During operation, the cutting edges of scissors are subject to increased wear, as a result of which they cease to cut efficiently. The way out of this situation may be to purchase a new tool. However, there is no need to rush, as using a scissors sharpening machine you can restore their functionality.

Sharpening scissors using a machine

Features of sharpening scissors

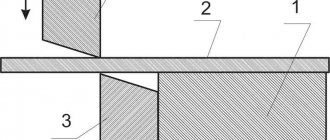

The blades of scissors are sharpened at a certain angle.

It is regulated by current standards. According to GOST R 51268-99, the sharpening angle of hairdressing scissors should be 60 degrees. When sharpening them, deviations are allowed: from +5 to -15 degrees. The sharpening angle of metal scissors is 75 degrees. Other types of scissors, including utility and tailor's scissors, are sharpened at an angle of 70 degrees. The permissible deviation for them is +10 degrees. The cutting properties of scissors depend on the sharpening angle of the blade.

Device, types, technical characteristics

The main design elements of all types of machines are an electric motor and a grinding disk, which can be mounted horizontally or vertically on the shaft.

Horizontal machines are used for sharpening scissors: hairdressing, manicure and surgical. All other types of knives can be sharpened on vertical machines.

Most modern sharpening machines have a laser “sight” in their equipment. It allows you to accurately set the sharpening angle of the cutting edge of the blade even for a non-professional. To protect the eyes of a person working on the machine from dust generated during sharpening of products, a special visor is provided in the design of the equipment.

All sharpening equipment produced by manufacturers is divided into two large groups: household and professional. The latest types of machines can work for a long time without stopping. Household equipment cannot withstand this operating mode.

According to their purpose, the machines are:

for nail scissors;

for medical instruments;

for professional tools.

Sharpening machines can be universal and highly specialized. The equipment can have: manual, automated and combined control. Abrasive and diamond wheels and belts are used as a sharpening element in machines.

The main technical characteristics of the equipment are:

- power;

- grinding disc size;

- rotation frequency.

An important role in the choice of equipment is played by its dimensions and weight.

Machines for sharpening manicure instruments

No matter how expensive manicure tools you buy, sooner or later they need to be sharpened. Manicurists especially know how important sharpened tools are for quality work. On the ZATOCHKA-SHARP website you have the opportunity to purchase machines for sharpening hairdressing and manicure tools. Using such equipment, you can restore:

- pushers;

- wire cutters;

- scissors;

- hairdressing tools;

- blades and other products.

If you don’t yet know how to sharpen correctly, then we will teach you and also provide detailed advice. You can buy a machine for sharpening manicure hairdressing tools in our online store ZATOCHKA-SHARP.RU. Here are the best prices for machines for sharpening scissors and manicure tools.

We work to ensure that you can sharpen various types of tools. Timely restoration will allow you to increase your safety performance, as well as the effectiveness and quality of your tools. Thanks to this, you can save on the purchase of new equipment.

Quick View Quick View Quick View Quick View Shown 1 to 4 of 4 (total 1 pages)

zatochka-sharp.ru

Best models

The rating is based on popularity among buyers.

Diold MZS-02

The model is intended for domestic use. The machine is multifunctional, designed for sharpening drills with a diameter of 3-13 mm, knives, scissors and axes with a narrow blade. The compact device operates from an electrical network with a voltage of 220 W.

The machine body is equipped with protective glass to prevent the spraying of metal dust during operation of the equipment. The period of non-stop operation is 15 minutes. After this, the equipment requires a 5-minute rest.

The machine has increased electrical safety, which is ensured by double insulation. Operating temperature range from -15 to +35°C. Sharpening of cutting surfaces is carried out using grinding wheels. They have a non-standard shape, so they cannot always be found on sale.

Advantages:

- several operating speeds;

- multifunctionality;

- compactness;

- light weight;

- ease of operation.

- The main disadvantage is the high noise level during operation.

VORTEX SZM-65

The universal model is designed for sharpening drills with a diameter of 3-10 mm, chisels with a blade width of 6-51 mm, knives and scissors. Sharpening of cutting surfaces is carried out with a grinding wheel having a diameter of 49.3 mm and a thickness of 7 mm. It is provided for cooling during operation.

The compact device weighs 2 kg. It is convenient to install on workbenches. The base of the machine has holes for attachment to various surfaces. A protective screen is installed on the body. The device operates from an electrical network with a voltage of 220 W.

Advantages:

- good power;

- compactness;

- ease of operation;

- low cost;

- high quality sharpening of cutting surfaces.

- The main drawback is the lack of illumination of the working surface.

