← Prev. article Sheet metal bending: what is it, types? Sheet metal bending is metalworking, plastic deformation of rolled metal to give it the desired shape and further use as a workpiece. Replaces welding work where possible, and has a significant advantage over welding: the design is seamless and monolithic.

Track. article →Metal cutting: what is it, types Metal cutting is called the separation of parts of sheet metal or pipes into parts for the production of blanks. Cutting takes into account the characteristics of specific metals and alloys, their physical and chemical characteristics, so that the result is as close as possible to the planned...

Date: 05/19/2020Author: MOP “Complex 1”

Views: 165

Track. article →Metal cutting: what is it, types Metal cutting is called the separation of parts of sheet metal or pipes into parts for the production of blanks. Cutting takes into account the characteristics of specific metals and alloys, their physical and chemical characteristics, so that the result is as close as possible to the planned...

The article is relevant to the services:Bending of round pipesBending of profile pipesBending of sheet metalBending of round and profile pipes

Rating: 5,001 votes

- 1. What is it?

- 2. Types of metal bending

- Video

What it is?

Metal bending (go to service) is plastic deformation of rolled metal, during which one part of it changes its position relative to another, the outer layers of the metal are stretched, and the inner ones are compressed. An effective replacement for welding (go to service), which leaves potentially brittle seams: the bent workpiece is characterized by solidity and strength.

Both sheet metal and pipes can be bent. Almost all types of metals and alloys are amenable to the procedure; it can be carried out manually on home equipment (for example, on a bench vice, using hammers, pliers and pliers) and automatically on special bending machines.

The blanks created by this method are used everywhere, in all areas of industry.

Classification and process features

In accordance with the assigned tasks, sheet metal bending technology is developed for the following options:

- Single-angle (sometimes called V-shaped flexible).

- Double corner or U-shaped bending.

- Multi-angle bending.

- Radial bending of sheet metal (rolling) - producing products such as hinges, galvanized clamps, etc.

The bending effort is small, so it is mainly performed in a cold state. An exception is bending steel sheets made of low-plasticity metals. These include duralumin, high-carbon steels (containing an additional significant percentage of manganese and silicon), as well as titanium and its alloys. They, as well as blanks made of thick sheet metal with a thickness of more than 12...16 mm, are bent mainly by hot bending.

Bending is combined with other sheet metal stamping operations: cutting and bending, with cutting or punching are often combined. Therefore, for the production of complex multi-dimensional parts, dies designed for multiple transitions are widely used.

A special case of sheet metal bending is stretch bending, which is used to produce long and narrow parts with large bending radii.

Depending on the size and type of the workpiece, as well as the required characteristics of the product after deformation, the following are used as bending equipment:

- Vertical press brakes with mechanical or hydraulic drive;

- Horizontal hydraulic presses with two sliders;

- Forging bulldozers - horizontal bending machines;

- Pipe and profile benders;

- Universal bending machines.

To obtain structures that are unique in shape and size, in particular, turbine boilers, etc., exotic technologies are used to bend sheet steel, for example, using explosive energy. In contrast, the question of how to bend tin does not cause difficulties, since the ductility of this material is very high.

A characteristic feature of sheet metal bending machines is reduced deformation rates, increased dimensions of the die space, and relatively low energy consumption. The latter is the basis for the widespread production of manual bending machines designed for deforming galvanized material. They are especially popular in small workshops, as well as among individual users.

Despite the apparent simplicity of the technology, the balance of stresses and state deformations in the workpiece is difficult to determine. In the process of bending a material, stresses arise in it, first elastic, and then plastic. At the same time, bending of sheet material is characterized by significant uneven deformation: it is more intense in the corners of bending, and is practically invisible at the ends of the sheet workpiece. Bending of thin sheet metal is distinguished by the fact that its inner layers are compressed, and its outer layers are stretched. The conditional line that separates these zones is called the neutral layer, and its precise determination is one of the conditions for defect-free bending.

During the bending process, rolled metal receives the following shape distortions:

- Change in thickness, especially for thick sheets;

- Springing/springing is a spontaneous change in the final bending angle;

- Folding of a metal sheet;

- The appearance of metal flow lines.

