Rolling, or rolling, as this technological operation is also called, involves plastic deformation of metal blanks to form them into products of the required configuration. In this case, both pipe rolling (to change the shape of their cross-section) and sheet metal processing can be performed, during which products of cylindrical, conical and oval configurations are created.

Profile forming on a three-roll machine

Rolling is performed on special equipment equipped with rollers, which are responsible for the plastic deformation of metal workpieces in the desired direction, which is why this technological operation received its name.

When rolling between rollers, the dimensions and distance between which are selected depending on the geometric parameters of the workpiece and the finished product, the workpiece acquires the required dimensions and shape. In some cases, metal rolling may involve not only rolling blanks from it, but also forging them.

You can roll not only workpieces made of metal, but also products made of polymer materials and rubber compounds, which are also characterized by high plasticity. If we talk about metal, then workpieces made of:

- certain grades of stainless steel;

- copper, aluminum and alloys of these metals;

- carbon steel alloys;

- galvanized steel.

In addition to rolling, there are technological operations such as flaring and rolling of edges, as a result of which the ends of tubes made of various metals are subjected to plastic deformation (and, accordingly, a change in geometric shape). For this purpose, a tool is used, the design of which may not have rollers. Using flaring and rolling, the ends of the tubes are prepared for their further connection. Miniature working rollers can be seen in a tool that is used to roll a pipe, that is, reduce its original diameter.

You can also roll the pipe using a lathe. A video with an example of performing such an operation can be seen below.

Corner bending (rolling)

It is thanks to the interaction with the rollers that radius bending of the corner is also called rolling.

Despite the apparent simplicity of the equipment, this is a very complex operation. When any solid material, including metal, is deformed, its inner layer experiences strong compression, and its outer layer experiences no less “extreme” tension. And if for such a product as a metal circle, these processes occur more or less evenly, in a corner, as in a profile workpiece, a longitudinal displacement of one of the layers can be observed. The risk of distortion of parts especially increases when using manual profile benders. Therefore, experts recommend bending a corner along a radius only on automated equipment, and better equipped CNC.

How to bend a metal corner 90 degrees

If you have already started a major renovation with your own hands, regardless of where it is carried out: at home or in an apartment, then you need to be prepared for many tests.

Among other things, a number of issues may arise that are very difficult to solve without the proper experience and special equipment. For example, not everyone knows how to bend a sheet of metal, reinforcement, profile, corner, etc., while obtaining a decent result.

In this article we will try to answer “inflexible” questions, while making do with a minimum amount of tools.

Very often, when installing metal structures, it is necessary not only to cut steel sheets, but also to give them a curved shape. This can be done at home without spending money on third party services.

For example, how to bend a sheet of metal? To do this we need a wooden or rubber hammer, pliers, and a table. If a 90-degree bend is expected, then this set of tools should be sufficient.

The sheet is simply hung over the edge of the table, after which the desired curvature is achieved by uniform tapping in the bending area. If the workpiece is relatively small, then you can use a vice, in which, using two gripping bars, you can firmly secure a sheet of metal, and only after that bend it with a hammer.

If necessary, the bend can be heated with a gas burner, but this method is not applicable to galvanized products!

Bend a sheet of metal

If we are talking about a thin metal sheet, then the bending procedure can be significantly simplified.

To do this, the metal is “scratched” at the bend (we use a rule or a metal ruler, and a pointed piece of a hacksaw blade for metal as a cutter).

The metal, cut to half its thickness, subsequently easily bends along the outlined line. We can say that we have almost figured out how to bend a sheet of metal.

We bend galvanized steel

How to bend galvanized steel? This can be either a galvanized metal sheet or a finished product, for example, a profile. The sheet is bent in the same way as when bending any other metal sheet. How to bend a profile? You'll have to tinker with him.

To obtain a large radius of curvature of a square or rectangular profile, you can use the following method: tightly fill the profile with fine sand, plug both holes with wooden stakes, and only then bend it by gently tapping it with a mallet.

