Electrochemical corrosion of metals has been one of the pressing problems of humanity since the moment metal products began to be used in the production of various objects necessary for humans. The problem of protecting metals from corrosion has always been acute, because under the influence of destructive oxidation processes, objects lost functionality, became deformed and became unusable, and it was necessary to look for ways to protect them.

When chemistry emerged as a separate science, and the use of metals began to acquire widespread industrial significance, humanity began to explore these processes and look for ways to combat destruction from external influences.

What is corrosion

The process of destruction of the top layer of a metal material under the influence of external influences is called corrosion in the broad sense.

The term corrosion in this case is only a characteristic of the fact that a metal surface enters into a chemical reaction and loses its original properties under its influence.

There are 4 main signs by which you can determine that this process exists:

- a process that develops on the surface and eventually penetrates into the metal product;

- the reaction occurs spontaneously because the stability of the thermodynamic balance between the environment and the system of atoms in the alloy or monolith is disrupted;

- chemistry perceives this process not simply as a destruction reaction, but as a reduction and oxidation reaction: when entering into a reaction, some atoms replace others;

- the properties and characteristics of the metal undergo significant changes during such a reaction, or are lost where it occurs.

Classification of corrosion processes according to the nature of corrosion destruction.

4.1 Contact corrosion.

Contact corrosion occurs when different metals come into contact in the presence of an electrolyte or moist air. In the resulting galvanic couple, the metal with a more electronegative potential becomes the anode and is destroyed first, while the more electropositive metal becomes the cathode.

As an example, consider iron (Figure 4). Zinc, aluminum and cadmium (the latter in a salt environment) are anodes for steel, which means they will be oxidized first, while tin, chromium, copper, lead, nickel are cathodes, which means iron will be subject to deep local corrosion, an example is shown in the figure.

Figure 4 – Examples of contact corrosion on steel.

4.2 Crevice corrosion.

Crevice corrosion

is corrosion that occurs when part of the metal is isolated from the main area by non-metallic material (rubber, wood, plastic, etc.). An example of such corrosion can be observed in pipes at the point of contact with the seal (Figure 5). The formation of a cavity under the seal causes leaks in the pipes. In the presence of such irregularities, the corrosive liquid stagnates in the crack, where rapid corrosion of the metal occurs.

The cause of crevice corrosion is a reduced concentration of oxidizing agents in the gaps compared to the volume of the solution and a slow removal of corrosion products. As a result of their accumulation, the pH of the solution in the gap changes, which also accelerates corrosion.

The metal in the gap and the metal on the open surface form a macropair:

Me - 2e = Me2+ (inside the gap) 0.5O2 + H2O + 2e = 2OH- (on the metal surface)

Since the exposed surface area is much larger than that inside the crevice, the corrosion current density inside the crevice is extremely high.

Figure 5 – Oxygen concentration cell under the seal. As corrosion progresses, excess positive charge accumulates inside the crack. OH- ions rush into the gap to neutralize this charge. As a result, metal hydroxide is deposited on the inner surface of the gap, which further reduces the effective area of the anode.

4.3 Pitting corrosion.

Pitting

are called deep lesions (pinpoint ulcers) on the metal surface (Figure 6). Pitting corrosion, due to its localization and low visibility, is one of the most dangerous types of corrosion damage. Pitting corrosion should not be confused with pitting on nickel coatings.

Since the passivating layer on the metal surface is not a homogeneous system, corrosion occurs due to the presence of anodic and cathodic areas on the surface. In the resulting galvanic couple, the anode is the pitting, and the cathode is the rest of the surface. At the anode, electrons are released, which reduce oxygen on the cathode passivated part of the surface.

Figure 6 – Types of pitting: a – open with a protective layer on the surrounding surface; b – closed, without a surrounding protective layer; c – closed, with a surrounding protective layer. 1 – metal; 2 – solution; 3 – protective layer; 4 – porous corrosion products; 5 – cover over the pitting; 6 – holes in the cover. The development of pitting is facilitated by various types of defects on the surface of the passive film, for example, scratches, chips, pores, and foreign inclusions. Also, for pitting to occur, it is necessary that the solution simultaneously contain pitting corrosion activators (Cl-, Br-, J-, CN-) and metal passivators (OH-, SO42-, NO3-, ClO4-).

4.4 Intergranular corrosion.

Intercrystalline corrosion

arises due to the difference in potentials at the grain boundary and in its matrix (Figure 7).

In air, a carbide phase forms at the grain boundary, which shifts the potential to more electronegative values. Thus, the grain boundary is the anode with respect to their matrix.

This type of corrosion is most dangerous for alloys, since in the place where the more electronegative metal accumulates, an anode will form, and the main one - a cathode. For example, for stainless steels containing chromium, the chromium content near the grain boundaries is lower than on the rest of the surface, which makes them less passivated. As a result, such places become anodes in relation to the grain matrix.

Figure 7 – Intercrystalline corrosion of stainless steel: 1 – cathode; 2 – anode; 3 – carbide phase; 4 – chromium-depleted zone; 5 – grain boundary.

4.5 Fretting corrosion.

Fretting corrosion

occurs between two surfaces that are in continuous contact with each other and undergo small vibrations. The surfaces are never separated from each other, so fragments of corrosion products accumulate at points of mechanical contact.

This corrosion occurs during minor vibrations, cyclic or reciprocating movements with small amplitudes and speeds. Bolts, rivets, hinges, couplings, valves, engine parts, etc. are subject to this corrosion.

4.6 Stress corrosion cracking.

Stress corrosion cracking occurs when a metal product is subjected to tension in a corrosive environment. Then, even at stresses below the fracture stress, cracking occurs, ultimately leading to the destruction of the structure or product.

