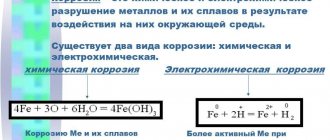

Anti-corrosion protection of metal structures can be divided into two different classes for solving the problem of emerging corrosion: 1) Corrosion inhibitors (the general name for substances that suppress or delay the course of physiological and physico-chemical corrosion processes), the application of which creates a protective layer of metal structures from corrosion. 2) Protectors - a surface insulated from corrosion is protected by another surface that is more susceptible to an aggressive environment, thereby forming an additional layer subject to corrosion.

This article will look at several options for corrosion inhibitors and protectors , namely anti-corrosion coatings from the AKTERM company.

Preparing the metal surface before applying anti-corrosion paint

The service life and anti-corrosion effectiveness of the coating depend on surface preparation

Surface preparation before treatment with primer-enamel 3 in 1 Before applying the coating, if necessary, wash the substrate from oil and grease contamination with solvents or aqueous cleaning solutions; remove dirt and water-soluble substances with clean fresh water. Loose layers of old paint or rust must be cleaned or sanded.

Surface preparation of steel structures is regulated in accordance with ISO 8501-1 to degree Sa 2½. In some cases, upon agreement with the manufacturer's technical service, preparation up to St 2 is possible.

Surface preparation before cold galvanizing Clean the metal from dust and dirt.

Preparing the surface before treating with quick-drying anti-corrosion on water Clean the surface to be treated from loose rust, dirt, dust, oils and old peeling paint.

Surface preparation before resin treatment and isocyanate curing Steel structures: sandblast to degree 2.5. New metal: degreasing with detergents, alkaline etching. Galvanized steel: no adhesion-reducing substances (fats, oils, dust, dirt, zinc corrosion products (white dust), etc.)

Mechanical removal

To mechanically treat rust, you will need a metal brush or coarse abrasive sandpaper. Using sandpaper, you can clean the material using the “dry” method or the “wet” method (wetting the sandpaper with kerosene or white spirit).

Other mechanical cleaning options include the use of the following hardware:

- orbital sander with abrasive wheels;

- sandblasting machine;

- electric drill attachments;

- Bulgarians.

The use of manual means (brush or sandpaper) is justified on small surfaces. The advantage of working the surface by hand is that it allows you to go more thoroughly into small or hard-to-reach areas.

An attachment to an electric drill, grinder or grinder can speed up surface cleaning significantly. However, such methods are not highly accurate: too much metal is removed.

Sandblasting equipment is the best way to remove rust.

Removal of corrosive products occurs by treating the metal with a powerful jet of sand. In this case, the undamaged metal completely retains its structure.

The disadvantage of this method is the high cost of new equipment.

Anti-corrosion paint as protection for metal structures

Anti-corrosion paint is a liquid material applied to metal using traditional paint methods, protecting it from corrosion, that is, it is a corrosion inhibitor. In the vast majority of cases, anti-corrosion paint is given the desired color by adding color pigments. The AKTERM company recommends using 3 in 1 enamel primer AKTERM Plast as an anti-corrosion protection for metal structures

AKTERM Primer-enamel Plast

A one-component, quick-drying decorative coating, used as anti-corrosion protection for metal structures, bridges, cell phone towers, ship hulls, vehicle bodies and rolling stock operating under the influence of external climatic factors. Weather resistance up to 10 years. Colored in RAL. Universal anti-corrosion protection of metal

Read more

Anti-corrosion paints can have heat-reflecting (heat-insulating) properties, in addition to anti-corrosion - the AKTERM Anticor material has such properties

Anti-corrosion paint can also have electro-chemical protective properties, in which case zinc is applied (cold galvanizing) as a metal coating - in fact, zinc paint is used, which is called a cold galvanizing composition.

