Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations. During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension. Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

DIY wire bending machine

The production of various products requires the use of wire parts, which are given a certain shape (the simplest example is wire frames).

If in everyday conditions the simplest wire bending can be done manually using the simplest tools and devices, then for industrial purposes equipment of varying complexity is used (up to 3D (volumetric) bending machines with numerical control).

Working with wire at home

There are several ways in which manual wire bending with your own hands becomes a fairly simple process. If we are talking about soft plastic material, then there are no problems in the work. This wire bends easily with bare hands, so giving it the desired configuration is very simple.

If we are talking about working with steel, fairly rigid wire or large-diameter material, then we have to use the simplest tools, devices and templates that allow us to give the product the required appearance:

- Round nose pliers allow you to bend the wire to a small radius.

- Using pliers, it is convenient to hold the workpiece; they can be used to bend the wire at different angles.

- Cutting of the material is carried out using side cutters (pliers, wire cutters).

- The most versatile tool is considered to be universal pliers - pliers.

Depending on the required configuration of the product, mandrels (templates) of various shapes can be used. So a regular rectangular clamp can be made by clamping one edge of the material in a bench vice, and then making the necessary bend using a regular hammer.

Complex shapes require the use of more advanced equipment.

Wire bending methods

Technologically, bending thin sheet metal and wire are similar in many ways. During the work process, the material undergoes plastic deformation, with one side being compressed and the other being stretched.

In practice, the following processing methods are used:

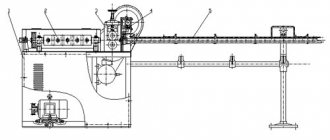

- Bending wire from a coil. Using this technology, the compacted material is unwound and fed into a two-plane roller straightening machine, which makes the wire even. Then the material goes to bending equipment, where it is given the required shape, after which it is trimmed.

- In cases where it is necessary to process the ends of the wire before giving it the required shape, bend the wire cut into measuring rods. Equipment for bending wire using this method has a simpler design.

The main methods of wire deformation can be divided into the following groups:

- Wire rolling. The simplest equipment for this process consists of a stationary template that has a specific radius of curvature (more complex templates may have several different radii). The deformation of the wire is done by rolling the material around the template with a pressure roller. This technology is widely used in the production of products with a small bending radius (approximately equal to the wire diameter).

- Wire pushing . A wire bending machine using this technology is similar to the 3-roll equipment of profile bending and spring-coiling machines. The material is pushed by a special drive into the working area, in which it is alternately pressed by a roller against various rolls, making it possible to change bending parameters and transition from one radius to another. Thanks to this equipment, it is possible to obtain products of complex configurations with a large bending radius.

- Straightening equipment is used to straighten the wire . Such a unit may consist of a rotating straightening frame or a two-plane straightening block. It is believed that the rotating frame aligns the wire more accurately.

Wire working machines

CNC wire bending machines can provide high productivity and processing accuracy.

At the same time, automation and control systems can be installed on different equipment:

A machine with one bending console is considered the simplest type of equipment for working with wire. It is most often used for the manufacture of simple-shaped products. At the same time, there are restrictions on the length of the sweep; it usually does not exceed one meter.

The double-cantilever bending machine is used for the production of complex products; they can work with structures that have a significant development length.

Before bending begins, the wire is cut into measured pieces, and the deformation process is performed from both ends of the rod in the opposite direction.

Products with a large number of bends can only be obtained using equipment of this type; single-console machines cannot cope with such a task. In addition, double-cantilever machines allow you to easily perform closed bends (more than 180 degrees).

Recently, 3D CNC wire bending (volume bending) has become increasingly popular. Spatial bending is provided through the use of a rotary bending console controlled by automation systems.

The disadvantage of this technology is the high cost of the equipment and the relatively low productivity of the line. Therefore, many manufacturers use equipment for simple flat bending, with the ability to automatically weld product parts.

But, at the same time, a product without welds, made on a three-dimensional machine, is more durable.

Improvement of bending equipment has made it possible to significantly increase the speed of work and increase the accuracy of bending. The use of such equipment is especially advisable when organizing mass production.

Well, individual products can well be made using the simplest devices, although without the appropriate experience it is not so easy to do it yourself.

Types of wire bending machines

Wire bending is one of the ways to give it a new shape using manual or mechanical action using special equipment.

