. Having completed this procedure, the bypass valve closes, and the plug from the oil tank is installed in its place. If everything is done correctly, the air from the working cavity will be completely removed, and the mechanism will again be able to operate at full capacity.

If such a procedure helps little or does not help at all, you can repeat it again. If necessary, you can use some other methods to eliminate the presence of air.

Another fairly effective way to help the jack is to unscrew the locking needle, use the screw to lift the plunger to the upper position and release it so that it returns to its original lower position. This procedure should be repeated several times for maximum effectiveness.

Another reason why the jack may not work well or not work at all is if dirt gets into the main cavity. In this case, you need to remove the housing head, pour kerosene inside without installing the locking needle, and bleed the mechanism. After this, the kerosene is drained and clean liquid is poured into the device.

Thus, the most common problems with the operation of a hydraulic jack can be corrected with your own hands: replacing the working fluid, cleaning the working cavity, and the like. If there are any serious faults, the device may require professional repair.

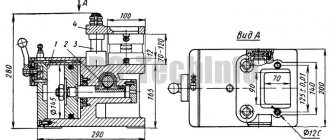

DIY screw jack

Assembling a screw jack with your own hands is cost-effective if you save on budget or have specific operating conditions. Self-production will cost less than a ready-made version if you have basic plumbing experience, guided by certain schemes.

For manufacturing you will need several rack pipes, a sheet of metal 4-6 mm thick, and a mechanical rod. The pipes are welded in parallel, the base and top are fastened with a piece of metal. Then a nut is welded and connected to a rod at the bottom of the future jack. Next, you need to complete the structure by attaching fastening mechanisms and a handle.

When making lifting devices yourself, it is important to be guided by the purpose of the mechanism. For basic wheel replacement, a compact screw-type device is suitable, which can easily fit in the trunk of a car.

Correct installation is associated with safe work; the process must be monitored to avoid injury or property damage. When working, it is possible to use a static stand as the main support, for example a large stump.

Conditions under which the purchase will be correct

If we talk about jacks, then there are numerous torments of choice.

Which one to choose: rolling or bottle, rhombic or hydraulic.

Of course, the crux of the matter lies in the question itself.

If you plan to use the device when lifting weights up to 2 tons, then this is one unit, but if you have to lift it up to 3 tons, then these are completely different loads and here it is better to approach the issue more carefully.

After all, if in the winter, outside the city, and even at night, you are left without a jack, and there is a need to replace a wheel due to a puncture, then the driver will not envy such grief.

First you need to understand which specific jack is needed for a particular case.

There are several types of lifting capacity of jacks up to 1.5 tons, up to 202.5 tons and up to 3 tons. How to choose car jacks. If you are using a regular sedan or hatchback, a jack with a lifting capacity of up to 1.5 tons is quite suitable.

When using a small SUV, a car jack with a lifting capacity of up to 2.5 tons is suitable. If you are using a fairly large SUV, you will need a full-fledged rolling jack with a lifting capacity of up to 3 tons.

The video tells you which car jack is best to choose: