Threaded connections are present in all machines, tractors and other mechanisms. They are used when parts must be detachable. This is very convenient and allows you to quickly replace what is broken. But sometimes it happens that the screw cannot be unscrewed, it is impossible to remove a stuck pin, or the head of the bolt has been licked off. How to unscrew a screw with a broken head? How to get a broken pin? How to unscrew a crimp in a hard-to-reach place?

We’ll talk about how to unscrew a broken, broken or licked bolt or screw later in the article.

How to unscrew a broken bolt without damaging the thread in the hole :: SYL.ru

Quite often, when using fasteners such as a bolt, situations arise when the head of the product breaks off, and the hardware itself remains inside. In this case, it becomes necessary to remove this residue without damaging the threads, so that the hole can continue to be used. Considering this, the topic of how to unscrew a broken bolt is very popular and requires more detailed consideration.

Types of fractures

Typically, such fasteners break at the end of the thread, although there may be exceptions. As a result, the hardware itself can be recessed into the hole, protrude above the surface, or be level with it

Based on this, you need to decide how to unscrew a broken bolt by paying attention to this very moment

Surface cliff

This type of failure includes the option when part of the hardware protrudes above the surface. We can assume that such a problem is easiest to solve without using radical measures. However, before any unscrewing of the broken bolt, it is worth treating the area with kerosene to remove carbon deposits and loosen the contact of the surfaces.

- If the protrusion is quite large, then the easiest way is to use tools such as pliers, pliers or a clamp, with which you can grab the part and unscrew it along the threads.

- Some experts, answering the question of what to do if a bolt that fits very tightly in the hole breaks, recommend using a welding machine. With its help, you can weld a lever to the hardware, which will result in a large arm for rotational movement.

- You can also use a drill with a diameter slightly smaller than the bolt itself. Using a drill, make a hole along the central axis of the bolt to the full depth. After this, the remaining fasteners are removed using a hook, trying to unscrew the thread from the very bottom.

Flush break

It is believed that this breakdown is the most difficult, since sometimes it is very difficult to determine the diameter of the hole, especially if the fastener has been cut off. Therefore, in order to determine how to drill out a broken bolt of this type, you should first clean the surface, determining the gaps.

Quite often, the break point has very uneven shapes, which, given this arrangement, are very difficult to straighten. It will not be possible to drill the product in this state. That is why a core is first used to prepare a place in the center for working with a drill.

Further steps describing how to drill out a broken bolt are described in the paragraph on surface breakage. After making the hole, the remaining threads are simply removed with a hook.

Cliff below the surface

Such damage is quite complex, especially if the part itself is made of soft metal. Therefore, you need to solve the problem of how to unscrew a broken bolt without damaging the threads in the hole.

First of all, using a core, mark the center of the hardware. In this case, it is best to use a thin tool made of durable metal so as not to accidentally damage the part.

The next step is to purchase a tap with reverse thread. Its diameter should be smaller than that of the bolt itself.

After this, a hole for the tap is drilled in the hardware itself, but not deepened too much. Next, it is enough to install the thread cutting tool and turn it as you go, which will lead to unscrewing. If this does not happen, then the tool is used as a regular bolt, but you should not apply too much force so as not to break it.

Extractor

The most correct answer to the question of how to unscrew a broken bolt is considered to be the one that suggests using a tool specially created for this purpose. It is called an extractor and is sold as a set of products of different diameters. Outwardly, it resembles a tap, but without longitudinal slots and with a conical notch for cutting.

To use the extractor, it is enough to drill a hole in the center with a diameter that allows the tool to go several turns. Then they begin to turn it all the way, and then until it is completely unscrewed.

Conclusion

There are several options for removing broken bolts from a hole that can be used for certain types of damage. However, it is best to purchase a set of extractors in advance, which can be considered the best tools for such tasks.

Why the screw does not come out: the main reasons for souring of bolts and stripping of threads

Every driver or auto mechanic faces the problem of how to unscrew a bolt with a torn head, a hexagon with torn edges, or a broken fitting. When operating cars, tractors and other special equipment, threaded connections often come into contact with oily or caustic liquids, become clogged with dirt and experience increased stress when the loads are exceeded. All this negatively affects the strength of bolts and studs.