The bending itself occurs due to the compression of the inner layer, due to which the outer layer can be stretched and bent. Such technological work is in great demand, as is equipment for manual bending.

You can create products from bent wire with your own hands.

In this case, it is advisable to choose softer plastic materials for the process so that the wire can bend easily and doing the work with your own hands does not create difficulties.

If the wire is rigid and has a large diameter, then to process it manually you need to use certain tools:

- using pliers you can create a small bend of a few mm; they are also convenient for fixing material for subsequent processing;

- You can cut the wire into separate parts with wire cutters or needle-nose pliers;

- pliers (a type of pliers) are considered one of the most convenient and versatile tools for bending wire with your own hands.

Before you start manually bending the material for the rings, it is better to create a certain template on paper and periodically check it as you work. Simple shapes can be made without templates.

For example, to create a regular rectangular clamp, it is enough to first clamp part of the wire with a bench vice, and bend the remaining piece at a right angle using pliers or a hammer.

Rules for manual bending

When performing manual wire bending work with your own hands, you should adhere to certain safety rules that can protect your hands from possible injuries:

- Before starting work, it is advisable to put on gloves made of thick, dense fabric;

- Materials should be well secured so that they do not jump out of the vice during bending;

- All machines and tools for manual work must be in good working order;

- Do not place heavy objects on the edge of the table (for example, if you hit the pliers, you can drop them on your leg and get a noticeable bruise, or even injury to your fingers);

- When working with the wire with one hand, try to keep the other away from the bend (the pliers can break off and injure your hand).

DIY sheet metal bending technology

In the process of building a house or cottage, there is often a need to equip drains, sewers, and metal frames.

When manufacturing such products, it is necessary to give the flat workpiece the necessary spatial shape. Advice from experienced craftsmen on how to bend a sheet of metal at home will allow you to produce good quality structures that will last a long time.

Bending technology - basic information

Metal bending is performed without welding seams, which avoids corrosion in the future and produces a product of increased strength. Deformation does not require significant effort and is usually performed in a cold state.

The exception is hard materials such as duralumin or carbon steels. Sheet metal bending technology is developed according to the assigned tasks in such options as:

- radius,

- multi-angle,

- single-angle,

- U-shaped.

A special case is flexion with stretching. This technology is used in the manufacture of parts with large bending radii and small diameters. When making parts with your own hands, the process is combined with operations such as cutting or punching.

Soft types of metals and alloys, such as brass, copper, and aluminum, are well suited for home processing. The production of products by bending is carried out on rolling or rolling machines, or manually.

The last procedure is quite labor-intensive. Bending is done using pliers and a rubber hammer. If the sheet is thin, use a mallet.

Types of wire bending machines

[Wire bending] is one of the ways to give it a new shape using manual or mechanical action using special equipment.

The bending itself occurs due to the compression of the inner layer, due to which the outer layer can be stretched and bent. Such technological work is in great demand, as is equipment for manual bending.

You can create products from bent wire with your own hands.

In this case, it is advisable to choose softer plastic materials for the process so that the wire can bend easily and doing the work with your own hands does not create difficulties.

If the wire is rigid and has a large diameter, then to process it manually you need to use certain tools:

- using pliers you can create a small bend of a few mm; they are also convenient for fixing material for subsequent processing;

- You can cut the wire into separate parts with wire cutters or needle-nose pliers;

- pliers (a type of pliers) are considered one of the most convenient and versatile tools for bending wire with your own hands.

Before you start manually bending the material for the rings, it is better to create a certain template on paper and periodically check it as you work. Simple shapes can be made without templates.

For example, to create a regular rectangular clamp, it is enough to first clamp part of the wire with a bench vice, and bend the remaining piece at a right angle using pliers or a hammer.

Processing methods

If we talk about bending wire on a large scale (in production or a specialized plant), then various methods are used to plastically deform it.

One of the most common and economical is the bay processing method.

In this case, wire rings are wound onto coils, and then they are fed to two-plane roller machines that straighten the wire.

:

Afterwards, the material is processed on bending equipment (the required shape is created), at the end the wire is cut, and the entire work cycle is repeated again.

IMPORTANT TO KNOW: Technology for stamping sheet metal parts

Moreover, all work is fully automated, which allows you to save time and money and use the device to create a simple curved structure with a development length of about 1000 mm.

For rolling wire with your own hands, there are special devices that consist of fixed templates of certain radii of curvature (the radius can be one or several).

