Post updated: May 25, 2020

Products made from gold alloys of various grades are used not only as jewelry; parts made from precious metals are also actively used in industry. The use of pure gold in these cases is usually not economically justified; most often, only an external gold coating is required, which gives the element the necessary properties. Surface gilding is one of the main galvanic processes in jewelry, which allows giving the product the required decorative or technical characteristics. How is electroplated gold produced?

What is gilding

Gold plating is a thin layer of gold that can hide almost any material. Its thickness can be from 1 to 20-25 microns, and the object becomes practically indistinguishable from gold. The method is used not only in jewelry, but also in architecture, design and even cosmetology.

Brief history of appearance

The art of gilding luxury items first appeared several thousand years ago in Ancient Egypt. It was he who became the first country in which gold mining took on an industrial scale. Since all the mines belonged to the pharaoh, it is not surprising that household items of the ruling family were the first to be gilded.

There is an alternative version that claims that the practice of gold plating originated in China. However, a simple comparison of historical facts speaks in favor of Egypt. The gold-plated sarcophagi of the Egyptian pharaohs date back more than 5,000 years, while in Lao Tang (the province of China considered the birthplace of gilding), thin gold plates have only been produced for about 2 millennia.

The art of gilding, having passed through the Middle East and reached Ancient Rus', received a significant impetus for development and reached a completely new level. It was in Rus' that gold became not just a sign of status and luxury, but also a symbol of faith and divine light.

Expert opinion

Vsevolod Kozlovsky

6 years in jewelry making. Knows everything about samples and can identify a fake in 12 seconds

The popularity of gilding, so beloved by Russian people, led to the creation of an original school, the development of its own methods and secrets. Gilding masters took boys from a very early age to teach them all the subtleties of their profession. And only a few of them actually reached the heights of mastery.

The next step in the development of art is the merit of architects, primarily Bartolomeo Rastrelli. It was he who brought into fashion the Baroque style, which is characterized by gilding not only furniture, but also stucco.

Discovery of the galvanic method by B.S. Jacobi made gilding jewelry safer and easier in the 19th century. Electroplating has taken the technique of applying gold plating to a new level.

Black rhodium

Black rhodium, like rhodium plating, is produced using galvanic processing. Only in this case black metal is used. Such decorative processing gives the products a beautiful pattern and the same incredible shine. All elements are more expressive and clear. Rhodium plating protects the surface from corrosion and wear.

Other types of electroplating

Using the galvanic method, a coating of any metal can be applied to the product. In this way you can produce:

- silver plating - especially relevant for cutlery, jewelry, interior items and rare accessories;

- Copper plating is a method that allows you to give any product an antique look; it is more often used for processing figurines and various souvenirs;

- nickel plating – used to improve the aesthetics of products such as furniture fittings, fastening elements, etc.

Arguments in favor of ordering services from the Jewelry House “Gold and Style”

The “Gold and Style” workshop performs any type of galvanic coating. We offer a choice of gold, silver, copper, nickel, black and white rhodium. Moreover, we accept any jewelry, antiques, decorative and interior elements, accessories, figurines, souvenirs, etc. We will give any product the required style.

Our services will be useful to you if necessary:

- restore the jewelry to its former shine;

- give jewelry or any item an antique look;

- restore the former beauty of rare things;

- create an original decoration in an individual style, etc.

You just need to give us a task, and our specialists will solve it efficiently and in the shortest possible time. We offer affordable prices for all services. We will take into account all your wishes. Call and we will definitely agree. The Jewelry House “Gold and Style” employs highly qualified craftsmen who will help you decide on the type of coating to make your product unusual and attractive.

Where is it used?

Today, gold plating is used in the following areas:

- jewelry making;

- art (in sculpture; in painting, gilding is used not only on frames, but also directly on paintings);

- Interior design;

- automotive industry (for decorative purposes);

- dentistry;

- electronics (gold is an excellent conductor);

- cosmetology.

The last area of application is the most controversial. Most often, the use of gold in cosmetology is just a cunning marketing ploy. Nevertheless, in Japan they are working on the latest technique of gilding the face. It is believed that this metal enriches the skin with oxygen, preserves collagen and helps relieve irritation.