All these circumstances must be taken into account when developing the stamping process.

Types of metal bending

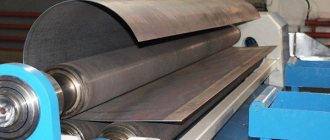

- Sheet metal bending (go to service) - processing of rolled metal sheets (go to services) on rolling machines, when the sheet is passed between three or four rolls until it takes the desired shape. Allows you to achieve any bends, including bending sides.

- Pipe bending (go to service) - processing of pipes (go to services) using automatic pipe bending machines, also using the cold rolling method (go to service) (possibly hot, with filler). The machines process profiles of any diameter and shape, of any length.

Basic techniques for bending pipe parts

Bending of pipe parts is carried out in cold and hot states by manual and mechanized methods, with and without fillers.

Fillers are used to prevent the formation of folds and flattening of pipe walls. Dried fine sand or synthetic granules are used as fillers.

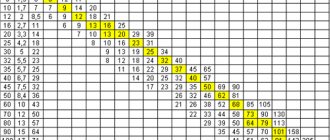

For each pipe, depending on its diameter and material, the minimum permissible bending radius is established. With a smaller radius, bending is unacceptable (Table 1).

Table 1. Values of the minimum permissible bending radii of pipes in a cold state, mm

| Pipe outer diameter, mm | Pipe material | Pipe outer diameter, mm | Pipe material | ||||||

| Steel 45 | Steel 35 | Steel 20 | Steel 10 | Steel 45 | Steel 35 | Steel 20 | Steel 10 | ||

| 18 | 74 | 62 | 56 | 43 | 105 | 450 | 344 | 282 | 240 |

| 24 | 95 | 79 | 65 | 55 | 110 | 510 | 377 | 310 | 264 |

| 32 | 115 | 96 | 79 | 67 | 130 | 536 | 450 | 370 | 315 |

| 38 | 156 | 131 | 107 | 91 | 145 | 578 | 484 | 398 | 339 |

| 50 | 197 | 165 | 136 | 115 | 155 | 620 | 522 | 430 | 360 |

| 60 | 238 | 199 | 165 | 139 | 181 | 720 | 600 | 498 | 425 |

| 75 | 280 | 260 | 194 | 173 | 194 | 752 | 630 | 516 | 444 |

| 80 | 324 | 270 | 224 | 190 | 206 | 835 | 702 | 575 | 488 |

| 90 | 362 | 302 | 250 | 213 | 220 | 920 | 770 | 635 | 540 |

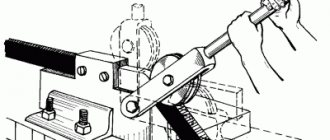

When cold bending pipes with a diameter of up to 25 mm, hand tools are used.

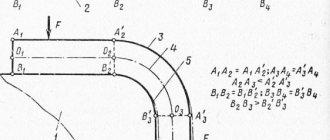

In Fig. 4, a shows a manual machine designed for bending pipes with a diameter of 12 to 20 mm. The machine has an axis 1 and a base plate 2, with which it is bolted to the workbench. The working parts of the machine are a fixed roller 4 with a clamp 5, mounted on axis 1, and a movable roller 3, mounted on a bracket 6 with a handle 7. The end of the bent pipe is placed in the clamp between the rollers, then the bracket with the movable roller is rotated around the axis of the fixed roller until the required bend, after which the bracket is returned to its original position and the pipe is removed.

Rice. 4. Bending using hand tools

To bend copper tubes of different diameters when assembling machines, a multi-strand pipe bender (5.66, b) is used. In this case, the tube is passed between rollers 1 and 2 until it comes into contact with the stop, then when the fork 3 is turned, the movable roller 2 rolls around the stationary one, bending the tube along a radius equal to the radius of roller 1.

Using a manual lever pipe bender (5.66, c), you can bend steel gas pipes with a diameter of 1/2, 3/4 and 1" in a cold state without filler.

