Structural changes in metal

When heating special structural steel 45 to the austenitic level, the state of the structural lattice of iron changes with a transition from a body-centered to a face-centered structure. The carbon included in pearlite and representing the smallest crystals of Fe3C (cementite) moves into a face-centered modified iron lattice.

Structure of steel 45 after annealing and hardening

During cooling, the temperature of the steel being processed rapidly decreases, but due to the slowdown in the speed of movement of carbon atoms, they remain embedded in the new iron lattice, forming a solid supersaturated structure with internal stress. The lattice is transformed into a tetragonal lattice with orientation in one direction.

The formation of needle-shaped small structures called martensite occurs. This type of crystal gives the metal high strength, hardness and improved characteristics. Two types of austenite and martensite crystals are simultaneously formed, which act on each other, creating internal excess stress. When external forces actively influence the metal, mutual compensation of the two types of crystals occurs, imparting strength to the structure.

Chemical composition

Anyone who deals with alloys knows that the elements that make up them affect their characteristics. Steel 45 is a high-quality structural carbon steel. From the name it becomes clear that it contains carbon - 0.45%. The majority, of course, is iron – 97%. The remaining 2.55% includes such chemical elements as manganese (0.7%), silicon (0.2-0.3%), nickel (0.25%), chromium (0.25%), copper (0.25%), arsenic (0.08), sulfur (0.04) and phosphorus (0.035%). Each of the alloying elements affects the characteristics of steel 45. For example, manganese is present in almost all grades of steel. It removes oxygen from it and reduces the sulfur content. Silicon affects the hardenability of steel. In addition, it increases the yield and elastic strength.

Heat treatment of metal

To change the characteristics of steel, heat treatment is carried out in compliance with the necessary exposure modes.

The heat treatment process consists of the following processes:

- annealing;

- normalization;

- aging;

- hardening and tempering.

Heat treatment modes for steel 45

Hardening and tempering of steel largely depends on a number of factors:

- temperature conditions;

- rate of temperature increase;

- time period of exposure of metal to high temperatures;

- cooling process (rate of change in cooling temperature of a medium or liquid).

Steel hardening

The steel hardening process involves heat treatment of workpieces with heating to a temperature above critical with further acceleration of cooling. This condition helps to increase the strength and hardness (HRC) of steel while reducing ductility and improving consumer characteristics.

The mode of influence of the metal cooling temperature depends on the amount of carbon content and alloying additives in the steel.

After hardening the steel, the workpieces are covered with a coating of scale and partially lose the carbon they contain, so the technology must be followed in accordance with the established regulations.

Cooling of the metal must occur quickly to prevent the transformation of austenite into sorbitol or troostite. Cooling must be carried out exactly according to the schedule; rapid cooling of the workpieces leads to the formation of small cracks. During the cooling process from 200 °C to 300 °C, an artificial slowdown occurs as the products gradually cool down; for this, coolants can be used.

Hardening technology for different grades of steel - how and why it is done

According to GOST for heat treatment of steel, hardening of different grades can be:

- With one cooler. The sample, brought to a certain temperature, is immersed in liquid. The metal remains there until it cools to the required level. The method is used for carbon and alloy materials, as well as products with a simple design.

- Intermittent. Two environments are used. The metal first undergoes rapid cooling. Water is suitable for this. The products are then immersed in oil. This is necessary to slowly reach a certain temperature mark. The method is used for high-carbon steel.

With different hardening methods, not only the resulting quality characteristics of the steel may differ, but also the colors of the heat.

- Stepped. Products are cooled in an environment whose thermal temperature exceeds the martensitic level of the grade being processed. During cooling and holding, the part along its entire perimeter reaches the temperature of the quenching container. After this, slow cooling with quenching is carried out. This is how austenite transforms into martensite.

- Jet. The surface is intensively sprayed with water pressure. In this case, a steam cocoon is not formed, thanks to which deep calcination can be achieved. Used if it is necessary to treat only part of the surface.