The material is rolled around the created template using pressure rollers.

Basically, this technology is used to create bent products that have a small bending radius (about the same as the diameter of the wire).

The method of pushing the wire is reminiscent of the way 3-roll equipment works on a profile bending and spring-coiling machine.

The material is pushed into the device using a special wire, then it is pressed against various rollers, which makes it possible to change the bending parameters and make transitions to different radii.

This device allows you to bend various structures that have a complex configuration and large bending radii on the development - from 1000 mm or more.

:

You can straighten the wire using straightening equipment or a special device. This equipment includes units consisting of rotating leveling frames or two-plane leveling blocks.

In this case, rotating frames are preferable, as they allow the material to be aligned more smoothly.

Professional equipment

If only the simplest devices (vises, pliers) are used to bend wire on their own, then for mass industrial processing of the material professional machines are used (for example, for the production of key rings or springs for handles).

IMPORTANT TO KNOW: Technique of artistic metal forging

A wire bending machine with one bending console is one of the simplest and makes it possible to create bent products of simple shapes. The length of the sweep in this case should not exceed 1000 mm.

Double-cantilever machines can work with a reaming length of more than 1000 mm.

The material is cut into the required pieces, then it is deformed from both ends simultaneously.

Such equipment allows you to create products with a large number of bends. Machines with only one console can no longer perform this work.

Also, on double-console machines you can make figures with closed bends.

Wire bending on so-called 3D machines is becoming more and more popular these days.

:

Three-dimensional spatial bending can be done using a rotary bending console, which is controlled by an automated system.

Unfortunately, such material processing is quite expensive, so parts are mainly created using simple flat bending, and then, if necessary, individual parts are automatically welded.

But due to welding seams, products become more fragile and short-lived, so their cost is relatively budget-friendly.

Homemade and industrial methods of wire bending

Wire bending made it possible to give products any shape. How this happens in production and how to bend the wire with your own hands - more on that later.

It is difficult to say where products made from wire, which is a metal thread or a thin rod, have not been used today. Wire bending

made it possible to give products any necessary shape. Both using hand tools and mechanical influences on special equipment.

From a physical point of view, the process of bending wire consists of simultaneous compression of the inner and stretching of the outer layers of the metal of the wire. The process can also be accompanied by a longitudinal displacement of these layers if twisting occurs. This technology for working with metal wire is widely used in many industries and in jewelry.

What is used for bending wire? How to make a machine with your own hands!

Objects of various configurations and purposes can be made from wire. During work, it is important to bend the material correctly, therefore, when the diameter of the metal thread is more than 1 mm, it is advisable to use special devices.

The main types of this type of tool, as well as how to make a wire bending machine with your own hands, will be discussed in this article.

Basic bending methods

If it is necessary to perform a small amount of work, then hand tools are used to bend the wire. For bending soft metal materials or when the wire diameter does not exceed 3 mm, pliers or round nose pliers are used. These tools allow you to securely clamp a part of the product in one tool, and use another to bend the wire to the desired angle.

In this way, you can bend the material using a carpenter's vice. In this case, the wire is fixed in a vertical position, and the change in direction is also carried out using pliers or any other clamping device or mechanism.

If it is necessary to make a rounded bend, then for this purpose any rod of suitable diameter is used, which is also clamped in a vice. A rounded bend will need to be made when making springs from elastic wire yourself.

To do this, it is enough to clamp a rod or pipe of a suitable diameter in a vice, fix the end of the wire on one side, and use pliers to wind the wire the required number of turns.

If the wire has to be bent too often, then the most correct solution would be to purchase special devices or machines.

Tools for bending this material are a design in which the wire is clamped and bent using human muscle power. Machine tools usually use electric drives, and for the manufacture of complex products such machines are equipped with electronic controls.

Rules for work

Wire bending is not a complicated process, but to work effectively with this material you must adhere to the following rules:

- For work, you must use gloves made of thick fabric.

- Use only working tools and automatic machines.

- If a vice is used to perform this operation, then before starting the process, you must make sure that the workpiece is securely fixed.

- Before bending, the workpiece should be leveled.

Following these recommendations will help prevent scraps and injuries in the event of a sudden release of material from the holding device. You should also take care of the wiring and proper grounding when using machines that run on electricity.

Equipment use

If the volume of work is large enough, then equipment equipped with an electric motor will allow you to perform a large number of operations. The use of machines will significantly increase labor productivity, but at the initial stage it will be necessary to make some efforts to study the process of operation of a wire bending machine.

