Safety precautions

The instructions require careful study; without them you cannot begin operation.

When installing the machine, you must carefully follow the recommendations given by the manufacturer. You must ensure that the table plane remains absolutely level. It is easier to achieve the desired result with the adjustment feet of the equipment. The platform that was used when installing the machine is also suitable. The basic rules are described as follows:

- The coolant reservoir is filled after the basic settings are set. Lubrication of the gearbox components occurs in the next step.

- Spindle speeds are separately adjustable. To do this, simply turn one of the handles to a suitable position.

It is also important to constantly monitor other parameters. This machine has been produced since 1956 by the Rostov plant of small-sized machines MAGSO, under the leadership of the ComTech Plus company. This enterprise itself is part of an industrial group of companies that consolidated its position in the market for the production of small-sized machine tools more than 10 years ago and maintains it to this day.

But what are the technical characteristics of the NGF 110 Sh4 itself and what should you know about it before purchasing?

This enterprise itself is part of an industrial group of companies that consolidated its position in the market for the production of small-sized machine tools more than 10 years ago and maintains it to this day. But what are the technical characteristics of the NGF 110 Sh4 itself and what should you know about it before purchasing?

This machine has been produced since 1956 by the Rostov plant of small-sized machines MAGSO, under the leadership of the ComTech Plus company. This enterprise itself is part of an industrial group of companies that consolidated its position in the market for the production of small-sized machine tools more than 10 years ago and maintains it to this day. But what are the technical characteristics of the NGF 110 Sh4 itself and what should you know about it before purchasing?

Features of modifications

The NGF-110 model was the first in a series of desktop school machines. It was modified and widely universal machines began to be produced.

NGF-110Sh1

Distinctive features of the model:

- round trunk;

- the vertical feed steering wheel is located at the base of the screw;

- The gear shift lever on the body is metal.

The bottom plate is cast, low, like the NGF-110 model.

NGF-110Sh3

Visually very different from previous models:

- a rectangular trunk with an arched top - “humpbacked”;

- the base is thin;

- engine start/stop buttons on the column, below;

- next to it is a plate with the model marking;

- plastic balls are screwed onto the ends of the gear shift knobs;

- engine inside the frame;

- vertical transmission is carried out by a handwheel on the console.

The model is considered transitional to the next modification.

110Ш4

The latest, modernized model, which was produced longer than the others. Differs from previous versions of the milling machine:

- a rectangular trunk with an earring moving along its guides;

- base high 100 mm, hollow;

- local lighting;

- Gear shift knobs are completely plastic;

- The label with the marking is located on the trunk.

On the side of the base there are power buttons, inside there is a current transformer for local lighting of 36 V. The motor is located at the bottom of the stand, inside.

Machine adjustment

During the operation of the machine, the need arises to adjust individual components and elements in order to restore their normal operation.

Spindle bearing

If spindle play occurs, it is necessary to loosen the spindle locknut, then adjust the normal tension and fix the position with the locknut.

Clearances in guides

Gaps in the guides of the console with the frame, the guide slides of the table and console, the guides of the table and slides are eliminated by tightening the wedges with screws in the appropriate mates so that after establishing a normal gap, the movement would be smooth and without much effort.

Backlash of longitudinal and transverse screws

Backlash in the screws of the longitudinal and transverse stroke of the table occurs due to wear of the bronze uterine nuts, which are replaced with new ones.

Modifications of the desktop horizontal milling machine NGF-110

manufacturer: Plant No. 5 named after. Dzerzhinsky, city of Shchelkovo, Moscow region, village named after Sverdlov.

manufacturer: Sapozhkovsky Mechanical Plant No. 7, Sapozhok city, Ryazan region.

manufacturer: , founded in 1956.

manufacturer: , founded in 1956.

- N – desktop machine;

- G – horizontal machine;

- F – milling machine;

- 110 – largest diameter of cutters used on the machine (mm);

- Ш – school;

- 1, 2, 3, 4 – machine model.

Main characteristics

The main parameters on which the performance and capabilities of horizontal milling machines depend:

- electric motor power;

- number of speeds, max/min revolutions;

- working stroke of the slide on all axes.

Engine power affects basic capabilities - the cutter should not get stuck in the workpiece just because there is not enough drive power.

The number of speeds allows you to choose the most optimal option, exactly suitable for each type of operation. The speed varies depending on the depth of processing, the properties of the metal, the number of teeth on the cutter, and the required processing accuracy.

The working stroke of the slide determines how much area of the part the cutter can process in one installation.

The size and weight of the machine may also matter. Heavy ones require pouring a special foundation. Large-sized takes up a lot of production space.

Brief description of the machine

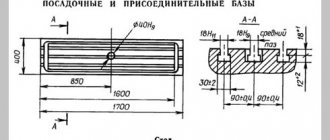

The NGF-110Sh4 machine allows you to perform milling operations for processing vertical and horizontal planes, grooves and other surfaces with cylindrical, disk, end, end, corner and shaped cutters.

A cast iron frame (stand) of trapezoidal cross-section ensures the rigidity of the machine.

Installing a vertical milling head VFG allows you to additionally process vertical planes, as well as planes at a certain angle up to 450 clockwise and counterclockwise.

The rigid classic design allows you to confidently process both steel and light alloys. The machine has increased reliability and ease of operation.

It is indispensable for gaining initial skills in working on milling machines, and when equipped with a vertical head, it can be used as training equipment for training in the milling machine profession.

The machine corresponds to accuracy class “N”.

