A tabletop metal lathe is a good model for a home, garage or small workshop, because the functionality of such a device allows it to be used effectively to perform a large list of technological operations. In fact, this is a miniature copy of the factory model, differing from it only in slightly limited technical capabilities.

Benchtop lathe for home workshop

Features and benefits of tabletop machines

A mini lathe, which is logical, is specially designed to process small-sized products. As with any turning equipment, a small machine can perform various technological operations on metal: turning cylindrical and conical parts, trimming their ends, grinding, drilling, reaming holes, cutting external and internal threads, etc.

Despite the fact that processing on such units is carried out at a much lower speed than on full-size devices, the quality of the finished products does not suffer at all from this. Their quality will be especially high if the mini-lathe is controlled by a CNC system.

Small models of metal lathes, which are very easy to operate, are used not only to equip home workshops, where with their help it becomes possible to produce many products or bring the quality of finished ones to the required level. Small workshops and vehicle repair shops are no less successfully equipped with such units. Since the times of the USSR, schools and technical educational institutions have been equipped with similar machines, where with their help young people were taught the basics of the turner profession.

Among the advantages that a small-sized lathe has, the most significant are:

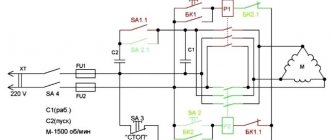

- use of a household electrical network with a voltage of 220 V to power such a machine;

- the ability to adapt such a device in order to connect it to a three-phase network;

- low power consumption;

- reliability, which allows such a micro-lathe to be successfully operated, subject to proper maintenance, for decades;

- affordable cost (many people can afford to purchase such equipment);

- compact dimensions and light weight, which makes it possible to install such a metal lathe even in a cramped workshop or garage;

- the opportunity to learn how to operate such a device in a short period of time, while the operation and maintenance of the machine will not cause any particular difficulties even for a novice turner.

Among desktop lathes there is a category of extremely compact models, which are commonly called mini-machines. The video below provides an overview of one of these portable machines.

An important advantage of such equipment is that it can be additionally equipped with various devices, which makes it possible to effectively use tools for milling and complex drilling of workpieces. With the help of such a simple modification, you now have at your disposal a desktop turning and milling machine, that is, universal equipment characterized by wide functionality.

Headstock

This is the heart of the machine. This unit must be solid, preferably cast. The headstock bearings must be spaced some distance apart to ensure spindle rigidity. Slight bearing spacing will cause rigidity problems when working with large diameters, so look for a machine with a large bearing spacing. The bearings themselves must be of high quality and designed to withstand heavy loads. The movement must be absolutely smooth and without vibration.

Recommendations for choosing a machine

Any desktop lathe, regardless of the model, can be characterized by several basic parameters. These include:

- the mass of the device, which is measured in kilograms;

- power, measured in kilowatts;

- speed, expressed as the number of revolutions per unit of time at which its spindle rotates;

- height of the centers (expressed in millimeters);

- the maximum length and diameter of the workpiece (in mm) that can be processed on such a unit;

- the number of speeds that the device drive can provide (as a rule, a tabletop lathe has no more than six such speeds);

- the diameter of the hole in the spindle assembly (measured in millimeters).

One of the representatives of compact tabletop machines

Lathe units, which are classified as small, can have a mass from 40 to 280 kg; accordingly, their overall dimensions also vary. To equip a home workshop, it is recommended to choose devices with a minimum weight: up to 50 kg, which are convenient to install and can even be carried if the need arises. Heavier equipment, even if it is a table lathe, already falls into the semi-professional category.

The power of small lathes usually does not exceed 2.25 kW. Some types of machines for the home, classified as low-power, are equipped with a drive whose power is 0.15 kW. Paying attention to this parameter of the machine, you should decide in advance for processing parts from what materials and with what dimensions you are going to use it. It is important to do this not only in order to initially select a household machine of the required power, but also in order not to overpay extra money for a unit that will not be used to its full potential.

