Steel has a wide range of applications, from screws and nails to bridge parts. With the development of metallurgy, many alloys and grades of steel were invented.

Steel consists of 2.14% carbon, permanent impurities and other chemical elements. Although, as practice shows, its concentration usually does not exceed 1.5%. The share of iron in the material is at least 45%. Steel is produced by recycling white cast iron using various methods.

The main advantages of all types of steel:

- hardness and strength;

- wide functionality;

- variety of properties;

- viscosity and elasticity;

- easy machining;

- high wear resistance;

- prevalence of raw materials;

- economic benefit from use.

The main disadvantages are the lack of resistance to rust and the ability to store electricity.

Cast iron is the closest material in composition. However, in comparison with it, steel:

- harder and more durable;

- has a higher melting point;

- easier to machine;

- has higher thermal conductivity;

- easily subjected to the hardening procedure.

Classification by chemical composition

The chemical composition of steel is carbon and alloyed. The former consist of iron, permanent impurities and carbon. In turn, they are divided into:

- low-carbon (up to 0.2-0.3% carbon);

- medium carbon (0.2-0.45%);

- high-carbon (from 0.45%).

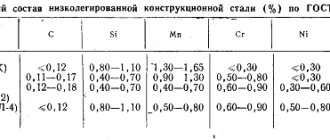

Alloy steel also contains metals and non-metals. They give the material higher mechanical and physicochemical properties. To alloy means to alloy. This type of steel is divided according to its chemical composition into:

- low-alloy (up to 2.5% additives);

- medium alloyed (2.5-10%);

- highly alloyed (from 10%).

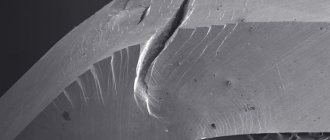

Cold brittleness

Cold brittleness is a phenomenon of reduced ductility of a material at room temperatures. The danger lies in the fact that outwardly the workpiece looks normal, but during machining it warps and then cracks. Cold brittleness causes especially great harm to parts with thin ribs and blades that are made of high-carbon steels.

To reduce the effect of cold brittleness, it is necessary to increase the viscosity of the product material. The criterion is the intensity parameter of the drop in impact strength, which is called the temperature of transition from the plastic to the brittle state. Typically this figure is around -75°C. The more carbon in the steel, the more intense the decrease in viscosity with temperature.

Cold brittleness is also affected by the presence of a martensitic structure, as well as an increased percentage of sulfur and phosphorus in the pulp composition. If it is not possible to change the enhancement mode, you should either change the material or constructively eliminate areas that have thin and sharp edges.

Classification by structure

The structure of steel is formed during its manufacturing process, during casting and processing under high temperatures. The chemical bonds of a material determine its relationship to any class. This ratio is taken into account for the use of steel in a particular area. Let's take a closer look at these classes:

- Austenite. This class is characterized by strength and uniformity. They are resistant to heat and rust, and can be used to work in hazardous environments or transport corrosive elements.

- Ferrite. Representatives of the class of ferrites are magnetic, making them optimal for use in radio engineering and electronics for the manufacture of antennas and other equipment.

- Martensite. This type of steel is obtained through alloying and heat treatment. The material can return to shape after mechanical processing. The use of martensite representatives is complicated by additional processing requirements.

- Perlite. Perlite is called decomposition upon cooling after heating. This condition is created artificially for plastic deformation.

- Cementite. Representatives of the species are physically elastic and hard.

How is steel grade determined?

During the production cycle, everything is simple and clear - metal blanks are purchased in rods, bars, sheets or strips. On one of the edges they are marked (engraved with numbers and letters) and have a special color - color is also a signal for metallurgists. In production, the bulk of the metal is used first, and this marked tip is used at the very end. But at home, craftsmen often buy steel sheets by hand or in such a form that the markings cannot be recognized. Therefore, below we will give several elementary ways to determine the material. To do this you will need:

- the workpiece itself (it is advisable to place it in a vice to reduce the risk of injury);

- hammer and chisel;

- grinding wheel;

- file;

- bake.

Also, create optimal conditions for the test in advance, namely, good lighting, equipment (wear safety glasses, protect exposed areas of the body), materials for comparison, if needed, Internet access.

Now we list the possible verification options.

Classification by degree of deoxidation

Deoxidation is a process that leads to a decrease in the oxygen content in the melt. This process is necessary in order to avoid the appearance of rust on rolled metal. The degree of deoxidation provides for the following classification:

- calm (SP) - have a homogeneous structure, contain a minimum amount of gases and non-metals; used for expensive alloys and the manufacture of metal structures;

- semi-quiet (PS) - their properties make it possible to produce load-bearing elements of welded and riveted structures; Bolts and nuts are made from PS, which can be used at low air humidity and high temperature;

- boiling steel (KP) – a brittle type of steel; suitable for the production of boiler parts and structures in contact with explosive substances; The main disadvantage is the rapid appearance of rust.