- Isothermal. The method is similar to step hardening, but differs in the exposure time. The steel remains in the environment exactly as long as necessary to complete the isothermal transformation of austenite.

Basic temperature and time conditions for heat treatment of steels - table of indicators for different grades

Hardening steel using HDTV

When carrying out surface hardening using high-frequency frequencies, the process of heating products is carried out to a higher temperature.

This is caused by two factors:

- Heating is carried out in a short time with accelerated change and transition of pearlite to austenite.

- The transition reaction must be carried out in a short time within a short period of time at high temperature.

Hardening with high-frequency currents

The processes occurring during conventional hardening in a furnace using high-frequency frequencies have different characteristics and lead to a change in the hardness (HRC) of the workpieces:

- When heated in an oven, the speed is 2-3 °C/sec up to 840 – 860 °C.

- Using HDTV - 250 °C/sec to a temperature of 880 - 920 °C or in mode at 500 °C/sec - up to 980 - and 1020 °C.

When using HDTV, parts are heated to a higher temperature, but the workpiece does not overheat. In the process of processing using HDF, the heating operation time is significantly reduced, which helps maintain grain size and structure. During the high-frequency hardening operation, the metal hardness (HRC) increases by 2-3 units. according to Rockwell.

How to harden 45 steel at home

The word “heat treatment” is not new to ordinary people. Everyone understands perfectly well why it is needed. Increasing the strength of steel.

But why does this happen? What processes are occurring in the metal at this moment? Most shrug their shoulders.

If you want to understand what heat treatment is, find out the difference between annealing and tempering, and why 45 steel is hardened in oil and not in water, then this article is for you.

General information about heat treatment

Heat treatment is a sequence of heating, holding and cooling processes aimed at changing the mechanical properties of steel.

Improvements in the properties of the metal occur due to the transformation of the internal structure. After heat treatment, steel can be in 2 states: stable and unstable.

The steady state is characterized by the complete completion of all ongoing processes in the steel. Unstable, on the contrary, is when the steel is still affected by factors that interfere with the stabilization of internal stresses. A striking example is the chemical heterogeneity of hardened steel.

An increase in the thermal movement of molecules helps to accelerate the recovery of steel from an unstable state. This is achieved by heating.

To better understand the processes occurring in steel during heat treatment, let us introduce several concepts about the structure of the metal. This refers to the size of the internal grains and their position relative to each other. Each structure corresponds to a certain temperature and a certain carbon content.

Their main types and properties they have:

- Ferrite is a solid solution of iron with carbon and a small proportion of other chemical elements. Ferromagnetic. Ferritic steel has high thermal and electrical conductivity. Plastic. Hardness is about 70-140 units on the Brinell scale.

- Cementite is an unstable compound of carbon and iron. Very hard and brittle (HB 790-810). Cannot be magnetized.

- Perlite is a phase solution of ferrite and cementite. Its mechanical properties are primarily influenced by the distance between the phases. The closer they are, the stronger the steel. Hardness is in the range of 160-230 HB, with a relative elongation of 9-12%.

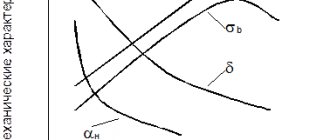

- Martensite is a supersaturated physicochemical mixture of carbon and iron. The value of its mechanical characteristics depends on the amount of carbon in the composition. Martensitic steel with a concentration of 0.2% C has a hardness of about 35 HRC. At 0.6% the hardness is 60 HRC.

- Austenite is a solid solution of carbon in iron. Austenitic steel is paramagnetic and ductile. The relative elongation is 42%.

The heat treatment process itself includes:

- Hardening.

- Annealing.

- Normalization.

- Vacation.

Annealing

The annealing process consists of heating, holding and slow cooling in a furnace environment.

There are two main varieties of it:

- Annealing of the first kind, in which the structure of the steel does not undergo changes.

- Annealing of the second kind, accompanied by transformations of structural zones.

Each of the presented types of heat treatment has a specific purpose.