It is imperative to unscrew the hexagon with the broken head. If this is not done, you will not be able to install the new part using standard connections. And drilling nearby will reduce the strength of the spare parts and compromise the integrity of the structure.

To prevent the appearance of broken studs and bolts with a torn head, it is important to carefully inspect the condition of the threaded connections during each maintenance and replacement of parts. If defective ones are found (with traces of corrosion, sagging, torn threads or licked hexagon faces), they must be replaced with new ones. This will help maintain the quality and strength of the connections.

But problems can arise even with proper and regular maintenance. The main reasons why it is difficult to unscrew a bolt with a broken head are the following:

- natural metal fatigue that occurs under constant stress during operation;

- contact with technical liquids (diesel fuel, oil, antifreeze, etc.);

- violation of the protective layer of fasteners, resulting in rust or corrosion processes;

- loss of metal strength as a result of constant overheating;

- fasteners that are too tight;

- manufacturing defects.

But whatever the reasons, it is important to know how to unscrew a screw with licked edges, a torn head or rust, as well as how to carefully remove the crook of the bolt. Let us further consider in detail with photos special cases and propose the optimal method for each situation.

How to unscrew a broken bolt if the fragment does not protrude above the surface of the product.

Method 4.

How to remove a nut with stripped edges and threads?

If you have a left-hand drill, you can try using it to unscrew it.

Drill diameter = pin outer diameter – tooth height x 2

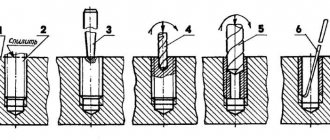

Make a hole in the center of the stud with a core. Install a regular “right-handed” thin drill into the resulting recess. Drill 1-2 cm.

Then install the “left” drill of a larger diameter into the chuck and drill at low speeds.

The peculiarity of the method is that the “Left” drill drills counterclockwise, which coincides with the direction of unscrewing the stud. And if it is not strongly stuck, the pin may begin to rotate during the drilling process.

Method 5.

Extractor.

Drill a hole in the center of the stud with a diameter corresponding to the type of extractor.

Insert the extractor into the resulting hole and unscrew your pin.

Method 6.

Drill a hole in the stud and cut a thread in it with a tap.

Screw in the corresponding bolt, tighten it with a lock nut, and unscrew the stud with a wrench placed over the head of the fixed bolt.

Method 7.

Select a drill with a right-hand stroke and a diameter as in “Method 4”.

Drill the pin along the entire depth of the hole. The idea of the method is this: only the thread teeth of the stud will remain in the thread body of the product, which can be removed with a tap.

Use a tap of the same diameter as the diameter of the stud to drive the threads through the solid body of the product.

The main condition for the successful implementation of this method is the precise placement of the drill in the center of the stud. Otherwise, you will ruin the thread in the solid product.

If the thread was damaged during the process of dismantling the stud, it makes sense to drill out the damaged hole for the next standard thread size and use a tap to cut a new thread of a larger diameter.

Method 8.

If a pin breaks off in an aluminum solid, you can use nitric acid (it’s hard to find, but in case you have it).

Fill the chip with acid. It corrodes steel, leaving aluminum (or duralumin) untouched. When the remaining stud is removed, be sure to neutralize the acid in the hole with an alkali (such as soda).

The process is of course long, so it is suitable if you are not in a hurry.

Method 9.

Drill a hole in the stud and drive into it either a triangular file or a tap sharpened to a cone with three edges.

Unscrew the pin by rotating the wedged file or tap.

How to drill out a broken bolt from an aluminum block?

It happens quite often that a small diameter bolt in an aluminum car engine block breaks. It is not easy to drill out such a remaining bolt. The Internet offers a lot of options on how to drill out a broken M6 bolt from aluminum without much difficulty.

In fact, the most reliable method is classic drilling followed by tapping. In this case, all the preparatory operations discussed above must be carried out very carefully.

All sorts of Chinese extractors are advertised, but they very often break inside the hole, which greatly aggravates the situation. In addition, this tool, with its conical shape, creates additional friction between the walls of the bolt and the block, which makes extraction difficult.