To bend a U-shaped profile (this, in principle, also applies to obtaining sheets of curved shape), it is necessary to additionally use a form object, the curvature of which corresponds to the finishing part. To facilitate the bending process, triangular elements can be cut out in the profile.

Then the bent product is “wrapped” around the object by uniform tapping with a hammer. Important! In order for the bend to be as even and correct as possible, the hammer blows should be light and lie as close to each other as possible .

How to bend galvanized sheet easier? Using a grinder, we make one or two cuts in the bend area (thereby temporarily weakening the structure), bend the product, and then weld the bend. This approach is important to use when bending profiled pipes and products of complex metal shapes.

We remember that you cannot heat galvanized steel to simplify bending!

Perhaps one of the most difficult tasks faces people who are thinking about how to bend a corner. To get a solid product, you will have to sweat, evenly and slowly tapping the surface of the corner, gradually bending it.

It is recommended to use a gas burner, which can be used to heat the bend. You can do it easier - use a grinder as in the case described above with a galvanized product.

It’s even easier to buy an already curved product, then the question “how to bend a corner” will disappear by itself.

How to bend reinforcement

At home, it is quite possible to bend the reinforcement, however, a lot depends on your physical characteristics and the diameter of the metal rod. How to bend reinforcement? To do this, we need two pieces of steel pipes, the diameter of which is greater than the diameter of the bent rod.

The longer the length of such pipes, the easier it will be to bend the reinforcement (gain in strength due to leverage).

All you need to do in order to bend the reinforcement is to insert it into two pipes and, securing one of the pipes (pressing it with your foot or resting it between the pillars), using the second as a lever to give the reinforcement the desired curvature. That's all!

| Technology of building a house from timber Where to start building a house from timber? What needs to be taken into account so as not to later regret the choice of building material? In one article, we sequentially examined the stages of erecting a cobblestone structure, taking into account the requirements of technology. Having such a short guide before your eyes, you will be confident in the correctness of your actions. |

| Metal grill and more If you're going outdoors, don't forget to take your grill with you! Is it not available? Of course, you can run to the store and buy it, but why not make the same, if not better, metal barbecue with your own hands? The work will take a maximum of a couple of hours. We will try to explain in detail the manufacturing process of this simple device. |

| Strengthening the foundation of a private house Are you preparing to build an extension to your house? Have you decided to add a second floor? Perhaps the old foundation of the house scares you with an abundance of cracks and uncharacteristic distortion? All this indicates the need to strengthen the foundation. We have tried to summarize data that will be useful in resolving this issue. |

Welding products from metal corners

In the manufacture of various metal structures, rolled steel angles (angles) are among the most commonly used materials. In addition to welding corner pieces together, it often becomes necessary to weld a corner to a pipe or to a flat surface. Such compounds are used in construction and installation work, in the manufacture of furniture and crafts.

Types of connection

Welding steel products using angle iron comes down to several main types of connections:

- butt welding of billets from angle bars;

- welding corner blanks at an angle of 90 °;

- welding of angle steel with other products.

When creating a structure, a good welder solves at least two problems. The first is to weld a strong product that can successfully withstand certain loads. The second task is to ensure that the completed work looks aesthetically pleasing. After all, the work of a true master is always pleasing to the eye.

Let's look at typical examples showing how to weld iron corners to each other, as well as to other surfaces.

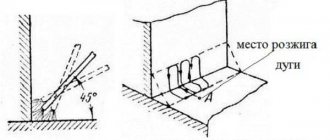

Butt joint

You can butt weld pieces of corner profiles. This type of welding is often required to lengthen an existing piece of steel. The technology for making such a connection is simple and basically does not differ from the butt connection of sheet blanks. But there are still some features.

Advantages of corner bending

Despite the existing risks, bending metal corners is used more often than other methods of changing the shape of a workpiece.

And there are several reasons for this: 1. This method is the most economical. It involves only a profile bender. Other possible works - cutting, welding operations, etc. - are not needed in this case; 2. The technology preserves the integrity of the metal, which means it remains invulnerable and its mechanical strength does not decrease; 3. That is why the use of bent structures, in contrast to welded ones and assembled using fasteners, greatly increases the service life of the product; 4. Unlike welding, after which the metal in the areas of impact is subject to corrosion, this does not happen with structures after radius bending of the corner.

