1.Welding wire

Welding wire is a material used in fusion welding of metals.

The main technical standard according to which welding wire is produced is GOST 2246-70. This wire is used in cases where it is necessary to connect any parts with high accuracy and reliability. Only with the right choice of welding wire can you obtain a ductile, strong, straight and corrosion-resistant welding seam. Welding wire is available in several types, differing in the structure of the rod and the composition of alloying components. In physical form, wire is produced and used in the form of coils (coils) or rods. Steel welding wire is produced in 77 grades, including: 6 grades - from low-carbon steel (Sv-08. Sv-08A, Sv-08AA, Sv-08GA, Sv-10GA, Sv-10G2); 30 grades - from alloy steel (Sv-08GS, Sv-12GS, Sv-08G2S, Sv-YUGN, Sv-IONMA, Sv-18KhMA, Sv-15GSTYUTSA, Sv-20GSTYUA, etc.; wire of the last two grades is used for arc welding without additional protection); 41 grades - made of high-alloy steel (Sv-06Х19Н9Т, Sv-07Х19Н10Б, Sv-07Х25Н13, Sv-13Х25Н18, Sv-08Х19Н10Г2Б, Sv-10Х20Н15, Sv-01Х23Н28МЗДЗТ, etc.). Steel welding wire is produced in the following diameters, mm: 0.3; 0.5; 0.8; 1; 1.2; 1.6; 2; 2.5; 3; 4; 5; 6; 8; 10; 12. Wire is supplied rolled into coils weighing 1.5...40 kg and with an internal diameter of 150...750 mm

General requirements for welding wire:

- should melt calmly and evenly;

- the melting temperature must be less than or equal to the melting temperature of the base metal;

- must be free of rust and dirt;

- The chemical composition must correspond to the chemical composition of the metal being welded.

2. Welding wire classification

When classifying welding wire, the following parameters are taken into account:

- appointment;

- type of surface;

- structure;

- chemical composition.

Let's take a closer look at the content of the parameters listed above.

2.1. Purpose The wire can be general purpose or special. The latter type of wire is used for special types of welding: underwater, fittings, bathtubs. Thanks to the special chemical composition of such wire, the above work is simplified and its high quality is ensured.

2.2. Type of surface Depending on the type of surface of the wire, it can be non-copper-plated or copper-plated (in the latter case, the letter “O” will be present in the designation of the brand of this type of wire). Copper-plated wire is used when welding parts for the manufacture of which carbon or low-alloy steel was used. This wire allows you to create a corrosion-resistant seam and contributes to obtaining a stable arc, which is extremely important when performing gas welding work.

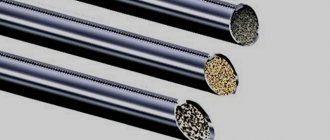

2.3. Structure Based on the type of structure, welding wire is divided into solid, flux-cored and activated wire.

2.4. Chemical composition This parameter of the wire is of great importance for high-quality welding. The choice of wire containing copper allows, for example, gas welding with minimal metal spatter and reduces tip consumption. Thus, by choosing wire of different chemical compositions, it is possible to ensure high-quality welding of products made from specific types of steel.

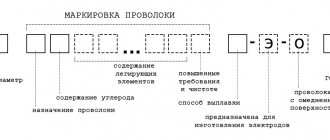

Welding wire designation

The steel grades used for its manufacture are standardized (GOST 2246-70). The following varieties are currently available:

- 6 grades of welding wire with low carbon content.

- 30 grades that use alloy steel.

- And 41 grades of welding wire, for the manufacture of which high-alloy steel is selected.

In the designation of the welding wire, information is encoded in letters and numbers about which chemical elements and how many (in percentage terms) are included in the composition of this particular brand.

For example, if the welding wire contains:

- molybdenum, then the Russian letter “M” will be present in its marking;

- niobium - “B”;

- nickel - “N”;

- tungsten - “B”;

- zirconium - “C”.

Accordingly, to indicate the presence of nitrogen, copper, silicon, titanium, vanadium, chromium and aluminum, the following Russian letters are used: A, D, S, T, F, X, Yu.

Before the designation of the wire grade, there must be a number indicating the diameter of the wire, and, separated by a hyphen, the letters “Св”, emphasizing that this is welding wire. Next, using numbers, the amount of carbon is shown as a percentage (or rather, these are hundredths of them, that is, for example, “08” should be understood as “0.08%)”. The subsequent alphanumeric combinations indicate the percentage of the previously listed chemical elements present in the wire, and if the content of any of them does not exceed 1%, then the number is not placed after the letter designation of this element.

