Main advantages

The FSS 1A machine is used in various areas of the woodworking industry. It can perform a variety of milling work using a tenon-shaped carriage. The machine itself is assembled on a solid cast iron frame with high vibration resistance parameters. The tenoning carriage is equipped with a rotating ruler with an eccentric clamp. Additionally, the machine can be equipped with an automatic feeder.

This unit allows you to carry out curved milling according to a template, cutting tenons, as well as other types of milling work. The main advantages of the equipment include its safety for the master and its high efficiency parameters. Processing of workpieces is carried out with the highest possible quality, and defects are almost completely eliminated.

general description

The functionality of FSS-1a allows it to be used to carry out several types of work at once:

- milling work on wood using the manual feed method;

- curved milling using the manual feed method according to a predetermined template;

- cutting tenons with a tenoning carriage.

The device of a vertical manual milling machine

The machine is operated under certain temperature conditions. Its use is possible at room temperatures not lower than +100C and not more than +350C. Indoor humidity is allowed within 80%. It is not allowed to use the milling unit if it is exposed to atmospheric precipitation.

The conditions of the workshop in which the device is located are of particular importance. The device must not be in contact with explosive objects.

Design Features

The main design feature of this machine is that the cutting tool is placed in a special housing with a pipe, which is designed to remove dust and chips that arise during operation.

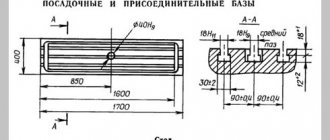

Dimensions, weight and general appearance

The weight of the unit is 810 kg, and the dimensions are as follows:

- length – 100 cm;

- width – 111 cm;

- height – 127 cm.

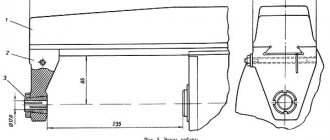

Tool protection design

Cutting tool protection is a structure consisting of the following elements:

- bracket;

- exhaust pipe;

- slider;

- guide rulers.

When moving the protective mechanism, the operating instructions recommend using the control flywheel. With its help, you can move the protection line mechanism towards the feed. The safety shield is installed in the extreme upper and lower positions using special screws. To fix parts in a certain position, a clamp with a ruler is used. Using clamping screws, the master can lock any movable security mechanisms.

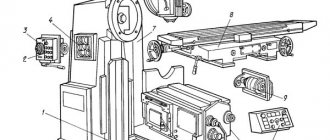

List and location of controls

The equipment is equipped with a compact control panel. The control panel has 2 buttons to turn the drive on and off, as well as 2 signal lights of white and green colors. All electrical equipment is located in the niche of the frame.

In addition, the machine has the following controls:

- handles for securing the rulers and the protection housing;

- spindle stop;

- a flywheel that moves the spindle head;

- handle for clamping the spindle head.

The machine also has buttons for fixing the ruler bracket and tool guard.

Arrangement of components

The main components of the unit are arranged as follows:

- Bed. Cast iron structure covered with a flat cast iron table.

- The table is also a cast iron structure, reinforced with stiffening ribs.

- The carriage is movable, tenon-cut, consisting of a cast-iron plate, a clamp with a ruler, as well as stroke limiters.

The carriage is movably mounted using rolling bearings.

Component mechanisms and units of the unit

The drive of the main movement of the equipment consists of the following parts:

- two-speed motor;

- spindle head connected to the submotor plate;

- V-ribbed transmission.

The spindle head itself consists of a cast iron body in which the spindle itself is mounted on rolling bearings. The spindle attachment has a removable mandrel.

Kinetic scheme

Electrical diagram

Electrical equipment

The two-speed electric motor is connected to the spindle head by a belt drive. The spindle braking and acceleration time is 2.3 seconds. The engine is equipped with protection against overheating and short circuit. The presence of interlocks in the electrical circuit provides protection to the operator.

Description of structural elements

Appearance

Using this machine model, you can perform a wide range of milling operations for processing wooden workpieces. The supply of materials occurs manually, there is the possibility of cutting tenons. For this purpose, the design has a special tenoning carriage. You can also process curved surfaces using templates.

The design of this model is simple, the kinematic drive diagram is not complicated. The basis of the equipment is a cabinet, inside of which the power plant is located. From it comes a rotational movement to the vertical shaft. The FSSH-1A model has an adjustable table, safety equipment and a set of guides for processing wooden workpieces.

