Principle of operation

The operation of a milling machine can be briefly described in this way: a cutter rotates in a certain place, towards which the part is approached. The movement of the workpiece is called feed motion and occurs in several directions, which are specified as the X, Y, and Z axes.

When a CNC milling machine operates, the feed movement occurs along guides specified by the program. The contact of a rotating cutter with the metal cuts off a layer from it.

A CNC-equipped machine almost independently calculates the necessary parameters, such as rotation speed or feed direction. The operator only needs to launch the desired program at the beginning of work.

The technical characteristics of CNC milling machines indicate the largest movements in millimeters along the X, Y, and Z axes. The complexity of the work performed depends on this. In our catalog you can view the detailed characteristics of each device in order to buy the most suitable machine.

Parameters to consider when choosing a milling machine

1. Size of workpieces to be processed: the part must fit completely on the work table. Therefore, we advise you to pay attention not only to the width and length of the part, but also to its height so that it does not touch the spindle. 2. Electric motor power: a parameter that must be taken into account when choosing a unit. If you are going to work on the machine regularly, for example, several hours a day, then it is better to purchase a more powerful device. Of course, in this case, the price of a milling machine will be higher than an analogue with a weaker engine, but you are guaranteed to be able to complete the planned amount of work. 3. Installation and connection of the machine: when purchasing a machine for use in a home workshop, you must pay attention to the voltage at which the unit can operate. If you have the ability to connect to a three-phase network with a voltage of 380 V at home, then it is better to take a machine specifically for such conditions, otherwise only machines operating on 220 V will suit you. Also pay attention to the overall dimensions of the machine. Of course, if you are buying equipment for a spacious workshop, then this nuance is not so important, but many craftsmen try to place the machine even in an apartment, and then the issue of the size of the machine comes first. 4. Maximum drilling diameter: this parameter is indicated in the technical characteristics of the machine and indicates the maximum drilling diameter in the steel part. For wood and plastic, this figure will be at least twice as large. 5. Weight: the heavier the machine, the higher its rigidity will be, and this parameter, in turn, will guarantee the absence of vibrations and, accordingly, improved quality of part processing. A professional milling machine weighs from 300 kg. Such units are often used only in production. The price of a professional-level wood milling machine, as you understand, is also not cheap, so it makes no sense to purchase this device for home purposes. For rare home use, it is enough to take a simple desktop model weighing about 50 kg.

Milling machine device

The standard equipment of the milling machine includes:

- Main building;

- Desktop;

- A set of tools for metal processing (in this case, milling cutters)

- Spindle (rotating shaft);

- Front disc brake.

The spindle is an important part of the machine. A cutter of the desired shape is fixed in a spindle, thanks to which the attachment rotates. For smooth operation of a CNC device, you need a spindle with high power and rotation speed, high-quality bearings and a cooling system.

Spindle power for working with metal is required from 1500 W (15 kW). To perform large volumes of work, you should buy a CNC milling machine with a higher spindle power.

Purpose

Mostly milling machines are designed for metal processing. Various parts of various profiles and sizes, including complex ones, with straight and curved contours, are cut from blanks using mechanical processing.

In addition to mechanical processing, various metal parts are made in other ways: casting into molds, stamping on presses, punching, cutting, forging. But these methods are not always technologically possible or justified. For example, stamping, gas or laser cutting cannot create a three-dimensional part or a high-precision part.

Sometimes heat treatment (high heating) is unacceptable for an alloy, since this changes the properties of the metals. Then the only way to produce parts is mechanical processing - milling.

In addition to milling, there is another type of mechanical processing of metals - turning. The process is similar to milling, but round parts are cut with cutters. As a separate type, there are combined turning and milling machines, which perform both processing along diameters and along straight lines - grooves, recesses, channels, splines, etc.

Turning and milling machine:

Cooling

When choosing a cooling system, you need to decide on the criteria. According to the type of action it is:

- Liquid;

- Air.

The first is based on the circulation of coolant and reliably removes heat. But this system requires a separate tank. The air cooling system is compact and simple, but it needs to be changed frequently.

In our catalog you can select and buy a CNC milling machine with the required level of spindle power and a suitable cooling system. For each device you can study the photo and technical characteristics.

Classification by type of material processed

The most common materials for milling are metals and wood.