Sturm BG6010S

Universal machine. The model has an inclined platform with precise adjustment of the sharpening angle of the cutting surfaces. The device can sharpen drills with a diameter of up to 10 m, chisels, knives and scissors. They are securely attached to the housing during operation with special clamps and magnetic latches.

Sharpening of the cutting tool is carried out with a small circle mounted on the spindle of the electric motor. The weight of the device is 2 kg. The machine operates from a power supply with a voltage of 220 W. Minimum permissible operating temperature is +5°C. The machine is manufactured in China, but is a German design.

Advantages:

- light weight;

- compactness;

- versatility;

- reliability;

- ease of operation.

Flaws:

- low power;

- It is difficult to find sharpening wheels for sale.

PATRIOT BG 100

The multifunctional machine is intended for household use. The model operates from an electrical network with a voltage of 220 W. The device can sharpen knives, scissors and other cutting tools with a narrow blade. It can sharpen drills with a diameter from 3 to 13 mm.

Machine weight 1.1 kg. Its compact dimensions allow it to be installed on a workbench in a small workshop or garage. The base of the device has holes for mounting. The machine has simple controls and conceptual settings that anyone can handle. There is a protective screen on the case. Grinding disc diameter 51 mm, thickness 8 mm.

Advantages:

- light weight;

- compactness;

- versatility;

- low cost.

Flaws:

- low power;

- not intended for intensive work.

BISON ZTSHM-150 686L

Machine for sharpening and grinding. Sharpening of cutting surfaces is done using a grinding wheel, and grinding with an abrasive belt. The model has a durable design and is intended for semi-professional use. There is a protective screen on the case. Machine weight 7.7 kg.

Sharpening of cutting surfaces on a machine can be done in two stages. First on a coarse abrasive, and then on a fine-grained one. The device switch is protected from dust. The bed rests on rubber feet, which prevent it from sliding on any type of surface. The device operates from an electrical network with a voltage of 220 W.

Advantages:

- reliable design;

- multifunctionality;

- high performance.

Flaws:

- heats up quickly during operation;

- strong vibration.

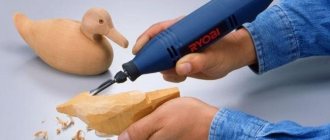

Kolner KBG 150F

Multifunctional machine with engraver. The model is designed to perform a wide range of work: sharpening, grinding, engraving, etc. On the front panel of the case there is a convenient control for setting the type of work. The machine body has a protective screen.

The machine has 2 grinding wheels: abrasive and flexible. The device operates from an electrical network with a voltage of 220 W. During operation, it must be turned off periodically to prevent the engine from overheating. Machine weight 2 kg.

Advantages:

- multifunctionality;

- low cost;

- light weight;

- compactness.

Flaws:

- there is curvature in the fit of the grinding discs;

- The discs brake when pressed hard.

Wester TSL170B

The machine is designed for sharpening cutting tools, including knives and scissors. Two grinding wheels are installed on the body, having working surfaces with different degrees of abrasive grain size. This allows you to do rough and finishing processing of the cutting surface on one machine.

There is a protective screen on the case. The device operates from an electrical network with a voltage of 220 W. The frame has holes for mounting the machine on a workbench. The weight of the structure is 3.8 kg. The start and shutdown button is protected from dust, moisture and dirt by a silicone pad.

Advantages:

- light weight;

- compactness;

- multifunctionality;

- low cost.

Flaws:

- small persistent platform;

- Not enough power to sharpen garden tools.

JET JSSG-10

The machine is designed for sharpening important cutting tools: chisels, wood cutters, scissors, knives, etc. One of them is equipped with a leather casing, which is intended for polishing. There are two grinding wheels installed on the common shaft of the structure. The machine does not overheat during operation. There is a protective screen on the case.

On the adjustable steel guide there is a bracket for attaching special devices. They help maintain the required sharpening angle of the tools being processed. To make it easier to carry the machine, there is a handle on its body. Machine weight 19 kg.

Advantages:

- the shaft bearings are protected from dust, dirt and moisture;

- there is a reservoir for wetting the abrasive disc;

- presence of a drawer for accessories.

Flaws:

- during operation, water spreads over the blade of the tool being sharpened in all directions;

- After use, the machine must be dried.

Interskol T-150/150

The machine is designed for sharpening cutting tools, including scissors, at home. The design is equipped with two sharpening abrasive discs of different grain sizes, which can be used for rough and finishing processing of cutting surfaces, as well as wood and metal.