How to unscrew different nuts?

How to unscrew a screw in different situations?

Many people are interested in what needs to be done if the nuts are very rusty, and how it is easier to unscrew such parts at home. There are many ways to remove rust. In each specific case, it is better to use certain methods to correct the defect.

There are mechanical and physical ways to cope with the task: this is tapping and using a lever. When tapping, take a regular hammer and tap the nut with it, being careful not to dent it. Usually this is enough for the “sticking” to go away and the connection to yield.

The use of chemicals that help dissolve the blockage and remove rust will also help resolve the issue.

Stuck

The kitchen and plumbing rooms are areas with high humidity, so rust may form on some products here. If the drain in the sink is clogged or corrosion appears on the toilet tank or pipe, it is advisable to use Coca-Cola. By the way, using any concentrated acid will help you get rid of rust at home. Lemon powder or vinegar essence is suitable for this purpose. Applying a few drops will eliminate the problem.

If you need to unscrew a part on the mixer, you can do this by tapping. Using a small hammer, you need to hit the edges. So, moving in a circle, you need to go through the part several times. This process leads to the formation of mini-cracks in the metal, then to deformation and rapid destruction of the corrosion layer.

To remove a stuck part, take one of the chemicals listed above and apply it to the surface to be treated.

It is important to moisten the element generously with the product and leave it for 20–30 minutes. After half an hour, you need to take the tool and try to unscrew the nut

If the part is very stuck, it is recommended to treat it again with the selected product and let it sit for a little longer. For better interaction, it is recommended to take a small cloth, wet it and screw it directly onto the nut.

The work process is as follows:

- you need to take a wire brush and clean the threads, then apply WD-40 penetrating lubricant to the hub nut;

- saturate the hub;

- let stand for 20–30 minutes;

- put the wrench head on the part and hit it with a hammer, increasing the force of the blows;

- unscrew the part.

Changing directions will help remove a stuck part. Before unscrewing the connections, you can try screwing them.

To speed up the unscrewing process, you can lightly tap the product with a hammer. If there is no result, you can try to move the part with a strong jerk. For a small element, the “swinging” method of unscrewing is suitable, that is, with back-and-forth movements.

It can be quite difficult to unscrew a soured, rusted nut on the exhaust manifold or muffler, as they become strongly stuck due to exposure to high temperatures.

Many people understand how difficult it can be to remove the hub nut. To speed up the process, you will need steel tools in the form of a powerful screwdriver, an iron tube, a stiff brush and WD-40.

torn off

If all the previous options were useless and the edges of the part were torn off, all that remains is to cut it off. This can be done with a grinder, a hacksaw, a chisel or an electric drill.

You can also hold the torn part in a vice or clamp, take pliers for work and unscrew it with a pipe wrench.

If the edges of the nut are licked, you can hammer a larger part on top, then drill a recess, then insert a strong metal rod and try to unscrew the fastener.

In addition, you can take a welding machine and weld two nuts with it, and then unscrew the upper part along with the welded one.

Plastic

Typically, plastic nuts are a different shape and size than metal nuts.

To unscrew the plastic part, you can take:

- special factory key;

- puller for oil filters;

- pliers with a wide opening.

If you press the part on both sides with wooden blocks and simultaneously hit them with a hammer in the direction of twisting, you can easily unscrew the plastic element.

In a hard to reach place

If parts are located in hard-to-reach places, it can be quite difficult to unscrew them with a regular key. In this case it is better to take:

- ratchet;

- a key with a short handle;

- a ratchet with the maximum number of teeth;

- extension cord and flexible wire for heads.

You can lengthen the handle or choose a longer “knob” and put a metal pipe on the key. Performing these actions will allow you to unscrew the connection

It is important to do the work carefully so as not to tear off the edges

Features and advantages of cylinder head studs

How to unscrew a broken bolt without damaging the thread

In any engine, the cylinder head (cylinder head) is attached to the block itself with studs. They are screwed into the block in such a way as to ensure the best and uniform pressing of the cylinder head to the block. A high-quality compressed gasket prevents the leakage of oil and antifreeze and the penetration of gases from the cylinder into the engine crankcase. Fasteners are made from high quality steel. However, over time, the threads on them may corrode and become clogged with various contaminants. Due to exposure to high temperatures, these contaminants are sintered, and the nut “sticks.” When you try to unscrew such a stuck nut and exceed the maximum force, either the thread breaks off or the fastener breaks off. In both cases, it is necessary to replace the broken part.