Specifications:

| Working surface of the table, mm | |

| length | 4002.0 |

| width | 1001.0 |

| Table movement, mm, not less: | |

| longitudinal | 250 |

| transverse | 85 |

| vertical | 170 |

| Movement by one division of the dial, mm | |

| longitudinal | 0,05 |

| transverse | 0,05 |

| vertical | 0,25 |

| Movement per one revolution of the dial, mm | |

| longitudinal | 4 |

| transverse | 4 |

| vertical | 2 |

| Table feeding | Manual |

| Distance from spindle axis to table, mm | 30200 |

| Distance from the end of the spindle to the suspension bearing, mm, not less | 230 |

| Number of spindle speed steps | 6 |

| Largest cutter diameter, mm | 110 |

| Spindle inner taper | Morse 3 |

| Spindle speed, min-1 (rpm) | 1251250 |

| Electric motor power, kW | 0,75 |

| Overall dimensions of the machine, mm | 690х565х82310 |

| Machine weight, kg | 20510% |

| No. | Designation | Name | Quantity, pcs. | Size | Note |

| I. NGF-110Sh4.01 Machine assembly 1 II. Accessories, tools and documentation included in the kit and cost of the machine: Separate place in the general packaging | |||||

| 1 | NGF-05-03 | Mandrel with a set of rings and a nut | 1 | ||

| NGF-05-02/1 | |||||

| NGF-05-02/5 | |||||

| NGF-05-01 | |||||

| 2 | NGF-05-04 | Ramrod | 1 | ||

| 3 | NGF-05-07 | Sleeve | 1 | ||

| 4 | GOST 2839-80 | Key | 1 | 24x27 | |

| Sticking | 2 | ||||

| NGF-09-04 | Bolts with nuts and washers | 2 | M10x50 | For clamps | |

| Bolts with nuts and washers | 2 | M10x30 | For vice | ||

| NGF-08-00 | Machine vice with key | 1 | |||

| 7 | TV4-06-12 | Handwheel with handle | 3 | ||

| 8 | TV4-06-09 | ||||

| 9 | Different cutters | 6 | |||

| 10 | Machine passport | 1 | |||

| 11 | NGF110Sh4-10.000 | Protective screen | 1 |

Preparing the machine for operation

Before starting you must:

- a) fill the oil reservoir with oil up to the oil indicator marks;

- b) use a grease gun to lubricate all rotation points of the feed screws, for which you need to unscrew the grease screws, lubricate and tighten the screws.

During operation of the machine, it is necessary to constantly monitor the oil level. To familiarize yourself with the machine in detail, it is recommended to run it at idle speed, understand the purpose and operation of the controls, try switching spindle speeds, and also check the supply of lubricant.

In this case, one must keep in mind the following: if, when switching spindle speeds, an obstacle to the movement of the handle is felt, this means that the gears have rested tooth against tooth.

In this case, you should not increase the force; you need to turn the gears by turning the spindle by the knurled nut. After turning the gear, continue switching; changing speeds while moving is not allowed, as this can lead to breakage of the gear teeth.

Setting spindle speeds

Setting the selected number of spindle revolutions is carried out by turning the handle until the locking finger with its tip enters the corresponding slot on the scale with numbers and letters A and B with the corresponding installation of the belt according to the diagram.

To install the belt, you must remove the guard by unscrewing two shaped nuts, and then install the belt and guard.

Fastening the cutter on the NGF-110sh1 machine

Fastening the cutter on the NGF-110sh1 machine

Depending on the type of cutter used, it is fastened using the following methods:

- 1. Insert the milling mandrel with the conical end into the spindle hole, aligning the grooves in the flange of the mandrel with the crackers at the end of the spindle, and secure the mandrel with a tightening screw using a wrench, having previously wiped the conical hole of the spindle and the cone of the mandrel.

- 2. Remove the installation rings from the milling mandrel and put so many rings on the mandrel so that after installing the mandrel it is as close as possible to the bed. When putting the cutter on the mandrel, you need to make sure that the cutting direction of the cutter coincides with the direction of rotation of the spindle. If the cutting direction of a cylindrical cutter does not coincide with the direction of rotation of the spindle, then you should remove the cutter and turn it with the other end. Having put the cutter on, you need to install the remaining mounting rings on the mandrel and tighten the nut. When screwing the nut onto the mandrel, you must ensure that the nut does not cover the neck of the mandrel.

- 3. Install the trunk suspension so that the end (neck) of the mandrel fits into the suspension bearing. The execution of these operations is shown in Figure 20, a and b.

- 4. Secure the cutter to the mandrel by tightening the nut with a wrench and secure the hanger. In this case, it is necessary to ensure that the jaw of the wrench fits tightly on the edge of the nut and cannot break off during operation in order to avoid injury.

- 5. Secure the trunk and lubricate the suspension bearing. When the cutter and the trunk are secured, you can turn on the machine and rotate the milling mandrel with the cutter attached. If the cutter hits when rotating, you should stop the machine and correct the installation or replace the cutter or mandrel. If it is necessary to perform work with face and end mills that have a shank with a Morse taper, installation is carried out with adapter bushings.

Design Features

The NGF-110 machine is distinguished by its simple design. Some models have survived and continue to work in home workshops. The model does not have mechanical feeds; all work is done manually.

Console

The console is the basic unit of the feed mechanism. It moves horizontally. The helical clutch converts the rotation of the screw into linear motion. The movement handle is located at the bottom.

Table

The table has one longitudinal T-shaped groove on the working surface for fastening workpieces and a vice. In the longitudinal direction, the table moves along guides on the slide, and together with them moves along the console along the mandrel. The handwheels on the ends of the screws are located on the left side of the table and directly on the slide.

Rack

The conical stand is mounted on the machine plate. Inside, its cavity is divided horizontally into 2 parts. At the bottom there is an electrical cabinet. Above is the gearbox and spindle assembly. A round trunk is fixed above them.

On the top left of the case is the gear shift knob. On the left is a lever for clamping the trunk. There are guides in front along which the console moves vertically. The motor is mounted to the side or below the base under the table top. It is connected to the gearbox drive shaft pulley by a belt drive behind the rack.

Trunk with earring

The round trunk passes through the bushings at the top of the post. It moves along the axis manually and is fixed motionless by a wedge during operation. The trapezoidal-shaped earring has a hole equal in size to the diameter of the trunk and is clamped onto it with a nut. The mandrel is fixed in it in the same way. Free rotation is ensured by a bearing.

