2ss1m tabletop drilling machine. Purpose and scope

The 2SS1 tabletop drilling machine has been manufactured according to TU 2-024-4345-83 since 1983.

The 2СС1 drilling machine has been manufactured according to TU 2-024-5748706-002-88 since 1988.

The 2СС1 machine is designed for drilling holes and cutting threads in small parts made of cast iron, steel, non-ferrous alloys and non-metallic materials in industrial enterprises, repair and household workshops.

On the 2SS1M machine it is also possible to mill non-metallic materials with end mills.

The spindle of the 2СС1 machine receives 3 rotation speeds from three-stage drive pulleys, which provides free choice of cutting speeds in the range from 600 to 1600 rpm.

The end of the spindle is an external shortened Morse taper KM2, designation B16 according to GOST 9953 (Shortened tool tapers) - shortened cone: D = 15.733 mm.

The shortened cone B16 corresponds to a three-jaw drill chuck of the 10th and 13th standard sizes in accordance with GOST 8522 (Three-jaw drill chucks) with a clamping range of 1..10 mm and 1..13 mm, respectively.

An example of a symbol for a 3-jaw drill chuck, size 10, with a connecting conical hole B16:

Cartridge 10-B16 GOST 8522-79

Cartridge 13-B16 GOST 8522-79

The drilling depth is measured using a dial mounted on the gear shaft. The dial division price is 1 mm of drill feed.

The belt tension design allows you to quickly change the position of the belt on the pulleys to obtain the desired cutting speed.

Using a stand to install the machine makes it possible to drill the ends of long parts, such as shafts.

The 2SS1M drilling machine allows you to perform the following operations:

- drilling

- countersinking

- deployment

- reaming

The spindle speed depends on the diameter of the drill installed in the chuck:

- 1..5 mm - 1600 rpm

- 5..7 mm - 1000 rpm

- 7.5..13 mm - 600 rpm

Drilling holes larger than 6 mm is carried out followed by reaming.

As the hardness of the material being processed increases, the rotation speed should be reduced.

Main technical characteristics of the 2ss1m tabletop drilling machine

Manufacturer: Saratov Plant of Heavy Gear Cutting Machines.

- Maximum drilling diameter: Ø 6 mm

- Maximum drilling depth: 70 mm

- Maximum height of the workpiece installed on the work table: 250 mm

- Spindle speed limits per minute - (3 stages) 600, 1000, 1600 rpm

- Spindle end - B16, outer shortened Morse taper 2 according to GOST 9953

- Standard drill chuck - Chuck 10-B16 or Chuck 13-B16 according to GOST 8522-79

- Electric motor power: 0.18 kW

- Machine weight: 53 kg

Tool Morse taper shortened

Tool taper - Morse taper is one of the most widely used tool mounts.

It was proposed by Stephen A. Morse around 1864. The Morse taper is divided into eight sizes - from KM0 to KM7 (in English: MT0-MT7, in German: MK0-MK7).

Morse taper standards: GOST 25557 (Tool cones. Main dimensions), ISO 296, DIN 228. Cones made according to inch and metric standards are interchangeable in everything except the shank thread.

For many applications, the length of the Morse cone turned out to be excessive. Therefore, a standard was introduced for nine standard sizes of shortened Morse cones (B7, B10, B12, B16, B18, B22, B24, B32, B45), these dimensions were obtained by removing the thicker part of the cone. The number in the designation of a short cone is the diameter of the thick part of the cone in mm.

Russian standard for shortened cones GOST 9953 Shortened tool cones.

Russian standard for drill chucks GOST 8522 Three-jaw drill chucks.

- B7 - Morse cone KM0, D = 7.067 mm;

- B10 - Morse cone KM1, D = 10.094 mm. Cartridge 4-B10 (0.5÷4 mm);

- B12 - Morse cone KM1, D = 12.065 mm. Cartridge 6-B12 (0.5÷6 mm), Cartridge 8-B12 (1÷8 mm);

- B16 - Morse cone KM2, D = 15.733 mm. Cartridge 10-B16 (1÷10 mm), Cartridge 13-B16 (1÷13 mm);

- B18 - Morse cone KM2, D = 17.780 mm. Cartridge 16-B18 (3÷16 mm);

- B22 - Morse cone KM3, D = 21.793 mm. Cartridge 20-B22 (5÷20 mm);

- B24 - Morse cone KM3, D = 23.825 mm;

- B32 - Morse cone KM4, D = 31.267 mm;

- B45 - Morse cone KM5, D = 44.399 mm.

