Brick has long been one of the most popular building materials, and structures made from it can be found in the vast majority of both old and modern buildings. To mount various objects on such structures, different types of fasteners are used, but the most effective and reliable of them are anchor bolts specially designed for brick, taking into account the strength characteristics and internal structure of this building material.

Types of anchors

Anchors for brickwork: types of fasteners, installation nuances

Brick has long been one of the most popular building materials, and structures made from it can be found in the vast majority of both old and modern buildings. To mount various objects on such structures, different types of fasteners are used, but the most effective and reliable of them are anchor bolts specially designed for brick, taking into account the strength characteristics and internal structure of this building material.

Amplifier options

Great demand and wide scope of application have forced anchor manufacturers to expand their product range into several types. Each of them has certain design features, differs in size, and specific use. A variety of anchors for hollow bricks allows you to solve the most complex problems with their help.

Healthy! Drilling holes in hollow bricks can only be done with a hammerless drill. An exception may be when working with masonry joints.

Double-spaced. Classic anchor element with a threaded rod and a sleeve equipped with opening double-spacer elements. As the rod is screwed in, the petals dig into the structure of the brick, making the contact much stronger.

Double-expansion anchor for hollow bricks Source goskrep.ru

Anchor and dowel - what's the difference?

The operating principle of these two fasteners is the same. Both anchors and dowels work to expand the wall material. The difference is that you can screw self-tapping screws into the dowel and drive nails into them. And the anchor always consists of at least two parts - a spacer part and a non-spacer part, which is screwed into the first. When the screw is screwed in, the anchor's petals open and, like an anchor at the bottom, clings to the wall material and is firmly held inside the wall. Since the anchor has a minimum of 2 elements, it is often called an anchor system.

Both fasteners are used for hanging fairly heavy objects: cornices, chandeliers, wall cabinets, sports walls. But the anchor system can withstand loads greater than dowel fasteners - more than 100 kg. Therefore, anchors are used for installing curtain facades and fastening heavy metal structures to the outer walls of buildings.

Dowel for hollow bricks

Visually it has a cylindrical shape, resembling a cork with a hole. Its body expands when the screw is screwed into the surface.

This leads to its reliable fastening in the walls of the hole. Equipped with a special cuff corresponding to the screw head, it does not allow a nail or screw to fall inside the dowel.

Type of dowels

Anchors are used for hollow or porous brick walls. Screwing into brickwork occurs in the form of a knot, with the end widening. Inside the voids, the resulting nut securely fastens any object.

Small nail dowels are used under the sheathing of the finishing material to secure the laths.

Umbrella dowels are used to fasten thermal insulation. A metal or plastic nail is driven into the insulation of the pre-installed umbrella. Dowels for brick and concrete are used for loads of several tons.

Metal fasteners are used for installing suspended ceilings. Because plastic ones can melt during a fire and cause the ceiling to collapse.

Advantages of dowels

Because their design is equipped with mustaches and spikes that do not allow them to scroll:

- Very practical to use.

- Withstand heavy loads.

- They are used outside and inside the building.

Features and Tips

Before drilling, it is necessary to accurately determine the wall material. To do this, in a non-impact mode, using a Victory drill, a test hole is slowly made in the wall.

It is important to keep the drill strictly perpendicular. The softness of the material is determined by the effort expended. If drilling occurs with alternating force: sometimes easy, sometimes hard, then you are dealing with a hollow brick.

Additionally, the material can be determined by the color of the dust hole:

- Red - brick.

- Flour-like, coarse-grained and soft indicates foam concrete.

- Sandy white color is a sign of sand-lime brick.

- Floury, white or light gray indicates concrete.

A mandatory parameter when selecting dowels is the predicted load. Fasteners with a depth of at least 85 mm are used when installing exercise equipment. Therefore, taking into account the size of the hole, dowels of the same size are selected.

Installation instructions

Mechanical stress on the seams between bricks can cause the wall to crumble, so it is better to use a drill instead of a hammer drill.

The blows of the hammer drill lead to the destruction of the brick. The damaged area complicates further installation of the dowel. You need to be extremely careful to create a hole of the right size and even shape in a crumbling wall. In order not to cause cracking of the hollow building material, it is necessary to completely abandon impact drilling.

Sequential installation algorithm

Using a pencil or pen, mark the location for the future hole.

To make drilling more convenient, use a knife or nail to make a small indentation.

When selecting a drill, keep in mind that the dowel should fit a little tight, with little effort. If you plan to use fasteners with a diameter of 9 mm, then the diameter of the hole should be the same.

The depth of the hole must correspond to the length of the fastening. Additionally, make sure that the sizes of the screw and dowel match. Since unreliable installation of the dowel can lead to it falling out under the weight of the load.

Position the drill strictly perpendicularly and, in non-impact mode, slowly drill to a depth of 1 cm. For further drilling to the desired depth, you can increase the speed.

How to anchor a safe to a concrete floor

In the current realities, the question increasingly arises of how and how to securely secure a safe in an apartment, because, firstly, not all merchants offer such a service, and secondly, many prefer to do the installation themselves. Securing a steel vault is usually done to prevent unauthorized removal. This can be done most reliably using anchor bolts on a cement-sand or concrete screed.