There is even a separate direction in alternative medicine - chrysotherapy, in which gold is used to treat inflammation. From a scientific point of view, such properties of the metal have not been proven, since a full-scale study of the effect of gold on the human body has never been carried out. But the placebo effect cannot be ignored.

Pencil gilding

Another “home” method is to use a galvanic pencil in which the tip serves as the anode and the surface of the product as the cathode. The principle of deposition is similar to the electroplating method, but the equipment used eliminates the use of a solution bath.

Noble metal not only decorates products, but also performs protective functions. The gilding process should be entrusted to professionals - lack of experience and the use of dangerous components often leads to undesirable consequences.

Application methods

There are many known methods of gilding. The choice is determined primarily by the nature of the surface and the professionalism of the craftsman.

Fire or mercury

One of the very first methods that was used for gilding temple domes. Its essence is that a special mixture based on mercury was prepared, which was subsequently evaporated. Due to the danger to the health and life of the master, this technique is a thing of the past.

Oil based

Another name for the method is Mordan gilding, from the name of a special glue. The method is suitable for both interior and exterior work. Mordan can be purchased in specialized online stores.

Clay based

Clay-based gilding (polyment) is used only for wood and is not suitable for exterior decoration. In the old days, this was one of the most difficult and time-consuming methods, since the preparation of polyment required rare and very expensive ingredients at that time, including whale oil. The mixture was diluted using egg white. Now you can find ready-made mixtures on sale.

Water-synthetic

For this method of gilding, mixtures based on water are used. The advantage is that you can quickly prepare the surface. The gold-plated product is glossy and does not require final polishing.

Garlic

One of the oldest methods. Fresh garlic juice was squeezed onto the surface. After it dried, the surface was polished, moistened and gold leaf was applied. According to experts, this method gives the gilding a special shine.

Kinds

The most common type is still gilding. Also in recent years, gold leaf gilding has become popular among decorators, which is much more accessible and cheaper.

Gold leaf

Gold leaf is 960-carat metal, rolled out to a thin sheet. In Rus', gold leaf was traditionally used to cover the domes of churches. In Russia it is sold in the form of books of 60 sheets with an area of 10 cm2 each.

The thickness is not regulated, but the most popular sheets are 10 times thinner than a human hair. It is used to decorate objects of art and for interior design. For outdoor decoration (fountains, domes, sculptures) thicker sheets are used.

Potal

Potal is a replacement for the usual gold leaf. It appears as gold sheets or strips and is an alloy of copper and zinc or aluminum. There is a potal imitating gold, silver and bronze. A drawing can be applied to the sheets. You can find gold leaf on sale in the form of multi-colored crumbs.

What are their differences?

The main difference between gold and gold is that it does not contain precious metal. This naturally affects its price: gold leaf is much cheaper. Without a protective coating, it may fade over time.

Difference between gold and gilding

The main difference is in the composition. Even a professional cannot always distinguish them by their appearance. Gold jewelry is durable, since the layer does not wear off, and is often much more expensive. Due to their short service life, gold-plated items are not worn every day and require more careful care.

With the development of technology, new methods of gilding have appeared. They allow you to achieve a thicker coating. Such bracelets and rings last much longer, but their price is higher than regular gold plated ones.

How to spot a fake

According to statistics, 4 out of 10 gold jewelry is fake. Unfortunately, you can buy gilding for the price of full gold even in a jewelry store. There is only one method of checking that would allow you to avoid counterfeiting at the purchase stage - make a transaction in large, trusted jewelry stores and be very attentive to the product itself.

Signs that jewelry is fake:

- Uneven color. Gold plating can wear off in places even with careful storage and transportation. Moreover, the fakes use a very thin layer.

- Some “experts” on the Internet advise checking with a magnet. Gold should not be magnetic. However, given that many metals do not react to magnets, this method is practically useless.

- Very often, scammers remove the stamped lock from real gold jewelry and attach it to gold plated jewelry. Therefore, one way to identify a fake is to carefully examine the links next to the lock. Any defects in this area may indicate that this is a fake.