Protective screen

The glass, inserted into a metal frame, is moved into position manually and held by a lever stand. It is located on the left side of the body.

Important! On the surviving NGF-110 machines, the protective screens are broken. Masters make new ones.

Special plate with equipment

Modernized machines, such as the widely universal NGF-110Sh4, have a high plate at the bottom. Its cavity contains electrical equipment, a push-button switching unit and a transformer. The rest have a screw attached to them to lift the console and a start button on the side.

Light source

Lighting is connected separately. The lampshade and lamp are attached with a long flexible stand to the side of the frame, above the electrical cabinet.

Mandrel

The mandrel is attached to the spindle cone, the free end is inserted into the shackle. To install the cutter in the desired position, spacer rings of various lengths and diameters are used. They are included in the tools kit.

A long key is inserted into the longitudinal groove, which allows you to fix the cutter and transmit rotational movement to it. A VFG is installed on the mandrel for drilling and milling the side surfaces.

Specifications

Part processing is carried out by moving the part mounted on the machine relative to the rotating tool.

Technical characteristics of the machine NGF-110:

- machine power 0.55 kW;

- spindle speed 125-1250 rpm;

- number of spindle speeds 6;

- table size 100×400 mm;

- number of T-slots 1;

- longitudinal movement of the table 250 mm;

- transverse – 85 mm;

- maximum cutter diameter 110 mm;

- maximum distance between the spindle axis and the table surface is 117 mm;

- machine dimensions 685×64×925 mm.

The displacement of the table by one division of the dial is equal to the transverse and longitudinal movement of 0.05 mm.

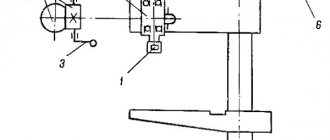

Design of a desktop horizontal milling machine NGF-110Sh1

Location of the main components on the NGF-110sh1 machine

Location of the main components on the NGF-110sh1 machine

Location of machine controls NGF-110sh1

Location of machine controls NGF-110sh1

The desktop horizontal milling machine consists of the following main components and parts (Fig. 1 and 2):

- 1. Bed with base;

- 2. Drive;

- 3. Gearbox with switching mechanism;

- 4. Console;

- 5. Longitudinal movement table;

- 6. Transverse movement carriage;

- 7. Vertical movement mechanism;

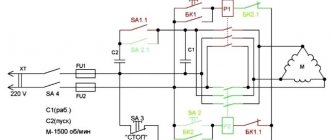

- 8. Reversing motor starter;

- 9. Trunk;

- 10. Mandrels for securing cutters;

- 11. Installation vise.

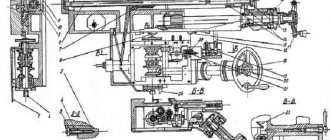

Bed with base

The bed is the simplest form of casting with four bored holes for the spindle, gear block shaft, drive shaft and trunk. At the bottom of the casting there is an internal solid jumper, which serves as an oil reservoir pan for lubricating the gears and bearings of the gearbox.

The base of the machine is a massive rectangular cast iron plate measuring 600 x 400 mm. The plate is intended for fastening the frame and installing the machine on the foundation.

Drive unit

Using a V-belt drive, rotation from the electric motor is transmitted to the gearbox drive shaft, which is mounted on three ball bearings. A gear is rigidly mounted on the shaft, transmitting rotation to the main shaft of the gearbox through a gear that is permanently coupled to it and mounted on the main shaft.

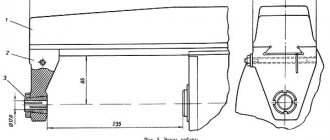

The electric motor is mounted on a hinged bracket 2 (Fig. 3). If the V-belt becomes loose due to its stretching, unscrew nut 5, tighten the belt with a second nut, and then screw nut 5 back on.

The belt drive is covered by a casing attached to the body.

The machine is started by a drum reversing switch type BP1-132.

The machine is connected to the electrical network through an input switch BB (batch switch for 25 A) type VP-25.

Grounding of the machine during installation, as well as its operation, is carried out in accordance with the requirements of the State Inspectorate for Industrial Energy under the Ministry of Energy of the USSR.

Gearbox with shift mechanism

The gearbox with shift mechanism consists of a main shaft with a rigidly mounted gear and a movable triple block and three gears sitting rigidly on the spindle. The shaft is supported by trunnions on ball bearings.

The spindle rotates in two supports. The gear block is moved by a special fork sitting on the shift lever.

When shifting, the gear unit occupies three operating positions, giving the spindle three different speeds, and in combination with a two-speed pulley, the spindle receives six speeds from 60 to 840 rpm.

The gear shift lever has a handle with a spring pin that locks the complete engagement of the gears in a certain position along the slots in the scale.

Switching speeds is carried out only when the machine is completely stopped.

There is a plate on the machine bed indicating the machine spindle revolutions per minute.

Console of milling machine NGF-110sh1

Console of milling machine NGF-110sh1

The machine console (Fig. 4) is a box-shaped casting on which the mechanisms for longitudinal, vertical and transverse movement of the table are mounted. The console is mounted on vertical guides with two straps, and is adjusted with a side wedge and two screws.

For longitudinal and transverse movement of the work table, the machine has a slide with dovetail-shaped guides. The slide is adjusted using wedges and screws. A table nut is fixed at the base of the longitudinal guide slide. The transverse movement of the table is carried out by a lead screw with a rectangular thread and a handle. The longitudinal movement of the table is carried out by a lead screw and handwheels, which are located on both sides of the table.

The lead screws have vernier bushings on both sides with a graduation value of 0.1 mm. There are three T-shaped grooves on the working surface of the table for securing a part or a vice.

To lift the table vertically, a lead screw is attached to the base of the machine. The lead screw nut is fixed at the base of the console. To rotate the lead screw, a handwheel is mounted on it.

