Types of metal drills and their purpose, characteristics of spiral drills

After reading this article, you will learn:

- what types of metal drills exist;

- where to find their markings;

- what important characteristics do these instruments have;

- what do they influence;

- What kind of equipment are metal drills installed on?

Photo No. 1: metal drills

Let's start with the basics.

About cobalt drills. Their review, alloy and characteristics.

Good afternoon. In this article we will write about drills, what kind of metal drills there are, their purpose and areas of application, as well as the alloys from which they are made. I’ll tell you right away what niche our company occupies - we sell tools for various purposes, including we import drills from China.

Metal drills come with different types of shanks. The most common of them are: cylindrical shank (c\x) and conical shank (k\x). There are also drills with a triangular shank and a hex shank.

Drills come in several series:

- The average series with c\x is described in GOST 10902-77.

- A short series with c\x is described in GOST 4010-77.

- A long series with c\x is described in GOST 886-77.

- Particularly long series - they are also called Extra long with c\x are described in DIN 1869. - Chinese standard.

If you carefully study these GOSTs, you will notice that they are all united by a reference to GOST 2034 - Technical requirements for drills. In GOST 2034, at the end of paragraph 1.2, the following is written: “At the customer’s request, it is allowed to manufacture drills from alloy steel grade 9ХС according to GOST 5950.” Those. Formally, drills can be made from any alloy.

The most popular are drills made of R6M5 alloy. What is R6M5?

Alloy R6M5 is otherwise called M2 (European name), HSS6542 - Chinese name.

Chemical composition of alloy R6M5 “W: 5.50-6.75; Mo:4.50-5.50; Cr:3.80-4.40; V:1.75-2.20;"

We often hear not the most flattering reviews about Chinese drills... Why does this happen? and what manufacturers and sellers hide behind this.

I’ll tell you a little about the standards and alloys that you buy and use not rarely, but most often.

The first place in cost in China goes to the HSS4241 alloy. Drills made from this alloy are available in “Black finish - black, not polished”, and they can also be ground (a little more expensive). In addition to the alloy, you can order a Titanium Nitride (TiN) coating - it’s also not that expensive, but the drill gets a marketable appearance for pennies. Another trick is Marking. The Chinese immediately warn that these drills are very cheap and can only be used on wood. However, this does not prevent the Russian importer from ordering the coveted “P6M5” marking. What kind of alloy is this? , the chemical composition of this alloy is “W: 1.50-2.50; Mo:0.60-1.20; Cr:3.80-4.40; V:0.50-0.70;" - which is translated into Russian designation as “Р2М1”. This alloy is very popular on the Russian market.

The second most expensive alloy in China is HSS4341. These drills are made in the same way as HSS4241 - they differ in different chemicals. composition in this case we get “W: 3.50-4.50; Mo:2.50-3.50; Cr:3.80-4.40; V:1.20-1.80;” - which translates into the Russian designation as “R4M3” - in terms of durability, these drills are significantly better than 4241. In terms of cost, they differ significantly from 4241. The buyer believes that these are good Chinese ones.

Third place goes to the alloy HSS9341. These drills are made in the same way as HSS4241 and HSS4341 - they differ in chemical. composition in this case we get “W: 8.50-9.50; Mo:2.70-3.30; Cr:3.80-4.40; V:1.30-1.70;” - which is translated into Russian designation as “Р9М3” - in terms of durability, these drills are almost like R6М5 (HSS6542). And the cost is almost no different from the R6M5. They are in very little demand in the Chinese market.

Fourth place deservedly goes to the alloy HSS6542 - P6M5. The execution is no different from its predecessors. The chemical composition is as follows: “W: 5.50-6.75; Mo:4.50-5.50; Cr:3.80-4.40; V:1.75-2.20;". They are popular in China, but they are brought to Russia much less than HSS4241 and HSS4341. The cost of these drills is significantly higher. Bringing these drills to Russia and honestly labeling them as R6M5 will be problematic due to the established market and this alloy simply cannot compete on prices.

The fifth place is occupied by the alloy “M35” - R6M5K5 or HSSCo, it is also a drill for stainless steel, it is also called a “cobalt drill”. This alloy has a new element - cobalt. Cobalt increases the heat resistance of the drill and also improves its mechanical properties. The design is slightly different from its predecessors; the Chinese do not coat them with titanium nitride - this makes no sense. The sharpening angle is 135°. Chemical composition “W: 6.00-6.70; Mo:4.70-5.20; Cr:3.80-4.50; V:1.70-2.00; Co:4.50-5.50;" , judging by the chemical composition, you can see that tungsten and molybdenum have a lower content tolerance - this means that the Chinese approach the manufacture of these drills more responsibly and with high quality than other alloys.

