Home > Articles > Marking of rolled metal products

Marking of rolled metal products is regulated by GOST 7566-94. However, during the construction process, not everyone wants to understand GOST standards. In addition, all markings, for example, of rebar or steel angles, are listed in the price list. And then you saw strange abbreviations there. To understand which rolled metal product is suitable in each specific case, it is enough to know the rules for reading labeling symbols.

For example, to fence an area with a fence made of corrugated sheets, you must purchase a metal profile of a certain marking. This type of rolled metal product is marked in the form of a set of numbers and letters: for example, 0.7x2000x3000 C9. This combination of characters carries the following information:

- 0.7 mm – thickness;

- 2000 mm – width;

- 3000 mm – length.

Now we can conclude that the profile sheet will have a size of 2 * 3 m and a thickness of 7 mm. The letter indicates the application: C – wall, N – roofing, and NS – mixed type, which is used for various purposes. Any metal warehouse is required to advise you on this matter.

However, you must figure it out yourself so that when purchasing products in the future, you can check whether the appropriate rolled metal alloy was delivered and whether it is marked according to accepted standards. Rolled metal is marked depending on its supply to the market: internal or external.

Marking steel by color with paint

Marking of steel of various groups

Marking of boiler pipes with paint Marking of steel is carried out with indelible paint, regardless of the steel group and the degree of deoxidation. By agreement of the parties, paint marking is not performed.

Ordinary quality steel St0; VSt0, BSt0 - Red and green St1, VSt1kp - Yellow and black St2, VSt2kp - Yellow StZ, VStZkp, VStZ, BStZkp, BStZ - Red St4, VSt4kp, VSt4, BSt4kp, BSt4 - Black St5, VSt5 - Green St6 - Blue

Carbon quality steel 08, 10, 15, 20 - White 25, 30, 35, 40 - White and yellow 45, 50, 55, 60 - White and brown

Alloy structural steel Chrome - Green and yellow Chrome-molybdenum - Green and purple Chrome-vanadium - Green and black Manganese - Brown and blue Chrome-manganese - Blue and black Chrome-silicon - Blue and red Chrome-silicon-manganese - Red and purple Nickel-molybdenum - Yellow and purple Chrome-nickel - Yellow and black Chrome onykel-molybdenum - Purple and black Chrome-aluminum - Aluminum

Corrosion-resistant steel Chrome - Aluminum and black Chrome-nickel - Aluminum and red Chrome-titanium - Aluminum and yellow Chrome-nickel-silicon - Aluminum and green Chrome-nickel-titanium - Aluminum and blue Chrome-nickel-niobium - Aluminum and white Chrome-manganese-nickel - Aluminum and brown Chrome-nickel-molybdenum Ethanova – Aluminum and Violet

High-speed steel P18 - Bronze and red P9 - BronzeHard sintered alloys VK2 - Black with a white stripe VKZ-M - Black with an orange stripe VK4 - Orange VK6 - Blue VK6-M - Blue with a white stripe VK6-V - Purple VK8 - Red VK8- B - Red with a blue stripe VK10 - Red with a white stripe VK15 - White T15K6 - Green T30K4 - Blue

Source of the article: https://mpkural.ru/markirovka_stali_po_cvetu_kraskoy

Color marking of steels

material provided by SIDOROV Alexander Vladimirovich

Color marking of steels is carried out with indelible paint, regardless of the steel group and degree of deoxidation, in accordance with the designations given in Table 1. By agreement of the parties, paint marking is not performed. [1]