Corrosion occurs on stretched areas of the metal, since they turn out to be anodes in relation to the unstretched part. This phenomenon is observed on any metals and alloys, as well as in any environment.

4.7 Corrosion fatigue.

Corrosion fatigue occurs due to simultaneous exposure to an aggressive environment and mechanical load.

Corrosion fatigue often causes “unexpected” failure of metal parts, so if a part in a corrosive environment is subject to continuous vibration, its failure will occur at a stress well below the endurance limit.

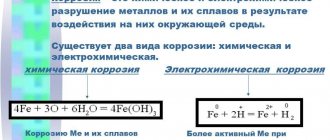

Types of corrosion

Depending on the type of metal and the redox reaction occurring with it, corrosion can be:

- uniform or uneven;

- local and point (individual areas for some reason reacted, while others did not);

- ulcerative, also known as pitting;

- subsurface;

- cracking;

- intercrystalline, occurring along the boundaries of a metal crystal.

Also, depending on what external factors affect the surface, corrosion can be chemical or electrochemical. Chemical corrosion occurs as a result of certain reactions under the influence of chemical interactions, but without the participation of electric current, and can even be inherent in oil and gas. Electrochemical is distinguished by certain processes; it is more complex than chemical.

On video: metal corrosion.

Main objects of corrosion

Inhomogeneous metal areas are randomly located on the surface of the product and depend on the technology and quality of their manufacture, so corrosion damage is often local in nature. In addition, the locality of corrosion depends on heterogeneity:

- protective oxide films;

- electrolyte;

- influence of external factors (heating, irradiation);

- internal stresses causing uneven deformation.

Welded and riveted joints are prominent representatives of the contact of foreign metals subject to active electrochemical corrosion. Welding and riveting are the most common technologies in the construction of permanent joints in all leading industries and large pipeline systems:

- mechanical engineering;

- shipbuilding;

- oil pipelines;

- gas pipelines;

- water pipes.

The most significant damage to welds and rivet joints occurs in sea water, the presence of salt in which significantly accelerates the corrosion process.

A catastrophic situation arose in 1967 with the ore carrier Anatina , when sea water from high storm waves entered the ship’s holds. Copper structures in the interior of the holds and the steel hull contributed to the creation of a corrosive element in the seawater electrolyte. Transient electrochemical corrosion caused softening of the ship's hull and the creation of an emergency situation, leading to the evacuation of the crew.

The positive effect of electrochemical corrosion is very rare. For example, when installing new pipes in hot heating systems of residential buildings. The threaded connections of the couplings begin to flow during the initial start-up until corrosion products consisting of hydrated iron fill the micropores in the threads.

Regardless of the type of corrosion, chemical or electrochemical, its consequences are the same - the destruction of products of enormous value . Moreover, in addition to direct losses from materials that have become unusable, there are indirect losses associated with product leaks, downtime when replacing unusable materials and parts, and violations of technological process regulations.

Causes and signs of electrochemical corrosion

Electrochemical corrosion differs from chemical corrosion in that the destruction process takes place in a system of electrolytes, which causes an electric current to arise within this system. Two coupled processes, anodic and cathodic, lead to the removal of unstable atoms from the crystal lattice of the metal. During the anodic process, the ions go into solution, and the electrons from the anodic process fall into the trap of the oxidizing substance and are bound by the depolarizer.

Thus, depolarization is the removal of free electrons from the cathode sites, and the depolarizer is the substance that is responsible for this process. The main reactions occur with the participation of hydrogen and oxygen as depolarizers.

There are many examples of electrochemical corrosion of various types that affect metal surfaces in nature and are influenced by various conditions. Hydrogen works in an acidic environment, and oxygen in a neutral environment.

Almost all metals are subject to electrochemical corrosion, and on this basis they are divided into 4 groups, and the value of their electrode potential is determined:

- active ones corrode even in an environment where there are no oxidizing agents;

- moderately active ones enter into an oxidation reaction in an acidic environment;

- low-active ones do not react in the absence of oxidizing agents in both neutral and acidic environments;

- do not react - high stability (noble metals, palladium, gold, platinum, iridium).

The most common type of electrochemical corrosion is atmospheric.

But the same reaction can also occur in water, in solutions of bases, salts and acids. In the highly specialized distinction of atmospheric corrosion, a distinction is made between soil and aeration, marine and biological (occurring under the influence of bacteria).

There is even electrical corrosion, which occurs under the influence of electric current, and is the result of stray currents that arise where electric current is used by a person to carry out a certain activity.

The homogeneous metal surface is destroyed due to thermodynamic instability to the environment. And heterogeneous - due to the composition of the crystal lattice, in which atoms of one metal are held together more tightly than atoms of foreign inclusions. These reactions differ in the rate of ionization of ions and the reduction of oxidative components of the environment.

The destruction of metal surfaces during electrochemical corrosion consists of the simultaneous occurrence of two processes: anodic and cathodic, and the differences between the processes are that dissolution occurs on the anodes, which are in contact with the environment through many microelectrodes, which are part of the surface of any metal and are closed to myself.

Typical examples of electrochemical corrosion can be considered the occurrence of corrosion processes on the bottoms of sea vessels or in the atmosphere on metal structures.

Main varieties

During corrosion in electrolytes, chemical energy is converted into electrical energy. In this regard, it is called electrochemical. It is customary to distinguish the following types of electrochemical corrosion.

Intercrystalline

Intergranular corrosion refers to a dangerous phenomenon in which the grain boundaries of nickel, aluminum and other metals are destroyed in a selective manner. As a result, the strength and plastic properties of the material are lost. The main danger of this type of corrosion is that it is not always visually noticeable.