Also, sometimes the letters “A” or “AA” may appear at the end of the brand designation. At the same time, the presence of one letter “A” indicates that phosphorus and sulfur are contained in the wire in reduced quantities, and the presence of two letters “A” at the end of the designation is a sign that this welding wire is maximally purified from sulfur and phosphorus.

Let's look at the symbol for wire using an example.

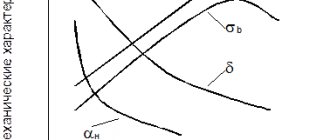

2Св-08А, where: 2 - wire diameter 2 mm; St - welding wire; 08 - 0.08% - carbon content; A - increased quality of metal. The brand may contain two letters AA (Sv-08AA), which indicates that this wire material is of particularly high quality. Quality means a reduced content of harmful impurities in steel - sulfur and phosphorus. An increased carbon content in the wire leads to a decrease in the ductility of the metal. Alloying elements may be present in the wire grade (Sv-12GS; Sv-15GSTYUTSA): G - 1% manganese; C - 1% silicon. If there is no number after the letter indicating the alloying element, then the content of this element in the steel is up to 1%. The number shows the content of the element in whole fractions of a percent. The wire varies in diameter. Wire diameter - from 1 to 12 mm. Wire with a diameter of 1.6 to 6 mm is used for manual arc welding (metal electrode rod). Wire with a diameter of more than 6 mm is called rods and is used for welding cast iron and non-ferrous metals, surfacing work. Wire with a diameter of 2 to 5 mm - for automatic welding. The diameter of the wire for gas welding is selected depending on the thickness of the metal and the welding method. For right-hand welding, the diameter of the filler wire is d=S/2. For left-hand welding, the diameter of the filler wire is d=S/2+1.

Wire GOST 2246 for welding. Wire SV08A

GOST 2246-70 defines the characteristics of welding wire of various grades. In addition, it can be used for surfacing and for the production of electrodes.

GOST 2246-70 wire for welding is divided depending on the steel grade into:

- low-carbon welding wire - grades SV08, SV08A, SV08GA

- alloyed welding wire - grades SV08GS, SV12GS, SV08G2S, SV10GN, SV08GSMT, SV15GSTYUTSA (EP-439), SV20GSTYUA, SV18KhGS and others

- high-alloy welding wire - grades SV12Х13, SV12Х11НМФ, SV10Х11НВМФ, SV13Х25Т, SV01Х19Н9, SV20Х13, SV06Х14, SV08Х14ГНТ, SV10Х17Т and others.

Depending on the type of coating, we produce: black and copper-plated welding wire.

Some brands of welding wire, for example, SV08A and SV08 wire, are also used for the manufacture of welding electrodes of different brands - UONI 13/55, MR-3, UONI 13/45, ANO-21, etc.

The chemical composition is given in the table:

Element, % Low-carbon alloy steel grade Sv08 Sv08A Sv08GA Sv08GS Sv08G2S Sv08ХМ S no more than Mn Si no more than PS Cr no more than Ni no more than Al no more than Cu no more

| 0,10 | 0,10 | 0,10 | 0,10 | 0,10 | 0,06-0,10 |

| 0,35-0,60 | 0,35-0,60 | 0,80-1,1 | 1,40-1,70 | 1,80-2,10 | 0,35-0,60 |

| 0,03 | 0,03 | 0,06 | 0,60-0,85 | 0,70-0,95 | 0,12-0,30 |

| 0,040 | 0,030 | 0,030 | 0,030 | 0,030 | 0,030 |

| 0,040 | 0,030 | 0,025 | 0,025 | 0,025 | 0,025 |

| 0,15 | 0,12 | 0,10 | 0,20 | 0,20 | 0,9-1,2 |

| 0,30 | 0,25 | 0,25 | 0,25 | 0,25 | 0,30 |

| 0,01 | 0,01 | — | — | — | — |

| 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 |

Wire GOST 2246-70, depending on the diameter and steel grade used, can be supplied in coils of 80-100 kg, in large coils of 800-1000 kg, as well as on special plastic spools or metal frames.

Welding wire is usually packaged in cloth or moisture-proof paper. Wire for the production of SV08A and SV08 electrodes in coils is supplied without packaging.

profmetiz.ru

Surfacing wire

Surfacing is the technological process of applying a layer of metal to the surface of a product by fusion welding. It is used to restore the original dimensions of parts and to give the surface layers of the part special properties required for its successful operation.