Table 1 – Color marking of steels

| steel grade | Color coding | Description | |

| Standard quality steel | |||

| St 0, B St 0, B St 0 | red and green | ||

| St 1, V St 1 kp | yellow and black | ||

| St2, V St 2 kp | yellow | ||

| St Z, V St Z kp, V St Z, B St Z kp, B St Z | red | ||

| St 4, B St 4 kp, B St 4, B St 4 kp, B St 4 | black | ||

| St. 5, V St. 5 | green | ||

| St. 6 | blue | ||

| Carbon quality steel | |||

| 08, 10, 15, 20 | white | ||

| 25, 30, 35, 40 | white and yellow | ||

| 45, 50, 55, 60 | white and brown | ||

| Alloy structural steel | |||

| Chrome | green and yellow | ||

| Chrome-molybdenum | green and purple | ||

| Chrome vanadium | green and black | ||

| Manganese | brown and blue | ||

| Chromomanganese | blue and black | ||

| Chrome-silicon | blue and red | ||

| Chromium-silicon-manganese | red and purple | ||

| Nickel-molybdenum | yellow and purple | ||

| Chrome-nickel | yellow and black | ||

| Chromium-nickel-molybdenum | purple and black | ||

| Chromium-nickel-molybdenum | aluminum | ||

| Corrosion resistant steel | |||

| Chrome | aluminum and black | ||

| Chrome-nickel | aluminum and red | ||

| Chromotitanium | aluminum and black | ||

| Chromium-nickel-silicon | aluminum and green | ||

| Chrome-nickel-titanium | aluminum and blue | ||

| Chromium-nickel-niobium | aluminum and white | ||

| Chromium-manganese-nickel | aluminum and brown | ||

| Chromium-nickel-molybdenum-titanium | aluminum and purple | ||

| High speed steel | |||

| R 9 | bronze | ||

| R 18 | bronze and red | ||

Metal marking methods

Currently, any part, assembly, tool or equipment undergoes mandatory marking or, in other words, the application of a number of symbols with which it can be identified.

There are several most common methods of applying inscriptions:

- Branding is carried out using a stamp under pressure on a mechanical press; thanks to a pre-prepared stamp with a mirror image of the symbols, a direct image is applied to the surface. Most often used for marking non-ferrous metals and steel parts;

More information about impact marking devices

- Electrochemical - widely used in the automotive and aviation industries, is economical and is used for marking metal of any degree of hardness;

- Thermal transfer printing, transfer of designation from a special coloring material to a thermal transfer label;

- Drop jet - used for marking parts and assemblies directly on the conveyor;

- Laser - fast and high-quality burning of marks on the metal surface using a fiber-optic laser; this method is used to mark locking equipment;

More information about laser marking machines

- Punch-dot - by applying dots using a series of blows, the required inscription is formed. The entire process is controlled by numerical control. This method is effective for marking products made of plastic materials and hardened metals;

More information about impact marking devices

- Engraving - Using a carbide needle, the machine engraves the part. The only disadvantage of this method is that marking is impossible for hard alloys

More information about devices for drawing

- Labeling with tags - used for gluing, hanging or screwing tags containing a description and barcode of the product onto products

Read more about printers and metal tags

According to regulatory documents and mandatory requirements imposed in modern society, all products must be labeled. It is this that allows the user to obtain complete information.

List of links

This site uses Akismet to reduce spam. Find out how your comment data is processed.

Similar posts

Introduction to Materials Science

material provided by SIDOROV Alexander Vladimirovich Materials science is a scientific discipline that studies the relationship between the composition, structure and properties of materials. The purpose of the material is determined by the design requirements (design criteria - strength, durability, corrosion properties, etc.) and the possibility of processing into a product (technological criteria - coefficient of machinability by cutting, welding and forming, etc.). Types of materials: metal materials; non-metallic materials (rubber, […]

Basic concepts of alloy theory

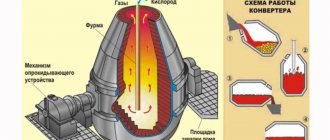

material provided by SIDOROV Alexander Vladimirovich Alloy - a macroscopically homogeneous mixture of two or more chemical elements. Alloys are obtained by: melting - the process of transition of materials from solid to liquid at elevated temperatures; sintering - the process of producing solid and porous materials from small powdery or dusty materials at elevated temperatures; Vapor deposition is a process [...]

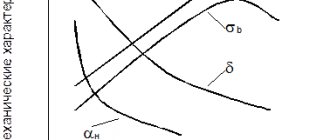

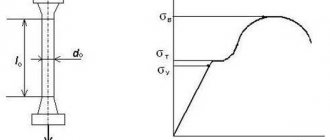

Properties of structural materials

material provided by Alexander Vladimirovich SIDOROV Mechanical properties are determined based on the results of mechanical tests, in which materials are exposed to external (static, dynamic, cyclic) forces that cause stress and deformation. Stress is the magnitude of the load per unit cross-sectional area of the test sample. Deformation is a change in the shape and size of a solid body under the influence of external forces. There are tensile, compressive, bending, [...]

Source of the article: https://eam.su/cvetovaya-markirovka-stalej.html

Marking paints

Type of paint material:

Composition of the paint and varnish material (type of film former PF, GF, EP, etc.):

Free consultation service 8-800-700-59-09 on purchasing paint in small and large wholesale

Online consultations via Viber

Inks for marking are produced with strong coloring power, good spreading, drying in seconds, dense clogging of the printing plate, resistance to light, water, alcohol, acids and alkalis.

Stamp inks are applied with a stamp to rubber products. Produced from a solution of ground pigments in glyphthalic varnish.