Pitting

Pitting electrochemical corrosion is a point lesion of individual areas of the surface of copper and other metals. Depending on the nature of the lesion, closed, open, and superficial pitting are distinguished. The size of the affected areas can vary from 0.1 mm to 1.5 mm.

Slotted

Crevice electrochemical corrosion is commonly called the intensified process of destruction of metal structures in the locations of cracks, gaps and cracks. Crevice corrosion can occur in air, gas mixtures, and sea water. This type of destruction is typical for gas pipelines, the bottoms of sea vessels and many other objects.

Corrosion occurs in conditions of a small amount of oxidizer due to the difficult approach to the crack walls. This leads to the accumulation of corrosive products inside the gaps. The electrolyte contained in the internal space of the gap can change under the influence of hydrolysis of corrosion products.

In order to protect metals from crevice corrosion, it is common to use several methods:

- sealing gaps and cracks;

- electrochemical protection;

- inhibition process.

As preventive methods, you should use only those materials that are least susceptible to rust, and also initially correctly and rationally design gas pipelines and other important objects.

Competent prevention in many cases is a simpler process than subsequent cleaning of metal structures from ingrained rust.

The need for anti-corrosion protection

Protecting metal from influences that have a destructive effect on its surface is one of the main tasks facing those people who work with mechanisms, units and machines, ships and construction processes.

Any metal, except noble ones, to one degree or another, is exposed to destructive processes.

The more actively a device or part is used, the more likely it is to be subject to the destructive effects of atmospheric conditions and liquids that are encountered during operation. Many branches of science and industrial production are working to protect metal from corrosion, but the main methods remain unchanged and consist of creating protective coatings:

- metal;

- non-metallic;

- chemical

Non-metallic coatings are created using organic and inorganic compounds; their operating principle is quite effective and differs from other types of protection. To create non-metallic protection in industrial and construction production, paint and varnish compositions, concrete and bitumen and high-molecular compounds are used, especially actively adopted in recent years, when polymer chemistry has reached great heights.

Chemistry has contributed to the creation of protective coatings using methods:

- oxidation (creating a protective film on metal using oxide films);

- phosphating (phosphate films);

- nitriding (saturation of the steel surface with nitrogen);

- cementation (combination with carbon);

- bluing (compounds with organic substances);

- changing the composition of the metal by introducing anti-corrosion additives into it);

- modification of the surrounding corrosive environment by introducing inhibitors that affect it.

Electrochemical corrosion protection is the reverse process of electrochemical corrosion. Depending on the shift of the metal potential to the positive or negative side, anodic and cathodic protection are distinguished. By connecting a protector or a direct current source to a metal product, cathodic polarization is created on the metal surface, which prevents the destruction of the metal through the anode.

Electrochemical protection methods consist of two options:

- the metal coating is protected by another metal that has a more negative potential (that is, the protecting metal is less stable than the protected one), and this is called an anodic coating;

- the coating is applied from a less active metal, and then it is called cathode.

Anodic corrosion protection is, for example, galvanized iron. Until all the zinc from the protective layer is used up, the iron will be relatively safe.

Cathodic protection is nickel plating or copper plating. In this case, the destruction of the protective layer also leads to the destruction of the layer that it protects. Attaching a protector to protect a metal product is no different from the reaction in other cases. The protector acts as an anode, and what is under its protectorate remains safe, using the conditions created for it.

Cathodic protection

The principle of cathodic protection can be implemented in one of two ways. The first is that the supply of negative potential can come from a special source of electricity called a cathodic protection station.

When using cathode stations, the following problem may arise.

Electricity to set the required potential is often supplied through a long cable. This cable is susceptible to lightning and certain other electromagnetic influences. To ensure that overvoltage does not occur as a result, it is recommended to use a comprehensive ZANDZ solution.

Methods for protecting metal

Electrochemical corrosion is one of the main obstacles encountered in the path of human activity. Protection from the effects of destructive processes and their occurrence on the surfaces of structures and structures is one of the permanent and urgent tasks of any industrial production, and any everyday human activity.

Several methods of such protection have been developed, and all of them are actively used in the daily life cycle:

- Electrochemical protection is an electrolytic operating principle using chemical laws that protects metal using the anodic, cathodic and sacrificial principles.

- Electric spark processing using various installations - non-contact, contact, anodic-mechanical.

- Electric arc spraying is the main advantage in the thickness of the applied layer and the relative cheapness of the process.

- Effective anti-corrosion treatment involves removing contaminants and cleaning the surface being treated, followed by applying first an anti-corrosion layer and then an additional protective layer to the surface.

All these methods have been developed in the process of human activity in order to protect tools, means of transportation and transportation at the junction of several industrial sectors, and using scientific achievements.

Electrochemical corrosion, which is a natural process of destruction of a metal surface under the influence of neutral or aggressive environmental factors, is a complex problem. Machine-building, transport, industrial enterprises and means of transportation suffer losses from it. And this is a problem that requires daily resolution.

More about corrosion and its processes (1 video)

Different types of corrosion (19 photos)

Technical progress in the development of corrosion control methods

Since the loss of metal from corrosion is astronomical, technological progress continues to offer new methods of combating it as research advances and hardware improves . These include:

- thermal spraying, forming ultra-thin protective coatings;

- thermal diffusion coatings that create durable surface protection;

- cadmium plating, which protects steel in sea water.

The growth of industrial production occurs with a constant increase in the production of metal products. Electrochemical corrosion, regardless of the historical era, poses a constant threat to a huge number of structures and critical structures. Therefore, the creation of new methods and means of struggle is one of the tasks of research into technological progress.