The sixth and last place is occupied by the M42 alloy. - R2M10K8. Drills made from this alloy are almost not represented on the Russian market, however, you can notice that Bimetallic Crowns are made from this alloy. Chemical composition “W: 1.15-1.85; Mo:9.00-10.00; Cr:3.50-4.25; V:0.95-1.35; Co:7.75-8.75;".

Chem summary compositions are given in the table

You can buy drills from us: Check out the availability and prices of drills by sending a request to our email address or call our phone number

A reputable supplier of drills should always have a chemical analysis of the drills. It is our custom to do a chemical analysis for each incoming batch and attach the results at the first request of the client.

There are many manufacturers of drills on the market. VIZ, Tulamash, TIZ and many others. We cannot say what alloy they use in the manufacture of drills, since we did not carry out chemical testing. analysis drilled them. In the near future we will compare drills from different manufacturers and post a video.

enes-tobin.ru

Marking of drills for metal (Russian and foreign)

According to Russian GOST, all metal drills with a diameter of two millimeters or more are subject to marking. The designations contain information about the tool diameter and steel grade. Some models bear manufacturer's marks. To find out the markings of the drill, look at the shank of the tool.

Russian labeling looks like this.

Image No. 4: rules for deciphering Russian markings

Foreign metal drills made of high-speed steel are marked HSS. Depending on the modifications and manufacturing features, various additional designations are added to it.

To mainChecking drills

The quality of drilling parts on drilling machines is characterized by the accuracy of the hole location and the smoothness of its surface, which largely depends on the condition of the cutting part of the drills. Therefore, all drills must be well sharpened. Drills can be sharpened manually with a whetstone or file, with the obligatory subsequent straightening of the cutting edges with a whetstone. In large enterprises with well-organized tool facilities, special sharpening machines and automatic machines are usually used for sharpening drills. In fig. Figure 31 shows a sharpening machine being manufactured. This machine is used for dry and wet sharpening of twist drills. On the machine bed, the working shaft is mounted in bearings, on which sharpening stones are attached on both sides. The machine is driven by a transmission through working and idler pulleys. Grinding wheels are installed with a diameter of 300 mm

with a width of 25 - 30

mm

.

The circles are located at a distance of 420 mm

from one another.

The machine makes 1600

rpm

and

consumes 1.5

kW

of .

To sharpen twist drills, a special machine is sometimes used, manufactured by the machine-tool plant named after. Ilyich (Fig. 32). When sharpening, the drill is placed in a guide sleeve, which is given a rocking movement by hand. To avoid uneven wear of the grinding wheel across its width, the grinding headstock has a reciprocating motion. The machine has an individual drive, from an electric motor installed inside the frame. This machine can sharpen drills with a diameter of up to 13 mm

.

The sharpening angle limits at the drill tip are provided from 50 to 140°. The power of the machine is 0.52 kW

and the speed

is

1500

rpm .

In the absence of special equipment at the factory, twist drills can be sharpened on a universal sharpening machine from the Ilyich plant (Fig. 33). The machine operates from a transmission through a counter drive or from an individual motor with a belt drive. The machine table has longitudinal, transverse and vertical strokes. The distance between the centers of the grinding wheels is 410 mm

.

wheel

speed, 3550 -

4800 rpm .

Machine power 0.8 kW

. The machine is equipped with a device for dressing a wheel without a diamond. When sharpening drills, use a tool rest, and sharpening is done by hand. This machine, when handled skillfully, gives a fairly high quality of sharpening. Proper sharpening and proper care of cutting tools ensure high quality processing and increase labor productivity and rational use of equipment. Feather and screw drills are sharpened by hand with a velvet file and guided with a whetstone. With proper sharpening of the tool, the most favorable relationship is established between the cross-section of the chips removed and the cutting speed, as a result of which processing the part takes a minimum of time. This allows you to rationally use the power of the machine, eliminate unnecessary losses, reduce energy consumption and increase the service life of the machine. A properly sharpened tool needs to be sharpened less frequently. The tool should be checked after each sharpening. Cutting angles and cutter sizes must meet the requirements of the application. To check drills, they often use a universal measuring tool - a protractor and scale rulers, but in some cases it is advisable to check drills with special templates. To measure the length of the cutting edges of a spiral drill, use a special template (Fig. 34), combining it with the cutting edge and the working part of the drill along the axis of the latter. The divisions marked on one of the template rulers indicate the length of the cutting edge. Having measured the length of one edge, turn the drill 180° and determine the length of the other edge. The disadvantages of this template is the inability to determine the size of the angle formed by the cutting edges. If these angles are not equal, the drill will beat, and the diameter of the drilled hole will be greater than the diameter of the drill.

A double-sided template is more convenient and reliable (Fig. 35).