For goods that are not exposed to heat, quick-drying marking paints FL-59 are used. To mark tubes made of polyvinyl chloride plastic, black paint MKECH is produced. Mechanically strong paint, with good writing ability and resistance to +90 degrees of heating.

Cadmium-plated steel is marked with ep-572 paint in black, white, red or green.

List of paints and varnishes for product labeling

| Material grade | Material to be marked |

| Paint GF-57 Sh | Rubber |

| Paint KF-513 blue | Aluminum and magnesium alloys |

| Paint MA-514 | Ferrous and non-ferrous metals |

| TNPF paint | Ferrous and non-ferrous metals, plastics; surface painted with enamels of ML, PF, HV, EP, NTs brands |

| Paint FL-59 black | Steel and brass surfaces |

| Enamel NTs-132 | Marking on a surface that was previously painted with EP, ML, GF, PF enamels |

| Enamels PF-115, PF-123 | Marking on wood, which is painted with HS, HV, EP, ML enamels, and GF and PF paints |

| Enamel UR-175 | Surfaces made of ferrous and non-ferrous metals and plastics are marked. The paint is applied to the surface painted with enamels and paints ML, GF, PF |

| Enamel ХВ-16 | Labeling of Wood and Wood Products |

| Enamel EP-572 | For ferrous and non-ferrous metals and plastics on previously applied enamels EP, UR, HV, HS, NTs and paints of the PF and ML brands |

The site developers prepared and checked information material for this site. However, we do not guarantee the accuracy of the data and are not responsible for errors or omissions. We are not liable for damages (including but not limited to damages due to business downtime and/or loss of profits) arising from the use of this site and the information contained therein or the failure to do so, or the actions and decisions taken as a result of the use of this site and this information. Server 4.0

Directory: Steel marking

Steel marking is done with indelible paint, regardless of the steel group and degree of deoxidation. By agreement of the parties, paint marking is not performed. Letters and numbers for steel: Grades of carbon steel of ordinary quality are designated by the letters St and number (StO, St1, StZ, etc.). High-quality carbon steels are marked with two-digit numbers showing the average carbon content in hundredths of a percent: 05; 08; 10; 25; 40, etc. The letter G in the steel grade indicates a high Mn content (14G; 18G, etc.). Automatic steels are marked with the letter A (A12, A30, etc.). Carbon tool steels are marked with the letter U (U8; U10; U12, etc. Here the numbers indicate the steel content in tenths of a percent).