Corrosion by stray currents (electrocorrosion) and protection

Atmospheric corrosion

Atmospheric corrosion is the corrosion of metals under the conditions of the earth’s atmosphere (in humid air and ambient temperature). It is the most common. It has a number of specific features. The corrosive medium (electrolyte) is water, which contains atmospheric oxygen (oxidizing agent), atmospheric gases, and dust. Water appears on the surface of the metal either immediately after precipitation or as a result of condensation. Air humidity plays a decisive role here. There are three cases: wet corrosion, wet and dry.

At relative humidity close to 100%, as a result of condensation, as well as precipitation, a visible layer of water or water droplets forms on the surface. This is a case of wet corrosion.

At an air humidity of 60–70%, an invisible adsorption film of water (of the order of several molecular layers) appears on the surface - wet corrosion.

When humidity is less than 60% there is no water on the surface - dry corrosion. Let us immediately note that it is of a chemical nature (see below). When reacting with oxygen, a protective oxide film is formed on the surface of metals (the metal only becomes dull). The rate of chemical atmospheric corrosion is low (due to low temperatures) compared to other types. She does not play a significant role.

When the surface is wet (electrolyte appears), the corrosion rate is already significant. Corrosion in this case is electrochemical in nature. Let us consider reactions during atmospheric corrosion of iron with oxygen depolarization

(–) A Fe | H2O, O2 | Fe (O2) K(+)

А(–) Fe– 2ē→ Fe2+

K(+) O2 + 4ē + 2H2O → 4OH-

___________________________

2Fe + O2+ 2H2O = 2Fe(OH)2.

The primary corrosion product Fe(OH)2 is light greenish in color and is unstable and quickly oxidizes to brownish Fe(OH)3

4Fe(OH)2 + O2+ 2H2O = 4Fe(OH)3

and then turns into rust - a hydrate of iron oxides of variable composition x

FeО

·y

Fe2О3

·z

Н2О.

In cases of wet corrosion, when oxygen easily penetrates the water film, the process is controlled by the anodic reaction and the ohmic component

environment. During wet corrosion, cathodic inhibition is observed, since the access of oxygen through thickened films is difficult.

Next, we will consider the main specific factors that increase the rate of atmospheric corrosion.

1. Increase in atmospheric humidity. As already noted, the increase

humidity above 60% leads to water condensation and, consequently, to increased corrosion. Humidity is affected by the weather factor. At certain times of the year, the duration and number of wetting cycles increases. In autumn (during a rainier period), corrosion is more intense than in summer. In winter, at subzero temperatures, there is no liquid water on surfaces at all and corrosion can be neglected.

2. Temperature can have two effects. At high humidity

(for example, during the rainy season in tropical areas), increased temperature significantly accelerates corrosion. When moving from negative to positive temperatures in spring, corrosion increases. But often an increase in temperature inhibits corrosion: air humidity drops, the surface of metals dries out, and the solubility of oxygen in water decreases.

3. Air pollution with various gases has a significant impact

mi, dust, smoke. This changes the composition of the wet film on the surface and accelerates corrosion tenfold. The most aggressive gases: SO2, NO2, HCl, H2S. When dissolved in water, they create an acidic environment that destroys protective films. Hydrogen sulfide H2S is dangerous for silver (electrical engineering). Ammonia NH3 in water produces an alkaline environment (dangerous for aluminum, zinc, lead, tin) and a good complexing agent (dangerous for copper). In coastal marine areas, the air contains aggressive salt chlorides. Dust settling on the surface promotes condensation and moisture retention. Clean, moist air is not so dangerous. Thus, if in a relatively clean atmosphere of rural areas the corrosion rate of conventional steels is about 0.1–0.15 mm/year, then in a highly polluted industrial atmosphere it is 0.45–0.5 mm/year.

On average, the rate of atmospheric corrosion in urban conditions for various metals is, in increasing order, in mm/year: 0.004 Pb; 0.008 Al; 0.012 Cu and Sn; 0.05 Zn; 0.2 Fe. Interestingly, the surface of copper in the presence of atmospheric CO2 and water can become covered with a greenish coating of basic carbonate (CuOH)2CO3. The most resistant metals in air include Ti, a number of rare metals (due to protective oxide films) and noble metals. But, silver darkens a little (copper does the same) in the presence of hydrogen sulfide

4Ag + O2 + 2H2S = 2Ag2S (black) + 2H2O.

Soil corrosion

It occurs in the soil and ground (soil under the soil and does not contain organic matter). It affects pipelines, piles, tanks, supports, etc. Corrosion is electrochemical in nature. Its mechanism is the same as during atmospheric corrosion (in the case of low humidity), or in electrolytes.

The rate of corrosion of metals depends on humidity, composition, pH and porosity of the soil, and the presence of microorganisms. Based on their aggressiveness, soils are divided into several types. Maximum corrosion occurs at humidity levels of 15–25%. The access of oxygen is more difficult due to the saturation of the soil with water. Soil mineralization varies widely - from 10 to 300 mg/l of different salts. Both factors, as well as the particle size distribution, determine the ohmic resistance of the soil. The lower the resistance, the more aggressive the soil (Table 2.2).