Where D is the diameter of the cone in the main plane.

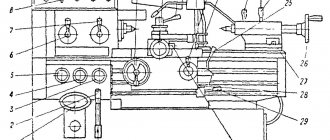

Review and description of tabletop drilling machines

Compact tabletop drilling machine designed for small jobs. It is widely used when it is necessary to make a small hole. You can make a homemade unit, but this is not always rational.

Photo of tabletop drilling machine

A tabletop drilling machine allows you to process small cabinet parts with your own hands by:

- Drilling;

- Countersinking;

- Reaming;

- Reaming holes.

If we are talking about a desktop drilling and milling machine, then sharpening becomes an additional feature of the equipment. For fine sharpening, such units are indispensable, since several useful functions are combined in one body.

The machines NS 12, NS 12a, JDP 10l, 2n106p, 2ss1m, Einhell products, GS2116k, Bosch pbd 40, AC2116m and many others have gained wide popularity.

When reaming holes, the capabilities of these machines provide drilling with a diameter from 0.2 to 16 millimeters. Some models, in addition to sharpening, are capable of thread cutting.

The design of the unit provides that household devices for working on metal, wood, and polymers are installed on tables. All such machines for drilling, sharpening and other operations are vertically located.

A tabletop drilling and milling machine, as well as its analogues, can be used in the arrangement of:

- Home workshops;

- Repair rooms;

- Vocational schools as training equipment;

- Small metalworking enterprises.

Specifications

DIY desktop drilling machine

Working with your own hands with vertically positioned machines designed for drilling, sharpening, and reaming holes is quite simple. Household models are great for home use. Their engine provides the necessary power and rotation speed.

In order to correctly select a vertical drilling unit for sharpening and other operations, you need to pay attention to several of its main characteristics.

Most models of vertical drilling machines have a belt on 3-5 speed pulleys. With its help, the rotation speed of the machine spindle is adjusted. This plays a vital role in achieving the desired result of processing the material. At the same time, the most significant characteristics when purchasing a compact vertical drilling machine for reaming, countersinking and sharpening are:

- Maximum permissible spindle movement. This determines what workpieces a small vertical drilling machine can process and how comfortable it will be to work with it.

- Drive power. The engine of a wood cutting machine may be less powerful than the engine of a metal cutting machine. Household models are the least powerful. But if you plan to work on wood, plastic, or metal, it is advisable to choose an engine with a power reserve.

- Distance between table and spindle. Determines the maximum permissible dimensions of processed workpieces. For sharpening, working on metal and wood, this plays a significant role, so try to make the right decision with your own hands.

- Table dimensions. There are both mini vertical drilling machines and simply compact ones. The first ones are used for processing the smallest parts, microcircuits. Household compact ones allow you to work with larger products. Hence the difference in table sizes. Although some people make the table with their own hands. A homemade unit is completely adaptable to the requirements of a particular master. Therefore, a homemade machine has every right to exist.

Try to build a homemade unit with your own hands, buy an inexpensive Soviet machine, or buy household factory models? The choice is entirely yours. Let's just say that building a homemade machine with your own hands is not an easy task. That’s why most people choose ready-made household devices for working on metal, plastic, wood, etc.

Is it worth building a homemade machine? If you have no experience, it will be impossible to make a homemade unit. Plus, a homemade device cannot meet all safety requirements and operating nuances. Therefore, if the choice is homemade or factory made, we recommend choosing the second option.

Popular models

Let's look at several devices that have gained impressive popularity among vertical drilling devices. They can be intended for sharpening, reaming, countersinking, etc.

We will study the following vertical drilling machines:

- NS 12, 12a;

- gs2116k;

- Einhell;

- JDP 10l;

- 2n106p;

- Bosch pbd 40;

- AS2116m;

- 2ss1m.

