What is it for?

The multi-purpose milling machine is designed for use in industrial enterprises. To process the surface with a horizontal spindle, the following cutters are used:

- disk;

- cylindrical;

- shaped.

When working with a rotary spindle, face and key cutters are used.

Model 675 includes the following tables:

- rotary with dividing head;

- inclined.

Using heads: cutting, high-speed slotting, boring, you can perform the following work on the machine:

- drill;

- countersinking;

- boring;

- Slotting.

The 675 machine produces bars, housings, cushions, levers, helical gears, and parts with complex configurations. Class H processing accuracy. The ability to install a horizontal rotary head on a vertical spindle makes the machine universal. It can be used to process all sides and the top surface of a part, drill it along all planes and at an angle, and make boring with high precision.

6720B wide-universal high-precision milling machine. Purpose and scope

The tool wide-universal machine model 6720B has been produced by the Odessa Milling Machine Plant since 1982 of the last century and replaced the outdated model.

The machine is designed to perform a variety of milling operations in various planes and at various inclination angles in a wide range of cutting modes. The presence of horizontal and vertical spindles and a large number of accessories allows you to perform the following operations: drilling, chiselling, grinding, boring, trimming ends, marking, milling screw surfaces.

The model 6720B milling machine is designed for milling parts with cylindrical, disk and shaped cutters using a horizontal spindle, and face, end and key cutters using a rotating vertical spindle, which can be rotated at an angle if necessary.

The 6720B machine is used in single and small-scale production in tool and mechanical shops of machine-building enterprises.

The wide technological capabilities of the machine allow it to be most effectively used in tool production.

Operating principle and design features of the machine

The workpiece can be mounted on a main table with a vertical work plane or on a corner table with a horizontal work plane. To process inclined surfaces, the part can be mounted on a universal table.

To process parts that require division, a round table or dividing head can be used.

Using cutting, high-speed, slotting heads and a set of auxiliary tools, you can perform boring, drilling and slotting work on the machine. A detailed description of these devices is given below.

The 6720B machine comes with an easy-to-use tool cabinet, as well as a set of fixtures and tools.

The technological capabilities of the machine can be significantly expanded by using accessories and devices supplied for a special fee.

The machine can perform a number of milling and boring operations with high precision, which can be achieved if the machine is installed in a room with a constant temperature of 20±2°C and humidity of 65±5%, if there are no sources of heat or vibration near the machine. The machine can also perform drilling and reaming, chiselling, centering, counterbore, countersinking, reaming, boring.

The presence of two horizontal and rotary vertical spindles, as well as a large number of accessories for the machine, makes it highly versatile and convenient for working in tool shops of machine-building plants in the manufacture of fixtures, tools, relief dies and other products.

A wide range of spindle speeds and feeds, the presence of mechanical feeds and fast movements ensure economical processing of various parts in optimal conditions.

The machine has mechanized clamping of tools and working parts, which increases productivity.

The lubrication system is centralized. The quality category of the machine is the highest.

Roughness of processed surfaces Ra 2.5 microns.

Machine accuracy class B according to GOST 8-77.

The corrected sound power level LpA should not exceed 88 dBA (without vertical head).

The year the machine was put into serial production was 1982.

Design organization - Odessa Milling Machine Plant named after. S. M. Kirov.

Main characteristics of the 6720B universal milling machine

Manufacturer: Odessa Milling Machine Plant named after. S.M.Kirova.

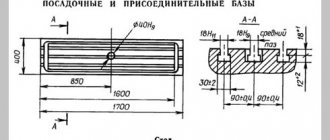

- Dimensions of the working surface of the vertical table (main) – 200 x 500 mm

- Dimensions of the working surface of the corner horizontal table – 200 x 630 mm

- Distance from the axis of the horizontal spindle to the surface of the corner table – 80..450 mm

- The distance from the end of the vertical spindle to the surface of the corner table is 22..392 mm

- Maximum longitudinal travel of the table (X) – 300 mm

- Maximum vertical table travel (Z) – 320 mm

- The largest transverse stroke of the spindle head (Y) is 200 mm

- Spindle end – Morse taper 4

- Rotation speed limits of the horizontal spindle – 40..2240 rpm

- Vertical spindle rotation speed limits – 40..2240 rpm

- Spindle drive electric motor – 1.5 kW; 1500 rpm

- Machine weight – 1.4 tons.

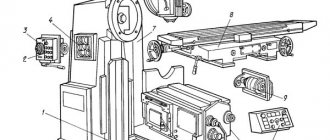

General view and controls

The base is tall with an electric box on the side and an electric motor at the rear. Feed box inside a thick-walled cast rack. The gearbox is assembled in a separate box and located on the side. A small console rises along guides, ensuring vertical movement of the part.