Basic Tools

Although this is not entirely true, the concept of metal rolling often refers to a whole list of technological operations by which the shape of a metal workpiece is changed. Such operations, in particular, include:

- formation of a round, square or rectangular profile from a narrow metal strip (using this method, welded pipes are produced; a similar technology is used to roll a metal angle);

- changing the cross-sectional shape, outer diameter and wall thickness of the finished tubular product - pipe rolling (using this technology, both seamless and welded tubular products can be processed);

- formation of bends with the required parameters in certain sections of the tubular product - pipe bending;

- production of sheet metal products of cylindrical (rolling of shells), conical (rolling of cones) and oval shapes;

- increasing the diameter (expansion) of the cut end of a metal pipe - flaring (using this technology, metal products are prepared for their connection with each other; in particular, this is how pipes for air conditioners are prepared for installation);

- reducing the diameter (narrowing) of the cut end of a tubular product - pipe rolling.

Rolling a profile pipe on a pipe bending machine

For rolling soft copper tubes, ordinary pliers can be used, and for flaring them, a tool whose working body is a conical element that expands the end of the pipe to the required amount. In fact, only those technological operations that are performed using equipment and tools that have rollers in their design can be called rolling.

Depending on the type of workpiece and the result that needs to be achieved, various equipment and tools can be used to perform rolling, which are most often quite versatile.

The industrial rolling machine is capable of bending large-sized sheet materials with high precision.

The process of rolling metal sheets, as a result of which they are formed into cylindrical, conical or oval-shaped products, is carried out on special equipment equipped with two, three or even four work rolls. Processing on a three-roll type machine consists in the fact that the metal sheet, pressing against two rotating lower rolls, the third - thrust, also begins to rotate around it, gradually turning into a cylindrical product. The bending radius of a metal sheet during rolling can be adjusted by selecting rolls of the appropriate diameter, as well as the distance between the lower working elements. Since rolls experience significant mechanical loads during operation, high-strength grades of steel alloys are used for their manufacture.

For pipe bending, which is often called rolling, equipment is used that is also equipped with a roll system. Bending around the work rolls during rotation, the product acquires the required angle or bending radius. This type of equipment, which is highly versatile, can also be used to roll angles.

The three-roll machine is designed for rolling profile pipes along an arc of any radius

Methods for bending a corner along a radius

Depending on the size of the workpiece and the thickness of the metal, bending can be done cold or hot.

Cold is preferable, since any heating is an effect at the level of the metal crystal lattice. Cold bending can be carried out not only on a rolling machine: for simple workpieces, the method of free bending of a corner along a radius is no less in demand - deformation of the corner “in weight”, without the use of special equipment. However, this technology may have errors, and it is better to use it for work that does not require high precision.

Based on the direction in which the workpiece is bent, a distinction is made between bending the corner with flanges outward or inward.

How to bend a corner into a ring with your own hands

To do this, it is best to use the hot method of metal processing. But you can achieve a given radius only with the help of a pre-prepared template. We preheat the metal and begin to bend the template evenly, while the horizontal shelf must be adjusted during the entire bending process using a sledgehammer or hammer, otherwise the shelves will not maintain the original angle of 90 degrees to each other.

It is necessary to heat the metal to half the value of its melting point, so, for example, an aluminum corner will have to be heated to at least 250⁰ C, and a steel profile - to 600⁰ C. To do this, you will need a natural gas burner or a gasoline blowtorch, and it is best to use welding acetylene cutter if the corner is large.

Using an angle grinder and a welding machine, you can also bend a steel corner into a ring, but for this you need to make fairly accurate calculations, mark and outline the sectors to be removed, bend and weld the seams. Unfortunately, no matter how hard you try, in this case you will end up with a circle in the form of a rounded polyhedron.

VIEW Bending machines on AliExpress →

Bending corners from different materials

Modern equipment for bending metal corners - machines equipped with CNC - can process products from any materials.