Drills with different sharpening angles are checked with appropriate templates. To check the point drill (see Fig. 18), you can use a scale ruler and a caliper. Measurements are taken with a caliper from the central tip to the end of the blade and to the scorer, and both measurements should be the same. The size of the central tip to the scorer is also measured with a caliper. These dimensions are best compared with the dimensions of a new, not yet developed drill. The simplest tool for measuring cutter angles is a template, which represents a plate with cutouts corresponding to the cutter angles. The service life of drills until complete wear (Table 1) is determined from the conditions of normal sharpening and operation of the tool.

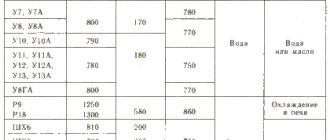

Table 1

Service life of drills until complete wear (in hours)

Tool name

| Drill diameter, mm | ||||||||

| 6 | 8 | 10 | 15 | 20 | 25 | 30 | 40 | |

| Twist drill Spoon drill Feather drill Twist drill Slot drill Two-cut slot drill Three-cutter slot drill Helix drill | 150 40 50 100 60 50 30 50 | 200 80 100 150 130 100 50 100 | 250 120 160 200 200 150 100 160 | 350 180 230 250 250 200 160 230 | 500 250 320 400 400 400 250 300 | 700 350 450 600 600 500 350 400 | 900 400 500 800 800 550 450 500 | 1100 600 650 1000 1000 600 500 650 |

| Previous page | table of contents | Next page |

Types of sharpening drills for metal

At the end of the article, we will talk about the types of sharpening of metal drills, which are used to restore dull tools and change their geometry.

Image No. 6: types of sharpening twist drills

- Normal (single) sharpening (N). Considered universal. During normal sharpening, two cutting edges and one transverse edge are formed on the surface of the drill. The angle between the cutting edges is 118–120°. This type of sharpening can be used for drills with diameters up to 12 mm. Other technologies are suitable for tools with diameters up to 80 mm.

- Single sharpening with sharpening of the cutting edge (NP). Reduces its length. Due to this, the load on the working part when performing drilling work is reduced.

- Single sharpening with sharpening of the transverse edge and ribbon (NPL). Additionally reduces its width in the area of the cutting part. The friction force is significantly reduced. In addition, an additional rear angle is formed. This results in easier cutting.

- Double sharpening with sharpening of the transverse edge (DP). With double sharpening, 4 cutting edges and one transverse are formed. They look like broken lines. The durability of drills with double sharpening increases by 5–7 times when processing cast iron workpieces and by 2.5–3 times when drilling steel.

- Double sharpening with sharpening of the transverse edge and ribbon (DPL). With this sharpening, drilling is further facilitated.

What does the color of a metal drill mean?

The color of a drill is a significant indicator by which you can determine how suitable the tool is for processing a particular material. Let's look at the properties that the most popular coatings give drills.

The presence or absence of a coating on a tool determines its resistance to temperature and mechanical loads, strength and service life.

Gray (metallic) shade

This color indicates that the drill has no coating. Such a tool has extremely low strength and is only suitable for processing soft materials. When drilling hard metal, an uncoated drill may not be enough to even make one hole. In general, the quality leaves much to be desired.

The gray drill does not have any special advantages. Besides the price. If you are willing to pay for a disposable tool, even inexpensively, then choose uncoated drills.

Black shade

These drills are a little more expensive than the previous ones. But their quality is much better. They can operate at higher speeds and last longer. And all because the drills are covered with an oxide film, which is obtained by treating the tool with superheated steam at the final stage of manufacturing. This is what gives the drill its black color.

Steam-oxidized drills are ideal for processing steel and non-ferrous metals. The coating protects the instrument from rust. In addition, such a drill tolerates significant overheating of the metal during processing, and also maintains the sharpening of the cutting edges in excellent condition for a long time.

Light golden hue

This shade is given to the drill by a specific heat treatment. First, the tool is heated to 250°C and then allowed to cool slowly (the so-called tempering procedure). This is done in order to relieve residual stresses in the internal structure of the drill. In the process of such heat treatment, the tool becomes very durable and wear-resistant.

Light golden-colored drills can be used to repeatedly process hardened metals. Even hard alloys can be cut with such a tool.

Bright golden hue

Titanium nitride gives the drill this color, making the tool the highest quality and most durable among its analogues. TiN coating increases the service life of the drill several times.

In addition, titanium has the ability to reduce friction during processing, which significantly reduces heating of the working area. Tools coated with TiN can drill cast iron, as well as steel with a hardness of up to 35 HRC.

The only drawback of bright golden drills is their high cost. However, the price is comparable to their high level of quality. It is often more economical to purchase a truly highly efficient drill than to work with a cheap tool with low efficiency.

When choosing metal drills with or without coating, you should first decide how often you are going to use them. Also consider the accuracy and quality requirements for the holes that need to be drilled in the workpiece.

In the TIGROTECH catalog there are many solutions for drilling holes in various materials. Prices start from 85 rubles per drill.