First type annealing performs the following technological tasks:

- Leveling the chemical composition of steel. When metal is processed by pressure, segregation causes the formation of fractures and microcracks. To reduce their likelihood of occurrence, steel is heated to 1250 ºС and kept at this temperature for 8-15 hours.

- Increasing the machinability of steel by pressure. Heat treatment takes place at 670 ºС with a holding time of 40-120 minutes. Annealing increases ferrite grains, which has a positive effect on ductility.

- Reduction of residual stresses arising after technological processing of steels: cutting, welding, etc. To do this, the steel is kept at 500-620 ºС for two hours.

Second-order annealing refines the steel grains and promotes the formation of a ferrite + pearlite structure. As a result, there is an increase in mechanical properties. The heating temperature for steel 45 is 780-830 ºС.

Annealing of the second type is considered a preparatory heat treatment. It is carried out before cutting operations to increase the machinability of the metal.

Normalization

This is the process of heating steel and subsequent cooling in air, as a result of which the coarse-grained structure is refined.

Compared with annealing, normalization gives an average of 10% higher viscosity and strength. The reason for this lies in air cooling, which promotes the decomposition of austenite phases in the lower temperature zone. As a consequence, an increase in perlite is observed, which is the reason for the increase in mechanical properties.

Normalization is an alternative to hardening and high tempering. Of course, the resulting mechanical properties are lower, but the normalization itself is less labor-intensive. In addition, compared to hardening, it causes less thermal deformation of the part.

Vacation

This is a heat treatment that is always carried out at the final stage. It involves heating hardened steel to the temperature point where pearlite transforms into austenite and then cooling it further. With its help, the mechanical characteristics of steels are brought to the required values.

In addition, the task of tempering is to relieve the stresses remaining after hardening.

Vacation is divided into 3 types according to heating temperature:

- Low vacation. It is carried out at 230-260 ºС. Promotes strengthening while simultaneously reducing internal tension. Hardened steel 45 after low tempering has a hardness of 55-60 HRC.

- Average vacation. Heating temperature 340-550 ºС. Allows you to achieve the highest value of elastic properties. Because of this, it is mainly used in the manufacture of springs. Hardness is at the level of 45-52 HRC.

- High holiday. Performed at 550 ºС. Relieves internal stress after hardening.

Mechanical properties decrease, but their value is no less than after normalization and annealing. There is also an increase in impact strength. The most optimal heat treatment from the point of view of the ratio of viscosity and strength is considered to be hardening the steel, and then conducting a high tempering.

Hardening

It is a heating process to a temperature 20-40 ºС above the dissolution point of ferrite in austenite and subsequent rapid cooling in water or oil.

The formation of significant internal stresses during hardening does not allow it to be the final heat treatment. It is usually followed by a vacation or normalization.

As a result of heating, the steel acquires an austenitic structure, which, upon cooling, transforms into fine-needle martensite.

Hardening of steel 45 is carried out at 840-860 ºС.

If steel is hardened before reaching the required temperature, the result will be ferritic zones, whose presence significantly reduces the strength of the metal.

If 45 steel is hardened at temperatures above 1000 ºC, this will provoke an increase in the martensite grain, which entails a deterioration in toughness and an increased risk of cracking.

Heating of steels for hardening is carried out in periodic or continuous electric furnaces.

Heating time depends on:

- Chemical composition of steel.

- Shapes and dimensions of parts.

The larger the size and carbon content, the longer the amount of time required to heat the steel.

After heating the steel, it is held at a given temperature. This is necessary to level out the inhomogeneity of austenite.

When severely overheated, the steel begins to react with furnace gases. This can lead to oxidation and decarbonization processes.

Oxidation is the chemical process of interaction of oxygen with iron. It negatively affects the properties of steel and causes a decrease in surface quality and scale.

Decarbonization occurs as a consequence of the chemical reaction of carbon with hydrogen and oxygen. As a result, forming compounds such as carbon monoxide and methane. The resulting gases carry away carbon molecules from the surface of the steel, thereby causing a sharp decrease in strength.