First of all, it is black and stainless steel. The operation is carried out so carefully that even rolled products coated with galvanization or a polymer protective layer can be passed through the rolls. Less common, but also in demand, is the bending of aluminum alloys. Very rarely, but such work is still performed for products made of copper, bronze and brass. These works are almost always decorative in nature.

Steel channel bending

The technology and quality of steel channel bending largely depend on the type of material.

Carbon steels that are simpler in composition are more susceptible to deformation. The effectiveness of the same operation on alloyed ones depends on the inclusions of other elements: some of them reduce the ductility of the material and can negatively affect the process. The method of manufacturing the channel also makes its contribution: it is known that a profile produced by the cold method tolerates deformation better than a heat-treated - hot-rolled one. Some types of steel (for example, especially strong structural steel) can only be bent after preheating.

Cost of bending a metal corner

Prices for bending corners along a radius are considered one of the most affordable. They are influenced by:

- features of the metal from which the blanks are produced;

- number of blanks;

- corner size;

- shelf thickness;

- bending radius;

- urgency of work.

Where can I order aluminum corner bending?

On our website you can order professional, inexpensive and very fast bending of metal corners and other long products.

We work with workpieces of any range and made from any raw material - from steel to copper. The CNC equipment that our workshop is equipped with will help transform even non-standard parts in order to fulfill your individual order. Leave us a request online or dial a contact phone number - and you will see how high-quality and fast metalworking can be.

How to bend a metal corner 90 degrees?

Sometimes it may be necessary to bend a metal pipe, metal corner or strip profile at home. Let's find out how this can be done without resorting to the services of a specialist.

Before starting manipulations, you need to take into account that you can work with a profile up to 5 millimeters thick, as well as a pipe up to 15 millimeters in diameter, even if the workpieces are cold. Bending larger workpieces without preheating may result in cracks or tears.

We bend the strip profile

If it is necessary to bend metal strips, they must be fixed, for example, in a vice, having previously placed metal corners, saving the vice from damage and the profile from deformation (in the case of corners, we increase the area of pressure on the point of the metal strip).

Then, with precise blows of a hammer, the profile is bent to the desired angle. To avoid damaging the metal and get an even bend, it is better to hit not the profile directly, but a flat wooden block placed on it.

In order to correctly bend the profile, giving it the most complex design, before work you need to put marks on it in the places of future bends.

It should be remembered that a perfectly right angle is almost impossible to obtain at home and the minimum bending radius, despite all the skill of the master, will still remain.

We bend the pipe

Pipes in a cold state are much more difficult to bend, because when bent, it has an inner side that contracts, and an outer side that expands significantly; when stretched, a cold pipe can become deformed and simply burst.

To prevent this from happening, you should fill the pipe with dry sand, which will distribute the pressure and make the bend more natural, preventing it from breaking.

To do this, pour dry, homogeneous sand into the pipe, after closing the outlet with a wooden or plastic plug (can be purchased at metal stores for your pipe diameter).

When filling in sand, the pipe must be tapped to compact the contents, and then the entrance must be closed.

After this, the pipe is bent by tightly holding one of the ends in a vice and using physical force. It is advisable, of course, to use a pipe bender (a special machine for bending pipes) for this, since in the case of a vice, special requirements are placed on their support (the support point must withstand significant shear loads and lifting off the ground).

Copper and aluminum (the most flexible) pipes are the best to bend. They are most often used in plumbing - here you cannot do without a specialized tool (most often, plumbing pipe benders work with radial curvature of pipes).

The situation is more complicated with steel or galvanized pipes.

The former are much more difficult to bend, but it is not recommended to bend galvanized pipes at all, since small cracks in the upper protective layer will form at the bends, and the pipe will rust, and when heated, the zinc may evaporate and corrosion will still begin at the bend, even if there are no cracks.

To successfully bend steel, cast iron pipes, as well as pipes made of various alloys, you can heat the area of the future bend with a blowtorch. However, it must be remembered that by heating the pipe excessively, you can significantly change the structure of the metal and increase its fragility.

Bend corner

With corners, as with pipes, the situation is more complicated than with simple strips.