Symbols of the main elements in grades of metals and alloys

| Element | Symbol | Symbols of alloying elements | Density, g/cm3 |

| Nitrogen | N | A | 1,25 |

| Aluminum | A.I. | YU | 2,698 |

| Barium | Ba | — | 3,61 |

| Beryllium | Be | L | 1,86 |

| Bor | B | R | 2,33 |

| Vanadium | V | F | 6,12 |

| Bismuth | Bi | In and | 9,79 |

| Tungsten | W | IN | 19,27 |

| Gadolinium | Gg | — | 7,886 |

| Gallium | Ga | Gl | 5,91 |

| Hafnium | Hf | — | 13,36 |

| Germanium | Ge | — | 19,3 |

| Holmium | Ho | — | 8,799 |

| Dysprosium | Dy | — | 8,559 |

| Europium | Eu | — | 5,24 |

| Iron | Fe | — | 7,87 |

| Gold | Au | — | 19,32 |

| Indium | In | — | 7,3 |

| Iridium | Ir | AND | 22,4 |

| Ytterbium | Yb | — | 6,959 |

| Yttrium | Y | — | 4,472 |

| Cadmium | Cd | Kd | 8,642 |

| Cobalt | Co | TO | 8,85 |

| Silicon | Si | C | 2,326 |

| Lanthanum | La | — | 6,162 |

| Lithium | Li | — | 0,534 |

| Lutetium | Lu | — | 9,849 |

| Magnesium | Mg | — | 1,741 |

| Manganese | Mn | G | 7,43 |

| Copper | Cu | D | 8,96 |

| Molybdenum | Mo | M | 10,22 |

| Neodymium | Nd | — | 7,007 |

| Nickel | Ni | N | 8,91 |

| Niobium | Nb | B | 8,55 |

| Tin | Sn | — | 7,29 |

| Osmium | Os | — | 22,48 |

| Palladium | Pd | — | 12,1 |

| Platinum | Pt | — | 21 |

| Praseodymium | Pr | — | 6,769 |

| Rhenium | Re | — | 21,04 |

| Rhodium | Rh | — | 12,5 |

| Mercury | Hg | — | 13,5 |

| Ruthenium | Ru | 12,3 | |

| Samarium | Sm | — | 7,53 |

| Lead | Pb | — | 11,337 |

| Selenium | Se | E | 4,792 |

| Silver | Ag | — | 10,5 |

| Scandium | Sc | — | 2,99 |

| Antimony | Sb | — | 6,69 |

| Thallium | Tl | — | 11,85 |

| Tantalum | Ta | — | 16,6 |

| Tellurium | Te | — | 6,25 |

| Terbium | Tb | — | 8,253 |

| Titanium | Ti | T | 4,505 |

| Thulium | Tu | — | 9,318 |

| Carbon | C | U | 2,2 |

| Phosphorus | P | P | 1,83 |

| Chromium | Cr | X | 7,2 |

| Cerium | Ce | — | 6,768 |

| Zinc | Zn | — | 7,13 |

| Zirconium | Zr | C | 6,5 |

| Erbium | Er | — | 9,062 |

Marking of rolled metal

Marking of rolled metal products is regulated by GOST 7566-94. However, during the construction process, not everyone wants to understand GOST standards. In addition, all markings, for example, of rebar or steel angles, are listed in the price list. And then you saw strange abbreviations there. To understand which rolled metal product is suitable in each specific case, it is enough to know the rules for reading labeling symbols.

For example, to fence an area with a fence made of corrugated sheets, you must purchase a metal profile of a certain marking. This type of rolled metal product is marked in the form of a set of numbers and letters: for example, 0.7x2000x3000 C9. This combination of characters carries the following information:

- 0.7 mm – thickness;

- 2000 mm – width;

- 3000 mm – length.

Now we can conclude that the profile sheet will have a size of 2 * 3 m and a thickness of 7 mm. The letter indicates the application: C – wall, N – roofing, and NS – mixed type, which is used for various purposes. Any metal warehouse is required to advise you on this matter.

However, you must figure it out yourself so that when purchasing products in the future, you can check whether the appropriate rolled metal alloy was delivered and whether it is marked according to accepted standards. Rolled metal is marked depending on its supply to the market: internal or external.

The World Steel Association has defined “green steel” and its variations

The global steel industry, like the rest of society, is transforming to provide products and services for a future in which emissions of carbon dioxide and other greenhouse gases are significantly reduced. The terminology for carbon footprint reduction is still evolving, and different stakeholders use a variety of expressions that are often synonymous but can mean very different things.

In order to somehow systematize and clarify the meaning of technological transformations in metallurgy, the World Steel Association decided to introduce specific definitions of what is meant by the term “green steel,” carbon-free or low-carbon steel.

Low carbon steel is produced using technologies and methods that result in significantly lower emissions than conventional production. In 2022, most steel will be produced using fossil fuel-based reducing agents; however, many steel producers have implemented or are developing technologies that significantly reduce emissions from the core steelmaking process.

Examples of low carbon steel production:

- Aço Verde do Brasil uses 100% charcoal to produce low carbon iron and steel products.

- ArcelorMittal is building a large-scale plant in Ghent, Belgium, to convert waste gases from steel mills into ethanol, which can be used in a variety of applications, including the production of synthetic fuels. A similar commercial facility began operations in 2022 at Shougang Steel in China, producing 30 million liters of ethanol for sale in its first year of operation.

- At Emirates Steel in the United Arab Emirates, up to 800,000 tonnes of CO2 per year are captured from the gas emissions stream from the iron plant before being injected into an oil field for permanent storage.

- EVRAZ Rocky Mountain Steel in Colorado is switching from coal to solar power. EVRAZ will become the largest single-customer solar power plant in the United States.

- HBIS, a leading steel producer in China, is building a 1.2 million tonne direct reduction iron production demonstration project. The project will use green and blue hydrogen technologies to explore a path to zero CO2 emissions from iron and steel production.

- Nucor's micromill in Sedalia, Missouri, is the first wind-powered steel mill in the United States. The plant is a partnership between a steel company and a local utility that will supply the plant with electricity following a power purchase agreement between the companies.

- Tata Steel is developing new innovative smelting technologies through its HIsarna project. HIsarna's technology allows the production of pig iron without coke ovens or sinter plants, producing a high-CO2 exhaust gas stream ideal for carbon capture and storage (CCS).

- thyssenkrupp Steel and Nippon Steel Corporation have begun a series of trials using hydrogen in an operating blast furnace to significantly reduce CO2 emissions from steelmaking.

Steel produced using all of these technologies can be considered low-carbon steel, although it is likely that what is currently considered low-carbon steel may change by 2050 when regulation, social expectations and technology completely change.

Many other expressions are used within the steel industry and stakeholders to refer to steel produced using these next generation production technologies.

The World Steel Association prefers and uses the term "low carbon steel" because, like "low carbon electricity", it believes it is intuitively easier to understand and its meaning is clear.