Regulatory conditions for the installation of safes are regulated by GOST R 50862-2005. For fastening, an anchor wedge fastening to the floor is used, which can withstand from 500 to 3,000 kg of tensile load. The optimal bolt length is 100-300 mm, and the diameter is from 8 to 20 mm. During installation, the following conditions must be taken into account:

- The thickness of the ceiling or subfloor must be at least 150 mm.

- If it is necessary to drill holes in places not provided for by the design, it should be taken into account that the tightness of a fireproof or backfill safe cannot be broken.

- Independent violation of the integrity of the case may lead to termination of the certificate.

Anchor bolt with nut: typical dimensions and technical characteristics

According to the technical characteristics, the use of an anchor bolt is possible in monolithic materials, such as concrete. During the installation process, you must always take into account that when you tighten the nut, the stud moves out. The minimum length of the anchor pin is 18 mm, and the longest can reach a size of 400 mm. Depending on the length of the stud, its diameter also changes and can vary from M 6.5 to M 24. Since the anchor fasteners are made of metal, it provides reliable fastening of structural elements in the event of a fire.

Typical dimensions of an anchor bolt with a nut, table

Attaching the canopy to a brick wall

Attaching the canopy to the wall is carried out taking into account certain rules. Since brick cannot be called a material with high strength, it is better to make holes with a drill. Even weak hammer drills can deform the masonry and lead to wall crumbling. Special drills are available in stores that create high-quality holes and do not destroy the fragile structure.

When starting drilling, you need to be careful and not rush. Next, you need to determine the height at which the canopy will be fixed, attach it to the wall and mark the attachment points. After this, you can proceed to screwing in the anchor bolts.

When making holes, it is important to avoid areas with cement joints. They are not strong enough, so when hanging heavy elements they will begin to crack, causing an irreversible deformation process.

Guided by the listed recommendations, you can correctly fasten the anchor elements and achieve better quality of fixation of hanging objects.

Installation features

In the practice of modern construction, anchors are in demand. They provide a reliable way to install equipment and fix massive objects and structures on the walls and ceilings of a building

It is important to choose the right hardware for the job

Fastenings for solid bricks will not provide the necessary adhesion to hollow material

Therefore, it is important to first determine the base raw materials from which the enclosing structure was erected

Sequence of work:

- The plane is marked. The work is done with the utmost care. Hollow ceramic bricks are fragile. If you make two holes with a small interval between them, the material will most likely be deformed.

- The hole in the brick is made with a specialized drill. The cross-section of the anchor element and the depth of its placement are taken into account. The perpendicularity of the hole produced is a guarantee of high-quality work.

- After creating the hole, it is cleaned of dust and debris. Depth accuracy is checked.

- When inserting the anchor, make sure that the gap between it and the wall is minimal. If it turns out that the product is loose, it is better to take larger hardware. It should be selected according to the diameter of the resulting hole.

Types of anchors used for working with brick structures

When working with bricks, mechanical and chemical type anchors are used. The most popular are hardware that uses mechanical methods of fixation in the wall. For brick walls, the most popular types of products are:

- Drive-in anchors, ideal for use with solid sand-lime bricks or cinder blocks;

- Wedge anchors used for installation of façade curtain systems and external glazing on brick walls of various types;

- Double-spacer, designed for mounting critical massive structures and objects to walls made of solid brick;

- MSA anchor systems for fixing lightweight parts to brick structures of any type;

- Anchor bolts with hexagonal head. Suitable for any walls made of piece elements.

Manufacturers also produce other types of hardware products, which are not very widely distributed and are used mainly for special types of work related to the installation of equipment or finishing elements.

Varieties

Anchors differ not only in size. There are design features of technical parameters. Anchor products for brick walls are divided according to their intended use. A specific type of hardware is used for certain installation work.

Important! To ensure reliable fixation of an object in a brick wall, it is recommended to take a responsible approach to the choice of anchor products.

Driven type

Allows you to secure critically heavy weights. Made from high-strength material or carbon steel. It is treated with a specialized anti-corrosion coating, which ensures an increase in service life. The product is manufactured in one piece, which increases the reliability of the fasteners. A popular type of hardware is the collet anchor.

Drivers

The anchor is driven into the brick with a hammer. Its working part becomes wedged. This way the element is securely fixed in the wall. Then the bolt or stud is screwed in.

Wedge type

The scope of application is identical to the hammer type analogue. The method of installation in a stressed and unstressed concrete plane is allowed. Refers to reliable fastening elements. Capable of withstanding high loads. Used in dry rooms.

Made from various types of steel. Differs in specific execution. On one side there is a stud with a metric thread, onto which a nut is screwed. On the other hand, there is a spacer system in the form of a coupling with an internal shank.

Wedge

MSA type

Brass products, the outer side of which is characterized by the presence of a special sleeve with a large notch. The design allows you to increase the density of fixation of fasteners in the wall cavity. The permissible intra-sleeve cross-section is in the range of 8-10 mm.