The main table with T-slots is equipped with additional accessories, including a removable horizontal table. On the right side of the stand and table there are handwheels for manual movement of the table and console. There are also start buttons and a handle for switching spindle rotation speeds.

Design Features

The 675 milling machine is characterized by its small size and the ability to process workpieces up to 600 mm long. The design includes two spindles, a working vertical table and a removable horizontal one. The machine kit includes a cabinet for accessories and tools.

Main movement chain

Rotation is transmitted to the horizontal spindle through gearing with a drum gear connected to the gearbox. The electric motor is connected to the drive shaft by a V-belt transmission. The vertical spindle rotates through a bevel gear connection with a horizontal motor. The speed of both working bodies is adjusted using one handle.

Feed chain

The feed chain transmits movement to 3 working units at once, ensuring movement along all axes:

- support – vertical;

- slide – longitudinal;

- spindle head – transverse.

The rapid stroke is 935 mm/min. 16 working feeds, from 12.5 mm/min to 400 mm/min. The feed mechanism operates from the main drive, receiving rotation from the gearbox through the toothing of the gears.

Caliper

Through the support, longitudinal and transverse movement of the table with the part is carried out through the lead screw and the drive shaft. The direction of movement in 3 directions is activated by one cross handle in the direction of movement. The parts are lubricated with a lubricator.

bed

The bed has a high base. On top there is a trunk used when working a horizontal spindle with cylindrical cutters. On the side of the frame body there is a box molded for the feed box. It closes with a door. In the front part there is a rack with console guides.

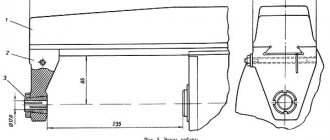

Horizontal spindle

The horizontal spindle is located in the upper part of the frame, under the trunk. It receives rotation from the gearbox through gearing. The spindle head is mounted on 2 radial supports and rests on 4 thrust bearings. To fasten parts in the spindle there is a Morse taper 4. When installing a mandrel with cutters, use an earring.

The trunk is moved manually. Clamped in working position on the right with 2 handles. The rotation speed is adjustable in steps and has 16 positions. The movement of the spindle head in the horizontal axis is limited by stops. Mineral oil lubrication is carried out by splashing. The liquid is supplied to the sump of the spindle head housing.

Vertical spindle

The vertical head is a removable unit. It is secured to the horizontal spindle head with two screws and receives rotation from it. Installation is carried out according to risks for the alignment of rotating parts. The trunk is retracted to the rearmost position.

The vertical spindle together with the head is rotated 90⁰ manually according to a scale marked on the base of its body and secured with pins. A spring built into the body balances the sleeve as it moves. Radial loads are absorbed by two supports. Axial vibrations are damped by thrust bearings.

Machine 676. Universal milling machine. Manual

This instruction manual for the “Universal Milling Machine 676” contains information necessary both for the operating personnel of this machine and for the employee directly involved in working on this machine. This manual is an electronic version in PDF format of the original paper version. This documentation contains the Passport and Manual (instructions) for the operation of the universal milling machine 676

Purpose Unpacking and transportation Foundation, installation and installation Passport Specification of controls Specification of machine gears, screws and nuts Specification of gears and worm wheels, worms, screws and nuts accessories Main motion mechanics Calculation of spindle speeds Feed mechanics Calculation of feed rates Specification of bearings, rolling components Complete statement Brief description of the machine and accessories

- General layout

- Headstock

- Caliper

- Gearbox

- Gearbox

- Vertical spindle head

- Base and cooling

- Corner table

- Universal table

- Vise

Round table Slotting head Dividing head

- Guitar to dividing head

- High speed head

Electrical equipment of the machine

- Description of the electrical circuit

- Protection

Specification of purchased equipment Specification for the lubrication scheme of the machine Specification of lubrication points and elements of the lubrication system of accessories Instructions for servicing the lubrication system Preparing the machine for start-up Setting up the machine Installing the tool Setting the number of revolutions Setting the feed value Installing accessories Complex division Selection table of replacement gears for cutting spirals Adjusting the machine

- Gearbox

- Gearbox

- Caliper

- Headstock

- Base and cooling

- Vertical spindle head

- Round table

- Dividing head

Machine acceptance certificate Testing the machine for compliance with accuracy standards Accessories and tools for the machine General conclusion on testing the machine Additional comments

Corner universal table

The removable corner table is hung on the support using the upper dowels. Screwed to the work surface with bolts. It has 5 T-shaped slots for securing the workpiece and rotates it around a horizontal axis. The table rotates manually, along the dial on the front. The clamp handle of the device is also located there.

Reference! The corner table allows you to process the side planes of the part with both spindles. Do drilling and boring, keyways, mill polyhedra around the perimeter.