Table 2.2

Soil resistivity and its corrosiveness

| Specific resistance, Ohm m | <5 | 5-10 | 10-20 | 20-100 | >100 | |

| Soil aggressiveness | Particularly high | High | Increased | Average | Low |

Acidic marshy and humus soils with pH = 3–6 are highly aggressive. Here the oxidizing agent is both H+ and O2. There are also alkaline soils - loams and saline soils with pH = 7.5–9.5, with oxygen as an oxidizing agent. Most soils have a pH value of 6–7.5. The air permeability of soils is of great importance: the higher it is, the greater the corrosion. For this reason, sandy soils are often more aggressive than clay soils. When there is a combination of sandy and clayey areas, differential aeration is very dangerous. In some cases, the anodic and cathodic sites may be located far from each other. Thus, on pipes (Fig. 2.13) at a distance of up to 2 km, macrogalvanic elements with a potential difference of 0.5 V can appear, leading to significant pitting.

Rice. 2.13. Schematic of a corrosion macrovoltaic cell

underground pipeline with different oxygen access

Where the access of oxygen is facilitated (sand area) there is a cathodic area, where it is difficult (clay) there is an anodic area. Pile corrosion taking into account groundwater is shown in Fig. 2.14.

Rice. 2.14. Corrosion of a steel pile in the ground: 1

– top layer of soil with a high oxygen content;

2

– cathode section of the pile;

3

– ground level

waste water; 4

– anodic area with corrosion products

And in general, due to insufficient oxygen supply, soil corrosion is local in nature. This leads to through-hole rusting in areas of ulcers and pitting.

Corrosion by stray currents (electrocorrosion) and protection

It is distinguished as a separate species due to its specificity. Occurs in the ground when leakage currents flow from DC

current: near electrified railways (the most dangerous), tram lines, electrolysis plants and even welding plants.

When an electric locomotive passes, part of the rail current flows (branches) into the ground due to incomplete insulation (Fig. 2.15).

Rice. 2.15. The occurrence of stray currents near railways

If there are metal structures (pipe, etc.) in the zone of stray currents, they become part of the circuit and are subject to corrosion (often increased). The exact pattern of leakage currents is complex and depends on a number of factors: contamination and moisture content of the embankment ballast; electrical conductivity of the earth itself (sometimes currents spread many kilometers from the road); the remoteness of the traction substation, where the current ultimately returns (on tram lines, traction substations are located close to each other, and leakage currents are not as high as on railways); locomotive power; the ability to change the direction of movement; movement of the anode and cathode zones, etc. Moreover, we can assume that electrolysis occurs due to the external current,

hence electrocorrosion. Simplifying somewhat, we can give the following basic picture of the processes.

Anodic zones with a more positive potential (in normal corrosion the anode is more negative than the cathode) are the drainage points on the rail

current into the ground, and on the pipe where

the current exits

back into the rail

A(+) Fe– 2ē→ Fe2+.

And vice versa, the cathode zones for the rail are the exit of current from the ground and for the pipe – the entry of current into the pipe with two main reactions

K(–) 2H2O + 2ē → H2+ 2OH-

O2+ 4ē + 2H2O → 4OH-.

The central part of the pipe constitutes the neutral zone. For the railway itself, electrocorrosion is most intensely observed in tunnels where there is no ventilation of the track from moisture. Thus, the main reason for replacing rails in tunnels is electrocorrosion of the rail base.

The main thing to reduce electrocorrosion is to combat current leakages: maintaining ballast in good condition and draining water from it; cleaning gaps between ballast and rails; electrical insulation of rails with non-electrically conductive gaskets from the canvas and sleepers; increased conductivity of joints (good condition of butt current connectors, tightening of bolts); use of seamless track; reducing the distance between traction substations.

Electric drainage is used to protect structures near roads. Corrosion can be virtually eliminated by connecting them with a wire to the rail. Then the current will flow not through the ground and the same pipe, but through the conductor back into the rail. To prevent the direction of the current from affecting the protection, valves - diodes - are installed in the drainage circuit. In general, drainage is a rather complex technical solution. Other methods of protection can be used: cathode stations (see below), when the protected structure is located at a great distance from the road (over 1 km); or protectors.

2.9. Biocorrosion and protection

This is the corrosion of metals under the influence of microorganisms and their metabolic products. It is not bacteria as such that are dangerous, but their metabolic products. Microorganisms are capable of producing not only organic acids - formic, acetic, citric, oxalic, but also strong inorganic acids - sulfuric, nitric.

There are aerobic and anaerobic

microorganisms whose effects on metals are different.

Aerobic cells develop only in the presence of oxygen. They are divided into thionic, nitrifying and iron bacteria.

Thionic acids first oxidize sulfur compounds from the soil (sulfides, for example, FeS2) to sulfuric acid, and then more ferric ions appear: FeS2 + O2 + H2O → H2SO4 + FeSO4+ O2 → Fe2(SO4)3.

Both H2SO4 and Fe2(SO4)3 further oxidize metals. There is a well-known example of the influence of biocorrosion during the construction of the Kyiv metro. Groundwater became acidified with sulfuric acid and steel structures upon contact with it collapsed by 40% in four months.

Nitrifying bacteria oxidize ammonia from air and water to aggressive nitric acid: NH3 + O2 + H2O → HNO3.

Iron bacteria love to settle in pipes (in places of unevenness) with running water. By forming clusters, they cause oxygen differential aeration during electrochemical corrosion, followed by the oxidation of divalent iron to trivalent: Fe + O2 → Fe2++O2→ Fe3++Fe→ Fe2+, etc.

In deep soil, with low or no oxygen concentrations, anaerobic bacteria can grow. They are capable of reducing sulfate ions in a slightly acidic environment: Fe + SO42-+ H+ → Fe2+ + FeS + H 2S + H2O.