Green steel is used and interpreted by many different parties to mean different things, often in the context of marketing new, more environmentally friendly products. The term has been used to cover steel produced using advanced technologies, steel produced from scrap, reused and recovered steel, and conventional steel with emissions offset through carbon credits or permits. Given the inherent lack of clarity and diversity of meaning, "green steel" is not an expression the association would use.

For steel to be truly carbon-free, it must be produced without any CO2 emissions. This is a very high bar, and it is difficult to imagine a manufacturing technology that could achieve this in 2022.

Many may be moving towards this, but zero is absolute and likely unattainable without the use of residual carbon offsets. These residual emissions may arise in the supply chain from the use of carbon-containing electrodes or the use of natural gas in related processes.

Ultimately, steel must contain some carbon as this is what differentiates it from pure iron. Although this important alloying carbon can be obtained from non-fossil sources, its presence renders the term "carbon-free" steel meaningless.

However, if a balance can be achieved between the greenhouse gases released into the atmosphere during steel production and the emissions removed from the atmosphere by sinks, the resulting steel can be called zero-emission steel or carbon neutral steel.

Zero emission steel production may require offsets in other sectors to achieve true neutrality, and it is important that when making carbon neutrality claims, manufacturers are transparent about the boundaries, their accounting methodologies, and the quality and reliability of any offsets used.

Several steel companies are starting to sell fossil-free steel. Fossil-free steel is steel produced without the use of fossil fuels such as coal or natural gas, or energy derived from fossil fuels.

All steel that does not contain fossil hydrocarbons will be low carbon, but not all low carbon steel can be called fossil free. For example, low-carbon steel produced in a plant using carbon capture and storage (CCS) may well use natural gas or coal but avoid emitting CO2 into the atmosphere. If biomass plays a role, it is important to ensure it is sourced responsibly.

Clean steel is a technical expression used in the steel sector to refer to steels with low levels of impurities, oxides, inclusions, or low to ultra-low levels of carbon dissolved in the metal. The phrase is widely used, including by the World Steel Association in its 2004 Clean Steel Study, and means something specific. Thus, worldsteel does not place the terminology of “clean steel” in the context of climate change.

Carbon-free steel is also a difficult expression to describe steel, after all, carbon-free steel is iron, and the carbon content of the steel is precisely controlled to achieve the properties required for a particular batch. Carbon will need to be added to the hydrogen-reduced iron to turn it into steel during the refining process.

Conversations about climate change are often framed in terms of the need to decarbonize society. Worldsteel does not generally use this expression to refer to steel production, since the emissions from steel production must be greenhouse gas/CO2 free, not the process itself.

Many promising breakthrough technologies will continue to use carbon as a chemical reducing agent, but will prevent the release of harmful greenhouse gases into the atmosphere. So while the iron and steel industry's emissions will eventually be decarbonized, the ironmaking process itself may remain the same as it is today.

The revolutionary technology makes it possible to produce low-carbon steel in a completely different way compared to traditional blast furnace, direct reduction or EAF technologies. Examples of breakthrough technologies being developed include hydrogen reduction, CCS applications, iron ore electrolysis, carbon utilization and storage (CCUS) technology suite, and new smelter recovery processes.

Hydrogen is a key vector that will significantly reduce greenhouse gas emissions in the steel industry, and many worldsteel participants are exploring this technology option. Hydrogen is often assigned a color based on its low-carbon characteristics.

When worldsteel talks about low carbon hydrogen, the association means:

Green hydrogen is produced by electrolyzing water using renewable electricity.

Blue hydrogen is produced from natural gas through a steam methane reforming process combined with CCS.

Hydrogen can also be produced by electrolysis using other sources of low-carbon electricity such as nuclear power or CCS. The association also considers it low-carbon.

Fossil hydrogen is produced from fossil fuels, mainly:

Gray hydrogen is produced from natural gas through a non-CCS steam methane reforming process, so the CO2 is released into the atmosphere.

Brown or black hydrogen is produced by gasifying coal and produces significantly higher greenhouse gas emissions than other shades.

Labels for marking rolled metal products

Labels must be firmly attached and easily visible. The material used for manufacturing is reliable and wear-resistant, so that during transportation and unloading they are not damaged or come off. Sometimes, for safety, labels are placed in special pockets.

When packing rolled metal into bundles, markings are placed in 2 places:

- the top sheet or strip of each bundle;

- marking card or label attached to the pack's binding.