The most economical machine for bending wire is considered to be coil equipment, in which the material is supplied from bulk coils.

The process of bending wire on such equipment is carried out in the following order:

- The wire from the coil is fed to a roller mechanism, which aligns the material.

- The straightened wire enters the bending mechanism.

- At the next stage, bending and separation of the wire products occurs.

- After cutting the finished product, the process is repeated.

To make wire bending work as comfortable as possible, CNC machines are used.

Despite the significant cost of such equipment, the return on investment in a business occurs within a few months. Machines equipped with a microprocessor allow not only to fully automate the process, but also to carry out welding work on curved products.

DIY device

If the wire bending device will be used only for home work, then you can make a manual machine yourself. Equipment made with your own hands will not be highly productive, but for performing daily operations in a small volume such a product will be quite sufficient.

For a homemade machine you will need to prepare the following materials:

- Sheet steel 4 mm.

- Steel rod 20 mm.

- Profile pipe 20*20 mm and 30*30 mm.

- Two 12 mm nuts.

- Steel pipe ¾.

- Bolt 12 * 70 mm.

- Bushing from the reaction rod of a VAZ 2106 car.

To perform this work you will also need to prepare the following tools:

- grinder;

- welding machine;

- drill and metal drill bit 20 mm.

A device for bending wire is made with your own hands in the following sequence:

- A rectangle measuring 150*80 mm is cut out of a steel sheet using a grinder.

- Stepping back approximately 30 mm from the shorter side, you need to make a hole with a diameter of 20 mm exactly in the middle.

- Cut a piece 45 mm long from the metal rod.

- Place a piece of rod into the previously made hole and weld it on the back side.

- Cut a 70*30 mm rectangle from a metal sheet.

- Make two holes with a diameter of 16 mm in the 70*30 mm plate. The holes should be equidistant from the edges of the plate, and the distance between them should be 20 mm.

- Weld M12 nuts to the 70*30 mm plate so that they align with the holes made earlier. In order to perfectly center the nuts before welding, it is recommended to place them on a bolt, which should be threaded into the hole.

- Cut a piece 45 mm long from a ¾ steel pipe.

- Weld a 70*30 mm plate to the resulting cylinder made of a metal pipe, so that the pipe hole is in the same row as the previously drilled 16 mm holes. When performing this work, the plate should be placed exactly in the middle of the height of the steel cylinder.

- Cut a piece 400 mm long from a 30*30 mm profile pipe.

- Weld a section of profile pipe to a 70*30 mm steel plate. The metal connection is made on the side opposite to the welded cylinder. This will create a lever with a cylinder and 2 holes at the end.

- A piece 100 mm long is cut from a 20*20 mm profile pipe.

- A section of profile pipe is welded to the edge of a 150*80 mm plate. This element must be positioned from one of the corners to the level of the previously welded metal rod.

- Cut a 70*40 mm plate from a metal sheet. This part will be intended to support the workpiece, so it must also be welded to a section of the profile pipe.

- The torque bushing fits onto a 12 mm bolt, which should then be screwed into a nut welded to the lever.

- The lever with the bushing is fitted as a cylinder onto a piece of metal rod welded to the frame.

- To securely fix the machine during operation, it is recommended to secure the frame to a flat horizontal surface using threaded connections or welding.

The manufacture of the machine can be considered completed.

Wire bending is carried out as follows:

- The workpiece is placed on the side platform so that the front part is inserted into the gap between the central cylinder and the bushing attached to the lever.

- The lever rotates to the required angle.

- The workpiece is removed from the machine, trimmed and used for its intended purpose.

If the homemade machine was made of high-quality materials, and the welding seams were made at a professional level, then the device can be used not only for processing wire. In this case, it is possible to use the product for bending pipes, including profile pipes, with a diameter of up to 10 mm.

Watch the video where a man shows how to assemble a simple structure of a reinforcement bender for bending rods and squares:

The second video shows an overview of the mechanism for bending wire and curling hooks:

Conclusion

What is used for bending wire is described in detail in the article. To work with this material, you can use both simple tools and complex installations that allow you to perform a large number of operations per minute.

If you have a limited budget, you can independently make a mechanical device that will not be inferior in quality to factory products.

Types of bending machines

Bending machines are distinguished by the type of raw materials used.