For manual bending of steel pipes with a diameter of up to 50 mm at an angle of 180° without filler in a cold state, a special head with a manual drive can be used.

Sheet metal bending

The technology of bending metal, which is a sheet, is implemented on special machines - sheet benders. According to the bending method, such mechanisms can be divided into three types:

- Press. The sheet is introduced under pressure into a stationary matrix using a punch and acquires the desired shape. Punches come in several types, differing in shape and bending radius. The matrix, as a rule, has the shape of a corner or groove. A press brake is the most versatile equipment because it can be easily adjusted to different tasks.

- Rotary. Main elements: bed, movable bending beam (crossbeam), pressure beam, back stop. The clamping beam is used to fix the sheet on the frame. To bend the sheet, it is done using a bending beam, which is the main working element.

- Rotary - two, three or four roll devices in which the working elements use rotational motion. The working drive, which creates the necessary force on such machines, can be implemented in one of the following ways:

- manual - human muscular strength is used;

- hydraulic - a hydraulic booster is used;

- pneumatic - compressed air is used;

- mechanical - the energy of a spinning flywheel is used;

- electromechanical - electric motors with gearboxes are used.

One of the widely used types of sheet bending equipment is folding or folding machines, which are designed to work with thin sheets. Such equipment is used in the manufacture of seam roofing, air ducts, and chimneys.

Metal pipe bending

Bending of metal pipes can be done using hot or cold methods. The latter method is more technologically advanced and productive. Devices and machines for this operation use different bending methods. There are the following types of pipe benders:

- lever - for manual bending of pipes made of soft metals, as well as steel pipes of small diameter at an angle of up to 180 degrees;

- crossbow - the pipe is bent by applying force in the middle between two points on which the workpiece rests;

- roller (roller) - a classic example is a three-roller pipe bender.

Roller pipe bending machines use a method of cold deformation of metal called rolling. This machine works with metals of any hardness: from non-ferrous to titanium and its alloys. The bending angle can reach 360 degrees, and the length of the bent workpiece often exceeds 5 meters.

For bending thin-walled pipes, mandrel pipe benders are used, which use special equipment called a mandrel. This device is placed in the pipe cavity at the bend and prevents deformation of the metal walls.

Free bending

Provides flexibility, but has some limitations in accuracy.

Main features:

- The traverse, using a punch, presses the sheet to the selected depth along the Y axis into the groove of the matrix.

- The sheet remains “in the air” and does not come into contact with the walls of the matrix.

- This means that the bending angle is determined by the position of the Y axis and not by the geometry of the bending tool.

The Y-axis adjustment accuracy on modern presses is 0.01 mm. What bending angle corresponds to a certain Y-axis position? It's hard to say because you have to find the correct Y-axis position for each angle. Differences in the position of the Y axis can be caused by the adjustment of the lowering stroke of the crosshead, material properties (thickness, tensile strength, work hardening) or the condition of the bending tool.

The table below shows the deviation of the bending angle from 90° at various Y-axis deviations.