When auto-marking thick and strip metal products, the side edge of the top sheet or strip of each bundle can be branded. On the sheets, the marking area is outlined using paint, bitumen or colored varnish. If the customer so requests, the markings are highlighted in a contrasting color, and the labels are perforated 10 mm from the edge for fastening with wire on all types of metal products.

Marking of rolled products in packs or without packaging if the size exceeds 3 cm and thickness exceeds 4 mm must contain:

The marking on the label, the end of the roll or the edge of the metal sheet contains the company name, steel grade, heat number, batch number, all sizes, group or strength class, weight. For reliability and clarity of marking, the label can be metal, wood, plastic or moisture-resistant film; their area must be at least 24 cm2, and the letters must have a height of 5-20 mm and a width of 3-12 mm.

Sometimes it is allowed to deviate from the specified font size when marking with paint. It can reach 1 m in height and 7 cm in width; on rods with a diameter of less than 6 cm and strips with a width of less than 5 cm it can be reduced to 2-4 mm.

The consumer may request additional marking with colored paint; for rolled metal made of mild steel, marking with a longitudinal stripe; for rolled metal made of mild steel, a transverse stripe; marking can occur at a specified font depth. Transport marking is regulated by GOST 14192.

Marking of rolled metal products supplied to the foreign market

Rolled metal supplied abroad is marked:

- In Russian – when delivered to countries that have signed the Agreement on International Freight Transport (SMGS);

- In English – to other foreign countries (if there are no other purchase orders or specification contracts).

Markings are applied:

- From two ends;

- On one longitudinal side (if it is not possible at the ends);

- On the longitudinal side and end (for sheet metal in packages);

- On the top sheet of the pack (if packaging is available);

- On each sheet (on sheet metal that is not subject to packaging);

- On a marking card measuring at least 200*290 mm;

- On a metal label for export (if it is not technically possible to apply markings to the marking card or the metal products themselves).

Labels are hung in the following order:

- For packs up to 6 m – 1 label;

- For packs over 6 m - 2 labels;

- Per skein – 1 label;

- Per roll – 1 label;

- For a bunch of skeins - 2 labels;

- There are 2 labels per stack of rolls;

- There is 1 label per coil of wire rod.

The standards for export labels are also slightly different from the requirements for labels used to mark rolled metal products for domestic sale.

Export labels with a size of at least 80*120 mm and an aspect ratio of 1:1.5 can be produced:

- from tinplate;

- galvanized thin-sheet anti-corrosion metal products;

- moisture-resistant film applied to a solid base of metal or some other dense material.

The export label must contain the following information about the metal product:

- Manufacturer's company name;

- Exporter company name;

- Contract specification;

- Destination country;

- Size of metal products (diameter, thickness, height, width, length, square side, profile number);

- Steel grade;

- Group and strength class;

- Heat and batch number (if there are several batches);

- Net and gross weight in kilograms (you can indicate the approximate weight for rolled metal products with a cross-section of less than 24 mm and not indicate the weight at all for thick sheet metal products supplied individually);

- The batch number in a fraction (may not be indicated for rolled metal products with a cross-section of less than 24 mm and for thick sheet metal products supplied individually).

TECHNICAL REQUIREMENTS

2.1. Reinforcing steel is manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Reinforcing steel is made from carbon and low-alloy steel of the grades indicated in Table 5. The steel grade is indicated by the consumer in the order. If there is no indication, the steel grade is determined by the manufacturer. For class A-IV (A600) rods, steel grades are established by agreement between the manufacturer and the consumer.

| Reinforcing steel class | Profile diameter, mm | steel grade | ||||||||||

| A-I (A240) | 6-40 | St3kp, St3ps, St3sp | ||||||||||

| A-II (A300) | 10-40 | St5sp, St5ps | ||||||||||

| 40-80 | 18G2S | |||||||||||

| Ac-II (Ac300) | 10-32 (36-40) | 10GT | ||||||||||

| A-III (A400) | 6-40 | 35GS, 25G2S | ||||||||||

| 6-22 | 32G2Rps | |||||||||||

| A-IV (A600) | 10-18 (6-8) | 80C | ||||||||||

| 10-32 (36-40) | 20ХГ2Ц | |||||||||||

| A-V (A800) | (6-8) 10-32 (36-40) | 23Х2Г2Т | ||||||||||

| A-VI (A1000) | 10-22 | 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR | ||||||||||

| Notes: 1. It is allowed to manufacture reinforcing steel of class A-V (A800) from steel grades 22Х2Г2АУ, 22Х2Г2Р and 20Х2Г2СС. 2. The dimensions indicated in brackets are manufactured by agreement between the manufacturer and the consumer. (Changed edition, Amendment No. 3, 4). 2.3. The chemical composition of reinforcing carbon steel must comply with GOST 380, low-alloy steel - with the standards given in Table 6. | Manganese | Silicon | Chromium | Titanium | Zirconium | Aluminum | Nickel | Sulfur | Phosphorus | Copper | ||