Cylinder head studs

Types of breakdowns

There are three cases. Let's look at the simplest ones first.

If the bolt is broken but part of it is sticking out of the threaded hole, you're in luck! In this case, the broken bolt can be easily unscrewed in two simple ways.

- If the protruding part of the hardware is large, clamp it with pliers or an adjustable wrench. There shouldn't be any problems with unscrewing the bolt.

- If a piece of hardware cannot be clamped due to its small size, proceed this way.

- Make a cut along the diameter of the protruding part using a grinder.

- Unscrew the broken bolt with a screwdriver.

Most often, bolts break flush with the surfaces or, even worse, at the depth of the holes.

Chemical

Now we will consider methods for those who do not rely on the help of physics, but want to solve the problem with the help of chemistry. Your laboratory should have: kerosene, white spirit, acidified sulfuric acid, zinc, plasticine, hammer, water, sandpaper, wrench, chisel.

Attributes of the chemical method for unscrewing the nut

We moisten the nut and bolt with kerosene (experienced people recommend making a mixture of White Spirit and kerosene), applying a swab to them, it doesn’t matter whether it’s cotton or gauze. After some time - from an hour to a day, and with repeated attempts, you may find that the hub nut can be easily unscrewed. But even here you cannot do without force: at a minimum, you will probably have to work with sandpaper to clean the parts from rust. If even after this things don’t work, you should help with a hammer: tap it on the edges of the hub nut.

If in this case you are not successful, make a small container out of plasticine, secure the hub nut on top, pour water with sulfuric acid into it, and put zinc in the container. A chemical reaction begins that does a very good job of removing rust. Usually a day is enough for even advanced corrosion to go away from a part. Finish the job with a wrench. But this method is valid only in the case when the reason is that the nut is tightly stuck and/or rusted, and if it was simply tightened, neglecting the required tightening torque (to “be sure”), then you just need to tighten it.

What is the result..

As you can see, unscrewing the hub nut is not an easy task, but it can be solved

Please note that the first step is to try to preserve the hub nut by using penetrating fluids such as Vedeshka. Physical efforts to twist the hub should be moderate

And, of course, you should refrain from strong blows and heating with a torch, as methods that can render not only the nut, but also the bearing unusable.

Due to the lack of the required number of guarded parking lots, car owners install not only alarms on their cars, but also secret bolts on the wheels. Fastening elements with non-standard head shapes are called “secret”. They cannot be unscrewed with a balloon tool; fastening can only be done with the special tool that comes with the kit.

The most typical failure situations

A bolt can break in different ways. The easiest case is when it breaks flush with the part. In this case, there will be no special problems in how to drill the bolt. But, nevertheless, it will be necessary to carry out some preparatory measures that will allow you to extract the remaining part without much difficulty. And they are as follows:

- The most important thing is to prepare yourself for the fact that you can only drill out a broken bolt without damaging the thread if you apply maximum patience and calm. Haste in this case is the main enemy

- First of all, you need to use a tool to quickly unscrew rusty bolted joints. There are a great many of them in the markets. But the overwhelming majority of such funds are absolutely useless. A self-respecting car enthusiast and mechanic should always have in stock a penetrating agent for loosening nuts and bolts, which contains substances that have the ability to penetrate any joint. Recommendations for choosing can be obtained from any well-known car service center. The most effective lubricants are those based on molybdenum disulfide and graphite.

- Next, you can try one of the simplest options on how to drill out a broken bolt without any problems. To do this, you need to use a thin drill and a low-speed drill to drill a slot for a screwdriver.

- You can purchase a gas torch for loosening bolts at any hardware store. If there is such a burner, then with its help it is necessary to slightly warm up the part itself in such a way that the remaining piece does not heat up. In this case, there should be a fire extinguisher nearby.

- Then try using a screwdriver with a wrench to slowly loosen the rest of the bolt. If the bolted connection is not old, then the piece should come off.