Metal and woodworking milling cutters have significant differences in the number of spindle revolutions. Metal is processed at cutter speeds of up to 3000 rpm, wood is 10 times higher. Moreover, the higher the speed, the cleaner the woodworking. A metal cutter at such speeds will burn out or break.

In addition to these materials, modern machine tool industry offers milling cutters for processing almost all production materials. Woodworking machines can work with materials similar in density and strength to wood:

- MDF, chipboard, chipboard, OSB, fiberboard, plywood;

- some types of plastics and plastics;

- plexiglass and composite materials.

There are special machines for processing super-hard materials: granite, marble, other natural and artificial stones.

The image shows a stone router at work:

A separate direction is jewelry milling machines for processing semi-precious and precious stones and metals.

Simple milling machines from the 20th century are almost never produced today. However, they still work in many workshops and factories. Modern, CNC machines are being produced more and more. And there is the opportunity to choose the most suitable option. The entire world market for such equipment is open to the buyer. Modern equipment of this profile are also produced in Russia.

Machine markings

Milling machines often have a narrow specialization, which is reflected in the markings. The first number is the group to which the machine belongs according to the classification table. The 2nd digit indicates the type of equipment:

- 1 – vertical milling console;

- 2 – continuous action – working on a flow. They produce the same parts.

- 3 – copying machines work according to a stencil mounted on a frame above the working part;

- 4 – engraving;

- 5 – vertical non-console ones have a cross table;

- 6 – longitudinal milling machines do not have a wide range of capabilities and are used in mass production;

- 7 – widely universal have a lot of capabilities, which makes them excellent equipment for workshops and small-scale piece production;

- 8 – cantilever-horizontal;

- 9 – different.

Classification of machines

The third and sometimes fourth digits indicate dimensions. A letter between 1 and 2 digits indicates that this is a modernized model. If the letter is at the end of the marking, then it indicates the characteristics of the modernization of the base model. The letters P, B, A, C - indicate the accuracy class. Ш indicates the wide versatility of the model, which has, in addition to a horizontal spindle, a trunk with a vertical head. G indicates that this machine is a horizontal milling machine.

Types of equipment

With the development of technology, people came up with new options for completing milling equipment. There are several main types of machines on sale:

- Vertical. This is a machine whose work table moves up and down. The working part (mill) is secured with a chuck above the work table. Moves vertically.

- Horizontal. Equipment that is used to process small parts. The spindle moves horizontally relative to the workpiece.

- Drilling and milling. Machines used for milling, drilling, boring, countersinking, threading. The spindle moves vertically, the work table can be moved horizontally. Has a reverse function.

- Universal. Equipment that allows you to perform various technological operations. It is installed in factories, large workshops, and enterprises. Replaces several individual machines. However, milling operators recommend using highly specialized machines. They perform individual operations more accurately, which reduces the risk of product damage.

Manual milling machines can be classified as a separate group. The tool is suitable for home, garage, private workshop, furniture production. This is a small machine that has control handles and a spindle with a cutter. Manual machines are used for making grooves, turning ends, drilling, and removing a layer of metal.

Application area

Milling machines are used in various industries:

- Metal processing. When you need to carry out precise processing of parts, make grooves, cuts or work the ends of the workpiece, milling equipment is used.

- Mechanical engineering. Milling machines make it possible to produce body parts for cars, ships, and airplanes. Milling is necessary to create parts that will be located inside the mechanisms.

- Manufacturing of household appliances and electronics.

- Furniture manufacturing. The grooves are selected using hand-held milling machines. Powerful tools are used in the construction of wooden buildings. With its help it is convenient to make cuts at the joints of beams.

Milling machines are popular in large enterprises and private workshops. For this purpose, low-power desktop models are produced. With their help you can process wooden and metal workpieces.

Woodwork

Widely versatile machines

Widely versatile milling machines are used for milling parts made of cast iron, steel and alloys of other materials. They differ from horizontal milling machines by the presence of another spindle head mounted on a retractable trunk. It can rotate at any angle in two mutually perpendicular planes. Both separate and simultaneous operation of both spindles is possible. The overlay milling head is mounted on the rotary head of the machine to add versatility. This makes it possible to process workpieces of complex shapes both by milling and by drilling, countersinking and boring.

Some widely-universal machines do not have a console panel, but instead a carriage moves along the vertical guides of the frame. The carriage has horizontal guides for the slide with a working vertical surface. They are often used to install additional devices, a dividing table, or any dividing device.