At home, if the product has already been purchased, it is much easier to check:

- Chemical method. You can purchase a special set of reagents for testing. This method is suitable for those who often buy gold and not always in reliable places.

- You can drop alcohol onto the surface: low-quality gold will darken.

- If in search of the truth you don’t mind spoiling the appearance of the jewelry, then you can scratch the surface. Small particles will fall off the gilding, leaving noticeable damage.

The most reliable way to check is always a consultation with a specialist. For a small fee, any pawn shop will conduct a series of tests and samples to ensure authenticity.

Section question - answer

Does gilding darken or not?

Expert opinion

Grishanov Mikhail Petrovich

Jeweler, director of the Grishanov and Co. workshop

Over time, gold plating may slightly change color and darken. When worn and stored correctly, gold-plated items retain their color and shine for a long time. Periodic cleaning prevents items from becoming dull, and wiping with alcohol will prevent darkening and loss of shine.

How to coat metals with gold at home?

Expert opinion

Pribrezhny Gennady Valentinovich

Jeweler 6th category

Gilding at home is carried out using chemical reagents. Several methods can be used:

- immersion in a chemical composition with zinc contact;

- use of electric discharge in solution;

- staining with chlorine gold.

Gold jewelry, bracelets

Is it possible to gild metal yourself without gold?

Expert opinion

Grishanov Mikhail Petrovich

Jeweler, director of the Grishanov and Co. workshop

Gilding without using gold at home is possible by using gold leaf. It does not contain noble metal components and is made from an alloy of copper mixed with aluminum or zinc.

Care, cleaning and storage of gold-plated items

In order for your jewelry to last as long as possible, you must follow a few simple rules for caring for gold plating.

| Wearing | Be sure to remove gold-plated jewelry before any contact with water (shower, swimming pool, washing dishes) or sports activities. Avoid contact with cosmetics. Don't forget that everyday wear shortens their service life. |

| Storage | Store only in a separate box or fabric bags so as not to damage the layer with other decorations. |

| Cleaning | Clean only with a soft cloth without using abrasives. If dark spots just appear, just wipe with ordinary vinegar and rinse in water. The shine will help return the egg white (after it you will also need to rinse in clean water). Once a year, items should be taken to a jeweler for professional cleaning. |

Despite the fact that sooner or later the coating wears off, it can always be renewed in a jeweler’s workshop.

Gold plating methods at home

With certain skills, compliance with safety precautions and the presence of a well-ventilated room, gilding can be done independently at home.

Preparation and use of gold chloride

Procedure:

- Prepare aqua regia.

- Dissolve any gold item in it.

- Carefully evaporate to a dry residue.

Attention: the process must be carried out very carefully, since acid fumes can cause serious harm to the respiratory tract, and there is also a high risk of chemical burns to the skin.

- Mix the resulting gold chloride with chalk and a solution of potassium cyanide to a mushy state.

- Using a brush, cover the product.

- After the surface has dried, it must be thoroughly washed and polished.

Application of zinc contact

If a thicker layer is needed, then zinc is used. It is also necessary to prepare gold chloride for it.

Procedure:

- Clean the item thoroughly and degrease it.

- Prepare the composition by mixing gold chloride with carbonic potassium, yellow blood and table salt in water.

- Heat.

- Place the item to be gilded in a container with a warm mixture.

- When the products are already in the solution, place a zinc stick in the container.

- Rinse, dry and polish.

If necessary, the product is covered with a protective layer.

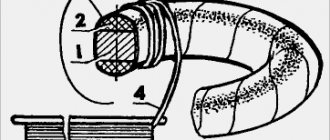

Galvanic method

The galvanizing method is similar to galvanizing, but produces a more durable coating. By changing the composition of the solution, you will get different shades of gold. You will need a current rectifier and any glass container that can withstand high temperatures.

Procedure:

- Clean, degrease the product, sand it using paste and sandpaper.

- If the product is made of steel, zinc or tin, first coat it with copper.

- Prepare electrolytes from water, sodium phosphorus, gold chloride, potassium cyanide and sodium disulfide.

- Heat the resulting solution to 60 °C.

- Install the anode.