| 1,5° | 2° | 2,5° | 3° | 3,5° | 4° | 4,5° | 5° | ||

| 4 | 0,022 | 0,033 | 0,044 | 0,055 | 0,066 | 0,077 | 0,088 | 0,099 | 0,11 |

| 6 | 0,033 | 0,049 | 0,065 | 0,081 | 0,097 | 0,113 | 0,129 | 0,145 | 0,161 |

| 8 | 0,044 | 0,066 | 0,088 | 0,110 | 0,132 | 0,154 | 0,176 | 0,198 | 0,220 |

| 10 | 0,055 | 0,082 | 0,110 | 0,137 | 0,165 | 0,192 | 0,220 | 0,247 | 0,275 |

| 12 | 0,066 | 0,099 | 0,132 | 0,165 | 0,198 | 0,231 | 0,264 | 0,297 | 0,330 |

| 16 | 0,088 | 0,132 | 0,176 | 0,220 | 0,264 | 0,308 | 0,352 | 0,396 | 0,440 |

| 20 | 0,111 | 0,166 | 0,222 | 0,277 | 0,333 | 0,388 | 0,444 | 0,499 | 0,555 |

| 25 | 0,138 | 0,207 | 0,276 | 0,345 | 0,414 | 0,483 | 0,552 | 0,621 | 0,690 |

| 30 | 0,166 | 0,249 | 0,332 | 0,415 | 0,498 | 0,581 | 0,664 | 0,747 | 0,830 |

| 45 | 0,250 | 0,375 | 0,500 | 0,625 | 0,750 | 0,875 | 1,000 | 1,125 | 1,250 |

| 55 | 0,305 | 0,457 | 0,610 | 0,762 | 0,915 | 1,067 | 1,220 | 1,372 | 1,525 |

| 80 | 0,444 | 0,666 | 0,888 | 1,110 | 1,332 | 1,554 | 1,776 | 1,998 | 2,220 |

| 100 | 0,555 | 0,832 | 1,110 | 1,387 | 1,665 | 1,942 | 2,220 | 2,497 | 2,775 |

Advantages of free bending:

- High flexibility: Without changing bending tools, you can achieve any bending angle between the V-die opening angle (e.g. 86° or 28°) and 180°.

- Lower tool costs.

- Compared to calibration, less bending force is required.

- You can “play” with force: greater opening of the matrix means less bending force. If you double the width of the groove, you only need half the force. This means you can bend thicker material at a larger opening with the same amount of force.

- Less investment as a press with less force is needed.

All this, however, is theoretical. In practice, you can spend the money saved on purchasing a lower force press that allows you to take full advantage of air bending on additional equipment, such as additional backgauge axles or manipulators.

Disadvantages of air bending:

- Less precise bending angles for thin material.

- Differences in material quality affect repeatability.

- Not applicable for specific bending operations.

Advice:

- It is advisable to use air bending for sheets with a thickness of over 1.25 mm; For sheet thickness of 1 mm or less, it is recommended to use calibration.

- The smallest internal bending radius must be greater than the sheet thickness. If the inner radius must be equal to the sheet thickness, it is recommended to use the calibration method. An internal radius less than the sheet thickness is permissible only on soft, easily deformable material, such as copper.

- A large radius can be achieved by air bending by using stepwise movement of the backgauge. If a large radius must be of high quality, only the special tool calibration method is recommended.

What effort?

Due to the different material properties and the effects of plastic deformation in the bending zone, the required force can only be determined approximately. We offer you 3 practical ways:

Table

In each catalog and on each press you can find a table showing the required force (P) in kN per 1000 mm of bending length (L) depending on:

- sheet thickness (S) in mm

- tensile strength (Rm) in N/mm2

- V - matrix opening width (V) in mm

- internal radius of the bent sheet (Ri) in mm

- minimum height of the bent shelf (B) in mm

An example of such a table is the required force to bend 1 meter of sheet in tons. Tensile strength 42-45 kg/mm2. Recommended ratio of parameters and force

Formula

1.42 is an empirical coefficient that takes into account the friction between the edges of the die and the material being processed. Another formula gives similar results:

"Rule 8"

When bending low-carbon steel, the width of the matrix opening should be 8 times greater than the thickness of the sheet (V=8*S), then P=8xS, where P is expressed in tons (for example: for a thickness of 2 mm, the matrix opening \/=2x8=16 mm means that you need 16 tons/m)

Bending force and length

The length of the bend is proportional to the force, i.e. the force reaches 100% only with a bend length of 100%. For example:

| An effort | Bending length |

| 100% | 3,000 mm |

| 75% | 2 250 mm |

| 50% | 1 500 mm |

| 25% | 750 mm |

Advice:

If the material is rusty or not lubricated, 10-15% should be added to the bending force.

Sheet thickness (S)

DIN allows a significant deviation from the nominal sheet thickness (for example, for a sheet thickness of 5 mm, the norm ranges between 4.7 and 6.5 mm). Therefore, you only need to calculate the force for the actual thickness you measured or for the maximum specification value.