Protective screens are installed on the body. There is illumination of the working area and stops for the tool being processed. The operating period without stopping is 30 minutes. The device operates from an electrical network with a voltage of 220 W. Machine weight – 5.9 kg.

Advantages:

- low cost;

- good sharpening quality;

- safety;

- reliability;

- compactness.

Flaws:

- increased level of vibration during operation;

- The backlight light is not strong enough.

PIT PMTS1003-C

The machine is designed for sharpening cutting tools, including scissors. The powerful engine and high performance of the model allows it to be used for work in workshops. A protective screen is installed on the body. The device operates from an electrical network with a voltage of 220 W. The weight of the machine is 1.65 kg.

Advantages:

- light weight;

- multifunctionality;

- compactness;

- good sharpening quality;

- high performance;

- low cost.

- No deficiencies identified.

What should you consider when choosing a sharpening machine?

When purchasing equipment, its performance, purpose and power are taken into account. Its ability to carry out the volume of planned work depends on these indicators.

It is important what kind of grinding wheels the machines are equipped with. If they are not available for sale, the equipment will be useless.

Other factors determining the choice of machine include:

- type of instalation;

- availability of additional functions;

- manufacturer;

- sharpening angles;

- method of fastening the tool being processed;

- price.

Selection principles

You need to choose sharpening equipment for scissors according to the following criteria:

- engine power;

- diameter of the installed abrasive disc, mounting dimensions for it;

- function of adjusting the motor spindle speed;

- type of machine installation, its dimensions, weight and operating requirements;

- method of fastening blades for turning;

- angles for adjusting the position of the edge relative to the disk;

- purpose: specialized or universal;

- functionality;

- manufacturer, cost of equipment, technical features of the model.

Advantages and disadvantages

Advantages of using scissor turning machines:

- convenient manipulator for positioning the blade at a given angle to the disk;

- choice of models: compact, stationary;

- processing quality control;

- safety at work;

- wide range of sharpening angles;

- high productivity when processing canvases;

- uniform sharpening of blades, elimination of minor defects.

Disadvantages of using machines:

- high cost of equipment compared to hand tools;

- the need to purchase sets of sharpening discs if equipment is purchased below a professional level;

- difficulty in servicing precision mechanisms.

Manufacturers and cost

Machines for turning various types of scissors are produced by the following manufacturers:

- Bison;

- Vortex;

- Interskol;

- Makita;

When choosing machines, you need to pay attention to the technical characteristics of the models, as well as the presence of a quality certificate, and the equipment’s compliance with current standards. Only with this approach there will be no problems with the machine components, since they will be operated under permissible loads.

Cost of equipment in Russia:

- manual - from 800 rubles;

- desktop household - from 2.3 thousand rubles;

- two-level professional - from 8.7 thousand rubles.

Questions and answers

Besides sharpening tools, what can you do on sharpening and grinding machines?

In addition to sharpening cutting surfaces, such machines can: process forged parts, clean the surface of various types of materials, polish glass products, etc.

Is it possible to avoid overheating of the blade of a cutting tool when sharpening it?

Avoid heating the blades of cutting tools when sharpening them on machines equipped with water tanks. Grinding discs are immersed in it during operation.

What models of sharpening machines can be used for professional use?

For professional work, you can use TSh-1.10, ZVS-20 machines.

How can you clean the aluminum oxide wheels of a sharpening machine quickly and efficiently?

The wheel is cleaned with a carborundum block.

Why are transparent protective screens installed on the body of grinding machines?

Protective screens prevent the spraying of metal dust when sharpening tools.

Exploitation

When using devices for sharpening various scissors, you must follow a number of rules:

- installation of equipment is carried out only on a flat, reliable surface;

- scissors should be firmly secured to prevent them from moving during processing;

- if problems are detected in the operation of one of the nodes, it is necessary to eliminate them;

- sharpening of nail scissors should be carried out continuously for no more than 5 minutes;

- it is important to keep the machine clean, carry out lubrication and maintenance in a timely manner;

- when switching from dry to wet sharpening or vice versa, you need to let the abrasive disc run at idle speed;

- To change the grinding wheel, you must stop the machine;

- working without a protective screen is strictly prohibited;

- the abrasive disk must be attached securely and motionlessly, even minimal imbalances must be eliminated;

- It is unacceptable to manually carry out manipulations with adjusting the sharpening angle or others while the machine is running, which could result in injury due to touching moving parts;

- You cannot install drives that are not recommended by the equipment manufacturer.

Operating conditions must meet the manufacturer's requirements. Failure to comply with them increases the risk of breakdowns, reduces processing accuracy, and reduces the service life of parts.