The most effective option for obtaining a curved metal corner would be the following operation: at the required bend location, a cut is made on one of the edges of the metal corner, and then the product is bent here like a regular strip of metal (as long as this allows making a cut).

To get the correct bend angle, you will need some practice and correct calculation of the cut section, since the final bend angle will depend on it.

A more difficult option would be to bend the corner without making cuts. In this case, as with a square profile, the bending angle will be insignificant, since sharp corners will lead to cracks in the material. Such bending requires a strong lever and reliable support with fixation of the product. If the edges of the angle are more than 15 mm, heating of the bend will be required.

conclusions

It is not so easy to bend a pipe or strip profile at home in a high-quality manner. But, as in any business, skill and knowledge of the basic features and rules of the process are important here. After trying a few times, working with different materials, you will soon become an expert in this field and add a new skill to your home crafts collection.

: 0.0/5 (0 missed)

Joining metal corners

In the manufacture of various metal structures, rolled steel angles (angles) are among the most commonly used materials. In addition to welding corner pieces together, it often becomes necessary to weld a corner to a pipe or to a flat surface. Such compounds are used in construction and installation work, in the manufacture of furniture and crafts.

Features of channel bending

In order for radial bending of a channel to be easy for the performer and harmless for the profile, the process cannot be approached “on the fly, with a turn.” Preparation is no less important than the technical implementation itself. To avoid problems, you must:

- study the properties of the workpiece in detail;

- determine the force that will be needed to bend it;

- calculate deformation values;

- configure the equipment.

And, as we have already mentioned, “practice” on a signal sample, take into account negative experience, if any, and only then proceed to serial production.

Metal rolling

Rolling makes it possible to obtain cylindrical and conical products with large bending radii and uniform deformation along a given direction. Various types of bending machines are used for rolling profiles or sheet metal.

Rolling of sheet metal is the simplest method of manufacturing cylindrical parts, components for capacitive equipment, and shells. A shell is a cylindrical or conical part (such as a drum, pipe or ring), which is used for the production of elements of welded structures, as well as for the production of containers, vessels, boilers, tanks and various reservoirs.

| Sheet metal rolling | Sheet metal rolling |

| Sheet metal rolling | Rolling of profiled metal products |

Our equipment

Our production uses the following sheet bending and roll forming equipment:

- sheet bending machine Sahinler 4R HSS 25-320

- roll forming machine Durma PBH 100

- press brake I1422

- press brake I-134

Sheet bending machine Sahinler 4R HSS 25-320

The 4-roll hydraulic sheet bending machine Sahinler 4R HSS 25-320 is designed for rolling metal sheets up to 20 mm thick. This machine is used for the production of cylindrical parts with constant and variable radius.

Technical characteristics of the sheet bending machine Sahinler 4R HSS 25-32

| Number of rolls, pcs | 4 |

| Roll length, mm | 2550 |

| Maximum sheet thickness, mm | 20 |

Roll forming machine Durma PBH 100

The 3-roll hydraulic roll forming machine Durma PBH 100 belongs to the class of roller rotary machines with rotational-translational movement of the working body and translational movement of the workpiece. The machine allows you to perform radius bending operations of various types of profiles: rectangular profile, strip, T-beam, I-beam, angle, rod, channel, pipe of round, rectangular and square sections.

Technical characteristics of the Durma PBH 100 roll forming machine

| Number of rollers, pcs | 3 |

| Roller diameter, mm | 315 |

| Maximum profile height, mm | 100 |

Press brake I1422

The I1422 hydraulic press brake is designed for bending sheet and strip metal products. Using a universal V-shaped die, the metal is bent at a certain angle, and the part is given the required configuration.

Technical characteristics of press brake I1422

| Nominal force, tons | 16 |

| Maximum length of bendable surface, mm | 1350 |

| Maximum sheet thickness, mm | 10 |

Press brake I-134

The I-134 crank press brake is designed for bending sheet and strip metal products.

Technical characteristics of the I-134 press brake

| Nominal force, tons | 100 |

| Maximum length of bendable surface, mm | 2550 |