04/25/2019 Author: VT-METALL

Issues discussed in the material:

- What are the features of bending sheet aluminum

- What kind of sheet aluminum can be bent?

- What is the technology of bending sheet aluminum

The properties of aluminum make it possible to make a huge number of useful things from it. In this case, the greatest convenience is sheet material. Bending of a thin sheet can be done using special devices in different ways. When working with this material, there is a specific process of bending and maintaining the integrity of the product at the point of deformation. We will tell you how to bend sheet aluminum and what the features of this process are in our article.

Aluminum grades for bending

However, radial bending of an aluminum sheet cannot be carried out for all types.

It all depends on the characteristics of the alloy and its constituent components. Grades 1105 and VD1, alloys containing aluminum and manganese, food alloys A5 and AD are considered to be the most malleable and do not pose any problems during deformation. The AMC alloy has unsurpassed bending capabilities: sheets based on it can be used to produce products of complex shapes. In contrast to these materials, duralumin, the main feature of which is considered to be strength, is not suitable for bending: parts of the required shapes can be made from it only by stamping technology. Grade B alloys used in aircraft construction are also classified as difficult to machine. Even bending a 2 mm aluminum sheet—rolled material of small thickness—is extremely difficult in this case. Such rolled products can only be processed using stamping equipment or a press.

Aluminum sheet bending technology

If there is an air gap between the walls of the V-shaped matrix and the sheet, “free” bending, also called “air” bending, is carried out. This is a very popular metal processing method.

Bending when the sheet is fully pressed against the die is called calibration. This method has been around for a very long time and is currently used for certain cases when another method is not effective. Let's take a closer look at these methods of bending sheet aluminum.

1.

Free.

This method bends the sheet, but with limited accuracy.

Main characteristics of the method:

- The sheet is pressed by a traverse using a punch to a selected depth along the Y axis into the matrix groove.

- The sheet has no points of contact with the walls of the matrix, remaining in the air space.

- Accordingly, the geometry of the bending tool is not decisive. The bending angle depends on the position of the Y axis.

Modern presses allow you to adjust the Y-axis accuracy to 0.01 mm. It is quite difficult to correctly determine the angle depending on the position of the Y axis, since this value will be different for each angle. The differences are due to the properties of the metal itself, the characteristics of the bending tool and the settings of the lowering stroke of the crosshead.

Free bending has a number of advantages:

- High elasticity: Any bending angle (within the range of the V-die opening angle) can be achieved without changing the bending tools.

- Tool costs are reduced.

- Doesn't require much effort to bend.

- Varying efforts allows you to achieve different results. The more the matrix is opened, the less effort is required for bending. If the width of the groove is doubled, the effort required will be half as much. Accordingly, you can process thicker metal by opening the die wider with the same force.

- Does not require large investments, since a press with less force is needed.

Of course, these are purely theoretical calculations, since you may want to purchase additional equipment for such an economical press in the form of a back stop axis, manipulators, etc.

Disadvantages of air bending:

- bending angles of thin sheets are not highly accurate;

- material properties can influence repetition accuracy;

- Specific bending operations cannot be performed using this method.

Air bending of sheet aluminum is suitable for sheets thicker than 1.25 mm. If your material is less than 1mm thick, then it is better to use sizing.

When bending, the smallest internal radius must be greater than the thickness of the sheet. Otherwise, only calibration is suitable. An internal radius smaller than the sheet thickness can only be made on very soft material. So, copper can be used for these purposes.

Air bending helps produce large radii. This is achieved by incrementally moving the back gauge. But if you want to get high quality with a large radius, we recommend using the calibration method.

Corrugated aluminum bending

As you know, there are two technologies for bending aluminum - free (air) and calibrated. In the first case, an air gap is maintained between the punch and the walls of the mold and the sheet bends almost by weight. In the second, there is no such gap and the sheet fits tightly into the mold. “Air” technology is more common, but is not suitable for all types of sheets. If the grade of aluminum is soft or you need to process a product of complex shape - for example, bending corrugated sheet aluminum - use the calibration method.