Installation vise

The installation vise (Fig. 5) is the main device for fastening small parts of various profiles and can have replaceable jaws in the case of fastening parts of complex shapes.

For ease of use, the vice is made rotating. On the rotary dial there are divisions in degrees. The division value is 1°.

The vice is secured in the desired position with a locking bolt and nut.

Machine trunk and mandrel with cutter

The guides of the upper part of the frame (Fig. 6) accommodate the trunk of the machine with an earring, secured in the working position with a special clamp with a handle.

A ball bearing is mounted in the shackle, carrying the milling mandrel.

A cutter is fixed on the shaft between the mandrels. Depending on the work performed on the machine, the trunk can be installed at different distances from the console guides, i.e., with different reach.

Purpose and scope

The machine of this model was called a school machine. The main reason is that the equipment is involved in teaching the basics of milling to high school students. The machine performs the following additional functions:

- Processing of grooves and horizontal surfaces.

- Working with curved planes that have a certain bend angle.

- Processing planes vertically.

- Up and down milling.

If there are no small chips, the machines can process products made of non-ferrous metals. The desktop horizontal unit must not be used in cases with other metals that do not meet this requirement.

Purpose

The main difference between such machines is the horizontal arrangement of the spindle on which the cutter is mounted. Machines of the same profile with a vertical arrangement are called vertical; their spindle is located in the same way as a drilling machine.

There are a number of metalworking operations that can be done equally successfully on both horizontal and vertical milling machines. However, there are also operations that are much more convenient and better done on a horizontal router. The use of a dividing head expands the capabilities of the machine. An incomplete list of parts that are made on horizontal milling machines:

- cutting grooves in shafts (including for jointing machines);

- keyways;

- splines on shafts;

- hexagons;

- ratchets;

- gears, etc.

A horizontal milling machine is indispensable for preparing workpieces on production lines with a large number of machines. It is most effective to cut workpieces with a disc cutter, adjust the size according to thickness, etc. Productivity is higher and the workpiece area is larger than that of vertical machines.

The image shows the processing of a workpiece with a disk cutter:

Milling cutters with different geometries are used to produce parts. Main types of cutters:

- end with cutting end;

- shaped complex profiles for special tasks;

- disk, in the image above.

For complex parts, it is possible to use modular cutters, which are assembled from separate disks of different profiles.

The machines are designed for processing ferrous and non-ferrous metals and alloys. In some cases, it can also be used to mill other materials with a monolithic structure: thick plastics, composite materials.

They are not suitable for woodworking because the spindle rotates at low speeds. Some operations on processing wood, MDF, and chipboard can be performed on it if you turn on the maximum speed and use suitable wood cutters. But in general, this is not what these machines are for.

List and location of components

This equipment belongs to a variety of widely universal machines. For educational purposes, the technical characteristics can be called ideal. The machine contains the following components:

- Mandrel.

- Lighting is locally supplied from a separate source.

- A special plate on which electrical equipment is placed.

- Screen for protection.

- Trunk with earring.

- Vise.

- The speed box is mounted on a stand.

- Table for installing the sled.

- Console.

A standard push-button station is used for control. This simplifies operation and increases safety for users. Two additional levers are used to select the rotation speed of the spindle assembly. There are three flywheels, they were already mentioned earlier.

There are three directions in which the table moves:

- In a place with consoles, along the rack guides. This is vertical.

- In the case of longitudinal movement, the support is on the slide guides.

- Movement based on cantilever guides, if we are talking about a transverse plane. Then the work surface and the slide move simultaneously.

Read also: How to measure a battery with a multimeter

Three additional screws are provided to the table structure. Each of them has its own separate task:

- Clamping the slide on the console.

- Clamping with a slide directly on the working surface.

- Performing feed in the longitudinal direction.

Two nuts are suitable for simultaneously adjusting the feed lengthwise and crosswise.

The mandrel allows you to fix the workpiece, which is used together with the unit. A nut and several mounting rings allow you to connect the structure into a single whole. A mandrel is mounted into the earring support, with the other end. The earring support is installed in the trunk. Thanks to this device, the cutters remain as rigid as possible.

NGF-110 Location of components on the machine

Location of components on the NGF-110sh4 machine

List of components of a milling machine

- rack with gearbox

- console

- table with sled

- trunk with earring

- mandrel

- stove with electrical equipment

- protective screen

- vice

- local lighting lamp

Related Posts via Categories

- Shell end mill – high-quality cutting of steel and cast iron

- Do-it-yourself copy-milling machine - we create reliable equipment!

- Mini milling machine - how to assemble it yourself?

- Homemade metal milling machine - assembled without problems!

- Dividing head for milling unit and other devices

- Milling and engraving machine - a high-precision unit with program control

- Turning and milling machine – what gives us its versatility?

- Tabletop CNC milling machine – high-precision machining of small products

- Corvette 83 – reliable equipment for milling wood blanks

- Classification of milling machines - all types of equipment

Description of the main components of the NGF 110 milling machine

“Dovetail” is the place where the trunk of the training machine is installed. The top section of the unit rack is where the part is installed. A special wedge is used for clamping. By tightening the screw, users can securely fasten this structure. The movement of the trunk is done only manually.

The earring is in the front. Its dimensions are adjusted to the parameters that each of the specific machines has. You cannot rearrange earrings among different units.

The connection between the trunk and the earring occurs with the participation of a nut. The earring is equipped with a bushing, essentially a bearing. It is made from a bronze alloy. The outer surface is a cone, cuts along are the main elements of the part.

Sometimes the gap inside the bushing changes its position, but periodic repairs help to cope with the problem. The same applies to regular lubrication, for which a composition designated I-30A is used.

If the bearing heats up too much during equipment operation, then it’s time to at least carry out diagnostics.

The machine stand is one of the basic components. The rest of the working units and mechanisms are mounted on it. It has its own characteristics.