Sheet metal bending machines

Used to give metal sheets different shapes. They are widely used in the manufacture of body parts, roofing elements, window structures, ridges, canopies, and ebbs.

All metal bending machines have the same design and differ only in the drive. The most widespread are hydraulic bending machines, electromechanical and manual.

The first ones are the most powerful and allow you to work with sheet metals with a thickness of more than 3.5 mm. Electric bending machines combine high performance, a wide range of functions and low price. This is the cheapest equipment among industrial sheet benders. The main advantage of the latter is compactness, mobility, and independence from the power grid. The price of manual bending machines is very low, which allows them to be used for domestic needs, in small workshops and on construction sites.

Machines for bending reinforcement

Machines for working with reinforcement, based on the type of raw material used, are divided into machines that work with rods and coils, and according to the degree of automation, they are divided into manual, electromechanical and CNC machines.

The operating principle of all bending machines for reinforcement is the same: a part of the reinforcement is placed between the bending pin and stops, the bending pin is set in motion and bends to the required angle.

Manual bending machines for reinforcement use a lever system that allows the force required for bending to be reduced several times. Such machines are compact, simple, reliable and are in great demand on construction sites.

Electromechanical machines differ from manual machines only in that bending is carried out not by the physical strength of the operator, but by an electric motor. These machines allow you to bend reinforcement with a diameter of up to 40-50 mm.

CNC bending machines for reinforcement allow automatic bending. The reinforcement from the unwinder passes through straightening rollers and enters the bending zone, where, using a rotating disk with stops and bending fingers, it is bent in accordance with the established program. Such machines are highly productive and do not require operator intervention in the work process, but they have restrictions on the diameter of the fittings, as a rule, no more than 16 mm.

Pipe bending machines

Pipe bending is necessary for the manufacture of air and gas lines, refrigerator radiators, heat exchanger elements, and in the production of POS products.

Pipe bending machines are divided into manual and hydraulic based on the type of drive.

Manual pipe cutters are typically used to cut small diameter pipes made from soft materials. In other cases, hydraulic pipe benders are used, the most widely used of which are three-roll bending machines.

In mass production of more complex products, such as refrigerator radiators, automatic CNC pipe bending machines are often used. The principle of their operation is similar to the operation of machines for bending reinforcement.

Strip bending machines

Our company offers machines for bending metal strips. Such machines produce clamps, staples, clamps, wheel rims, etc. There is also a specialized machine for making letters from aluminum and steel strip for signs.

bending>

There are 2D and 3D bending machines. The former are used for the manufacture of simple flat products: hooks, hangers, wire frames, etc. 3D wire machines are universal bending machines suitable for the production of almost any wire product: trays, brackets, baskets, etc. Three-dimensional bending is made possible thanks to the presence of a rotary console. Spring winding machines should be included in a separate group. Their use allows you to make springs of various diameters and with different numbers of turns in a matter of seconds.

Wire bending: manually and on wire bending machines

Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations.

During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension.

Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Manual bending rules

If you are going to manually bend the wire, you must adhere to a number of recommendations that will allow you to complete this procedure without harm to your own health.

- All bending procedures should be carried out only with gloves made of thick fabric.

- The wire that is being bent must be secured in a vice as securely as possible so that it does not jump out during operation.

- All tools and equipment that you are going to use for work must be in good working order and perform their assigned functions efficiently.

- Heavy tools and equipment that you use when bending should not be placed on the edge of the workbench, so as not to accidentally hit them and drop them on your feet.

- When carrying out all manipulations with the wire bending tool with one hand, the other should be kept as far as possible from the future bend. Pliers or any other tool can break off and injure a hand located close to the bending area.

Wire bending using improvised means is possible only in small quantities, since such a procedure is quite labor-intensive. In addition, this operation can only be used to create products of the simplest configuration.

A specialized wire bending machine allows you to produce various products in large volumes, including those with complex shapes.

Working with a wire bending machine

To produce a large number of bent products from wire, various techniques can be used, each of which uses special equipment. The most common and economical method is the coil bending method.

Bending using this technology occurs in several stages.

- The wire, which is wound on coils, is fed to a two-plane roller machine, which aligns it.

- After alignment, the wire is fed to a wire bending machine, on which the product of the required configuration is formed.

- The formed product is cut off, and the entire bending cycle is repeated again.

The use of this technology allows you to fully automate the bending process and thereby achieve high productivity.