The following additives usually participate in the deoxidation reaction: aluminum, manganese, silicon.

Designations of alloying elements

In order to recognize the qualitative and quantitative composition from the markings, letter designations are used for alloying elements. Basically, Russian letters correspond to the names of elements, although there are exceptions, since there are elements that begin with the same letters. The table of alloying elements is as follows.

Designation of alloying elements in steels

| IN | Tungsten | B | Niobium |

| TO | Cobalt | E | Selenium |

| M | Molybdenum | R | Bor |

| N | Nickel | F | Vanadium |

| T | Titanium | C | Zirconium |

| X | Chromium | YU | Aluminum |

| G | Manganese | A | Nitrogen |

| D | Copper | WITH | Silicon |

As can be seen from the table, it contains two non-metals - silicon and nitrogen, but no carbon. The presence of carbon is implied in the composition of any steel, therefore the designation indicates only its content

Classification of steel by impurity content

The classification includes three types. The fewer harmful elements there are in the material, the higher quality it is considered. This parameter is determined by the production method and the identification of S and P content.

Ordinary quality

This type includes carbon steel. It is produced in a furnace or converter using oxygen. Ordinary quality steel is affordable, has a wide range of applications, is easy to process, but does not have wear resistance or strength.

Quality

It can be either carbon or alloyed. Compared to the previous type, this composition is produced in accordance with more stringent requirements. They are manufactured to strict melting specifications. High-quality steel is more expensive and is used for the manufacture of elements intended for high load levels.

High quality

This type of steel is produced using more modern methods, for example, smelting in electric furnaces. This method makes it possible to achieve a minimum content of gas inclusions and harmful non-metallic impurities, which ensures high mechanical properties of the material. High quality steel has a higher cost and is used to create particularly strong structures.

Particularly high quality

These are alloys with the minimum possible amount of impurities. They are of the highest quality available and are priced accordingly, close to jewelry. Particularly high-quality steel is an alloy steel that is used in unique cases. For example, for the production of spaceship parts.

Marking of carbon steels

The marking of carbon steels is not very different from the requirements for the marking of other alloys. The meaning of the markings is usually indicated in special tables.

The letter “U” is indicated at the beginning and denotes that the alloys are classified as tool alloys. The quality group to which steel belongs is indicated by the designations “A”, “B”, and “C”; they are indicated at the end. The amount of carbon for a material of improved quality is indicated in hundredths of a percent, and for the other two groups - in tenths.

Carbon steels are often marked with the letter “G”; it appears after the numbers indicating the amount of carbon. The letter indicates a high manganese content in the alloy. The level of deoxidation is indicated as “sp”, “ps” or “kp”.

Classification of steel by purpose

It is quite conditional, since one group can contain many brands, while another can contain only a few. Some of them are applicable for adjacent values. To determine the classification of steel, products are subjected to various tests: acids, extreme loads, shock loads.

Structural

It belongs to the class of ordinary quality and is one of the most extensive groups. They are able to withstand various mechanical loads: shocks, bends, stretching. The construction material is resistant to fatigue, as well as the effects of negative environmental factors. Used for the production of structures and parts of increased strength.

Construction

These include carbon and low-alloy steel. Complex structures are made from it, in which the load is distributed equally to all areas. There are no special requirements for construction steel other than weldability.

For cold stamping

Cold stamping significantly changes the shape and dimensions of a metal workpiece. The following requirements are imposed on this type: a high level of ductility and tensile strength.

Cementable

The purpose of case-hardened steel is the production of parts and assemblies that are subject to periodic loads. Cementation is a procedure that increases the resistance of a material to wear.

Upgradeable

The purpose of the steel being improved is special types of heat treatment, for example, tempering or hardening. These procedures are used to improve strength and other characteristics.

High strength

To create a high-strength type of steel, a special composition and ratio of alloyed elements, as well as processing programs, are selected. During the procedure, high strength of the material is achieved, which is several times higher than the parameters of structural steel. High-strength elements are used in units of special strength.

Spring

Spring steel grades can withstand repeated elastic “fatigue” deformations inherent in metals. They are widely used in automobile production, the transport industry and other areas where there is a need for depreciation, returning elements to their original position after performing work functions. Carbon alloys can be alloyed with silicon, boron and other chemical elements.

Bearing

The purpose of bearing steel is the operation of equipment and mechanisms that use bearings. In this case, the material must have high strength, wear resistance and be durable. Foreign matter and uneven texture should be kept to a minimum. Bearing steel is subjected to special heat treatment and compaction.