- Section with a trapezoidal shape in height.

- Well developed base.

- Thanks to such details, the structure boasts a high level of rigidity.

Any rack is equipped with two compartments, top and bottom. Below is the electric engine, at the top is the gearbox. The latter supports six gears and is equipped with three shafts.

The spindle assembly moves at certain frequencies, controlled by the gearbox. Shift handles allow you to easily select the desired indicator for a specific situation. The handles themselves are located on the left side of the milling equipment.

The gearbox is closed using a special cover, which must be removed when carrying out inspections of the equipment.

The main element in the feed mechanism is the machine console. Guides – places for mounting the slide with the working surface. The classic-looking spindle is a hollow shaft with two supports. The part neck goes to the radial type bearing from the back. The part at the back is directed towards the other two radial bearings.

The parts fit rings and spacer elements between each other. The spindle assembly also has a compensation ring. This will protect against axial displacement of the structure.

Online auction Antiquity

Online auction Antiquity

All from the ruble!

- Why register?

- How to buy?

- How to sell?

- FAQ

Basket

Sell

Registration Recent

- Lots

Sections Searches Favorites

- Lots

Sections Searches

- Recent

- Lots

- Sections

- Search

Favorites

Lots Sections Searches Buying Bargaining now I bought Didn't buy Subscribe to new lots Requests for lots from sellers Sellers' offers Selling Transactions Completed auctions Top up account Demand Seller settings My store Activation Settings

Bargaining now I bought Subscription to new lots Requests for lots from sellers Sellers' offers Selling Sell On sale Transactions Completed auctions Top up your account Demand Seller settings

| Welcome to the online auction Antiquity Use the topic sections on the left, the search bar at the top, or the tags on the right to search for items. Want to know more?

Recommended lots: (show all) 190 RUR 5 hryvnia Ukraine 2022 Academy of Sciences 100 years of the National Academy of Sciences unc 350 RUR Photo of a girl, little lady. Vintage. collectible. Atelier L. Smelyansky. Alexandria RUR 749 1 cent 1911 d USA wheat one cent original RARE! 385 RUR 2004 Poland Vatican Joint issue Coats of Arms Flags Heraldry Pope John Paul-2 ** 410 RUR RSFSR Certificates 1921 190 RUR Civil Aviation. Aeroflot. Certificate. 1984 295 RUR 2 SEPTEMBER 1934 PRE-WAR ESTONIA. EXCELLENT CONDITION . No. 295 15 RUR Transnistria 1 ruble 2007(2012) p42b EU press unc 130 RUR 15 KOPEEKS 1923 USSR. GOOD CONDITION . ORIGINAL. No. - 1313 690 RUR Circus set of 2 blocks 1500 RUR “premiere” No. 5-98 Sharon Stone, Lavrov, E. Shevchenko, Ethan Hawke, Paltrow Hoffman, Takeshi Ketano, “Titanic” 120 RUR 1 KOPEYKA 1949 USSR. GOOD CONDITION . ORIGINAL. No. - 264 | |

| 500.00 rub. | 52 seconds |

| 50.00 rub. | 52 seconds |

| 650.00 rub. | 52 seconds |

| 20.00 rub. | 01 minute |

| 155.00 rub. | 01 minute |

| View more → |

Entrance:

| For you and your site: |

| • Auction on your website! |

| • Open your own store |

| • Affiliate program |

| Frequently asked questions and support |

| Terms of Use | Sell | Registration | Open your auction | Affiliate program | Profile | Help All rights reserved 1999 - 2022. Old man |

Information correct on Sun, 26 Apr 2022 00:52:50 +0300

How do the trunk and gearbox work together with other components?

To install the trunk on this tabletop machine, “dovetails” are used, which are located in the upper part of the unit rack and are clamped using special wedges to ensure structural rigidity. This, in turn, is tightened tightly by tightening the screw and spindle, which allows you to securely fasten the unit and ensure safe use of the device at school. A special earring, individual for each configuration, is inserted into the front part of the trunk, which is prohibited from being reused. But even taking all this into account, milling on such a machine still cannot be done.

Next, the trunk is tightened with the earring using a nut and the first bearing is located, consisting of an alloy of bronze and several other metals. For the convenience of the router, it has several longitudinal cuts and an outer surface in the form of a cone.

Design of the machine NGF 110 Ш4

The base of any machine is considered to be its stand, on which each mechanism and working unit is mounted. The stand is made from bottom to top using a trapezoidal section, and is placed with a massive base towards the floor. This ensures a rigid structure on any surface. It includes several compartments - upper and lower. The first contains a gearbox (6 in total), a spare spindle and 3 shafts, and the second contains an electric motor, which runs the entire device, allowing it to prepare parts according to the master’s drawings.

Device

To install the router trunk, there is a “Swallow Tail”, this is the upper section in the unit rack, and a special shaft clamps the entire structure. The fastening force can be adjusted by tightening the screw, which allows for reliable fixation and safe milling; the shaft in this case acts as an additional fastener. The trunk must be moved manually in three planes. The front part includes a fixed shackle, which is adjusted to the specific machine and its dimensions, and it cannot be moved to another unit. Thus, this element remains the only one indispensable when repairing equipment, unlike the VFG for NGF 110. The drawing of the device also says this.

Read also: What can an electric engraver do?

The school milling machine NGF 110 is still a universal training device for young professionals learning milling. Due to the fact that the NGF 110 technical characteristics are inferior to more powerful devices, it is ideal for training and at the same time for creating simple parts at a professional level. The drawing NGF 110 includes:

- console for controlling the machine;

- a table with a slide installed on it and a mounting shaft;

- gearbox on a special stand;

- clamps for the part, which allows you to conveniently manufacture it according to the drawing;

- trunk, spindle and earring;

- several protective screens for the safety of students and workers;

- a stove on which a variety of electrical equipment is installed;

- lamp for ease of work at night;

Design of the NGF 110 Sh4 machine and its kinematic diagram

Automatic feeding is carried out on the NGF 110 using a special push-button station, which is as safe as possible and simplified for inexperienced users. A special shaft secures the entire structure. The horizontal milling machine NGF 110 Ш4 is also equipped with several levers for selecting the rotation speed of the spindle units and three different handwheels. Depending on the configuration, the price for the NGF 110 training milling machine may vary; the basic version costs an average of 20 thousand rubles. The NGF 110 shaft, as the drawing indicates, is capable of moving in three directions:

- Vertically along with the console, rack guides are used for this.