How to unscrew a stuck hairpin

A soured pin must be unscrewed using additional tricks, both in terms of tools and in terms of methodology.

- Apply several blows with a hammer to the end of the stud along its axis without damaging the edge of the thread;

- apply several gentle blows from different sides to the side surfaces of the stud (at the same time screw a nut onto the threaded part to avoid damage), without allowing it to bend;

- apply special penetrating compounds - WD-40, liquid key and their analogues, giving the necessary time in accordance with the instructions for these drugs from their manufacturer before attempting to unscrew;

- use an extension to the hand tool to increase the applied force (a longer wrench or by placing a pipe of a suitable diameter on the rotating end of the hand tool;

- When unscrewing a welded nut, use not an open-end wrench, but a Super Lock head, in which the force is applied not to the corners (edges), but to the planes;

- instead of using physical force and hand tools, use an impact wrench (if you don’t have one in your home workshop, you can go to the nearest tire shop or car service center and deliver the part with the stuck pin there);

- when using the method of screwing two nuts, screw the first one all the way with such great force that it cuts into the cylindrical part of the stud, and use the second nut not a standard one, but a self-locking one (this will allow you to use much greater forces, reducing the risk of unscrewing the nuts);

- Heat it several times and let it cool, at the final stage heat it up and unscrew it.

Repeated heating is also indispensable for unscrewing studs mounted on special compounds - thread lockers.

When unscrewing a stuck stud by a welded or screwed nut, it is better to use a tool that is structurally stronger and more tightly covers the perimeter of the working surfaces of the nut, eliminating the licking of the edges:

- 6-point head instead of 12-point;

- Super Lock head instead of the usual one;

- ring wrench instead of an open-end wrench;

- a crank instead of a ratchet.

Method 3 - welding on the nut or head

Of course, not everyone is good at welding, but you can ask a friend. The essence of the method is to weld a nut onto the problem bolt and then unscrew it.

But, in most cases, this nut also breaks off, so many experts recommend welding a head instead, preferably an already broken one, so that it won’t be so bad.

The advantages of this method:

- The head is higher and you can insert a key with a large lever into it;

- It is more convenient to scald, the scalding area will be larger, which means the head will hold tighter.

The ideal option is to use a semi-automatic device; for a conventional inverter, a 2 mm electrode is used.

After welding, wait until the metal cools down. Then insert a wrench with a large lever into the head and begin to unscrew the bolt.

1Unscrewing the stud using the threaded part

This is one of the most common and accessible methods that even beginners can use. This process will not take much labor or time. There are two proven ways to unscrew the stud by the threaded part:

- Method 1 - if the threaded part of the stud is clearly visible and accessible, then you need to screw the nuts onto it one by one until it stops. In this case, you do not need to use full force, as you may break the pin. After two or more nuts have been screwed on, use a wrench or other plumbing tool to unscrew the stud.

- Method 2 - use a hairpin driver, this is a special tool that can easily help you unscrew a hairpin. It is best to use a universal pin driver.

Advice: if the pin “does not want” to unscrew, then it is better to heat it a little using a gas heating pad. As a rule, after a little heating, such soured studs are unscrewed without problems.

Method 6 - drill, use a hexagon and a lever

Suitable for VAZ 2108, 2199 and other cars with cylinder head bolts having internal edges. The essence of the method is to drill a hole in the bolt and unscrew it with a wrench. The hole is drilled so that the bolt loses its rigidity.

Take a drill with a power of at least 750 W (the more the better) and a drill with a diameter of 10 mm. The depth of the hole should be greater than the distance from the upper edge of the bolt to the washer, that is, go below the latter.

Next, we set the bolt using a hammer and a powerful spacer, which is inserted into the hole. The essence of the method is described above.

Next, we drive a four- or hexagon or a 25 Torx wrench into the hole.

Using a lever tube, unscrew the bolt. This method is described in more detail in the video.