Tensile strength (Rm)

Here too, tolerances are significant and can have a major impact when calculating the required bending force. For example: St 37-2: 340-510 N/mm2 St 52-3: 510-680 N/mm2

Advice:

Don't skimp on bending force! The tensile strength is proportional to the bending force and cannot be adjusted when you need it! Actual thickness and tensile strength are important factors when selecting the right machine with the right force rating.

V—matrix expansion

As a rule of thumb, the opening of the V-shaped matrix should be eight times the sheet thickness S up to S=6 mm: V=8xS For greater sheet thickness it is necessary: V=10xS or V=12xS

The opening of the V-shaped die is inversely proportional to the required force: • greater opening means less bending force, but a larger internal radius; • smaller opening means more force but smaller inner radius.

Inner bending radius (Ri)

When using the air bending method, most of the material is subject to elastic deformation. After bending, the material returns to its original state without residual deformation (“reverse springback”). In a narrow region around the point of application of the force, the material undergoes plastic deformation and remains in this state forever after bending. The greater the plastic deformation, the stronger the material becomes. We call this “strain hardening.”

The so-called “natural internal bending radius” depends on the sheet thickness and die opening. It is always greater than the sheet thickness and does not depend on the punch radius.

To determine the natural inner radius we can use the following formula: Ri = 5 x V /32 In the case of V=8xS, we can say Ri=Sx1.25

The soft and easily deformable metal allows for a smaller internal radius. If the radius is too small, the material may wrinkle on the inside and crack on the outside of the bend.

Advice:

If you need a small inside radius, bend at slow speed and against the grain.

Minimum shelf (B):

To avoid the flange falling into the die groove, the following minimum flange width must be observed:

| Bend angle | IN |

| 165° | 0.58 V |

| 135° | 0.60 V |

| 120° | 0.62V |

| 90° | 0.65 V |

| 45° | 1.00 V |

| 30° | 1.30 V |

Elastic deformation

Part of the elastically deformed material will “spring back” after the bending force is removed. How many degrees? This is a relevant question, because only the actually obtained bending angle is important, and not the theoretically calculated one. Most materials exhibit fairly constant elastic deformation. This means that a material of the same thickness and with the same tensile strength will spring back by the same amount at the same bending angle.

Elastic deformation depends on:

- bending angle: the smaller the bending angle, the greater the elastic deformation;

- material thickness: the thicker the material, the less elastic deformation;

- tensile strength: the higher the tensile strength, the greater the elastic deformation;

- fiber directions: elastic deformation is different when bending along or across the fibers.

Let us demonstrate what was said above for the tensile strength measured under the condition V = 8xS:

| Tensile strength in N/mm2 | elastic deformation in ° |

| 200 | 0,5-1,5 |

| 250 | 1-2 |

| 450 | 1,5-2,5 |

| 600 | 3-4 |

| 800 | 5-6 |

All bending tool manufacturers take elastic deformation into account when offering free bending tools (eg an opening angle of 85° or 86° for free bends from 90° to 180°).

Variety of technologies

Depending on the orientation of the workpiece, bending is divided into longitudinal and transverse.

With longitudinal bending, only bending is performed, and with transverse bending, the metal is additionally stretched and upset. Such procedures are performed, for example, when bending the sides and planting workpieces.

- Longitudinal is performed on machines designed for cold processing of metal.

- Transverse is used if it is necessary to process a thick workpiece, or in cases where the radius of curvature is not too large, and cold processing will lead to significant stresses in the structure.

If there is a need to heat a workpiece that has a large area, you need to take into account the likelihood of curvature appearing on it: it occurs along a helical and spherical surface.

If heat is not applied, curvature does not form: its formation is prevented by the ability of the metal to spring. During transverse bending, the metal almost always heats up.

When workpieces that are flat sheets of metal are processed, for example, in the manufacture of ship hulls, they are bent in a cold state without heating and without upsetting, using specialized presses.

When edges are processed and holes are made, bending is done hot: then, as the temperature rises, the distance between the holes changes, and the edges change shape when drawn and upset.

When cold bending is used, the edges are processed first, holes are made at the next stage, and only after that the workpiece is bent.