Methods of protection against biocorrosion include the following. Application of paint and varnish coatings with bactericidal (biocide) additives. Maintaining optimal external conditions as much as possible: humidity no more than 80%, temperature no more than 20°C. Availability of good ventilation. Removing contaminants (nutrient medium) from surfaces. If necessary, use electrochemical protection (sacrificial or cathodic).

Contact corrosion

If metals with different potentials are in contact in the electrolyte (a difference of more than 0.25 V), then their corrosion rate changes significantly compared to the absence of contact. Obviously, the more negative metal will be the anode and its speed will increase, and the positive metal will be the cathode and its corrosion will decrease or stop. Increased corrosion of some metals in contact with others is usually called contact corrosion.

Many structures, machines, and devices cannot be built from one metal. Coatings with other metals, welded or soldered joints, bolts, etc. will always be available. And the prefabricated structures themselves include the use of different alloys. In these cases, mistakes should not be made.

Here are examples of errors. The first is historical - from the time of the sailing fleet. At a certain point, English ships gained an advantage in speed over French sailing ships. The wooden bottoms of English ships began to be sheathed with copper sheets. But after some time, sheets of expensive copper began to fall off into the sea. The reason is that the copper was fastened with iron nails, which quickly anodicly corroded. It is clear that they need to be replaced with copper ones. There were some nasty mistakes in rocket science (60s). For example, bearings made of brass and steel quickly failed. I had to chrome plate all the parts in the bearings. Or a number of examples without direct contact of metals. Steel and aluminum tanks for heating solutions corroded unexpectedly quickly. It turned out that the coils in them were copper (but, we emphasize, without direct contact). A small amount of copper ions from the coils entered the solution. Then they were reduced on the surface of the tanks: Cu2+ +Al(Fe) → Cu + Al3+(Fe2+). Microgalvanic cells (with a Cu cathode) were formed with further increased corrosion of the tanks. Another example. Titanium sheets were covered with a coating of rust?! It turned out that they were subjected to surface cleaning with steel shot. Traces of steel remained in the titanium and rusted.

Do not connect copper wire directly to aluminum wire outdoors. At the point of contact, aluminum will become an anode and will begin to oxidize when moisture enters. Over time, conductivity will be impaired. It is not advisable to place a steel bolt (anode) on copper. Corrosion products may not allow it to be easily dismantled.

Let us consider the compatibility of the most important practical contact pairs of metals during atmospheric corrosion.

Al-steel, Al-Ti in most cases contact is allowed (aluminum is protected by an oxide film), except for sea air. Al-Zn, Al-Cd, Al-Pb are well compatible. Al-Cu cannot be used, even with anodized aluminum. Fe- Not a dangerous pair for the first time. Fe-stainless steel, Fe-Cu are undesirable pairs (especially in marine conditions). Fe-Pb, Pb-Cu are highly compatible.

If contact cannot be avoided, then the points of contact must be insulated: with varnishes, lubricants, mastics, polymer gaskets (plastic washers for bolts). Electrical contacts use an intermediate metal: steel is sandwiched between aluminum and copper.

Atmospheric corrosion

Atmospheric corrosion is the corrosion of metals under the conditions of the earth’s atmosphere (in humid air and ambient temperature). It is the most common. It has a number of specific features. The corrosive medium (electrolyte) is water, which contains atmospheric oxygen (oxidizing agent), atmospheric gases, and dust. Water appears on the surface of the metal either immediately after precipitation or as a result of condensation. Air humidity plays a decisive role here. There are three cases: wet corrosion, wet and dry.

At relative humidity close to 100%, as a result of condensation, as well as precipitation, a visible layer of water or water droplets forms on the surface. This is a case of wet corrosion.

At an air humidity of 60–70%, an invisible adsorption film of water (of the order of several molecular layers) appears on the surface - wet corrosion.

When humidity is less than 60% there is no water on the surface - dry corrosion. Let us immediately note that it is of a chemical nature (see below). When reacting with oxygen, a protective oxide film is formed on the surface of metals (the metal only becomes dull). The rate of chemical atmospheric corrosion is low (due to low temperatures) compared to other types. She does not play a significant role.

When the surface is wet (electrolyte appears), the corrosion rate is already significant. Corrosion in this case is electrochemical in nature. Let us consider reactions during atmospheric corrosion of iron with oxygen depolarization

(–) A Fe | H2O, O2 | Fe (O2) K(+)

А(–) Fe– 2ē→ Fe2+

K(+) O2 + 4ē + 2H2O → 4OH-

___________________________

2Fe + O2+ 2H2O = 2Fe(OH)2.

The primary corrosion product Fe(OH)2 is light greenish in color and is unstable and quickly oxidizes to brownish Fe(OH)3

4Fe(OH)2 + O2+ 2H2O = 4Fe(OH)3

and then turns into rust - a hydrate of iron oxides of variable composition x

FeО

·y

Fe2О3

·z

Н2О.

In cases of wet corrosion, when oxygen easily penetrates the water film, the process is controlled by the anodic reaction and the ohmic component

environment. During wet corrosion, cathodic inhibition is observed, since the access of oxygen through thickened films is difficult.

Next, we will consider the main specific factors that increase the rate of atmospheric corrosion.

1. Increase in atmospheric humidity. As already noted, the increase

humidity above 60% leads to water condensation and, consequently, to increased corrosion. Humidity is affected by the weather factor. At certain times of the year, the duration and number of wetting cycles increases. In autumn (during a rainier period), corrosion is more intense than in summer. In winter, at subzero temperatures, there is no liquid water on surfaces at all and corrosion can be neglected.

2. Temperature can have two effects. At high humidity

(for example, during the rainy season in tropical areas), increased temperature significantly accelerates corrosion. When moving from negative to positive temperatures in spring, corrosion increases. But often an increase in temperature inhibits corrosion: air humidity drops, the surface of metals dries out, and the solubility of oxygen in water decreases.