Methods

When aluminum is processed on a production scale, it is bent in two ways.

- Free. At the moment of bending the metal, there is an air gap between the sheet and the pressing apparatus. This method allows you to work with thicker materials and produce products with complex shapes, but when working with thin sheets it gives low bending accuracy.

- Calibration. In this case, there is no air layer between the device and the aluminum. This allows you to accurately bend thin sheets, but requires a lot of effort and expensive equipment.

You can bend a sheet of aluminum at home without using expensive tools.

Specifics of bending aluminum sheet

To set up a machine for serial bending of sheet aluminum in Moscow, a specialist usually needs two or three “training” workpieces.

The maximum possible radius is determined by the thickness of the sheet and other geometric features, the type of alloy and even the time that has passed from the moment the rolled product is produced to its processing. Before bending, sheets of metal are thoroughly cleaned, otherwise scratches and scuffing may occur on their surface when passing through the rollers. For the same reason, the master monitors the timely cleaning of the rollers themselves. Indicators of correctly completed work are the parallelism of the sides of the bent sheet and a straight fold line.

Bending at home

The most common and proven method of household bending of aluminum is cutting grooves. This gives high angular accuracy and allows you to work with materials of different thicknesses.

- The bend location is marked on the aluminum sheet in accordance with the measurements.

- Guides are fixed along the lines - iron corners, profiles, sheets of harder metal are suitable.

- According to the applied markings, an incision is made with a depth of approximately half the thickness of the sheet itself. Cut along the outside of the fold. Most often this is done using a router, but on small thin sheets you can get by with a sharp construction knife.

- After the cut is ready, they begin to bend the sheet without removing the guides. Do this carefully and gradually along the entire length of the marking until the desired angle is reached.

Features of aluminum bending

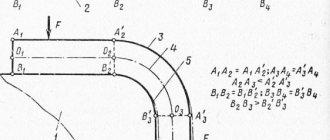

The custom aluminum bending process can be divided into four stages:

- Preliminary work. At this stage, specialists evaluate the features of the aluminum sheet alloy, the dimensions of the sheets, get acquainted with the project, determine how many bends of the material need to be made;

- Cut the sheets if they came to work undivided;

- Fixing the workpiece in the machine. In this case, the role of clamps is performed by hydraulic cylinders;

- Actually flexible. When bending a sheet along a radius, a rounding is formed on it instead of a corner.

Profile bending capabilities

Essentially, when bending an aluminum profile, the rolled product is cold deformed as it passes through the rolls of a profile bending machine. The equipment differs in the number of rollers (there can be three or four) and their location - on a horizontal or vertical plane.

On three-roller machines, bending of an aluminum profile of a minimum radius is carried out not in one, but in several passes. Each of them increases the curvature of the arc more and more, bringing the workpiece closer to the final shape. Four-roller ones are more suitable for producing products of complex shapes: with them, the initial workpiece can even be brought into a spiral or circle. When using CNC equipment, the bending radius is set by software.

Which brands can be bent and which cannot?

The production produces aluminum billets of various grades. They differ in characteristics and material features. Types of aluminum:

- Tempered - a material with high strength and hardness. When bending, it is necessary to preheat the working surface. Without heating, the sheet cracks. Low flexibility requires compliance with the rules of working with the material.

- Annealed - considered a soft type of metal, which is most often used for bending. Does not withstand stretching.

- Cold-worked is sheet metal that has undergone a cold compaction process. Withstands heavy loads, bends without cracks.

- Semi-hardened - metal with a high rigidity index. Withstands bending up to 90 degrees. Increased rigidity prevents the surface from denting during impacts.

- Duralumin - this material is designated by the beech “D”. It is considered a durable material with high wear resistance. It is used for stamping because it bends poorly.

- Brands VD1 and 1105. Materials with low specific gravity and good strength properties. Often used for bending.

- AMC alloys. Materials that are used during the manufacture of parts of complex shapes. They have a high ductility index.

- AMG alloys. The components of such materials are magnesium, manganese, aluminum. They bend well, are resistant to acids and alkalis. The sheets are used to make containers for storing chemicals and fuel.