The milling group of lathes consists of all the previously listed models. They are distinguished by size and nature of the work performed, but they are all equally used in industry. Each type is used to perform special work that cannot be performed on other types of machines.

Technical data entirely depends on the manufacturer and brand of a particular machine, and the quality of the work performed depends on the professionalism of the master who works on it.

To mainChapter II

MILLING MACHINE AND ITS COMPONENTS

§ 3. TYPES OF MILLING MACHINES

Milling machines can be used to process flat or shaped surfaces, cut threads, splines, teeth, and perform drilling and boring work. Milling machines make up a significant part of the fleet of metal-cutting machines in the USSR - about 10% (up to 180,000 machines); by 1965, it is planned to increase the fleet of milling machines to 12.7%. Of all the milling machines, the most widely used are machines for processing flat and curved surfaces: cantilever-milling, non-cantilever-milling, longitudinal milling and copy-milling. Among the machines for other types of milling processing, gear hobbing, thread milling, spline milling and key-milling machines have become widespread. In mass production, they mainly use multi-spindle longitudinal milling machines and continuous machines - rotary milling and drum milling. The milling machine fleet is replenished with modern models produced by domestic machine tool factories.

Cantilever milling machines

This is the most common type of machine used for milling work. Cantilever milling machines get their name from the cantilever bracket (console), which moves along the vertical guides of the machine bed and serves as a support for the horizontal movements of the table. The simplest and most common type of equipment used for milling work is a horizontal milling machine

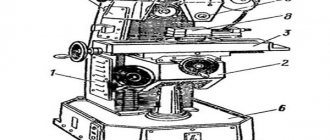

. In Fig. Figure 7 shows a horizontal milling machine produced by the Gorky Milling Machine Plant. Horizontal milling machines are designed to use cylindrical and disc cutters, but they can also use face mills.

Spindle

The horizontal milling machine on which the tool is mounted rotates around a horizontal axis.

It receives rotation through a gearbox from an electric motor. The table of

a horizontal milling machine has three directions of movement: (longitudinal, transverse and vertical. These movements of the table, or its feed, can be carried out manually using handles or mechanically from the machine drive. On some horizontal milling machines, the table can be rotated relative to the spindle. Machines with such a rotary table are called

universal horizontal milling machines

, or, in short,

universal milling

machines. A machine of this type is shown in Fig. 8. The machine table can be rotated along circular guides on the top of the slide 45° in each direction and after installation on the specified angle is secured with a screw on scale 1. Apart from the ability to rotate the table, a universal milling machine is no different from a horizontal one.

Shown in Fig. 9 milling machine differs from the considered horizontal milling machine only in the design of the upper part of the bed; all other components of the machine are the same (compare Fig. 9 and 7). The spindle of this machine rotates around a vertical axis. This type of machine is called vertical milling

.

To expand the possibilities of use, new models of vertical milling machines are manufactured with a rotating spindle head 3. It can be installed both in a vertical position and at an angle to the table plane. This is especially convenient when milling inclined surfaces. The necessary rotation of the spindle head 3 relative to the bed 1 is set on a scale of 2. Vertical milling machines are designed to work with face milling cutters, milling heads, end and key cutters. The standard sizes of cantilever milling machines are usually characterized by the size of the working (mounting) surface of the table. Cantilever milling machines can have horizontal universal and vertical execution with the same size of the working surface of the table. The combination of different versions of the machine with the same basic dimensional characteristics of the table is called the dimensional range of machines

. In the USSR, the production of cantilever milling machines of five sizes has been mastered: No. 0; No. 1; No. 2; No. 3 and No. 4, and for each size a full range of machines is produced - horizontal, universal and vertical.