Steel is protected from oxidation and decarburization by heating in a vacuum or molten salt.

Water or oil are used as quenching media.

Water has a high cooling rate, but it drops sharply as the temperature increases. Another disadvantage of water is the occurrence of significant stresses and, accordingly, warping of parts.

In this regard, the oil cools more evenly, which reduces the risk of microcracks during hardening. Among its disadvantages, it is worth noting the low ignition temperature and thickening, which reduces its hardening properties.

Heat treatment features

Hardening of steel 45 is a method widely used in metallurgy and mechanical engineering. But how to harden 45 steel to get the expected result? To change the characteristics, it is necessary to carry out heat treatment. In this case, certain modes of exposure must be observed. This process can be schematically represented by the following processes:

- Annealing.

- Normalization.

- Aging.

- Hardening and tempering.

The quality of 45 steel during heat treatment depends on a number of factors.

- Temperature regime.

- At what rate does the temperature rise?

- The period of time during which the metal is exposed to high temperature.

- At what speed does the cooling process occur?

Heat treatment consists of heating the part to a specified temperature. Cool it at the same or slightly different speed. Iron-carbon alloys are characterized by transformations when heated to certain temperatures. They are called critical points. These transformations are associated with a crystallization character. When hardening steel 45, the hardness of products increases significantly.

Chemical composition

What does number 45 mean for steel? This suggests that this alloy contains 0.45% carbon. Other impurities are presented in insignificant quantities. Among its main substitutes are steel 40 and 50. They are also characterized by high strength.

If we consider the chemical compounds that make up steel as a percentage, then the largest share is iron. His figure reaches 97%. Other chemical elements are also included in varying quantities. Phosphorus has the lowest value.

It contains only 0.035%.

Structural changes in metal

In the initial state, the structure consists of two phases that are mixed with each other - ferrite and cementite. If you slowly heat it to low temperatures, then no changes will occur in it. If further heating is carried out, the ferrite will dissolve into austenite. When heated above the critical temperature, their structure will become homogeneous.

The atomic lattice of iron has a body-centered character. When heated strongly, it becomes face-centered in type. Before heating, carbon atoms enter pearlite (cementite crystals), after which it will take a different state and become a solid solution. In this case, its atoms will end up in the iron lattice. With sudden cooling, for example, with water, it can be hardened.

In this state, it will acquire values characteristic of room temperature. It would seem that everything will be rearranged in the reverse order. But such temperature parameters will not give carbon atoms pronounced mobility.

The speed in this case is so insignificant that the atoms simply do not have time to leave the solution when rapid cooling takes place. They remain in the lattice structure. This creates a strong internal stress in the metal.

The use of hardened steel significantly increases the possibility of using parts made from such steel.

Hardening with HDTV

Using HDTV, the heating temperature is higher in its performance.

This circumstance becomes possible due to the presence of two factors:

Heating causes an accelerated change and transition of pearlite into austenite. The process occurs within a compressed time frame. The temperature is very high in its magnitude.

But the workpiece does not overheat. During such operations, the characteristics of the metal that determine its hardness increase by 3 Rockwell units. Using this method, you can harden a part quite thoroughly.

Hardness testing, and, consequently, the hardenability of parts, is determined using the Brinell method.

Precautionary measures

Such operations pose a certain danger to human life and health. Electrical heating installations involve hazardous exposure to electrical current.

Working with hardening baths is associated with the release of harmful vapors and gases into the surrounding space. In this regard, equipment and good proper operation of local exhaust ventilation systems are of great importance.

In addition, such places are equipped with general ventilation.

If the process is carried out using oil or kerosene, it is possible that their vapors will ignite. It is necessary to protect against chemical burns. Nitrate is stored in accordance with the required rules.

The nitrate solution in the molten state should not be at a temperature above 60 degrees. Cyanide salts are packaged only with local exhaust ventilation. All work is carried out only using personal protective equipment.