JDP 10l from JET

- The power of the JDP 10l device is 450 W;

- Powered by 220V voltage;

- The JDP 10l machine weighs 19 kg;

- Spindle stroke - 50 mm;

- Reach value - 104 mm;

- The table for JDP 10l measures 16 by 16 cm;

- Rotation speed - from 580 to 2650 rpm;

- The tilt of the table is 45 degrees.

Einhell

Vertical drilling machines from Einhell have a number of distinctive characteristics:

- Einhell machines produce power from 350 to 650 W;

- Einhell can have speeds from 5 to 12 units;

- The rotation speed of different Einhell models is 210-2650 rpm;

- The simplest models are household ones, but there is a semi-professional unit;

- Designed for DIY wood and metal work, and for sharpening workpieces;

- The diameter of the cartridges for Einhell is the same for all models - 16 mm;

- Einhell models vary in price. Household Einhell costs about 7.5-8 thousand rubles, and a semi-professional vertical drilling unit Einhell will cost 22 thousand rubles.

NS 12, NS 12a

NS 12 and NS 12a are a Soviet drilling machine project, developed during Soviet times in Odessa. It is noteworthy that NS 12 was produced not only by factories, but also by some technical schools under the USSR. This happened in the 50-70s of the last century.

At the same time, the Soviet unit is still in great demand. The NS 12 model received a number of modifications, including the NS 12a.

- The mass of NS 12a is 121 kg;

- The drilling diameter for NS 12 and NS 12a is maximum 12 mm;

- The spindle on units NS 12, NS 12a extends by 85 mm;

- The distance from the table to the spindle can be 2-42 cm;

- The spindle head on NS 12, NS 12a moves by a maximum of 30 cm;

- The blanks in NS 12, NS 12a are fixed with 3 T-shaped grooves;

- The sleeve stroke does not exceed 100 mm;

- Drive rotation speed NS 12, NS 12a - 450-4500 rpm;

- The machines have 5 speeds.

Like the HC 16 tabletop drilling machine, models 12 and 12a have earned enormous popularity.

Bosch pbd 40

- The Bosch pbd 40 model has a power of 710 W;

- Equipped with a 2 m laser assistant;

- For metal work, the maximum diameter of the Bosch pbd 40 drill is 13 mm;

- For woodworking - 40 mm;

- With Bosch pbd 40 shanks from 1.5 to 13 mm are used;

- When drilling with a Bosch pbd 40, the maximum lifting height is 90 mm;

- The Bosch pbd 40 unit weighs 11.2 kg;

- Rotation speed Bosch pbd 40 - from 200 to 2500 rpm;

- The Bosch pbd 40 desktop has dimensions of 330 by 350 by 30 mm;

- The Bosch pbd 40 wood and metal machine is equipped with built-in lighting.

gs2116k

- GS2116k has a maximum drilling diameter for metal of 18 mm;

- The GS2116k machine cuts threads from M4 to M16;

- Spindle stroke - 100 mm;

- The speed of revolutions on GS2116k is from 200 to 2100 units;

- The spindle reach of the GS2116k machine is 190 mm;

- The GS2116k unit weighs 125 kg;

- Device power GS2116k 550 W;

- Powered by a voltage of 380 W.

2n106p

- Model 2n106p has a maximum drilling diameter of 6 mm;

- Can use homemade work tools;

- The distance from the table to the spindle is 250 mm;

- Electric motor, power 400 W;

- The machine 2n106p weighs 80 kg.

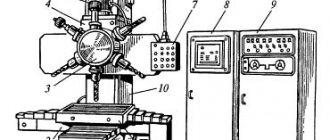

Operating principle and design features of the machine

The 2N125 machine belongs to the design range of medium-sized vertical drilling machines (2N118, 2N125, 2N125L, 2N135, 2N150, 2G175) with a nominal drilling diameter of 18, 25, 35, 50 and 75 mm, respectively. Compared to previously produced machines (with index A), the new range of machines have a more convenient location of the gearbox and feed control handles, better appearance, simpler technology for assembling and machining a number of critical parts, and a more advanced lubrication system. The aggregate layout and the ability to automate the cycle ensure the creation of special machines based on them.

The limits of spindle speeds and feeds make it possible to process various types of holes using rational cutting conditions.