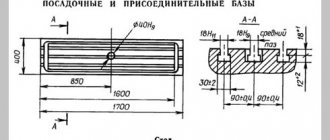

Each machine of the same size range has the same designation in the code, corresponding to the size of the working surface of the table. Depending on the size of the working surface of the table, the following sizes of cantilever milling machines are distinguished: Size

| Range of machines | table dimensions, mm | |

| 0 1st 2nd 3rd 4th | 6P80G, 6P80,6P10 6N81G, 6N81, 6N11 6M82G, 6M82, 6M12P 6M83G, 6M83, 6M13P, 6M84G, 6M84, 6M14P | 200 X 800 250 X 1000 320 X 1250 400 X 1600 500 X 2000 |

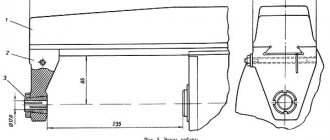

In accordance with the size of the table, the overall dimensions of the machine itself and its main components (bed, table, slide, console, trunk), the power of the electric motor and the magnitude of the greatest movement (stroke) of the table in the longitudinal direction, the slide in the transverse direction and the console in the vertical direction change. In Fig. Figure 10 graphically shows the largest movements of the table, slide and console.

Based on the main models of cantilever milling machines, modifications are produced that allow expanding the areas of application of machines of this range. Thus, on the basis of vertical milling machines 6M12P and 6M13P, machines 6M12PB and 6M13PB are produced, which have high spindle rotation speeds (high-speed modification), which allows these machines to be used for processing light alloys. Based on universal milling machines, modifications are produced that have an additional vertical head. The highly versatile milling machine 6M82SH (Fig. 11) is a modification of the horizontal milling machine 6M82G. It has two spindles, of which one is horizontal, like the 6M82G machine, the second is located in the rotating head and can be installed at an angle of ±90° in the longitudinal plane of the table and at an angle of ±45° in the transverse plane of the table. Widely versatile machines can perform a wide variety of milling operations, as well as drilling, boring holes, and trimming ends in different planes of the workpiece from one installation.

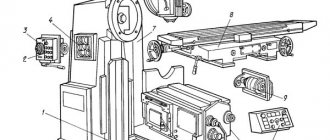

Consoleless milling machines

The console is the weakest component of a milling machine in terms of rigidity, therefore, for high-speed processing of large and heavy parts, milling machines without a console, the so-called non-cantilever

machines; however, such machines are less versatile than console machines. In Fig. Figure 12 shows a cantileverless vertical milling machine produced by the Gorky Milling Machine Plant. The table 3 of the machine has longitudinal movement along the horizontal guide slides 2, which have transverse movement along the guides of the frame 1. Thus, the table of cantilever-less milling machines has only horizontal movement in the longitudinal and transverse directions (cross table). Vertical movement is received by the spindle head 4 along the vertical guides of the rack.

Longitudinal milling machines

Horizontal milling machines are manufactured in different sizes, since as the size of the workpieces being processed increases, milling machines with larger worktable sizes are required. On large machines, lifting and lowering the table console becomes inconvenient, so on these machines, lifting console tables are replaced with tables that have only longitudinal movement. Such machines are called longitudinal milling machines.

. Longitudinal milling machines are designed for processing the surfaces of large workpieces.

In Fig. 13 shows one-sided

longitudinal milling machine with one horizontal spindle, and in Fig.

14 - double-sided

longitudinal milling machine with two horizontal spindles. A machine with two spindles is used for simultaneous processing of two surfaces.

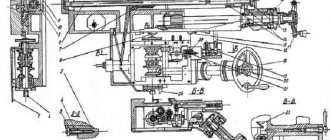

Table 1 of longitudinal milling machines (Fig. 13 and 14) has only longitudinal movement. The cutter is approached vertically to the workpiece being processed by raising and lowering the spindle heads 2 along the racks 3. If it is necessary to process more than two surfaces simultaneously, multi-spindle machines

longitudinal milling machines that, in addition to horizontal ones, also have vertical spindles. In Fig. Figure 15 shows a four-spindle longitudinal milling machine with tables 3.6X12 m, designed for processing on three sides of four surfaces of large-sized workpieces weighing up to 120 tons, length up to 12 m, width and height up to 3.6 m. The machine has four rotary spindle heads: two vertical ones 1 and 2, located on the traverse (cross member) 6, and two horizontal ones 3 and 4, located on the side posts. Table 5 of the machine has only longitudinal movement. Vertical installation of spindle heads 1 and 2 is carried out by moving the traverse 6 along the racks of the machine, and transverse (lateral) installation is done by moving the heads themselves along the traverse 6. Vertical installation of spindle heads 3 and 4 is carried out by moving them along the racks of the machine. The machine is controlled from the central console 7. The required number of revolutions of each spindle is set using handles located on each spindle head. To turn on and off the rotation of spindles, working feeds and rapid movements of the table, traverse and spindle heads, and turn on cooling directly from the workplace, there are two push-button stations and two hanging panels 8, duplicated with each other and located at each spindle head. Longitudinal milling machines are manufactured in the USSR in various sizes, starting from small machines (Fig. 13 and 14) with table dimensions of 450X1600 mm and up to giant machines, similar to that shown in Fig. 15. Spindle heads can have a horizontal and vertical arrangement, in addition, can be rotary, which makes it easier to process inclined surfaces of the workpiece. Such machines are manufactured to order with the number of spindles corresponding to the number of surfaces being machined. In Moscow, for the simultaneous processing of all the guides of the lathe bed, longitudinal milling machines are used, each having 9 spindles, on which up to 17 different cutters can be installed.