Tough guys who are serious about saving money often choose the path of making their own machine

Even with small overall dimensions, a lathe for a garage or home workshop does not cease to be a complex technical device, the quality of its components directly determines the accuracy of processing, as well as the reliability and durability of the equipment. The build quality of such components, as well as the material from which they are made, is also of great importance. The last two parameters are especially important for the following structural elements of the turning unit:

- machine support, which is responsible for the reliability and accuracy of fastening the cutting tool, as well as for its movement during processing;

- bed - a supporting element on which all components and mechanisms of the machine are placed and fixed.

The metal from which these structural elements are made must be exceptionally durable and have a carefully polished surface. Only if these important conditions are met can you count on the fact that your household machine will last for many years without losing its original characteristics. When choosing a home turning device for metal work, you should also take into account the frequency of its use, which determines the wear rate of its components.

On the domestic market, tabletop lathes are presented in a wide range of models and brands. It is very easy to get confused with such a variety of options, so to help you make the right choice, we will look at some models of metal lathes from the most popular manufacturers.

Not expensive for beginners

There are many cheap lathes on the market, they all look the same and offer a lot of features for the money. This product is suitable to get an idea of what carpentry is. Having worked more and advanced a little in skills, it becomes clear that the functionality is limited. Some options are equipped with a stand and mechanical speed control, but it is worth understanding that there is a relationship between price and quality of components.

JET brand machines

It is no coincidence that tabletop lathes, which have been produced by the Swiss company JET for more than 50 years, have gained enormous popularity among home craftsmen and owners of small businesses. Even though some of the components of these machines have recently been produced in Chinese factories, their quality remains impeccable. Providing high quality, precision and processing efficiency, these units do not cause problems during operation and are easy to maintain.

The most popular models of machines of this brand include the following.

BD-3 is a miniature machine that can be used equally well by both amateurs and professionals. The frame of such a device is made of cast iron, which significantly reduces vibration during its operation. The machine guides, which can be adjusted according to the transverse slide, are carefully polished, this ensures precise movement along them. The equipment is equipped with a low-power (0.15 kW) but very efficient motor, which reduces energy consumption. The spindle of such a miniature unit can rotate in the range of 100–3800 rpm. The manufacturer has even provided for the possibility of independent servicing of the equipment, for which the standard kit includes an additional tool holder and a three-jaw chuck with a working section of 50 mm.

JET BD-3 machine, costs from 42,000 rubles

BD-7 is a machine for home or small business, distinguished by a number of remarkable design features: a massive cast-iron frame that reduces vibration of the unit, two spindle speed ranges, the data of which is reflected on a digital indicator, the spindle itself is equipped with roller-type bearings. This metal cutting machine is very reliable. The tailstock of this model can be adjusted, which makes it possible to use it for processing conical surfaces. Due to the presence of a reverse mechanism, the workpiece on such a unit can be fed in two directions. With such a device it will be possible to cut threads, since its spindle can rotate in different directions. Compared to the previous model, this machine has more power; it has a 0.37 kW electric motor.

JET BD-7 machine, costs about 80 thousand rubles

BD-8A is a table-top machine in which longitudinal and transverse feed are automated. The spindle head of such a machine can be quickly rearranged; it is also equipped with a reversible mechanism that allows it to be used for thread cutting. Four tools can be installed simultaneously in the unit holder, and its thrust center is made according to a non-rotating pattern. The three-jaw chuck of the machine with a working diameter of 100 mm is protected by a special screen, which increases operator safety. This machine is driven by an electric motor with a power of 0.55 kW.

JET BD-8A machine, price from 170,000 rubles

The JET company also produces more powerful machines, which are often purchased not for home use, but for equipping small workshops. Such equipment, in particular, includes BD-9G, BD-920W, BD-11W.