Chemical principle

The external design is a cylindrical tube. Inside there are two ingredients - organic and inorganic. Reacting with each other, they harden and provide the required degree of strength.

Chemical

Important! Chemical-type fastening structures are in high demand because their use is allowed in places with high humidity, in porous substrates. Even in such extreme conditions, they are able to hold the elements together.

The name of the hardware was given in view of the chemical principle of operation - a chemical reaction. Has no smell. It is an environmentally friendly product. Does not harm the environment and the human body.

The negative aspects of using the product include the high price and different setting times of the composition. The latter depends on the variety of adhesive mixtures.

With ring

The peculiarity of the product – the presence of a ring – ensures its scope of application. It is convenient to install suspended structures on wall and ceiling surfaces. In construction it is used for securing scaffolding. Allowed to be used for bricks with a dense internal structure - only solid ones. In porous and hollow materials, fasteners lose their effectiveness.

With ring

Double-spacer

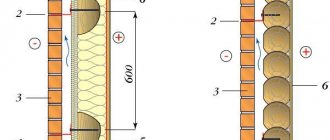

Additionally, a spacer sleeve is provided that opens simultaneously in two places. The first spacer element does not come into contact with the solid masonry surface. The reliability of fixing the product in the wall increases. The sample shows good results in the tensile test, therefore it is used in difficult operating conditions.

Double-spacer

What it is?

Anchors are universal fasteners that are used for major repairs and simple improvement of individual premises or buildings as a whole.

Anchors are used for fastening pieces of furniture, chandeliers, suspended ceilings, curtain facades, a canopy over a door, etc. The heavy structure is firmly held on a wall made of facing, hollow, refractory and other types of bricks due to its design. The fastener is a special sleeve, which is inserted into a pre-prepared hole. During installation of the anchor, the sleeve expands and, through friction, securely adheres to the bricks. Then the main fastener is inserted into the fixed part, which can be a pin, screw, screw. Anchoring brickwork involves determining the required type of fastening device and installing it. Due to the incorrect selection of the size, material and type of anchor, the adhesion weakens. Neglect of installation rules provokes the formation of cracks in the walls, destruction of fastenings and installed structures in general.

Types of anchors

For fastenings in brick, anchor systems are used that differ in size and

technical specifications.

- The driven anchor system includes a sleeve (spacer element), a bolt and a nut. A spacer is inserted into the punched hole, a bolt and nut are screwed into it, and then the nut is removed. This type of anchor is used later to secure hinges and corners. Well suited for wall cabinets, shelves, cornices.

- The wedge anchor system is equipped with a wedge-shaped part and a screw that has a recessed head. Suitable for through-hole mounting. First, the anchor is installed on the brick, then the screw is screwed in, the wedge expands and the hardware is secured inside the wall.

- MSA type anchors. They have a cone-shaped sleeve made of brass; there is a notch on its outer surface for better adhesion to the wall material. When screwed into the anchor, the sleeve becomes wider, thereby securing it into the brick. The cross-section inside the sleeve cannot be more than 8 mm. This fastening system is suitable for light objects.

- The double-expansion anchor system is equipped with two expansion sleeves located at the end and in the middle of the anchor. This double expansion helps to secure objects more firmly to the brick wall (including hollow bricks) and can withstand greater weight.

- Anchor systems equipped with rings or hooks that are located on the hardware instead of the usual hexagon. Used for convenient fastening of various communications, lighting fixtures, ropes, gates. The ring helps to secure the object tightly; the hook is used when the suspended object is supposed to be removed (for example, chandeliers).

- Chemical anchoring is the most reliable of all methods. A capsule filled with special resins is inserted into the prepared hole; when it is pierced, the substance spreads inside and, solidifying, secures the part in the wall. This type of fastener is especially suitable for porous and hollow brickwork.

Anchor system design

The principle of operation of the system is the same as that of dowels. The system consists of two parts: a support rod (bolt) and a spacer sleeve. Anchors for brick walls are made in various lengths and diameters, that is, a certain type of fastener is selected for each load value.

To install supports in brickwork, you need the following tool:

- perforator;

- brick drills;

- hammer;

- spanners;

- brush for cleaning holes.

Recommendations

The hollow brick anchor bolt has successfully replaced the nails, bolts, screws and self-tapping screws that were previously used for fastening. This method, which allows you to hang something or connect elements with hollow brick masonry, is considered the most reliable today. True, to obtain durable fasteners, it is recommended to follow some rules.

When installing a slotted brick anchor, do not use a hammer drill. Its impact will create cracks in the fragile material, and a new hole will have to be made.

It is prohibited to select seam sections of masonry as a point for drilling and mounting an anchor. Cement and sand do not guarantee the required strength, and if there is a significant load on the fasteners, the anchor system will soon fall out.

When hammering in the anchor structure, place a piece of wood under the hammer so as not to damage the threaded area. Before you start screwing, clean the inside of the sleeve to avoid damaging the threads.

Purchase anchor fastening systems that have appropriate quality certificates.