Budget wire bending machine

A wire bending machine can also look like a stationary template around which the wire is rolled using movable pressure rollers.

Using such devices, bends of even the smallest radius can be formed on the surface of the wire, the value of which is comparable to the outer diameter of the workpiece.

At the same time, the configuration of the product formed on such a machine can be quite complex.

The adjustable stops and variable arms of this template allow you to create many combinations of wire bends

A wire bending machine can also operate on the principle of pushing the workpiece through a system of rollers.

When using such equipment, the end of the wire is connected to a special wire, which pulls the product through the working parts of the machine.

A wire bending machine of this type, due to the features of its design, allows the production of products with even very complex shapes.

When leveling the wire, a wire bending machine is also used, which in this case is used for straightening.

The working parts of such equipment can be straight frames or two-plane straight blocks.

At the same time, rotating straightening frames are more efficient, which is why they are used in cases where leveling the surface of the wire needs to be done as smoothly and efficiently as possible.

Types of professional equipment

The simplest type of professional equipment used to bend wires are machines with one console. Meanwhile, such devices can only produce products of simple geometric shapes, the development length of which does not exceed 1000 mm.

More complex products with a development length of over 1000 mm make it possible to create double-cantilever equipment, in which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex curves.

The most complex wire products allow the creation of 3D machines on which bending can be performed simultaneously in three dimensions.

The machines of this category are endowed with such unique functions by a rotary bending console, all movements of which are controlled by an electronic automated system.

Despite all the advantages of processing using such equipment, it is quite expensive, so these machines are used in exceptional cases.

Types of professional equipment

The simplest type of professional equipment used to bend wires are machines with one console. Meanwhile, such devices can only produce products of simple geometric shapes, the development length of which does not exceed 1000 mm.

More complex products with a development length of over 1000 mm make it possible to create double-cantilever equipment, in which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex curves.

The most complex wire products allow the creation of 3D machines on which bending can be performed simultaneously in three dimensions. The machines of this category are endowed with such unique functions by a rotary bending console, all movements of which are controlled by an electronic automated system. Despite all the advantages of processing using such equipment, it is quite expensive, so these machines are used in exceptional cases.

DIY wire bending device - Do it yourself

Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations.

During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension.

Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Methods for bending metal wire

There are several main ways to give metal wire the required shape of the finished product, so we can highlight:

- manual method of bending wire using special tools and simple devices. It is used for wire with a diameter of up to 3 mm in the manufacture of simple products in utility production or households. As a rule, it does not require virtually any financial investment or special knowledge;

- manual method of making jewelry from wire up to 2 mm in diameter. Requires special tools and devices, as well as certain knowledge and skills for working with precious metals;

- bending wire from a coil, which is based on a special device called an unwinder;

- bending wire from a metal rod;

- bending using wire rolling method;

- bending metal wire using the pushing method.

Bending machines for wire and fittings: device, design

The CNC bending machine has the following main design elements.

Unwinder

Included in the package of machines capable of working with wire or reinforcement from coils. It is necessary for unwinding and feeding the wire into the correct machine unit. Either a mechanical or motorized unwinder can be used.

Correct knot

Rollers are used as the correct mechanism. The use of this straightening method is due to the fact that the wire is fed into the bending unit in jerks, and the use of the correct drum involves continuous pulling of the wire.

Bending unit

The bending mechanism consists of a stop and several bending fingers that perform bending under the control of a CNC system, as well as guide rollers. 3D wire bending machines are also equipped with a rotating console.

Bending machine: diagram of the bending mechanism

Cutting device

After completing the bending program, the CNC system sends a control signal to the cutting mechanism, which is a guillotine-type knife; it lowers, cutting the finished product.

Buy a bending machine with maximum benefit in

In addition to supplying equipment to our customers, we provide quality service:

- consulting support on operation and maintenance of the machine during the warranty period and after;

- supply of components and spare parts for the bending machine in the shortest possible time;

- free installation and commissioning of equipment supplied by us;

- Warranty and post-warranty repair of the bending machine if necessary.

All machines are delivered according to the agreed configuration and within the specified time frame with all accompanying documentation: instructions for connecting the bending machine and operating it in Russian, electrical diagram, drawings.

Didn't find the right model? Contact our specialists and explain your tasks. We can select a bending machine, the price and technical characteristics of which will suit even the most demanding customers.