Distance between centers and height from center to bed

The distance between centers determines the maximum length of the workpiece that can be machined. For standard work you will need 760 mm - 915 mm. There are machines with longer beds. They seem to be more efficient, but remember, the longer the workpiece, the more likely vibration will occur. It is better not to buy a machine with a large center distance if there is no need for it. The diameter of rotation is important. It is related to the location of the main spindle above the bed and determines the maximum diameter of the workpiece that can be processed if the machine is not equipped with the ability to rotate the headstock. It is recommended that the diameter be at least 230 mm, but in practice, the larger the value, the better.

Equipment from other manufacturers

The products of the Czech company PROMA, which has been producing similar equipment for more than 20 years, have proven themselves to be excellent on the domestic market. Among the variety of lathes and screw-cutting lathes for home or small enterprises that this company produces, the following devices should be noted.

- The SM-250E is a true micro-lathe that weighs only 23 kg. With its modest dimensions, such a unit boasts excellent technical characteristics. It is this machine that is best installed at home if you are going to perform metal turning work at an amateur level. What is important is that due to the high reliability of its design, such a miniature machine practically does not require special maintenance throughout the entire warranty period.

- SK-400 is a universal unit whose weight is already 120 kg. This machine, with which you can perform a full range of metal turning and drilling workpieces, is mainly used to equip vehicle service stations.

- SPA-500 is a semi-professional model of a metal lathe, which can often be found not only in small workshops, but also in repair shops of manufacturing enterprises.

PROMA SPA-500, cost about 130,000 rubles

A number of other models of machines produced under this brand are deservedly popular: SPA-500P, SK-550, SPB-400/400, SPA-700P.

Domestic lathes for metal work are also presented on the modern market; they can often be found in educational and home workshops. Using such devices, which are easy to operate and maintain, you can quickly learn the basics of the turning profession. Among the models of miniature lathes produced by domestic manufacturers, one can note TV-6, TV-9, TV-16.

In addition, to equip a home workshop or small business, you can pay attention to lathes from the following manufacturers.

- OPTIMUM is a German brand that produces lathes, including miniature ones, which are well known and appreciated by specialists throughout Europe. The most famous models of machines for metal work of this brand, on which a CNC system can be installed, are D140x250, D210x400, D250x550.

- Chinese company Weiss Machinery, which produces inexpensive but high-quality, reliable and functional turning equipment. The most popular models, which are known in many countries around the world, are: WM-180V, WM-250V, WM-250G, WMP-300A, ML-200.

Weiss Machinery ML200 machine, cost about 160,000 rubles

What to pay attention to

You should not buy a machine based on an advertisement if you cannot check the equipment in person. You should check with the seller for the following information:

- The period of use of the equipment and under what conditions it was operated.

- Was the machine repaired before sale? Is there a guarantee?

- How long can you test the machine in operation and return it in case of malfunctions?

- Completeness of equipment, availability of software for CNC.

- Possibility of purchasing spare parts.

Of course, it would be nice to invite a qualified specialist to conduct a thorough technical inspection of the machine, but such services cost a lot.

This is interesting: Making sliding gates with your own hands

Morse cone

It is important that the product is equipped with a Morse taper in the front and tailstock. This is a universal means of installing turning centers and other tools, and does not limit the use of only original manufacturer accessories. For example, you can install a drill chuck or lathe chuck. There are many Morse taper lathe chucks on the market, so you should not buy a machine exclusively for threaded equipment. Morse tapers come with numbers 1 or 2: the higher the number, the thicker the cone.

Spindle

The threaded headstock spindle accepts screw-on accessories such as chucks, so the threads must be standard or you will be limited in your choice of accessories. On small machines, 1″x8TPI or M33x3.5 thread is standard, which makes upgrading the machine less expensive. This means that the existing threaded equipment of the machine can be transferred to the new unit if you decide to update the machine. An important point, since lathe chucks and consumables cost a significant amount of money.