Continuous milling machines

In large-scale production, cantilever vertical milling machines with a round rotating table

(Fig. 16). The use of such machines allows you to remove the finished part and attach a new workpiece while the cutter is processing the next workpiece. This allows you to overlap manual time for installing the workpiece and removing the part with machine time and reduce processing time.

Further improvement in the design of machines with a rotating table led to the creation of a rotary milling machine

machine This is the name given to non-cantilever vertical milling machines with a large round rotating table like a carousel. Such machines have two or three spindles, one of which is used for finishing, which also increases productivity, since two operations (roughing and finishing) are combined in time. In the USSR, rotary milling machines are produced with a table diameter of 1000 mm (mod. 621 in a two-spindle version) and 1500 mm (mod. 623 in a two-spindle version and mod. 623B in a three-spindle version).

In Fig. 17 shows a two-spindle rotary milling machine mod. 621 produced by the Gorky Milling Machine Plant. For simultaneous continuous processing of workpieces from both ends, drum-milling machines

machines. On a drum milling machine (Fig. 18), the workpieces are fixed on a round drum table rotating around a horizontal axis in such a way that both ends of them can be simultaneously processed alternately with roughing and finishing cutters.

Processing workpieces in which both ends are processed on a drum-milling machine will be twice as productive as compared to a rotary-milling machine. Securing workpieces and removing parts on drum milling machines is also carried out continuously during the processing process. In the USSR, drum milling machines are manufactured with drums with a diameter of 1000 mm (mod. 6021), 650 mm (mod. 6022) and 900 mm (mod. 6023). Rotary milling and drum milling machines are widely used for processing blanks of car and tractor body parts at ZIL, MZMA, GAZ, MAZ, KhTZ, LTZ, VTZ, Zavolzhsky Motor and other plants in large-scale and mass production.

Special milling machines

On milling machines it is possible to process all types of surfaces quite accurately. Cantilever-milling, non-cantilever-milling, longitudinal milling and continuous

are general-purpose machines and can be used for processing workpieces of a wide variety of parts.

Unlike general-purpose machines, special-purpose

.

Such machines include gear-milling, thread-milling, key-milling, etc. In connection with the development of large-scale and mass production, milling machines designed to produce parts of a certain configuration are currently being widely introduced into production. Such machines are designed for maximum productivity and often have automated controls. In contrast to machines for specific purposes, they are called special

.

Special machines include those used in the watch industry; machines for milling drills, taps, reamers; machines used in the automotive, tractor and machine tool industries for milling on automatic and production lines; copy-milling machines, etc. Due to the rapid development of technology, products often change configuration, so the use of special milling machines, which, unlike general-purpose machines, do not allow them to be reconfigured for processing any workpieces, is not always profitable. In recent years, so-called modular milling

machines have begun to find widespread use, which make it possible to produce any combination of their constituent replaceable unified units (units) in accordance with the configuration of the part being manufactured and the location of the surfaces being processed. To switch to processing other workpieces, it is enough to change or rearrange individual components of the modular machine. In Fig. Figure 19 shows an aggregate milling machine.

| Previous page | table of contents | Next page |

Universal milling

In small-scale production, this type is used to produce parts by milling. In small mechanical repair shops, as well as in tool shops.

Together with the main components, the spindle assembly and gearbox are located inside the frame. The console moves along vertical guides , and along the cantilever guides move a slide with a rotating mechanism, on which a special table is placed, which moves in a horizontal plane at various angles relative to the spindle axis. With the help of design features, the work performed on such machines is done efficiently and quickly.