The presence of mechanical spindle feed on machines, with manual control of work cycles.

Allows processing of parts in a wide range of sizes from various materials using tools from high-carbon and high-speed steels and hard alloys.

The machines are equipped with a device for reversing the main motion electric motor, which allows them to cut threads using machine taps while manually feeding the spindle.

Placement category 4 according to GOST 15150-69.

Developer: Odessa Special Design Bureau of Special Machine Tools.

Chronology of the plant's production of vertical drilling machines 2125 series with drilling diameters up to 25 mm:

- 2125 - the first model of a series of vertical drilling machines, produced from 1945 to 1950.

- 2A125, 2A125A, 2A125K - the next models in the series, produced from 1950 to 1965.

- 2N125, 2N125A, 2N125K, 2N125F2 - the most popular and widespread model of the series, produced from 1965 to the early 90s

- 2S125, 2S125-01, 2S125-04 are the latest models in the series. Discontinued in 2022

Modifications of drilling machines 2n125

To process holes of different diameters, basic vertical drilling machines are used: 2H125.

The last two digits of each model number indicate the largest hole diameter in mm that can be drilled on this machine in 45 steel workpieces. Based on the above basic machine models, the following modified models have been created:

2N125A - vertical drilling machines with automated control (control is carried out using pre-configured cams and buttons);

2N125K - coordinate vertical drilling machines with a cross table;

2N125S - special single-position vertical drilling machines with a flanged quill used for fastening multi-spindle heads;

2N125N - multi-position drilling machines designed for installing multi-spindle heads and rotary tables;

2N125F2 - drilling machines with CNC, cross table and turret head, etc.

Analogues of vertical drilling machines 2N125, currently produced:

- 2T125, 2T140, 2T150 - manufacturer: Gomel Machine Unit Plant

- 2AS132, 2AS132-01 - manufacturer: Astrakhan Machine Tool Plant

- 2L125, 2L132, 2L135, LS25, LS35 - manufacturer: Lipetsk Machine Tool Enterprise (PJSC STP-LSP)

- MN25L, MN25N-01 - manufacturer: Molodechno Machine Tool Plant

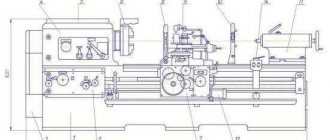

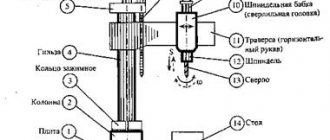

Specification of components of drilling machine 2ss1m

- Machine base;

- Switch;

- Belting;

- Electric motor;

- Traverse;

- Pinol;

- Adjusting bolt;

- Spindle feed handle;

- Rack;

- Gear shaft;

- Protective casing (electric motor guard)

- Table;

- Table clamp handle.

Spindle head of tabletop drilling machine 2ss1m

The spindle head is based on a cast iron body. The housing contains a spindle unit, a belt tensioning mechanism, and local lighting of the machine.

An electric motor is attached to the back of the headstock.

Driller 2SS1M – Restoration and modification – Drilling machines

The 2SS1M desktop drilling machine can successfully handle drilling and milling a small batch of workpieces. The unit performs drilling operations in steel workpieces, milling non-metals and turning wood.

The unit is designed for domestic use and work in single production.

The machine is equipped with a three-jaw lathe chuck and a clamp with a mounting kit.

As an option, a device is included that allows turning.

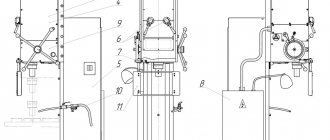

Kinematic diagram of the 2ss1m drilling machine

Kinematic diagram of a drilling machine

The torque on the spindle 1 arises from the electric motor 6 and is transmitted through the V-belt transmission 5. The spindle speed is adjusted by moving the drive belt to the appropriate stage of the stepped pulley.

The quill 2 is moved by the handle 3 through the rack and pinion gear 4.

Setting up the 2SS1M machine for drilling

Milling a groove in a wooden block on a 2SS1M machine

Bearing layout of the 2SS1M machine

Machine setup and operating mode

Setting up for drilling is done as follows:

- lift the quill with spindle 1 (Fig. 5) and with drill 3 fixed in chuck 2 to its highest position

- Set the movable table 5 in height so that the gap between the upper plane of the workpiece 4 and the end of the drill is at least 5 mm

- When drilling holes to a given depth, it is necessary to use a dial mounted on the gear shaft.

