SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

The modern market is distinguished by a variety of tools used for all types of work. Cone drills for metal are professional products that are characterized by a long service life, versatility and ease of use. To select the necessary tool, it is recommended to study the basic properties of such devices.

Cone drills for metal are characterized by versatility, long service life and ease of use

Application area

Conical metal drills are used to make holes in sheet and thin-walled metal. Typically, the thickness of the metal being processed is from 1 to 4 millimeters and depends on the height of the drill step. If the height of the step is 4 millimeters, then the maximum thickness of the sheet or rolled metal that can be processed will be, respectively, 4 millimeters. A step drill allows you to work even with thin sheet metal.

The main difference from other types is that with the help of one drill you can get several standard sizes of holes at once.

Note that there are also conical drills for processing not only metal, but also wood, plastic, drywall, and textolite.

A conical drill (sometimes craftsmen call it a carrot drill) is also distinguished by the fact that when used correctly, the hole has virtually no defects. Proper use of the tool allows you to obtain smooth walls and edges of the hole, the absence of burrs and cracks. After drilling, there is no need for additional hole processing. Therefore, craftsmen often use them to correct defects in holes made with another type of drilling tool.

A high-quality metal cone drill bit has hard, sharp edges, which allows it to work with metal of high density and hardness. Some drills also have an abrasive coating, which further increases their effectiveness. Where another tool is powerless, it is often very convenient to use this type of drill.

The cone drill has a sharp tip, which allows the drilling operation to be carried out without preliminary core punching and additional centering.

Cone drills

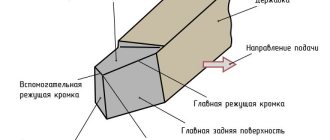

The shape of the working part of such drills is a conical series of step-by-step annular transitions and a longitudinal-spiral or simply longitudinal groove, forming sharp cutting edges.

This makes it possible to use one tool to produce holes of different diameters. Thus, we save not only time on replacing drills during work, but also money on their assortment. Progressive changes in size are made with smooth transitions between steps. This surface shape promotes easy rotation and increased processing efficiency of sheet materials. The use of high-strength steels for the manufacture of cutting edges on step drills provides them with longer service life without sharpening.

An example of a cone drill

The tool allows you to perform technological operations at a time, which under normal conditions require the sequential use of several tools. The material can be processed at high speed, guaranteeing excellent edge quality, even with the smallest sheet thickness. This form of arrangement of cutting edges makes it possible to drill not only sheet steel, but also soft non-ferrous alloys, wood, plastics, gypsum and other products.

The sharp tip eliminates the need for pre-punching and ensures precise positioning of the tool during operation. Step drills can be installed on stationary machines, portable hand drills, and with adapters, even on a hammer drill and grinder.

Conclusion . Considering the design features and technical capabilities of drills, we can say that the main purpose of this tool is to drill holes in thin sheet workpieces. In addition, they are used to correct defects formed after the use of traditional drills in the form of burrs, misalignment, triangular holes and others. Therefore, such drills are widely used in car repair, plumbing installation, electrical panel manufacturing, construction and finishing work.

Types of stepped (conical) drills

As noted, cone drills come with a smooth transition of diameter and with a step, stepped one. Step drills are most widely used, since they make it possible to obtain a hole of a strictly defined size with smooth walls. A hole made with a smooth tapered drill will always have a slight slope. In the case of working with thin sheet metal, this will be hardly noticeable.

In general, the quality of step drills can be classified by color:

- Metallic grey. Typically, such a tool is made of low quality tool steel. No additional heat treatment was provided during its manufacture either. There is no abrasive coating on the surface of the drill. Such drills should not be purchased if they are expected to be used regularly, as well as to work with thick and durable metal.

- Drills are black. Such a tool was subjected to heat treatment during production. Steam treatment and subsequent hardening were carried out. This treatment increases the hardness of the tool and increases its service life. But it is still not recommended to use such drills with stainless and other high-strength steels.

- Dull golden color. A step drill for metal, which has a pale yellow color, is made of metal with the addition of alloying additives, most often cobalt. Such a tool is subjected to hardening and subsequent tempering, which relieves internal stress and increases the strength and durability of the tool. Drills of this color can be used to process durable alloy and stainless steels.

- Bright golden hue. Tools of this color are the highest quality and are designed to work with thick-walled, high-strength steels. The steels from which the tools are made are obtained by adding titanium nitride and subsequent heat treatment.