Overview of hardware components:

- bed. This is a molded rigid box required to install the main components. Some modifications of the machine involve manufacturing the frame by welding;

- Desktop. It is mounted in the upper part of the frame and is made from cast iron. The surface of the table is carefully polished, additional stiffening ribs are installed in the lower part;

- drive device. Consists of a two-speed electric motor, which is connected to the spindle headstock by a belt drive;

- spindle head. A working spindle is installed on it using rolling bearings. Its shaft has a tapered hole for a mandrel. The cutter is installed using a differential nut;

- tenoning carriage. It is installed on the edge of the desktop. Its movement relative to the working cutter occurs with the help of rolling bearings. The tenon carriage plate has several mounting holes for mounting additional components.

To remove chips, the design includes a pipe for connection to the exhaust ventilation system. The workpiece fixation system with a measuring ruler contributes to increasing the processing accuracy. It can be used for milling at an angle.

For operational safety, most of the cutter is covered with a steel protective shield. However, it does not affect the functionality of the equipment, since the design has a convenient lighting system for the shield relative to the working tool.

Specifications

Main technical characteristics of the FSSH 1A milling machine:

- the maximum width of the workpiece that can be installed on the table with a tenon depth of 10 cm is 70 cm;

- nominal diameter of the spindle attachment – 32 mm;

- maximum cutting tool diameter – 250 mm;

- the optimal diameter of the round workpiece is 9 cm;

- rated spindle speed – 3000, 45000, 6000, 9000 rpm.

The maximum thickness of the processed product is 100 mm.

Operation and maintenance, passport

The equipment must operate at a temperature not lower than 10 ° C and humidity does not exceed 80%. The unit requires mandatory grounding. Wooden blanks that are processed must be of 1st grade quality, and the moisture content of the wood used should not exceed 15%. If the workpieces are long, they should be placed on supports or 2 people should handle them.

The passport of the milling machine can be downloaded for free from the link - Passport of the woodworking milling machine FSSH-1A with a tenoning carriage.

Operating rules

The machine is installed in a room where the temperature does not fall below 10 C and the humidity does not exceed 80%. The device must be reliably grounded. For this purpose, a special contact clamp is provided in its design. It is connected to the general circuit of the room. The operator, before starting daily work on this equipment, must know the structure and operating principle of the components and the product as a whole. To do this, he reads the operating instructions supplied by the product manufacturer for a specific model and undergoes appropriate instruction.

Analogs

This machine is produced by several domestic factories with slight differences in design. Usually the name of the equipment in brackets contains the first letter of the city where the machine was produced:

- Kirov Machine Tool Plant;

- Dnepropetrovsk LLC "Stankostroitel";

- Kurgan plant of woodworking machines.

A little earlier than the FSSH1A version, a similar F4 machine was produced. Its main differences:

- spindle speed – up to 8000 rpm;

- The diameter of the tool used is 15 cm.

Owner reviews

All users note the reliability and durability of this equipment. In their opinion, this machine is distinguished by safety and quality of processing. That is why it is used in small-scale serial woodworking production, as well as in private workshops, including the production of cabinet furniture.

The FSSH 1A milling machine is produced at several domestic factories and is popular among milling machines and woodworkers. A distinctive feature is a special design that ensures the safety of the master while working on this equipment.

Machine components

The milling machine has a simple design, the basis of which is a stand. Inside it is a power plant. The power plant transmits rotational motion to a vertical shaft.

The milling machine includes:

- Desktop;

- bed;

- drive unit;

- spindle head;

- tenoning carriage.

The working table of the mechanism is made of cast iron using the casting method. It is located at the top of the bed. There are stiffening ribs at the bottom of the table, and its surface itself is polished.

The bed is a box. All the main components of the device are mounted in it. In some cases, the frame is made by welding.

The milling FSSH has an electric motor with two speeds as part of its drive. The motor is connected to the spindle head by a belt drive.

The spindle is fixed to the spindle head. Its fastening to it is ensured by bearings. The spindle shaft has a cone-shaped hole intended for a mandrel. The cutter is mounted using a nut.

The tenoning carriage is mounted at the extreme part of the work table. Rolling bearings ensure the movement of the tenoning carriage relative to the cutter. The carriage has holes on which the master can install additional elements.

The machine used allows for milling at an angle. This is ensured by the presence of a locking mechanism on the unit. The mechanism is equipped with a measuring ruler, which allows you to increase the accuracy of operations performed on the machine.

At the heart of the machine design there is a pipe. It is connected to the ventilation system, which allows you to remove chips while working on the device.