- Move the drill to the surface of the workpiece, then, turning the dial counterclockwise (looked from the dial side), align the “zero” division of the dial with the mark on the machine.

- The price of one division of the dial is equal to 1 mm of drill feed.

The required rotation speed of the tool is adjusted by rearranging the drive belt.

The following rotation speed is recommended depending on the drill diameter:

- Drill Ø up to 5 mm – 1600 rpm

- Drill Ø 5—7.5 mm — 1000 rpm

- Drill Ø 7.5-13 mm - 600 rpm

Drilling holes with a diameter greater than 6 mm should be carried out by subsequent drilling.

As the hardness of the material being processed increases, the rotation speed should be reduced.

When drilling large parts installed directly on the floor or stand 2 (Fig. 6), it is necessary to rotate the traverse 1 by 90°.

Having secured the end mill 2 in the chuck 1 (Fig. 2) and the stop 3 on the movable table 5, you can mill a groove in a wooden block 4 by manually feeding the block along the stop onto the cutter. The quill must be locked with bolt 9 (Fig. 2).

Attention! The duration of continuous operation of the machine under load is no more than 30 minutes. Resumption of work on the machine is possible when the electric motor cools down to a temperature of 50° C.

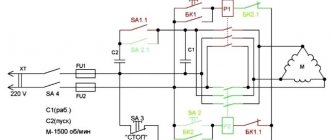

Electrical equipment and electrical circuit of the 2ss1m drilling machine

Electrical diagram of the drilling machine 2СС1М

Power supply of the drilling machine 2СС1М ~220 Volts.

The machine is started by connecting plug Ш1 to the network, voltage 220 V and pressing the start button of switch B 1. When pressing the button of switch B1, the inching contact is turned on, turning on the starting winding PO and the working winding RO of the electric motor.

After turning off the switch button B1, the inching contact opens, turning off the starting winding of the electric motor.

To avoid failure of the working winding of the motor during an arbitrary stop, you should press the stop button of the switch.

2Сс1 engine

» Engine » 2Сс1 engine

The 2SS1M desktop drilling machine can successfully handle drilling and milling a small batch of workpieces. The unit performs drilling operations in steel workpieces, milling non-metals and turning wood.

The unit is designed for domestic use and work in single production.

The machine is equipped with a three-jaw lathe chuck and a clamp with a mounting kit.

Three-jaw lathe chuck

As an option, a device is included that allows turning.

Main technical characteristics of the machine

The characteristics of the unit are quite standard:

| No. | Parameter name | Meaning |

| 1 | Maximum drilling diameter in steel, mm | 6 |

| 2 | Maximum drilling size, mm | 13 |

| 3 | Maximum distance from the table mirror to the end of the spindle, mm | 250 |

| 4 | Marking the distance from the base to the end of the spindle, mm | 370 |

| 5 | Amount of rotation of the desktop, degrees | 360 |

| 6 | Maximum quill shift, mm | 70 |

| 7 | Spindle reach from the stand, mm | 150 |

| 8 | Table size, Length × Width, mm | 200×200 |

| 9 | Base size, Length × Width, mm | 200×200 |

| 10 | Cone in spindle | Morse B16 |

| 11 | Maximum diameter of a wooden workpiece for turning, mm | 70 |

| 12 | Number of spindle speed steps | 3 |

| 13 | Rotation speed according to drilling diameter, rpm | |

| up to 5 mm | 1.6 thousand | |

| from 5 to 7.5 mm | 1 thousand | |

| from 7.5 to 13 mm | 600 | |

| 14 | Machine dimensions, Length × Width × Height, mm | 620×240×700 |

| 15 | Equipment weight, kg | 52,5 |

Device Description

The 2SS1M drilling machine is a vertical design for desktop installation with a massive base in the form of a plate.

Drilling machine device

The slab support includes:

- Cylindrical stand - it contains a movable work table and a traverse.

- To secure the table, a clamping mechanism with a handle is provided.