3. Air pollution with various gases has a significant impact

mi, dust, smoke. This changes the composition of the wet film on the surface and accelerates corrosion tenfold. The most aggressive gases: SO2, NO2, HCl, H2S. When dissolved in water, they create an acidic environment that destroys protective films. Hydrogen sulfide H2S is dangerous for silver (electrical engineering). Ammonia NH3 in water produces an alkaline environment (dangerous for aluminum, zinc, lead, tin) and a good complexing agent (dangerous for copper). In coastal marine areas, the air contains aggressive salt chlorides. Dust settling on the surface promotes condensation and moisture retention. Clean, moist air is not so dangerous. Thus, if in a relatively clean atmosphere of rural areas the corrosion rate of conventional steels is about 0.1–0.15 mm/year, then in a highly polluted industrial atmosphere it is 0.45–0.5 mm/year.

On average, the rate of atmospheric corrosion in urban conditions for various metals is, in increasing order, in mm/year: 0.004 Pb; 0.008 Al; 0.012 Cu and Sn; 0.05 Zn; 0.2 Fe. Interestingly, the surface of copper in the presence of atmospheric CO2 and water can become covered with a greenish coating of basic carbonate (CuOH)2CO3. The most resistant metals in air include Ti, a number of rare metals (due to protective oxide films) and noble metals. But, silver darkens a little (copper does the same) in the presence of hydrogen sulfide

4Ag + O2 + 2H2S = 2Ag2S (black) + 2H2O.

Soil corrosion

It occurs in the soil and ground (soil under the soil and does not contain organic matter). It affects pipelines, piles, tanks, supports, etc. Corrosion is electrochemical in nature. Its mechanism is the same as during atmospheric corrosion (in the case of low humidity), or in electrolytes.

The rate of corrosion of metals depends on humidity, composition, pH and porosity of the soil, and the presence of microorganisms. Based on their aggressiveness, soils are divided into several types. Maximum corrosion occurs at humidity levels of 15–25%. The access of oxygen is more difficult due to the saturation of the soil with water. Soil mineralization varies widely - from 10 to 300 mg/l of different salts. Both factors, as well as the particle size distribution, determine the ohmic resistance of the soil. The lower the resistance, the more aggressive the soil (Table 2.2).

Table 2.2

Soil resistivity and its corrosiveness

| Specific resistance, Ohm m | <5 | 5-10 | 10-20 | 20-100 | >100 | |

| Soil aggressiveness | Particularly high | High | Increased | Average | Low |

Acidic marshy and humus soils with pH = 3–6 are highly aggressive. Here the oxidizing agent is both H+ and O2. There are also alkaline soils - loams and saline soils with pH = 7.5–9.5, with oxygen as an oxidizing agent. Most soils have a pH value of 6–7.5. The air permeability of soils is of great importance: the higher it is, the greater the corrosion. For this reason, sandy soils are often more aggressive than clay soils. When there is a combination of sandy and clayey areas, differential aeration is very dangerous. In some cases, the anodic and cathodic sites may be located far from each other. Thus, on pipes (Fig. 2.13) at a distance of up to 2 km, macrogalvanic elements with a potential difference of 0.5 V can appear, leading to significant pitting.

Rice. 2.13. Schematic of a corrosion macrovoltaic cell

underground pipeline with different oxygen access

Where the access of oxygen is facilitated (sand area) there is a cathodic area, where it is difficult (clay) there is an anodic area. Pile corrosion taking into account groundwater is shown in Fig. 2.14.

Rice. 2.14. Corrosion of a steel pile in the ground: 1

– top layer of soil with a high oxygen content;

2

– cathode section of the pile;

3

– ground level

waste water; 4

– anodic area with corrosion products

And in general, due to insufficient oxygen supply, soil corrosion is local in nature. This leads to through-hole rusting in areas of ulcers and pitting.

Corrosion by stray currents (electrocorrosion) and protection

It is distinguished as a separate species due to its specificity. Occurs in the ground when leakage currents flow from DC

current: near electrified railways (the most dangerous), tram lines, electrolysis plants and even welding plants.

When an electric locomotive passes, part of the rail current flows (branches) into the ground due to incomplete insulation (Fig. 2.15).

Rice. 2.15. The occurrence of stray currents near railways

If there are metal structures (pipe, etc.) in the zone of stray currents, they become part of the circuit and are subject to corrosion (often increased). The exact pattern of leakage currents is complex and depends on a number of factors: contamination and moisture content of the embankment ballast; electrical conductivity of the earth itself (sometimes currents spread many kilometers from the road); the remoteness of the traction substation, where the current ultimately returns (on tram lines, traction substations are located close to each other, and leakage currents are not as high as on railways); locomotive power; the ability to change the direction of movement; movement of the anode and cathode zones, etc. Moreover, we can assume that electrolysis occurs due to the external current,

hence electrocorrosion. Simplifying somewhat, we can give the following basic picture of the processes.

Anodic zones with a more positive potential (in normal corrosion the anode is more negative than the cathode) are the drainage points on the rail

current into the ground, and on the pipe where

the current exits

back into the rail

A(+) Fe– 2ē→ Fe2+.

And vice versa, the cathode zones for the rail are the exit of current from the ground and for the pipe – the entry of current into the pipe with two main reactions

K(–) 2H2O + 2ē → H2+ 2OH-

O2+ 4ē + 2H2O → 4OH-.