Automatic

The main requirements for free-cut steel are high machinability, the formation of short chips and reduced friction between the part and the tool. This type is used for mass production of fasteners in automated production. The disadvantage of automatic steel is reduced ductility.

Wear-resistant

Wear-resistant steel is obtained by adding large amounts of manganese. Its purpose is to manufacture units that are constantly exposed to friction and heavy loads (both dynamic and statistical). For example, wear-resistant steel is used to make tracks, mining equipment, and rail equipment.

Corrosion resistant stainless steel

Low carbon steel is alloyed with chromium and manganese. Chromium crystallizes and forms a thin surface layer of oxides, which protects the part from exposure to chemical environments. Corrosion-resistant stainless steels can be used at temperatures up to 60 degrees in slightly aggressive (for example, steam or water) and very aggressive (alkalies and acids).

In turn, corrosion-resistant stainless steels are divided into:

- Corrosion resistant. They are designed to produce springs, valves and shafts that can withstand temperatures up to 600 degrees.

- Heat resistant. They can operate under limited loads and temperatures up to 1200 degrees Celsius.

- Heat resistant. Steel is alloyed with silicon, nickel or other elements. It can withstand severe loads and interact with high temperatures (up to 75% of the melting temperature).

- Cryogenic. They can interact with low temperatures (up to -200 degrees), while maintaining viscosity and elasticity. They can be used for the production of components for refrigeration units (scientific or industrial).

Areas of application

Improved steels are those used to produce:

- Critical parts of heavily loaded gear and rack and pinion transmissions operating under conditions of shock and reverse loads;

- Products with thin fabrics and cross sections that vary significantly by zone;

- Metal-cutting tools with sharp edges, mainly made of high-speed steels;

- High-precision control and measuring devices;

- Medium loaded springs and springs.

Other products made from medium-carbon steels, for which it is important to have a sorbitol microstructure, are also subject to improvement.

Tool steels

Tool steels are products without alloying that are durable. Additives are used to seal some areas. They are subject to special requirements related to their specific use.

Tool steels are also divided into several subtypes:

- for cutting tools;

- for measuring instruments;

- stamped;

- roller

For cutting tools

Steels for cutting tools are quite expensive, so not everyone can create products from them. Typically, some parts of the tools are made from constitutional steel, such as plates or blades.

Steel of this type, in turn, is divided into the following subtypes:

- carbon tool alloys (usually contain 0.5-1.3% carbon, common for use in the manufacturing process);

- alloyed tool tools (from which you can make cutters, drills and broaches);

- high-speed (can create products with heat resistance up to -660 degrees).

Steels for measuring instruments

Steel for measuring instruments must have stable shape and dimensions during alteration and storage. Also, its surface must be perfectly smooth, well processed and polished.

Such steel can be carbon and alloyed with chromium, nickel and other elements. To increase wear resistance and improve surface quality, products are cemented and hardened. Steel is still in demand in the manufacture of the most modern measuring instruments.

Die steels

Die steel is characterized by hardness, resistance to temperature changes and hardenability. It must be wear-resistant and have a permanent shape. These alloys include the following:

- cold stamping (in addition to hardness, wear resistance, stability of dimensions and shape, a high level of viscosity and resistance to temperature changes are added; they can work under conditions of impact and high pressure; they are produced on the basis of alloys with chromium and other elements);

- hot stamping (they must have increased strength and toughness when heated to 500 degrees and high thermal conductivity in order to avoid overheating; they are subject to an alloying procedure with chromium, nickel, vanadium, etc.).

Roll steels

Rolling steel is used to produce rolling mills, dies, punches, and blades for working with metal products. They can also be used to produce components for mining and paper-making equipment.

Basic requirements for roll steel:

- high level of hardenability for product strength (hardening of steel is carried out slowly, immersing it in oil for cooling);

- high wear resistance (it allows the entire rolling mill to operate for a long time and without interruption, ensuring stable parameters);

- contact strength (it must be greater than the voltage that occurs during the process, taking into account the load from the resistance and the mass of the device).

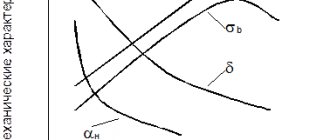

Mechanical properties after improvement

For some of the most commonly used brands, they are tabulated:

| Material | Tensile strength, MPa | Plastic limit, MPa | Relative extension, % | Impact strength, MJ/m2 | Cold brittleness range, 0C |

| 45 | 610 | 370 | 16 | 0,5 | 0…-75 |

| 40X | 1000 | 800 | 9 | 0,4 | -20…-60 |

| 30ХГСА | 1100 | 850 | 10 | 0,5 | -20…-60 |

| 40ХН | 1000 | 800 | 11 | 0,7 | -30…-100 |

| 40ХН2МА | 1100 | 950 | 12 | 0,8 | -40…-120 |