Electroplating takes from 12 to 16 hours. At the end of the process, the product is dried on sawdust and polished.

If gilding of a small surface is required, it is easier to purchase a special galvanic pencil.

Gilding on the Gulfarba

Gilding “on Gulfarba” allows you to get a matte finish. Gulfarba is a mixture of varnish, drying oil, and pinene. The surface is treated with Gulfarba, and the next day a layer of gold leaf is applied to it. Thanks to the solvent in the composition, the surface becomes matte.

Methods and methods of gilding metal

The quality and appearance of the coating depend on the technology used. The most common methods of applying gold are:

- mechanical;

- chemical gilding using active substances;

- galvanic gilding.

For each method, different chemicals and tools are used.

Chemical method

Chemical gilding is the application of gold chloride to the item to be treated. To create a reagent, you must sequentially perform the following steps:

- The metal is broken into small pieces.

- The elements are placed in a pre-made mixture. The reagent is made based on a compound of hydrochloric (30 g) and nitric (10 g) acids.

- For each gram of spraying, about 10 ml of reagent should be consumed. Therefore, it is necessary to prepare the required amount of solution in advance.

Acids in everyday life should be handled carefully, avoiding contact with the skin of the hands and mucous membranes.

The ingredients are mixed in a porcelain flask, and dissolution can take three days. Once the preparation of the noble metal is complete, it is evaporated at 80 °C to form a liquid solution. To obtain a homogeneous composition of the required consistency during the evaporation process, the solution must be periodically shaken with a glass stirrer.

The following is prepared directly for the process:

- filtered water heated to 60 °C;

- golden chlorine salt – 15 g;

- sodium chloride or potassium carbonate – 65 g.

Items are processed after preparation has been completed in advance. To remove grease, it is recommended to wipe with 20% caustic soda, then wash in a 25% soda solution.

The item is placed in the mixture, and after a certain time (according to the type of metal) the surface turns gold-plated. After natural drying, the item is wiped with a soft, dry cloth. The surface is polished with a woolen cloth until it shines.

Mechanical gilding methods

Gilding gives the product certain properties that make it aesthetically attractive and resistant to environmental influences.

Mechanical processing is performed infrequently, because obtaining a uniform surface layer is not easy. This technology has the following features:

- It is necessary to use a special paste, produced in a special laboratory or independently. Paste ingredients may vary significantly for different products.

- The coating applied mechanically in domestic conditions, unlike galvanic coating, has a small thickness. Therefore, such products will not last long.

- The most common solutions are based on cream of tartar and yellow blood salt.

- To form a homogeneous porridge-like composition, rubbed into the surface of the product with a woolen rag, the substance is thoroughly mixed.

- Before applying gold plating, it is necessary to degrease the surface.

- The paste is applied in one layer with an even distribution of the golden mixture. When rubbing, it is necessary to avoid contact of the substance with the skin of your hands.

Mechanical gilding, unlike galvanic gilding, is a complex process, used in everyday conditions only for individual parts of objects. Other methods involve complete immersion of the part to be treated in a special solution.

Galvanic gilding of metals

Gold plating of sufficient thickness and quality is obtained by using a special technology that involves immersing the item in an electrolytic composition. The galvanic method is intended for processing products of almost any size; in fact, it is one of the types of electrochemical reactions.

It is necessary to take into account that the composition of the galvanic solution affects the shade acquired by the surface.

At home, an electrolytic solution for creating galvanic gold plating is prepared in the following sequence:

- 60 g of sodium phosphate is added to filtered water with a volume of 0.7 l;

- to dissolve 2.5 g of gold chloride, add 0.15 liters of water;

- 1 g of potassium cyanide and 10 g of sodium sulfide are dissolved in 150 ml of liquid.

When gilding using the galvanic method, the ingredients used to make the mixture must be handled carefully, avoiding spillage or contact with the skin, eyes, or mucous membranes.

The galvanic method involves heating the solution to 60 °C.

An anode is installed to electrolytically deplete and initiate reactions, reducing operating time and increasing the efficiency of the galvanic method. Gilding items in these solutions using the galvanic method takes about 15 hours, and a matte gold film is formed on the surface.