- Aviation alloys, designated by the letter “B”. Used in mechanical engineering. To bend them, stamping and pressing processes are used.

- Alloys A5, AD. Metals are used in the food industry.

Any of the produced aluminum grades is manufactured in accordance with GOST.

Aluminum grades

How to bend parts made of duralumin and silumin?

When trying to bend D16T aluminum (duralumin) and silumin sheets may crack. To maintain the integrity of the metal sheet, it is necessary to carry out preliminary heat treatment. To do this, the duralumin blank is heated until a red tint appears. The room should be dark to see the color change and not to overheat the alloy. After heating, you need to let the metal cool at room temperature. Then you can bend the sheet without fear of damaging it.

Source

To come in

Already registered? Sign in here.

There are currently 0 users on the page

There are no users viewing this page

Source cccp3d.ru

We need advice from the collective wisdom. Given: 5 aluminum tire plates. It is necessary to bend them. How to bend is shown in the picture. Do not offer a vice or hammer.

Why is it worth ordering a service from us?

We offer to order bending of aluminum profiles in Moscow on favorable terms, taking advantage of the advantages of the Stimul K Company:

- high quality of the final product - possible, bending along a radius of 150 - 175 mm with a workpiece width of 45 - 50 mm;

- compliance with the technological process - twisting of the profile is eliminated by ensuring free sliding of the workpiece along the machine shelves;

- the workpiece being processed has ideal external characteristics - scuffing and scratches are excluded due to the perfectly clean surface of the rollers;

- processing of an unpainted aluminum profile is carried out without the formation of scratches - oxide particles detached from the cladding element will not be smeared on the surface, spoiling the appearance due to timely wiping of the rollers to remove accumulated dirt;

- Bending of painted aluminum profiles is carried out with a quality guarantee.

Profile processing is carried out for metal building structures, commercial equipment, advertising media, shower cabins, facade, door, and window structures. The equipment used allows us to perform all types of technological operations. Having its own drive allows you to bend workpieces with a significant cross-section. Products of great height are subjected to high-precision deflection. The aluminum profile is processed along different radii with a smooth transition from an arc to a line, an approximated ellipse.

Bending methods

The following bending methods can be used in this equipment:

- Pushing . In this case, the aluminum pipe is pushed between the rollers of the machine: one of the rollers is assigned the task of deflecting the workpiece. In this way, an arcuate bend is achieved with a very small radius of curvature. The bend radius is determined by multiplying the pipe diameter by 6.

- Rental _ An aluminum pipe with a diameter of 10 to 100 mm is rolled through bending rollers, which must strictly correspond to the diameter of the pipe being bent. To carry out this operation, a three-roll pipe bender is used, which is capable of bending in the form of a ring, spiral and arc. It can be used to process both round and rectangular profiles. Rolling is carried out in several passes.

- Rolling in . For bending, the rolling head of a pipe bender is used, which bends the workpiece under pressure. In areas without pressure, the pipe bends in the opposite direction. Rolling in is not accompanied by heating. To prevent the workpiece from shrinking, you need to ensure that the minimum bend radius is observed: it is equal to the radius of the pipe multiplied by three.

- Pressure bending . Here, for pressing, stamps are used that deform the workpiece from the outside, or hydroforming, when the pipe is filled with water or oil under pressure to bend it from the inside within the boundaries of the mold.

Primary aluminum grades

An example of this group is primary aluminum grade “A5”. To obtain it, enriched alumina is used. It is impossible to find the metal in its pure form in nature, since it has high chemical activity.

When interacting with other elements, the metal forms bauxite, nepheline and alunite. Subsequently, these ores are used to produce alumina, and then, through certain chemical and physical reactions, pure aluminum.

We recommend articles on metalworking

The requirements that grades of primary aluminum must meet are established in GOST 11069. Marks indicating that a metal belongs to a certain class are vertical and horizontal stripes applied to the workpieces with indelible paint of certain colors. Primary aluminum is used in leading industrial fields, mostly in those where increased technical characteristics of the raw material are required.