To prevent the formation of poisonous hydrocyanic acid, it is impossible to store cyanide salts together with acid solutions.

How 45 steel is hardened: process, methods, hardness after hardening Link to main publication

Hardening steel 45

The word “heat treatment” is not new to ordinary people. Everyone understands perfectly well why it is needed. Increasing the strength of steel.

But why does this happen? What processes are occurring in the metal at this moment? Most shrug their shoulders.

If you want to understand what heat treatment is, find out the difference between annealing and tempering, and why 45 steel is hardened in oil and not in water, then this article is for you.

Application of protective measures

During the heat treatment process, carbon gradually burns out and scale forms. To prevent deterioration of the quality of the metal and protect it, shielding gases are used, which are pumped during the hardening process. Ammonia or methane gas is pumped into the furnace, which has a sealed chamber, where heat treatment occurs using a special generator.

In the absence of sealed furnaces, processing operations are carried out in a special sealed container, into which cast iron shavings are first poured to prevent carbon burnout.

When processing workpieces in salt baths, the metal is protected from oxidation, and to create the necessary conditions for maintaining the carbon level, the contents of the bath are deoxidized 2 times during the day with boric acid, blood salt or borax. At processing temperatures in the temperature range of 760-1000 °C, charcoal can be used as a deoxidizing agent.

Use of special coolants

During the technological process, water is mainly used to cool parts. The quality of the coolant can be changed by adding soda or special salts, which can affect the cooling process of the workpiece.

To preserve the hardening process, it is strictly forbidden to use the water contained in it for extraneous operations. The water must be clean and have a temperature of 20 to 30 °C. It is forbidden to use running water to harden steel.

Composition of mixtures of salts and alkalis used as quenching media

This hardening method is used only for cemented products or those with a simple shape.

Products with complex shapes made from special structural steel are cooled in a 5% caustic soda solution at a temperature of 50-60 °C. The hardening operation is carried out in a room equipped with exhaust ventilation. Mineral oils are used to harden workpieces made of high-alloy steel, and the cooling rate in an oil bath does not depend on the oil temperature. Mixing oil and water is unacceptable, as this can lead to cracks in the metal.

When quenching in an oil bath, a number of rules must be followed:

- Be careful not to ignite the oil.

- When the metal cools in the oil, harmful gases are released (exhaust ventilation is required).

- Plaque forms on the metal.

- Oil loses its properties when intensively used to cool metal.

When carrying out the hardening process of steel 45, it is necessary to follow the technological process in compliance with all operations.

characteristics, weight, hardness, analogues of steel grade 45

Steel grade: 45.

Class: high-quality carbon structural steel.

Industrial uses: Pinion shafts, crankshafts, camshafts, gears, spindles, bands, cylinders, cams and other normalized, tempered and surface heat treated parts that require increased strength.

Hardness: HB 10 -1 = 170 MPa

Weldability of the material: difficult to weld. Welding methods: RDS and KTS. Heating and subsequent heat treatment are required.

Forging temperature, oC: beginning 1250, end 700. Sections up to 400 mm are cooled in air.

Flock sensitivity: low sensitivity.

Tendency to temper brittleness: not prone.

Type of delivery:

- Long products, including shaped steel: GOST 1050-88, GOST 2590-2006, GOST 2591-2006, GOST 2879-2006, GOST 8509-93, GOST 8510-86, GOST 8239-89, GOST 8240-97, GOST 10702 -78.

- Calibrated rod GOST 1050-88, GOST 7417-75, GOST 8559-75, GOST 8560-78.

- Polished rod and silver GOST 14955-77.

- Thick sheet GOST 1577-93, GOST 19903-74.

- Thin sheet GOST 16523-97.

- Tape GOST 2284-79.

- Strip GOST 103-2006, GOST 1577-93, GOST 82-70.

- Wire GOST 17305-91, GOST 5663-79.

- Forgings and forged blanks GOST 8479-70, GOST 1133-71.