- Also, the NGF 110 spindle moves longitudinally thanks to the guide slide.

- And transversely along the console guides, due to the fact that the dimensions of the NGF 110 described above allow the working surface to move along with the slide.

School milling machines NGF 110 also have 3 screws for clamping the working surface and console, as well as feeding workpieces in the longitudinal plane. Also, a pair of nuts, which are used for longitudinal and transverse movement of workpieces, helps with the automatic feeding of the NGF 110. Horizontal milling machines NGF 110 Ш4 are equipped with a mandrel, which is used to attach the milling tool required in a particular case to it. The tools are connected to the frame using several nuts and mounting rings, and their other end is attached to the shank of the wide-universal milling machine NGF 110 Sh4 VFG, thus achieving optimal rigidity for the operation of the cutters.

School milling machine NGF 110 technical characteristics

Before starting work, the responsible person must carefully check whether the unit is installed and configured correctly. Start of work is allowed only after safety instructions have been given.

The Dubof company produces high-quality furniture according to individual measurements and wishes. They work with high-quality modern equipment, which allows them to offer consumers the execution of any ideas and design solutions.

The mass of the machine is equal to 340 kilograms. The final weight of the workpiece along with the occupied area is taken into account separately. The equipment has the following dimensions in millimeters:

The main work is performed on a table mounted separately on the unit. It’s good if you can choose an option with height adjustment.

The characteristics of the technical plan are accompanied by the following description:

- 6-horizontal spindle supports so many speeds.

- The spindle head allows adjustment of rotation speeds. Its limits are 125-1250 rpm.

- The displacement along and across to the bottom of the limb is 0.05 mm. For the vertical, the indicator is 0.25 mm.

- To fix the workpiece, use one T-shaped slot for the table.

- Certain parameters are observed when moving the table. For the vertical it is 17 cm, in the case of the transverse direction - 8.5 cm. Longitudinal movement - 25 cm.

- 11 centimeters is the maximum diameter for a cutter that is installed on the machine.

- 85 millimeters - this is how far the horizontal trunk is from the spindle, which makes fixing easier.

- Desk with dimensions 10 by 40 cm.

The main machine drive begins to move due to the electric motor and its operation. The standard power of modern installations is 0.55 kW. Some standard features are excluded:

- Additional effort applied for each serve.

- Rotating movements.

- Acceleration of the working part.

The machine will not help small-scale, professional production facilities.

Local lighting comes from lamps standing on the machine. During installation, flexible corrugation is used. It allows you to adjust the position in relation to the part being processed.

Design and scope of the machine

Model NGF-110 is designed for horizontal processing of steel blanks by milling. When installing an additional vertical milling head, the functionality of the machine increases significantly.

Equipment of this type is conventionally divided into several models. The most common is the machine of the NGF-110-Sh4 series. It differs from the basic version in its wide versatility (W) and belongs to the fourth generation. The difference between the models does not affect the general principle of arrangement of elements.

The design and technical features of the NGF-110-Sh4 machine include the following nuances:

- stand design. In its upper part there are dovetail guides along which the trunk moves. This is done manually. For fixation it is necessary to use a special wedge;

- simplified frame shape. It is designed for installing cutters of various shapes. They are clamped to the frame using a set of rings and a nut;

- desktop versatility. It has a three-way displacement mechanism. This simplifies the milling procedure of the workpiece.

The rigidity of the stand is ensured by its trapezoidal shape. It is divided into two sections. The gearbox is located at the top. To install the electric motor, the designers provided a niche in the lower part of the rack structure.

On the console there is a table with a slide. The workpiece is mounted on it, which moves relative to the cutter in three directions. Feeds are carried out from different screws. Therefore, the worker should be careful when simultaneously changing the position of the workpiece.

Principle of operation

The cutter on such machines is fixed in one position. The accuracy of processing depends on how accurately the workpiece will be placed and moved relative to the cutting edges of the cutter.

For precise and convenient positioning of the fixed workpiece relative to the cutter, there are special mechanisms on the machines. These are located in the console under the desktop:

- work table slide cross feed screw;

- longitudinal feed screw;

- vertical feed screw.

Handwheels are attached to the screws for manual adjustment of positions. Machines of this type are non-automated, completely manual. Therefore, the accuracy of processing largely depends on the qualifications of the milling operator.

The processing accuracy is controlled using a variety of measuring instruments: various rods, calibers, pendulum protractors, plugs, rulers, indicator tools.

How do the trunk and gearbox work together with other components?

To install the trunk on this tabletop machine, “dovetails” are used, which are located in the upper part of the unit rack and are clamped using special wedges to ensure structural rigidity. This, in turn, is tightened tightly by tightening the screw and spindle, which allows you to securely fasten the unit and ensure safe use of the device at school. A special earring, individual for each configuration, is inserted into the front part of the trunk, which is prohibited from being reused. But even taking all this into account, milling on such a machine still cannot be done.

Next, the trunk is tightened with the earring using a nut and the first bearing is located, consisting of an alloy of bronze and several other metals. For the convenience of the router, it has several longitudinal cuts and an outer surface in the form of a cone.

Design of the machine NGF 110 Ш4

The base of any machine is considered to be its stand, on which each mechanism and working unit is mounted. The stand is made from bottom to top using a trapezoidal section, and is placed with a massive base towards the floor. This ensures a rigid structure on any surface. It includes several compartments - upper and lower. The first contains a gearbox (6 in total), a spare spindle and 3 shafts, and the second contains an electric motor, which runs the entire device, allowing it to prepare parts according to the master’s drawings.