Speeds/min. step drill for drilling machine

| Material | Steel | alloy steel | Cast iron | Aluminum |

| Ø, mm | RPM | RPM | RPM | RPM |

| 4,0-12,0 | 1700-580 | 1550-520 | 800-250 | 2350-790 |

| 4,0-20,0 | 1700-350 | 1550-300 | 800-160 | 2350-470 |

| 12,0-20,0 | 600-350 | 520-300 | 250-160 | 790-470 |

| 4,0-24,0 | 1700-280 | 1550-250 | 800-130 | 2350-400 |

| 6,0-30,0 | 1200-230 | 1000-200 | 530-100 | 1590-310 |

How to use a step drill for metal

- For more accurate positioning, it is better to mark the hole with a core to prevent slipping.

- Use machine oil or special products (spray, pencil) to lubricate the drill from overheating during operation.

- For high-quality drilling, it is better to use a drill from 3000 rpm. and higher, with an additional handle to avoid distortions.

- When drilling a hole of a larger diameter, you need to slowly reduce the speed so that the hole does not become larger in diameter due to chamfering with the conical part.

Shape and dimensions

All cone drills for metal, as already mentioned, have a cone shape and can have a smooth or stepped diameter transition. The most widespread among mechanics is the step metal drill.

This is due to the fact that it is easier for them to work, since the transition from size to size when drilling is clearly visible, and achieving the desired diameter will not be difficult. The resulting hole has a fairly high surface quality and does not require additional finishing. And a fairly smooth transition from one step to another forms a chamfer for a pre-drilled hole.

Step drills differ in the number of steps, their height, diameter range and pitch. Typically, the diameter of the smallest drill step is 4 millimeters. The maximum size of the hole that a stepped tool can drill is up to 40 millimeters. The standard step height is 4 millimeters. This value determines what thickness of metal the tool can process.

The successive increase in diameter can be 2 or 3 millimeters. The standard step is 2 millimeters. Typically, if a cone drill has a wide range of diameter sizes (for example, from 4 to 40), then the step in this case can be 3 or 4 millimeters.

In specialized stores you can find step drills with a different range of diameters, so they should be selected for a specific set of tasks.

In addition to the working part of the drill, the tool also differs in the shape and size of the shank. The shank can have a cylindrical shape of various diameters, a hexagonal or triangular shape, as well as a specialized profile for specific connectors from hand tool manufacturers. A step drill for metal can be installed on a screwdriver, hammer drill or drilling machine.

Criterias of choice

| Manufacturer | Popular manufacturers include: matrix, BARS, BISON, Enkor, Vira, STAYER, |

| Drill type | Two types (picture above) - with a spiral and a straight groove. With a straight groove - they have a simple geometric shape and are easier to sharpen. With a spiral blade - good smoothness, high cutting performance and better chip removal. |

| Number of steps | There are small drills with 3-6 stages, as well as multi-stage ones with 10 levels, which makes it possible to make 10 different holes in diameter. |

| Drilling diameter | It can vary from 4 to 12, from 6 to 30, from 4 to 40 mm, it all depends on the number of steps and the size of the working part. |

| Working part length, mm | 57, 70, 76,, 81, 100, 105, 115 mm. Step 1, 2, 3 mm |

| Shank type | By type of shanks they can be divided into: hexagonal, cylindrical, triangular, canonical. |

| Shank diameter, mm | Ranges from 6 to 12 mm |

| Drill material | HSS (High Speed Steel) - high-speed steel drills, made from 3 types of steel: Tungsten (T1–T15), Molybdenum (M1–M36), High-alloy (M41–M62). HSS-G - the cutting edge is treated with cubic boron nitride, which extends the life of the drill. HSS-G TiN - containing titanium nitride. HSS-E - contains cobalt and other high-strength metals |

Marking features

Step drills for metal may not always be marked. You should not look for markings on cheap Chinese tools or domestic drills of dubious manufacture. Such manufacturers can sometimes put on drills or their packaging only symbols that they understand, which do not characterize the tool in any way, but serve only for internal classification. But a high-quality professional tool from a trustworthy manufacturer always has a marking.

In the standard case, proper marking should contain in its designation all the main dimensions of the tool, material of manufacture, as well as characteristics of hardness or strength.