- Pipes GOST 8732-78, GOST 8733-74, GOST 8734-75, GOST 8731-74, GOST 21729-76.

| Foreign analogues of steel grade 45 | |

| USA | 1044, 1045, 1045H, G10420, G10430, G10440, G10450, M1044 |

| Germany | 1.0503, 1.1191, 1.1193, C45, C45E, C45R, Cf45, Ck45, Cm45, Cq45 |

| Japan | S45C, S48C, SWRCh55K, SWRCh58K |

| France | 1C45, 2C45, AF65, C40E, C45, C45E, C45RR, CC45, XC42h2, XC42h2TS, XC45, XC45h2, XC48, XC48h2 |

| England | 060A47, 080M, 080M46, 1449-50CS, 1449-50HS, 50HS, C45, C45E |

| European Union | 1.1191, 2C45, C45, C45E, C45EC, C46 |

| Italy | 1C45, C43, C45, C45E, C45R, C46 |

| Belgium | C45-1, C45-2, C46 |

| Spain | C45, C45E, C45k, C48k, F.114, F.1140, F.1142 |

| China | 45, 45H, ML45, SM45, ZG310-570, ZGD345-570 |

| Sweden | 1650, 1672 |

| Bulgaria | 45, C45, C45E |

| Hungary | A3, C45E |

| Poland | 45 |

| Romania | OLC45, OLC45q, OLC45X |

| Czech | 12050, 12056 |

| Austria | C45SW |

| Australia | 1045, HK1042, K1042 |

| Switzerland | C45, Ck45 |

| South Korea | SM45C, SM48C |

Properties of steel St 45

When purchasing metal products, you need to know the properties of the material from which they are made. The type of steel the product is made from affects its cost, strength, and reliability. This also determines the service life and possible scope of application.

In this case, you will find information about steel grade 45, which is often used for the manufacture of a variety of metal products. It is considered structural carbon quality. To purchase rolled metal products made from 45 steel, check out the company’s catalogs and contact our managers.

It is supplied in the form of long and shaped products. You can find an extensive list of products for which it is used. For example, silver, sheets of metal of different thicknesses, rods with different types of surface treatment, forgings and forged blanks, long wire products, tapes and strips, as well as pipes.

Steel 45 and its characteristics

- Low sensitivity to flakes.

- Steel 45 and its specific gravity: the figure is 7826 kg/m3.

- Not prone to temper brittleness.

- Heat treatment: Delivered condition.

- Steel hardness 45: the indicator is equal to the following values: HB 10 -1 = 170 MPa

The strength of this material is increased. That is why objects are made from it that can be normalized, improved, and whose surfaces can be subjected to heat treatment.

This material contains 0.45 percent carbon. Other impurities are extremely minor.

Steel is a difficult-to-weld material. To carry out the welding procedure, the steel must first be heated and then thermally treated. When forging, the temperature should first be 1250 degrees Celsius and finally drop to 700 degrees.

If the product has a cross-section that is less than or equal to 400 millimeters, then it can be cooled in air.

Steel 45 and its analogues

Such material can be replaced by the following three grades of steel: 50, 50 G 2 and 40 X.

They are also used to create gears, cylinders, eccentric shaft attachments, rotating shafts, crankshafts and distribution shafts, as well as other products used in industry.

Steel grade 45 may be called differently in other countries and have several analogues. For example, in the USA, its properties are equal to 8 grades of steel, in Germany - 10, in France - 14. In Poland there is only one analogue and it is simply called 45, in Austria - C45SW.

atl-met.ru

Steel tempering 45

The technological process of steel tempering is carried out depending on the required temperature:

- in ovens with forced air circulation;

- in special baths with saltpeter solution;

- in oil baths;

- in baths filled with molten alkali.

The temperature for the tempering process depends on the grade of steel, and the process itself changes the structure and helps reduce the stress of the metal, and the hardness decreases by a small amount. After all operations, the workpiece is subjected to technical control and sent to the customer.

When hardening and tempering metal at home, it is necessary to strictly observe the technology and safety precautions for carrying out work.