| no more | ||||||||||||

| 10GT | No more than 0.13 | 1,00-1,40 | 0,45-0,65 | No more than 0.30 | 0,015- 0,035 | — | 0,02- 0,05 | — | 0,040 | 0,030 | 0,30 | |

| 18G2S | 0,14-0,23 | 1,20-1,60 | 0,60-0,90 | — | — | 0,30 | 0,045 | 0,040 | ||||

| 32G2Rps | 0,28-0,37 | 1,30-1,75 | No more than 0.17 | 0,001- 0,015 | 0,050 | 0,045 | ||||||

| 35GS | 0,30-0,37 | 0,80-1,20 | 0,60-0,90 | — | 0,045 | 0,040 | ||||||

| 25G2S | 0,20-0,29 | 1,20-1,60 | ||||||||||

| 20ХГ2Ц | 0,19-0,26 | 1,50-1,90 | 0,40-0,70 | 0,90-1,20 | 0,05-0,14 | 0,045 | ||||||

| 80C | 0,74-0,82 | 0,50-0,90 | 0,60-1,10 | No more than 0.30 | 0,015- 0,040 | — | 0,040 | |||||

| 23Х2Г2Т | 0,19-0,26 | 1,40-1,70 | 0,40-0,70 | 1,35-1,70 | 0,02- 0,08 | 0,015- 0,050 | 0,045 | |||||

| 22Х2Г2АУ | 1,50-2,10 | 0,005- 0,030 | 0,02- 0,07 | 0,040 | 0,040 | |||||||

| 22Х2Г2Р | 1,50-1,90 | 1,50-1,90 | 0,02- 0,08 | 0,015- 0,050 | ||||||||

| 20X2G2SR | 0,16-0,26 | 1,40-1,80 | 0,75-1,55 | 1,40-1,80 | ||||||||

2.3.1. In steel grade 20ХГ2Ц, it is allowed to increase the mass fraction of chromium to 1.7% and replace zirconium with 0.02-0.08% titanium. In steel grade 23Х2Г2Т it is allowed to replace titanium with 0.05-0.10% zirconium. In this case, in the designation of grade 20KhG2Ts steel, the letter T is placed instead of the letter C; grade 23Kh2G2T steel is marked with the letter T instead of the letter T. In grade 32G2Rps steel, aluminum can be replaced with titanium or zirconium in equal units.

2.3.2. The mass fraction of nitrogen in steel grade 22Х2Г2АУ should be 0.015-0.030%, the mass fraction of residual nitrogen in steel grade 10GT should be no more than 0.008%.

2.3.3. The mass fraction of boron in steel grades 22Kh2G2R, 20Kh2G2SR and 32G2Rps should be 0.001-0.007%. In steel grade 22Х2Г2АУ, the addition of 0.001-0.008% boron is allowed.

2.3.4. It is allowed to add titanium to steel grades 18G2S, 25G2S, 35GS based on its mass fraction in finished rolled products of 0.01-0.03%, to steel grade 35GS based on its mass fraction in finished rolled products produced in coils of 0.01-0 .06%.

2.4. Deviations in the chemical composition in finished rolled products from carbon steels - according to GOST 380, from low-alloy steels, subject to compliance with the standards of mechanical properties - according to Table 7. Minus deviations in the content of elements (except for titanium and zirconium, and for steel grade 20Kh2G2SR - silicon) are not limited.

| Elements | Prev. off, % |

| Carbon | +0,020 |

| Silicon | +0,050 |

| Manganese | +0,100 |

| Chromium | +0,050 |

| Copper | +0,050 |

| Sulfur | +0,005 |

| Phosphorus | +0,005 |

| Zirconium | +0,010 -0,020 |

| Titanium | ±0,010 |

| Note. By agreement between the manufacturer and the consumer, steel can be manufactured with other deviations in the content of chromium, silicon and manganese. | |

(Changed edition, Amendment No. 3).

2.5. Reinforcing steel of classes A-I (A240), A-II (A300), A-III (A400), A-IV (A600) is made hot-rolled, class A-V (A800) - with low-temperature tempering, class A-VI ( A1000) - with low-temperature tempering or thermomechanical treatment in the flow of a rolling mill. It is allowed not to carry out low-temperature tempering of steel of classes A-V (A800) and A-VI (A1000) provided that a relative elongation of at least 9% and a uniform elongation of at least 2% are obtained when tested within 12 hours after rolling.