The central part of the pipe constitutes the neutral zone. For the railway itself, electrocorrosion is most intensely observed in tunnels where there is no ventilation of the track from moisture. Thus, the main reason for replacing rails in tunnels is electrocorrosion of the rail base.

The main thing to reduce electrocorrosion is to combat current leakages: maintaining ballast in good condition and draining water from it; cleaning gaps between ballast and rails; electrical insulation of rails with non-electrically conductive gaskets from the canvas and sleepers; increased conductivity of joints (good condition of butt current connectors, tightening of bolts); use of seamless track; reducing the distance between traction substations.

Electric drainage is used to protect structures near roads. Corrosion can be virtually eliminated by connecting them with a wire to the rail. Then the current will flow not through the ground and the same pipe, but through the conductor back into the rail. To prevent the direction of the current from affecting the protection, valves - diodes - are installed in the drainage circuit. In general, drainage is a rather complex technical solution. Other methods of protection can be used: cathode stations (see below), when the protected structure is located at a great distance from the road (over 1 km); or protectors.

2.9. Biocorrosion and protection

This is the corrosion of metals under the influence of microorganisms and their metabolic products. It is not bacteria as such that are dangerous, but their metabolic products. Microorganisms are capable of producing not only organic acids - formic, acetic, citric, oxalic, but also strong inorganic acids - sulfuric, nitric.

There are aerobic and anaerobic

microorganisms whose effects on metals are different.

Aerobic cells develop only in the presence of oxygen. They are divided into thionic, nitrifying and iron bacteria.

Thionic acids first oxidize sulfur compounds from the soil (sulfides, for example, FeS2) to sulfuric acid, and then more ferric ions appear: FeS2 + O2 + H2O → H2SO4 + FeSO4+ O2 → Fe2(SO4)3.

Both H2SO4 and Fe2(SO4)3 further oxidize metals. There is a well-known example of the influence of biocorrosion during the construction of the Kyiv metro. Groundwater became acidified with sulfuric acid and steel structures upon contact with it collapsed by 40% in four months.

Nitrifying bacteria oxidize ammonia from air and water to aggressive nitric acid: NH3 + O2 + H2O → HNO3.

Iron bacteria love to settle in pipes (in places of unevenness) with running water. By forming clusters, they cause oxygen differential aeration during electrochemical corrosion, followed by the oxidation of divalent iron to trivalent: Fe + O2 → Fe2++O2→ Fe3++Fe→ Fe2+, etc.

In deep soil, with low or no oxygen concentrations, anaerobic bacteria can grow. They are capable of reducing sulfate ions in a slightly acidic environment: Fe + SO42-+ H+ → Fe2+ + FeS + H 2S + H2O.

Methods of protection against biocorrosion include the following. Application of paint and varnish coatings with bactericidal (biocide) additives. Maintaining optimal external conditions as much as possible: humidity no more than 80%, temperature no more than 20°C. Availability of good ventilation. Removing contaminants (nutrient medium) from surfaces. If necessary, use electrochemical protection (sacrificial or cathodic).

Contact corrosion

If metals with different potentials are in contact in the electrolyte (a difference of more than 0.25 V), then their corrosion rate changes significantly compared to the absence of contact. Obviously, the more negative metal will be the anode and its speed will increase, and the positive metal will be the cathode and its corrosion will decrease or stop. Increased corrosion of some metals in contact with others is usually called contact corrosion.

Many structures, machines, and devices cannot be built from one metal. Coatings with other metals, welded or soldered joints, bolts, etc. will always be available. And the prefabricated structures themselves include the use of different alloys. In these cases, mistakes should not be made.

Here are examples of errors. The first is historical - from the time of the sailing fleet. At a certain point, English ships gained an advantage in speed over French sailing ships. The wooden bottoms of English ships began to be sheathed with copper sheets. But after some time, sheets of expensive copper began to fall off into the sea. The reason is that the copper was fastened with iron nails, which quickly anodicly corroded. It is clear that they need to be replaced with copper ones. There were some nasty mistakes in rocket science (60s). For example, bearings made of brass and steel quickly failed. I had to chrome plate all the parts in the bearings. Or a number of examples without direct contact of metals. Steel and aluminum tanks for heating solutions corroded unexpectedly quickly. It turned out that the coils in them were copper (but, we emphasize, without direct contact). A small amount of copper ions from the coils entered the solution. Then they were reduced on the surface of the tanks: Cu2+ +Al(Fe) → Cu + Al3+(Fe2+). Microgalvanic cells (with a Cu cathode) were formed with further increased corrosion of the tanks. Another example. Titanium sheets were covered with a coating of rust?! It turned out that they were subjected to surface cleaning with steel shot. Traces of steel remained in the titanium and rusted.

Do not connect copper wire directly to aluminum wire outdoors. At the point of contact, aluminum will become an anode and will begin to oxidize when moisture enters. Over time, conductivity will be impaired. It is not advisable to place a steel bolt (anode) on copper. Corrosion products may not allow it to be easily dismantled.

Let us consider the compatibility of the most important practical contact pairs of metals during atmospheric corrosion.

Al-steel, Al-Ti in most cases contact is allowed (aluminum is protected by an oxide film), except for sea air. Al-Zn, Al-Cd, Al-Pb are well compatible. Al-Cu cannot be used, even with anodized aluminum. Fe- Not a dangerous pair for the first time. Fe-stainless steel, Fe-Cu are undesirable pairs (especially in marine conditions). Fe-Pb, Pb-Cu are highly compatible.

If contact cannot be avoided, then the points of contact must be insulated: with varnishes, lubricants, mastics, polymer gaskets (plastic washers for bolts). Electrical contacts use an intermediate metal: steel is sandwiched between aluminum and copper.