Let's take an example of the marking designation ø4-20/2 HSS4241-Co HRC 62.

This cone drill marking should be read as follows:

- ø4 – diameter of the first smallest stage of the tool (diameter of the smallest hole that can be obtained);

- ø20 – diameter of the last largest step of the tool (diameter of the largest hole that can be obtained);

- 2 – diameter pitch value (4-6-8-10-12-14-16-18-20);

- HSS 4241 – designation of the material from which the tool is made. HSS (High Speed Steel) – high-speed steel, 4241 – steel grade;

- Co – the material from which the tool is made contains cobalt, which gives it strength and durability;

- HRC 62 – Rockwell hardness value.

But most often, instead of marking, the manufacturer indicates on the packaging the main characteristics of a cone drill for metal. Moreover, the description of the characteristics is often accompanied by explanatory images to facilitate consumer understanding.

Advantages and disadvantages of these drills

In order to summarize the material presented and help you make a decision about the need to purchase a step drill, we will highlight the positive and negative aspects of this type of tool.

The advantages include the following characteristics:

- one stepped cone drill can replace a whole set of drilling tools (up to 16 ordinary drills);

- the resulting holes have a very high surface quality, which makes subsequent finishing processing unnecessary;

- ability to work with thin sheet steel;

- savings on purchasing a full set of drill sizes;

- cone drills have a short length compared to other types of drills, which simplifies the work;

- high-quality drills have high reliability and durability;

- the ability to drill at high speeds improves process productivity.

Among the disadvantages of step drills, we highlight the following features:

- Compared to other types of drilling tools, cone drills have a higher cost;

- when working with smooth conical drills, obtaining an exact diameter value is quite difficult even for a professional;

- to work with this type of tool you need to have certain skills;

- Sharpening stepped cone drills is quite difficult, especially at home.

How to choose the right step drill?

To choose the right step drill, you need to decide on the purposes for which the tool will be used. Thus, it is necessary to determine what size holes need to be drilled. The values of the smallest and largest diameters that are planned to be made are especially important.

You should also decide on what hand tool or machine the drill will be used. The type of shank that should be on the drill depends on this. Therefore, you should carefully study the drill chuck connector and clearly know the shape and dimensions of the shank. If the shank does not fit the existing connectors, you will have to separately purchase a special adapter.

It is important to decide on the manufacturer and level of the tool. As already noted, bright golden-colored stepped conical drills are made with cobalt and titanium impurities, with an abrasive coating and have high hardness. They will last longer and allow you to work with thick rolled products, stainless and alloy steels.

Look for the HSS designation on the label or packaging, which means the drill is made of high-speed steel. Try not to buy dubious Chinese-made drills.

Why does an electrician need a step drill for metal?

A step drill can be used by an electrician. He needs this device when installing electrical wiring. For example, an electrician must drill a hole in a steel profile to thread a wire through the plasterboard sheathing. The thickness of the metal profile sometimes reaches 0.5 mm. The diameter of the cable to be passed through is 16 mm. It is difficult to drill this profile with a simple tool, since the holes will come out uneven. Using a multi-stage option, you can make a hole in a workpiece with a thickness of 16, 20, 25 mm.

Step drills are necessary for electricians to work in electrical panels. It is often necessary to drill a hole in the panel to install control buttons, indicators, various switches, fittings or a lock. The electrical panel is 1 mm thick. Installing the seal on the shield requires drilling a large opening in the shield.

The stepped product makes openings in metal cable boxes for wire exit. If the openings in the box for removing the wire are rigidly fixed, then it is necessary to make an additional hole for installing the gland and plug.

How to sharpen cone drills?

Cone drills are expensive, but at the same time quite reliable and durable cutting tools.

But in any case, after some time, their cutting edges become dull, and the tool loses its characteristics. Some step cone drills are designed to be sharpened, and some are not sharpened. Those that are not intended for sharpening are characterized by high quality cutting edges and durability. If the drill has a straight longitudinal groove, then sharpening can be done manually. If the groove is spiral-shaped, then sharpening should be done on a sharpening machine using an abrasive wheel. It is important to maintain the angle and dimensions of the cutting edge on each step drill diameter. The abrasive wheel used for sharpening must be fine-grained. If you have a similar drill at hand with non-blunted edges, you can take it as a template and focus on its dimensions and the profile of the cutting edge.