- Above the working area of the table there is a quill mounted in a traverse.

- The quill has the ability to move in a vertical plane along a rack and pinion transmission. The quill is lowered by rotating the manual feed handle.

- An electric motor is installed in the opposite part of the traverse of the 2SS1M machine.

- The three-stage pulley of the electric motor and the quill are connected by a belt drive.

The rotation speed is adjusted by moving the V-belt to the desired pulley stage. The top of the belt drive is covered with a protective casing. On the side of the traverse there is a push-button control station.

Preparing the machine for operation

The specialist needs to know the operating instructions for the unit:

- The machine is secured to a workbench or work table using holes in the base.

- A drill of the required diameter is clamped in a spindle with a chuck.

- The handle moves the quill to its highest position.

- The workpiece is placed on the table and secured with clamps or other equipment.

- By moving the table, you need to establish a gap of at least 5 mm between the top plane of the part and the top of the tool.

The movement of the tool during processing is controlled by the dial ruler. The division value of the reading device is 1 mm, the mark corresponds to the amount of movement of the tool on the part. Before starting processing, you should connect the zero of the dial with the mark on the machine by rotating the dial counterclockwise.

The principle of operation of the electrical circuit

The 2SS1M machine is powered from a 220 V mains voltage. The type of current is alternating, single-phase, and the current frequency is 50 Hz.

After connecting to the network and being completely ready for work, press the start button on the control panel. After electricity is supplied, the inching contact for turning on the starting winding is triggered, and the working winding of the electric motor is started.

When the button is turned off, the terminals on the contactor open, and the starting circuit of the electric motor is turned off.

The equipment is stopped by the red stop button. It is also necessary in an emergency and when stopping the engine unnecessarily. The button prevents damage to the machine drive and injury to the machine operator.

The 2SS1M drilling machine has an electric motor with a rated power of 0.18 kW.

Electric motor with a power of 0.18 kW

Engine speed 1420 rpm. The motor has a class II product with double insulation.

Recommendations for processing

Experts who work with the unit advise craftsmen to adhere to several rules:

- The choice of processing modes is made taking into account the hardness and type of material. High-hardness workpieces are processed at low speeds.

- Large parts are installed on the floor or stand. The traverse is deployed to the desired position.

- Milling of grooves is carried out with a fixed quill. The workpiece is placed along the stop and fed manually.

During the turning operation, a comb is installed in the quill instead of a chuck. A rotating center is fixed into the hole in the worktable. The part being processed is located between them. Processing is carried out with cutters with the installation of a special device.

Kinematic diagram of a tabletop drilling machine 2ss1m

The torque on the spindle 1 arises from the electric motor 6 and is transmitted through the V-belt transmission 5. The spindle speed is adjusted by moving the drive belt to the appropriate stage of the stepped pulley.

The quill 2 is moved by the handle 3 through the rack and pinion gear 4.

Electrical diagram of a tabletop drilling machine 2ss1m

The machine is started by connecting plug Ш1 to the network, voltage 220 V and pressing the start button of switch B 1. When pressing the button of switch B1, the inching contact is turned on, turning on the starting winding PO and the working winding RO of the electric motor.

After turning off the switch button B1, the inching contact opens, turning off the starting winding of the electric motor

To avoid failure of the working winding of the motor during an arbitrary stop, you should press the stop button of the switch.

Setting up a tabletop drilling machine 2ss1m

Raise spindle 1 with the drill fixed in chuck 2 to its highest position.

Using the movable table 5, set the minimum gap (5 mm) between the top surface of the workpiece and the end of the cutting tool.

Secure the workpiece on the table using clamps 6.

Drilling a part to a given depth is carried out using a dial, turning counterclockwise, align the “zero” division of the dial with the mark on the machine. The dial division price is equal to 1 mm of drill feed.