2.6. The mechanical properties of reinforcing steel must comply with the standards specified in Table 8. For steel class A-II (A300) with a diameter of St. 40 mm, it is allowed to reduce the relative elongation by 0.25% for each millimeter increase in diameter, but not more than 3%. For steel class Ac-II (Ac300), a reduction in tensile strength to 426 MPa (43.5 kgf/mm) is allowed with a relative elongation of 30% or more. For steel grade 25G2S class A-III (A400), it is allowed to reduce the tensile strength to 560 MPa (57 kgf/mm) with a yield strength of at least 405 MPa (41 kgf/mm), relative elongation of at least 20%.

| Reinforcing steel class | Yield strength | Tensile strength | Relative extension | Uniform elongation, % | Impact strength at minus 60 °C | Cold bending test (mandrel thickness, rod diameter) | |||

| N/mm | kgf/mm | N/mm | kgf/mm | MJ/m | kgf m/cm | ||||

| no less | |||||||||

| A-I (A240) | 235 | 24 | 373 | 38 | 25 | — | — | — | 180 C |

| A-II (A300) | 295 | 30 | 490 | 50 | 19 | 180°; =3 | |||

| Ac-II (Ac300) | 441 | 45 | 25 | 0,5 | 5 | 180° | |||

| A-III (A400) | 390 | 40 | 590 | 60 | 14 | — | — | 90°; =3 | |

| A-IV (A600) | 590 | 60 | 883 | 90 | 6 | 2 | 45°; =5 | ||

| A-V (A800) | 785 | 80 | 1030 | 105 | 7 | ||||

| A-VI (A1000) | 980 | 100 | 1230 | 125 | 6 | ||||

| Notes: 1. By agreement between the manufacturer and the consumer, it is possible not to test the impact strength of AC-II class reinforcing steel. 2. (Deleted, Amendment No. 3). 3. For reinforcing steel of class A-IV with a diameter of 18 mm and steel grade 80C, the cold bending rate is set to at least 30°. 4. For reinforcing steel class A-I (A240) with a diameter of St. 20 mm when bending in a cold state by 180°, =2, class A-II (A300) with a diameter of St. 20 mm - =4 5. Symbols of the class of reinforcing steel according to the yield strength are indicated in parentheses. | |||||||||

(Changed edition, Amendment No. 1, 3, 5).

2.7. Statistical indicators of the mechanical properties of reinforcing steel bars of periodic profile must correspond to Appendix 1, with increased uniformity of mechanical properties - Appendix 1 and Table 9. The probability of achieving the mechanical properties indicated in Table 8 must be at least 0.95. (Changed edition, Amendment No. 3).

2.8. On the surface of the profile, including the surface of the ribs and protrusions, there should be no rolled cracks, stress cracks, flaws, rolled films or sunsets. Minor damage to the ribs and protrusions is allowed, in the amount of no more than three per 1 m of length, as well as minor rust, individual rolled out stains, prints, sagging, traces of rolled out bubbles, rippling and scaliness within the permissible deviations in size. (Changed edition, Amendment No. 2).

2.9. The weldability of reinforcing steel of all grades, except 80C, is ensured by the chemical composition and manufacturing technology.

2.10. The carbon equivalent for welded rod reinforcement made of low-alloy steel of class A-III (A400) should be no more than 0.62. (Introduced additionally, Amendment No. 5).

| Reinforcing steel class | Profile number | ||||||||

| For | For | For | For | For | For | For | For | ||

| MPa (kgf/mm) | MPa (kgf/mm) | ||||||||

| no more | |||||||||

| A-II (A300) | 10-40 | 29 (3) | 29 (3) | 15 (1,5) | 15 (1,5) | 0,08 | 0,06 | 0,05 | 0,03 |

| A-III (A400) | 6-40 | 39 (4) | 39 (4) | 20 (2,0) | 20 (2,0) | 0,07 | |||

| A-IV (A600) | 10-32 | 69 (7) | 69 (7) | 39 (4,0) | 39 (4,0) | 0,09 | 0,06 | 0,05 | |

| A-V (A800) | 78 (8) | 78 (8) | 49 (5,0) | 49 (5,0) | |||||

| A-VI (A1000) | 88 (9) | 88 (9) | 0,08 | 0,05 | 0,04 | ||||

| Notes: 1. ;- standard deviation in the general population of tests; — standard deviation in batch-smelting; — average value in the population of tests; — the minimum average value in a batch-smelting. 2. For reinforcing steel in coils with a diameter of 6 and 8 mm, it is allowed to increase the standards by 4.9 MPa (0.5 kgf/mm). 3. (Deleted, Amendment No. 5). | |||||||||