If you find an error, please select a piece of text and press Ctrl+Enter.

NGF 110 milling machines are suitable for teaching high school students the basics of the craft. The equipment has been working stably in factories and workshops for many years.

The equipment represents a class of technology for study. "MASGO" from the city of Rostov-on-Don is a specialized enterprise responsible for the production of the machine.

Small dimensions and modest weight make NGF 110 milling machines easy to install in special classes and help solve various problems.

Before starting work, the responsible person must carefully check whether the unit is installed and configured correctly. Start of work is allowed only after safety instructions have been given.

The Dubof company produces high-quality furniture according to individual measurements and wishes. They work with high-quality modern equipment, which allows them to offer consumers the execution of any ideas and design solutions.

The mass of the machine is equal to 340 kilograms. The final weight of the workpiece along with the occupied area is taken into account separately. The equipment has the following dimensions in millimeters:

The main work is performed on a table mounted separately on the unit. It’s good if you can choose an option with height adjustment.

The characteristics of the technical plan are accompanied by the following description:

- 6-horizontal spindle supports so many speeds.

- The spindle head allows adjustment of rotation speeds. Its limits are 125-1250 rpm.

- The displacement along and across to the bottom of the limb is 0.05 mm. For the vertical, the indicator is 0.25 mm.

- To fix the workpiece, use one T-shaped slot for the table.

- Certain parameters are observed when moving the table. For the vertical it is 17 cm, in the case of the transverse direction - 8.5 cm. Longitudinal movement - 25 cm.

- 11 centimeters is the maximum diameter for a cutter that is installed on the machine.

- 85 millimeters - this is how far the horizontal trunk is from the spindle, which makes fixing easier.

- Desk with dimensions 10 by 40 cm.

The main machine drive begins to move due to the electric motor and its operation. The standard power of modern installations is 0.55 kW. Some standard features are excluded:

- Additional effort applied for each serve.

- Rotating movements.

- Acceleration of the working part.

The machine will not help small-scale, professional production facilities.

Local lighting comes from lamps standing on the machine. During installation, flexible corrugation is used. It allows you to adjust the position in relation to the part being processed.

What it offers and how to order

can offer not only a machine, but also cutting tools, technological and tool equipment, coolant, i.e. everything necessary for its successful operation. Tools, equipment, coolant are selected based on the technological development of the received technical specifications. Our service department provides comprehensive operational support and high-quality warranty and post-warranty service.

To make a request for a portal CNC milling machine, please contact us using our toll-free number 8-800-333-0-222

or send an application with technical specifications by email. You can also make a request using the feedback forms on our website or by contacting the representative office of your region.

Equipment operating rules

To carry out preparatory work on the NGF-110-Sh4 machine, it is necessary to study the operating instructions in detail. It describes in detail methods for carrying out preventive maintenance, methods for replacing and turning cutters, and reference characteristics of equipment.

Installation of the machine is carried out only in accordance with the manufacturer's recommendations. The surface of the desktop must be level. To achieve this, you can use the leveling feet of the equipment or the platform on which the machine is mounted.

Basic rules for operating the NGF-110 machine:

- equipment startup. After setting the initial parameters, it is necessary to fill the coolant reservoir. Then the gearbox components are lubricated;

- spindle speed adjustment. This is done using handles. It should be turned until the pointer reaches the desired position;

- rules for fastening the cutter. Place the cutter in the mandrel so that their grooves coincide. Secure the cutter using the mounting rings. The final fastening of the cutting tool is carried out using a nut;

- mandatory compliance with safety regulations. Work must be carried out only in special clothing, using personal protective equipment. When changing a cutter to another, you should wait until the spindle head comes to a complete stop.

A video review of the NGF-110 series machine will help you become more familiar with its capabilities:

NGF 110 milling machines are suitable for teaching high school students the basics of the craft. The equipment has been working stably in factories and workshops for many years.

The equipment represents a class of technology for study. "MASGO" from the city of Rostov-on-Don is a specialized enterprise responsible for the production of the machine.

Small dimensions and modest weight make NGF 110 milling machines easy to install in special classes and help solve various problems.

Before starting work, the responsible person must carefully check whether the unit is installed and configured correctly. Start of work is allowed only after safety instructions have been given.

The Dubof company produces high-quality furniture according to individual measurements and wishes. They work with high-quality modern equipment, which allows them to offer consumers the execution of any ideas and design solutions.

The mass of the machine is equal to 340 kilograms. The final weight of the workpiece along with the occupied area is taken into account separately. The equipment has the following dimensions in millimeters:

The main work is performed on a table mounted separately on the unit. It’s good if you can choose an option with height adjustment.

The characteristics of the technical plan are accompanied by the following description:

- 6-horizontal spindle supports so many speeds.

- The spindle head allows adjustment of rotation speeds. Its limits are 125-1250 rpm.

- The displacement along and across to the bottom of the limb is 0.05 mm. For the vertical, the indicator is 0.25 mm.

- To fix the workpiece, use one T-shaped slot for the table.

- Certain parameters are observed when moving the table. For the vertical it is 17 cm, in the case of the transverse direction - 8.5 cm. Longitudinal movement - 25 cm.

- 11 centimeters is the maximum diameter for a cutter that is installed on the machine.

- 85 millimeters - this is how far the horizontal trunk is from the spindle, which makes fixing easier.

- Desk with dimensions 10 by 40 cm.

The main machine drive begins to move due to the electric motor and its operation. The standard power of modern installations is 0.55 kW. Some standard features are excluded:

- Additional effort applied for each serve.

- Rotating movements.

- Acceleration of the working part.

The machine will not help small-scale, professional production facilities.

Local lighting comes from lamps standing on the machine. During installation, flexible corrugation is used. It allows you to adjust the position in relation to the part being processed.