AKTERM Zinc

The composition of cold galvanizing, which is based on 96% zinc, has electrochemical protection of the metal, as well as a protective effect - comparable in protective properties to hot and galvanic methods of galvanizing. The composition is suitable for outdoor and indoor ventilated areas. Electro-chemical protection of metal + anti-corrosion of metal

Read more

Polyurethane compounds are also used to give the anti-corrosion material increased abrasion resistance properties and prevent metal destruction - AKTERM Anticor PU - this composition can be classified as a “metal corrosion protector”.

AKTERM Anticor PU

Two-component coating, used as an independent protective and decorative anti-corrosion protector for external surfaces, tanks, tanks, cars, bodies and components of vehicles and rolling stock, structures made of steel, cast iron, aluminum and titanium alloys, operated in all types of atmosphere and load categories C2 -C4. Protection up to 20 years. Colored in RAL. Abrasion resistance + fracture prevention + anti-corrosion

Read more

Electrochemical protection of metal structures

Cold galvanizing composition is used as a protector for electrochemical protection of metal . The process of deep electrochemical protection of metal from corrosion is called cold galvanizing of metal . Zinc projectors are used to protect products from destructive corrosion caused by extreme weather conditions and the presence of salty sea water in direct contact with the metal surface.

AKTERM Zinc

The composition of cold galvanizing, which is based on 96% zinc, has electrochemical protection of the metal, as well as a protective effect - comparable in protective properties to hot and galvanic methods of galvanizing. The composition is suitable for outdoor and indoor ventilated areas. Electro-chemical protection of metal + anti-corrosion of metal

Read more

AKTERM Anticor PU

Two-component coating, used as an independent protective and decorative anti-corrosion protector for external surfaces, tanks, tanks, cars, bodies and components of vehicles and rolling stock, structures made of steel, cast iron, aluminum and titanium alloys, operated in all types of atmosphere and load categories C2 -C4. Protection up to 20 years. Colored in RAL. Abrasion resistance + fracture prevention + anti-corrosion

Read more

Direct and indirect problems associated with metal corrosion

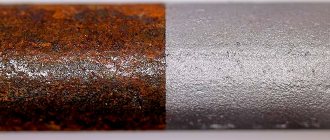

The main problem with corrosion is the gradual destruction of corroded parts of structures and products. At the same time, the degree of damage cannot always be assessed by appearance, and the loss of strength becomes unexpected and critical.

Intercrystalline corrosion, that is, passing along the boundaries of crystals, is especially strong. Externally, the process may be completely unnoticeable, while the level of strength loss reaches 50...60%.

Surface destruction has the least impact on the strength properties of products.

The photo shows part of the structures of the Shukhov Tower in Moscow. Surface rusting has significantly reduced structural strength, but has not led to the destruction of the structure (yet)

It is extremely difficult to estimate the level of losses from metal corrosion. The point is not even in direct losses from the destruction of corroded parts or structures, but in downtime of equipment and structures and disruptions in their performance as a whole, associated with the corrosion destruction of individual elements.

Rust converters for protecting metal structures from corrosion

The company's product range includes a material with rust converter properties - AKTERM Plast Primer-Enamel 3 in 1 - one of the three properties is rust conversion, in addition to enamel and primer. When working, it is necessary to apply the material to a pre-treated surface, removing loose rust using handy means that allow you to “sand” the surface.

AKTERM Primer-enamel Plast

A one-component, quick-drying decorative coating, used as anti-corrosion protection for metal structures, bridges, cell phone towers, ship hulls, vehicle bodies and rolling stock operating under conditions of external climatic factors. Weather resistance up to 10 years. Colored in RAL. Universal anti-corrosion protection of metal

Read more

Safety at work

In order to most effectively eliminate the likelihood of poisoning and illnesses arising from work related to the application of paint and varnish coatings, you will be required to strictly follow safety regulations.

First of all, in the rooms where work will take place, it is necessary to ensure good ventilation. Then, if this is a large room, then the people performing paint and varnish work must be provided with all the necessary personal protective equipment - that is, mittens and overalls.