2Unscrewing the stud by the cylindrical part

If the thread is broken, then other options for unscrewing the stud come to the rescue - using the smooth cylindrical part. In this case, it is necessary to use different types of tools: pliers, pipe wrench, vice, etc.:

- Method 1 - use pliers to clamp the cylindrical part and forcefully unscrew the pin in the direction of unscrewing;

- Method 2 - using welding, weld a small rod onto the broken area, using which you can unscrew the pin;

- Method 3 - use a nut one size larger, which must be welded to the stud and unscrewed with a wrench.

- Method 4 - use a die, in which the end of the pin must be carefully ground to the desired size;

- Method 5 - use a pin driver.

If, when unscrewing the stud, it does not “give” in any way, then it is better to use two working tools at once, for example, using a screwdriver and pliers at the same time.

Why do bolts break?

The main reason for bolt failure is corrosion, which metal structures are inevitably subject to during operation (especially severe in humid and aggressive environments).

Oxidation causes uneven wear of fasteners. Devices collapse at the most unexpected moments, unable to withstand the load. Also, bolts often break for the following reasons.

- When tightening the hardware, too much force was applied to the key.

- The fasteners turned out to be defective (there were microcracks and other defects invisible to the eye).

- Strong sticking occurred. In this case, the bolt heads come off due to the large forces applied to unscrew them.

How to unscrew the threads remaining in the block?

There are two options here, but each of them begins with drilling out the fragment. To do this, you should cover the engine block with a thick cloth to prevent sparks and dirt from entering the engine, then cut off the top part with a grinder and place it strictly in the middle.

Drilling out the threads of a broken stud

Using a drill of a slightly smaller diameter, we drill out the fragments on a drilling machine, or most often with an electric drill

Here it is very important to hold the instrument strictly vertically, without distortion. We reach the edge of the trim and try to unscrew the rest of the thread

To do this, before unscrewing, you can try to drive it with a tap or try to hammer the edge of the metal inward with a thin chisel, freeing the threads.

If you fail when unscrewing or drilling, you need to move on to the second option.

Replacing a stud with a repair part and cutting a larger thread

For example, a stud on a VAZ with an M-8 thread. On the repair one, on one side there will be an M-8 thread, and on the other, the best option would be to roll an M-9 thread. With this option, we use a 7.8 mm drill to drive through our hole with the fragment. We clean the hole from the remains of the old thread. Using an M-9 machine tap, we cut the thread and screw on the repair pin. Next we install the head.

Using the same algorithm, you can replace a broken spark plug. Repairing the spark plug hole and removing the broken spark plug is carried out in several stages. There are many videos on YouTube that will tell you how to unscrew a broken spark plug. First, let's try to unscrew the fragment. As a rule, it breaks right behind the hexagon, so we wet the threads with WD-40 or brake fluid and let it sit. Then use a special wrench with a dynamometer to unscrew the fragment.

It turned out well. No, in this case we turn to a turner to turn the foot. While this is being done, we move the piston under this hole to block the channel and prevent chips and dirt from falling into the crankcase. We drill a larger hole, cut a thread and tighten the fitting. The internal thread is made to fit your spark plug, screw the spark plug into it and use the car.

Having completed all the work on replacing, repairing and cutting internal threads on the engine of your car, you gain new knowledge and skills, and also save your family budget.

How to drill out a high strength bolt?

The sequence of actions is the same until the thread is cut in the drilled hole. In this case, before drilling the hardened bolt, it is necessary to make the following part: a bolt with a wrench head is machined from carbon steel. The end of the bolt is given a tetrahedral conical shape using a forging hammer.

Next, the bolt is driven into the drilled hole to the full depth where it should jam. Using a spanner wrench, loosen and gradually unscrew the broken piece of the bolt.

But how to drill out a broken bolt if no other method helps? In this case, the only drastic way is to completely drill out the rest of the part. This is the most difficult and responsible way to drill a bolt without damaging the threads in the mechanism parts.

To begin with, a hole is drilled in the fragment using a thin drill. Then thicker. And so on until most of the remaining piece is drilled out. This is one of the most effective ways to drill a bolt from a car hub.