When surfacing by fusion welding, a pool of liquid metal is formed, which includes part of the molten metal of the product and the deposited electrode metal. Thus, the metal of the electrode turns out to be diluted with the metal of the product. When restoring worn parts, unless it is necessary to increase their wear resistance or other properties, electrodes and filler wire of a composition are used that ensures the production of deposited metal that is similar or close to the composition of the metal of the product. If, according to operational requirements, it is necessary to increase wear resistance, heat resistance and other properties, a variety of alloyed electrodes and wires are used, which, taking into account the partial dilution of the deposited metal, ensure the formation of a surface layer of the required quality. In addition to increased alloying, technological methods are used to reduce the proportion of the base metal in the surfacing, in particular, they reduce the welding energy (surfacing at low currents), increase the transverse vibrations of the electrode, etc.

The main raw material for arc surfacing of metal on worn parts is steel surfacing wire. They produce 19 grades of surfacing wire, including: 8 grades - from carbon steel Np-25, Np-30, Np-35, Np-40, Np-45, Yp-50, Np-65, Np- 80); 8 grades—alloy steel (Np-40G, Np-50G, Np-65G, Np-ZOGSA, Np-30Kh5, Np-40Kh2G2M, Np-5KhNM, Np-50KhFA); 3 grades - made of high-alloy steel (Np-30X13, Np-40X13, Np-PZA).

Steel surfacing wire is produced in the following diameters, mm: 0.3; 0.5, 0.8; 1; 1.2; 1.4; 1.6; 1.8; 2; 2.5; 3; 4; 5, 6; 6.5; 8. The hardness and purpose of the surfacing wire are shown in the table below.

Hardness and purpose of surfacing wire

| Wire grade | Approximate hardness of deposited metal | Welded products |

| Np-25 | NV 160…220 | Axes, spindles, shafts |

| Np-30 | ||

| Np-35 | ||

| Np-40 | NV 170…230 | |

| Np-45 | ||

| Np-50 | NV 180…240 | Tension wheels, trolley ramps, support |

| Np-65 | NV 220…300 | Support rollers, axles |

| Np-80 | NV 260…340 | Crankshafts, cardan shaft crosspieces |

| Np-40G | NV 180…240 | Axes, spindles, rollers, shafts |

| Np-50G | NV 200…270 | Tension wheels, support rollers for tracked vehicles |

| Np-65G | NV 230…310 | Crane wheels, support roller axles |

| NP-ZOHGSA | NV 220…300 | Crimping rolls, crane wheels |

| N l-30X5 | HRC3 37.. 42 | Rolling rolls of section rolling mills |

| NP-40ХЗГ2МФ | HRC3 38…44 | Parts exposed to impact and abrasive HOCV |

| Np-40Х2Г2М | HRC3 54…56 (after hardening) | Machine parts working with dynamic loads (crankshafts, steering knuckles: axles of road wheels) |

| Np-55ХНМ 60 | HRC3 40…50 | Forging and punching dies, forging machine rolls |

| NP-50HFA | HRC3 43…50 | Splined shafts, crankshafts of internal combustion engines |

| NP-30Х13 | HRC3 38…45 | Hydraulic press plungers, crankshaft journals, dies |

| NP-40X13 | HRC, 45…52 | Support rollers for tractors and excavators, conveyor parts |

| Np-GIZA | NV 220…280 | Railway crosspieces, crusher jaws, bucket teeth |

Other types of welding wires

For welding most non-ferrous metals and their alloys, welding wires of various diameters made of aluminum, copper and brass are used.

For aluminum wire and wire made of aluminum alloys there is a domestic GOST 7871-75, which specifies its dimensions (from 0.8 to 12.5 mm) and chemical. compound. GOST 16130-72 applies to wire made of copper and copper-based alloys. Copper wire is available in Ø from 0.8 to 8 mm.

The diameters of welding wire produced in accordance with GOST in our country differ from foreign analogues. And since automatic and semi-automatic welding machines are mostly foreign-made, there is a need to know analogues of wire produced abroad. For example, an analogue of the most used brand Sv08G2S is copper-plated wire ER-70S-6, manufactured by the well-known manufacturer FARINA from China. Supplied with row wound spools. Foreign wire is marked according to AWS standards.

Welding wire can be supplied:

- in coils (Ø 830 ÷ 850 mm, height 700 ÷ 1000 mm, weight up to 1.3 t);

- skeins (Ø 220 ÷ 730 mm, thickness 60 ÷ 180 mm, weight 15 ÷ 120 kg);

- on cassettes and reels weighing 5, 15 and 18 kg.

Coils, skeins, cassettes and reels can be supplied unpackaged and packed in polyethylene or special boxes. If the wire is supplied unpackaged, then before use it must be dried at a temperature of at least 200 0C for half an hour