Vise

The vice is installed on the work table and rotary table. They allow processing small parts with high precision and making complex reliefs.

Round table

The removable accessories included with the machine include a round table. It is attached to the longitudinal table. Thanks to the dividing head, its functionality is increased. The side and top surfaces of the workpiece are processed using a horizontal spindle.

Dividing head

The dividing head allows you to rotate the part at a given angle with high accuracy. The device allows you to produce gears and other complex parts with repeating elements.

Purpose

An industrial milling machine is used to perform milling. Using a horizontal spindle, you can process:

- disk cutters;

- shaped;

- cylindrical.

A vertical rotary spindle can be used to work with cutters:

- keyed;

- end;

- end

When equipping the equipment with a special attachment, you can perform slotting operations. Due to the presence of the rotation function of the working milling head, metal processing can be carried out at an angle.

Specifications

The power of the machine is determined by its electric motor and is 1.5 kW. Accuracy class N and P according to GOST 8–82. Technical characteristics of the SF675 model:

- vertical table dimensions 200×500 mm;

- corner 200×630 mm;

- vertical stroke 300 mm;

- longitudinal movement 320 mm;

- transverse 300 mm;

- number of horizontal table feeds 16;

- number of spindle speeds 16;

- horizontal spindle rotation speed 50–1600 rpm;

- vertical 63–2000 rpm;

- machine dimensions 1110×1170×1650 mm;

- weight 1100 kg.

The vertical head can be rotated up to 90⁰. This allows processing of all planes except the base one. Do milling, drilling and boring, cutting threads, cutting grooves.

Description of individual components and accessories

When describing the composition of the Model 675 machines, the following working units can be distinguished.

bed

This is the base of the machine on which all other working units are located. Controls for milling and drilling modes, as well as turning the device on and off are also located here.

Caliper

This unit ensures the supply of the workpiece through lead screws 1 and 8, as well as the main drive shaft 24. Its direction is changed using the cross handle (position 16).

In extreme positions in all planes of movement of the caliper, its supply is turned off due to special stops with limit switches 6 and 15.

Horizontal spindle

The horizontal position of the spindle is its main operating state, in which milling operations are carried out on parts fixed on an angular inclined table. It is mounted on the frame on the right and is controlled by a separate rotating feed handle.

Vertical spindle

The vertical head is a removable unit, when installed, the equipment can be easily adjusted to another operating mode. It is fixed to the headstock using two bolts coaxially with the second spindle. The head, placed vertically, can be rotated 90° on both sides, for which purpose there are markings on the body flange in the form of divisions in degrees.

Corner universal table

The plane of the horizontal universal table has a built-in tilt adjustment mechanism, which ensures the convenience of processing workpieces mounted on it.

Round table

The rotary round table is located in the center of the bed; it is needed to fix workpieces processed using a tool fixed in the spindle.

Parallel vice

Special parallel vices are used to clamp the workpiece in the main work table. Their presence significantly simplifies the fixation of workpieces before processing and increases the productivity of operations.

Dividing head

A special dividing or impact head is not included in the standard configuration of this piece of equipment. It is usually purchased separately and installed on a vertical spindle. It is used when it is necessary to cut various grooves and splines on metal workpieces or for sawing.

Passport of a universal machine

The passport begins with an indication of the brand of the machine and an indication of the manufacturer. Next, there is an image of the equipment in all projections, a description of the main components. All accessories and devices included in the equipment are listed with their functions. The document includes all diagrams, drawings of the main components and a list of wear parts. To transport the machine, the passport contains diagrams for slinging and installation on the foundation.

The passport of the milling machine can be downloaded for free from the link - Passport of the wide-universal milling machine SF 675.

Features of modification 675P

The model of the wide-universal milling machine 675P is equipped with a tool cabinet. The machine has advantages over other units of the 675 series:

- increased processing accuracy;

- increased size of processed parts up to 250 mm in width and 800 mm in length;

- powerful pump with a supply of 22 liters of oil per minute;

- additional control panel on the side of the rack.

The small-sized machine can be installed in small workshops and garages.

Reviews

Sova.

675 were produced by several factories. Odessa and Saratov residents did them best. These machines are distinguished by their reliability, high build quality and durability. They are in great demand among specialists and work well, despite their age. Vladimir. I use my 675 to cut axle shafts and torsion bars. I normalize the steel. It doesn’t catch hundreds, but it works up to tens. I want to change the rulers and clean up the guides so that I can work more accurately. Despite being over 50 years old, the 675 milling machines are well preserved and are in demand among specialists. They are almost half the price of their Chinese counterparts, they work better and are more reliable. They produce spare parts for repairs and parts for various components.