Kinds

Different machines of this type differ in many parameters. These are the design, specialization, dimensions, weight and power of the engine.

There are desktop options. For example, NGF110Sh3, NGF110Sh4. The first letter “N” means the “desktop” version. Machines of this class have a 0.75 kW electric motor.

Other horizontal milling machines can weigh around 12 tons with an 11 kW motor.

Consoleless machines are characterized by a low work table location. It is not raised on the console, but is located low, right on the bed. It may also contain mechanisms for moving the table, but the main adjustments to the position of the workpiece are carried out by a movable cutter.

On most models of non-cantilever machines, the cutters are movable, this is their main difference from console ones. The low location of the work table and the large space between the table and the cutter are designed for processing large parts. Most of them are modern and CNC.

Depending on the dimensions and power, the size of the parts that can be processed is determined. The work tables of powerful machines can withstand the weight of a part of about 2 tons or more.

Several of the most common models of horizontal milling machines.

6Р81

The 6P81 horizontal milling machine was produced by the Dmitrov milling machines plant (Moscow region). Currently out of production.

Peculiarities:

- you can choose from two ways to move the desktop: manually using a screw mechanism and automatically, for this there is a separate electric motor;

- increased power of the main electric motor. Possibility of cutting with carbide cutters at high speeds;

- When turned off, the spindle instantly stops the electromagnet.

Similar machines are produced today in Gomel (Republic of Belarus) and in China.

6Р83

The 6Р83 machine has been produced at the Gorky Milling Machine Plant since 1972. Belongs to the powerful category.

They replaced the 6P82 machines, received an enlarged work table and a more powerful engine.

The machine base allows it to be equipped with semi-automatic and automatic CNC systems. Widely used in industrial production. On 6P83, gears are made, horizontal and vertical planes are processed to a given size, grooves are selected, etc.

With the help of dividing, universal overhead heads, a rotary table and other equipment, the capabilities of the machine are significantly expanded.

Main characteristics:

- engine power 11 kW;

- number of speeds – 19;

- machine weight 3800 kg;

- maximum workpiece size 1000x320x350 mm.

6Р80

The 6P80 horizontal milling machine was produced by the Vilnius Machine Tool Plant.

Medium power. Installation into an automatic industrial line is not provided. Used in small industries and workshops. Despite how long ago it was developed, it remains in demand today.

Main technical characteristics:

- engine power 3 kW;

- number of speeds – 12;

- machine weight 1260 kg;

- maximum workpiece size 500x160x300.

Appearance of the 6Р80 machine

NGF110Sh4

The letter Ш in the marking means that it is intended for school teaching in technology (labor) lessons. For this reason, they were produced more than all other brands of horizontal milling machines. They could be found in the workshops of most schools.

The basic model is the NGF110Sh machine. The number 2,3 or 4 at the end indicates the model. For example, from 1972 to 1979, the NGF110Sh 3 machine was produced, and from 1979, an improved model 4. The machine was a training machine, but quite functional. With its help you can do everything the same as with other GFS. Limitations on engine power and workpiece size. Accuracy class N (normal), like many industrial machines, except precision (high-precision) ones.

Main characteristics:

- engine power 0.6 kW – 0.75 kW (from model);

- number of speeds – 6;

- machine weight 340 kg;

- maximum cutter diameter 110 mm;

- working table size 100 x 400 mm.

Produced at different factories. Mainly at the Rostov (Rostov-on-Don) plant of small-sized machine tools.

IR500

A powerful, large-sized machine that belongs to heavy engineering products. Produced at the Gomel and Ivanovo factories. Today, modern machining centers are produced on the design basis of this machine (Ivanovo IS-500 (IS-500PMF4, ISB500PMF4) with a weight of processed parts up to 25 tons, Gomel - modern machining centers GDN-500, GDN-630).

Main technical characteristics of IR500:

- engine power 14 kW;

- spindle speed from 200 to 3000 rpm;

- machine weight 11.3 tons;

- maximum workpiece weight in the center of the table is 700 kg.

DF831

Produced at the Dmitrov Milling Machine Plant since 1979. Refers to special longitudinal milling machines, designed for processing parallel planes with two cutters (processing two stages of a workpiece).

DF831

Main characteristics:

- engine power 7.5 kW;

- spindle speed 63-1250 rpm;

- machine weight 7100 kg.

Horizontal milling machines are wonderful machines; with their participation, the material and technical base was created, which modern civilization uses today. But their era is fading into the past. Working on such machines requires a highly qualified machine operator. They have been replaced by robotic lines and machining centers, CNC machines in 3D projection, which, according to a given program, themselves turn out the most complex parts with the highest accuracy.

But a small niche for the use of traditional milling machines still remains. These are small production and repair workshops, producing piece parts, spare parts for any machines and mechanisms (in one or several copies). In short, all industries where there is no point in buying expensive modern robotic machines for continuous production.

Analogs

To train teenagers in milling, a series of NGF-110 machines of various modifications were produced. Manufacturers are now offering multifunctional desktop milling equipment. These are mainly vertical milling machines and universal CNC equipment.

JET JUM-X2 is a highly versatile benchtop milling machine. Has vertical and horizontal spindles. The largest diameter of the disk cutter is 63 mm, the face cutter is 30 mm. Optimum MH50G is a tabletop machine with threading function. There is a head lift drive. The largest diameter of the end mill is 80 mm.

Important! There is a large selection of desktop models on the milling machine market. They are mechanically driven in all gears, high-performance, multifunctional.

General view of the desktop milling machine NGF-110sh1, NGF-110sh2

Photo of desktop milling machine NGF-110sh1

Photo of desktop milling machine NGF-110sh1

Photo of desktop milling machine NGF-110sh1

Photo of desktop milling machine NGF-110sh1

Photo of desktop milling machine NGF-110sh1

Photo of desktop milling machine NGF-110sh1