Features and advantages of cylinder head studs

In any engine, the cylinder head (cylinder head) is attached to the block itself with studs. They are screwed into the block in such a way as to ensure the best and uniform pressing of the cylinder head to the block. A high-quality compressed gasket prevents the leakage of oil and antifreeze and the penetration of gases from the cylinder into the engine crankcase. Fasteners are made from high quality steel. However, over time, the threads on them may corrode and become clogged with various contaminants. Due to exposure to high temperatures, these contaminants are sintered, and the nut “sticks.” When you try to unscrew such a stuck nut and exceed the maximum force, either the thread breaks off or the fastener breaks off. In both cases, it is necessary to replace the broken part.

Cylinder head studs

Replacing the stud

It is better to carry out planned replacement of studs and repair of the head at the same time. For a simple replacement, before unscrewing it, it should be moistened with brake fluid or a brake fluid. It should be unscrewed using a special stud puller or a gas wrench. Unscrewing, especially at the beginning, should be done smoothly, without jerking.

If the force is not enough, you can use an extension cord

It is important to feel the effort here and not miss the moment when the pin begins to twist and break. At the first sign, it is better to reapply brake fluid and let it sit

Move on to the next detail. The pin is unscrewed, move on to the next one. After unscrewing all the studs, we return to the soured part.

We are trying to unscrew it. It may work out, but often such a part breaks off. If it works, install the head with the gasket in place and begin tightening the nuts according to the diagram, observing the tightening torque:

- First, we tighten each nut, going in a circle with a special wrench with a dynamometer;

- Then we go through it several times after a short break to seal the gasket;

- We do the final tightening of the nuts. The cylinder head tightening torque is different for different engine models; it is better to find out this value from the repair manual.

Effective ways to deal with broken bolts and studs

Professional locksmiths know several effective methods on how to unscrew a broken pin. Before you start this task, you need to prepare. By these works we mean cleaning the surface from dirt and grease. It is recommended to pre-treat the threaded connection with WD-40 or ordinary machine oil. You can also ease the situation by hitting the piece of wood with a hammer several times. Often the problem is solved by heating - a pin or bolt, provided that it looks out of the hole, is heated with a soldering iron. Then it can be removed relatively easily.

Drilling

And finally, the third and most radical way. It is used to remove broken bolts and studs from the hole. This is drilling. The method is very difficult. It is much more complex than all of the above and is the most dangerous. There is a risk of damaging the threads in the bore of the engine block or cylinder head. The drill should be held securely, as if it is a cylinder block, there is a serious risk of damaging an expensive part. The stud is often made of harder grades of steel, and the head is made of aluminum. The commutator body is cast iron, so it is also softer than a steel stud. The drill will definitely move away from the hard stud and towards the softer metal. This happens especially often if the work is carried out in a confined space and the drill is installed at a slight angle. The principle of drilling is as follows: you need to make a hole strictly in the center of the stud with a thin drill, having previously cored it, then install a thicker one in the drill and repeat the entire procedure.

The main thing here is to drill strictly in the center. When practically nothing remains of the stud body, the wall will become thin. It can be broken. You should very carefully break off the remaining pins using pre-sharpened wire or tweezers. It must be remembered that any action is carried out as slowly and carefully as possible. If you act rashly, you will need to think not about how to unscrew the broken block stud, but also about how to restore the cylinder head itself. And these are significant costs.

A universal algorithm for unscrewing a bolt with a damaged head

The mechanics of how to unscrew a bolt if the head is broken will be similar to the situation with unscrewing a stud. You can unscrew a bolt without a head using one of the methods described above.

Tips on how to unscrew a bolt if the head has been licked are briefly given in the table.

| If the edges of the bolt are licked (not too much) | Use a file to sharpen the edges and unscrew the bolt with a wrench. |

| Place a 6- or 12-point socket under the socket wrench and unscrew the bolt with the wrench. | |

| Weld a nut whose inner diameter corresponds to the outer diameter of the bolt head. Unscrew using a wrench. | |

| Use a chisel to make a groove along the diameter of the bolt head, and unscrew it with a screwdriver. | |

| If the bolt head is torn off or severely damaged | Cut off the head with a grinder, unscrew the rest of the fasteners using one of the methods for studs. |

| If a bolt with a broken head has a protrusion, place a thick screwdriver at its base and hit it with a hammer in the direction of unscrewing. | |

| Use an extractor or a suitable sprocket. |