Moreover, special attention from this list should be paid specifically to respiratory protection equipment - that is, masks and half masks - respirators. Also, you or your workers should remember about personal hygiene. To clean your hands from paint and varnish materials, you can use special cleaning pastes. But under no circumstances use solvents to clean the skin, as this leads to the appearance of a rash on the skin, as well as various allergic irritations.

In order to promptly identify various diseases of this nature, it is necessary that people who do paint and varnish work undergo periodic medical examinations in order to prevent the occurrence of these dermatological diseases.

Rust coatings

The Anti-corrosion protection section presents all current anti-rust coatings produced by AKTERM. Depending on the conditions of use, application conditions, as well as other reasons, you can choose the most suitable anti-rust coating for yourself.

Primer-enamel 3 IN 1 for rust or enamel for rust

AKTERM Plast Primer-Enamel 3 in 1 - is positioned as a universal anti-corrosion agent with triple action, after application: 1) anti-corrosion primer 2) rust transformation 3) decorative properties (tinting in RAL color).

Compared to existing analogues, the development of AKTERM - Primer-enamel Plast 3 in 1 has key features: the material dries quickly and has excellent properties: water resistance, chemical resistance, anti-corrosion.

AKTERM Primer-enamel Plast

A one-component, quick-drying decorative coating, used as anti-corrosion protection for metal structures, bridges, cell phone towers, ship hulls, vehicle bodies and rolling stock operating under conditions of external climatic factors. Weather resistance up to 10 years. Colored in RAL. Universal anti-corrosion protection of metal

Read more

Cold galvanizing composition

The principle of operation of cold galvanizing compositions as anti-corrosion protection of metal structures belongs to the class of protectors ; zinc applied to the protected surface acts as an anode, thereby donating electrons to the cathode - the protected iron surface, forming zinc compounds that stop the physical processes of corrosion.

AKTERM's product range includes two types of cold galvanizing compositions, AKTERM ZINC and AKTERM ZINC Pro. Their fundamental difference is that ZINC Pro is a two-component coating, which can be called a zinc primer. ZINC Pro is designed for extreme weather conditions, frequent surface contact with salty sea water and other harsh weather conditions.

You can find out more about the compositions of cold galvanizing, as well as their features, in the article Cold galvanizing.

AKTERM Zinc

The composition of cold galvanizing, which is based on 96% zinc, has electrochemical protection of the metal, as well as a protective effect - comparable in protective properties to hot and galvanic methods of galvanizing. The composition is suitable for outdoor and indoor ventilated areas. Electro-chemical protection of metal + anti-corrosion of metal

Read more

AKTERM Zinc PRO

two-component zinc-rich epoxy primer will provide reliable protection of the structure outdoors in conditions of high humidity, salt and sea water, alkalis, fuels and lubricants, chemical-resistant, impact-resistant glossy coating. Application: ships, offshore structures, oil refineries, pulp and paper plants, bridges, power plants, rolling stock. Service life up to 25 years. Cold galvanizing composition for extreme weather conditions

Read more

Advantages

All of them are quite simple to use and apply; the work does not require special training. Using these compositions, you can quickly and efficiently process metal structures of complex design and large dimensions.

The coverage also has a number of bonuses. They are not only inexpensive, but also have the following advantages:

- the coating can be of any color, you just need to choose one or another palette;

- the compositions have high protection characteristics;

- If the coating becomes damaged during operation, they can be easily restored.

Most corrosion control products are primarily used for long-term insulation of metal elements present in the structure. This processing method can be successfully combined with decorative finishing. External aesthetics in the final result are important. Moreover, if the work is carried out carelessly, then there is a possibility that after a while corrosion will reappear and be more dangerous.

Methods of applying anti-corrosion protection to metal structures

Application by brush

The most popular application method is to use a synthetic fiber brush.

Roller application

Use any fine-pile construction roller