Machine bearing arrangement

No. in fig. Bearing No. Installation location Quantity

| 1 | 205 | in the traverse under the pulley | 2 |

| 2 | 8102 | in pintles | 1 |

| 3 | 202 | in pintles | 2 |

Technical characteristics of the tabletop drilling machine 2ss1m

Main parameters 2ss1m

| Largest drilling diameter in steel, mm | 6 |

| Maximum drilling diameter, mm | 13 |

| Spindle taper | B16 |

| Maximum distance from the end of the spindle to the table surface, mm | 250 |

| Maximum displacement of the quill, mm | 70 |

| Spindle overhang from the column, mm | 150 |

| Table dimensions: | |

| length | 200 |

| width | 200 |

| Number of speed steps | 3 |

| Overall dimensions, mm: | |

| length | 620 |

| width | 240 |

| height | 700 |

| Machine weight, kg | 52,5 |

www.metalstanki.com.ua

Accessories for benchtop drilling machines

A drilling machine is the simplest, but at the same time extremely important equipment for its purpose in production. With its help you can create a huge number of different parts.

And in the right hands, this machine is not only capable of creating many different tools, but also works at extremely high speed.

Rotary vice for clamping parts

However, you should understand that the machine alone will not give you sufficient efficiency in your work. It doesn’t matter whether you use a powerful sample NS 12A or a small desktop drilling machine GS2112, in any case you need to buy additional accessories for it, which will be discussed now.

Technical characteristics of the machine 2ss1m

| Parameter name | 2m112 | NS12A | 2SS1M |

| Basic machine parameters | |||

| Largest drilling diameter, mm | 12 | 12 | 6 |

| Maximum drilling diameter, mm | 13 | ||

| The smallest and largest distance from the end of the spindle to the table (base) | 0…400 | 20..420 | 0..370 |

| The smallest and largest distance from the end of the spindle to the table | No | No | 0..250 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 190 | 185 | 150 |

| Desktop | |||

| Width of the working surface of the table (base), mm | 250 | 360 x 360 | 200 x 200 |

| Width of the working surface of the table, mm | No | No | 200 x 200 |

| Desktop rotation angle, degrees | No | No | 360° |

| Number of T-slots | 3 | 3 | 1 |

| Spindle | |||

| Maximum movement of the spindle head, mm | 300 | ||

| Spindle sleeve stroke, mm | 100 | 100 | 70 |

| Spindle speed, rpm | 450, 800, 1400, 2500, 4500 | 450, 710, 1400, 2500, 4500 | 600, 1000, 1600 |

| Number of spindle speeds | 5 | 5 | 3 |

| Spindle taper | Morse B18 | Morse B18 | Morse B16 |

| Drive unit | |||

| Main motion drive electric motor, kW (rpm) | 0,55 | 0,65 | 0,18 (1420) |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 795 x 370 x 950 | 770 x 465 x 700 | 600 x 240 x 700 |

| Machine weight, kg | 120 | 121 | 53 |

Drilling machine 2ss1

The 2SS1M desktop drilling machine can successfully handle drilling and milling a small batch of workpieces. The unit performs drilling operations in steel workpieces, milling non-metals and turning wood.

The unit is designed for domestic use and work in single production.

The machine is equipped with a three-jaw lathe chuck and a clamp with a mounting kit.

Three-jaw lathe chuck

As an option, a device is included that allows turning.

The characteristics of the unit are quite standard:

| No. | Parameter name | Meaning |

| 1 | Maximum drilling diameter in steel, mm | 6 |

| 2 | Maximum drilling size, mm | 13 |

| 3 | Maximum distance from the table mirror to the end of the spindle, mm | 250 |

| 4 | Marking the distance from the base to the end of the spindle, mm | 370 |

| 5 | Amount of rotation of the desktop, degrees | 360 |

| 6 | Maximum quill shift, mm | 70 |

| 7 | Spindle reach from the stand, mm | 150 |

| 8 | Table size, Length × Width, mm | 200×200 |

| 9 | Base size, Length × Width, mm | 200×200 |

| 10 | Cone in spindle | Morse B16 |

| 11 | Maximum diameter of a wooden workpiece for turning, mm | 70 |

| 12 | Number of spindle speed steps | 3 |

| 13 | Rotation speed according to drilling diameter, rpm | |

| up to 5 mm | 1.6 thousand | |

| from 5 to 7.5 mm | 1 thousand | |

| from 7.5 to 13 mm | 600 | |

| 14 | Machine dimensions, Length × Width × Height, mm | 620×240×700 |

| 15 | Equipment weight, kg | 52,5 |