How to choose the right turning cutting tool

Turning cutting tools can machine virtually any type of surface. Depending on the holder used, it is possible to produce a part either cylindrical or with a shaped surface. When choosing a tool for metalworking, you should pay attention to many factors that determine their quality. Thus, reliable equipment cannot be cheap. If you choose between price and quality, it is better to bet on the latter aspect, but of course you have to pay for quality. But it should be understood that a good cutting unit will last much longer and will save money overall.

Particular attention should be paid to the material of the cutting part. Currently, the vast majority prefer to choose products made from hard alloys, which, along with wear resistance, allow you to work with almost any metal.

An important detail is the cutting edges. They must be durable, since durability during processing of the part depends on this. With rapid wear of the cutting edge, it is necessary to change equipment more often, and this leads to an increase in the cost of processing and, accordingly, the cost of the product.

Depending on the metal being processed, one or another type of hard alloy from which the cutting part is made and cutting modes are selected. High speed steel is only suitable for low speed work and soft materials. But products made of hard alloy, mineral ceramics or cubic boron nitride have a high level of wear resistance and allow you to work with a high level of productivity.

Turning tool accessories, service life

If you decide to purchase a turning tool, then you should think in advance about what additional equipment you need. The fact is that due to high operating speeds, even the most expensive equipment will not be able to work efficiently if the equipment lags behind, so it is necessary to acquire a holder. They help keep it in a fixed position, which has a positive effect on work results. If you need to make a precise cut, you must be sure that the tool will not slip - the holder will help ensure this. It is attached directly to the machine. Many holders have several holes at once, which will allow you to change attachments directly during operation, which will significantly speed up the process. You can also select holders with adjustable locking, allowing you to vary the supported turning tool within a given range. This again will allow you to save on equipment by buying one product instead of one.

Turning tools

is a tool that is used for turning, which must be of high quality in order to make a quality product.

Tools for working on a lathe are cutters (mandrels) and carbide plates, which are clamped into these mandrels. What types of tools are there for turning?

There are cutting tools for turning: cutters, drills, taps, dies, reamers.

There are measuring instruments: these are calipers, micrometers, bore gauges.

Features of tools for turning.

Tools come in different alloys for each metal. There are alloys for cast iron, aluminum, steel, and stainless steel. The most important thing is to choose the right turning insert grade for each metal.

Features of the design of tools for turning.

The tool comes with mechanical fastening and with soldering. The peculiarity is that tools with mechanical fastening are easy to change, but tools with soldering have to be sharpened, which affects the speed and convenience of work.

Differences between tools for turning wood and metal.

Wood turning tools are very special cutters. We supply tools for metal turning.

A few words about turning tools for woodworking. For woodworking, cutters are used, which are popularly called “spoon” or “feather”. Their main difference from cutting tools for metal turning is that wood cutters require more precise and clean sharpening. Cutters for wood turning differ in length, fasteners and, in general, appearance. The main difference is that when using a tool for wood turning, the tool can be held by hand while turning. When carrying out turning work on metal, the tool must be firmly held “in the center,” which is only possible if it is rigidly fastened to the machine.

If you want to buy a tool for metal turning, then:

When purchasing a cutting tool for turning, it is important to pay attention to: - quality of workmanship - tilt angles - surface cleanliness - hardness of the mandrel (must be carbon steel)

When purchasing a measuring tool for turning, it is important to pay attention to:

— clear contact of the jaws so that there are no gaps (on calipers and micrometers) — no backlash in threads on bore gauges — clear touch of the control rollers — surface cleanliness

You can buy tools for turning work from us with delivery throughout Russia in a couple of days and at the most attractive price while maintaining high quality, comparable to their German counterparts.

You can buy tools for wood turning in specialized stores, which are widely represented on the Internet.

Why do we need metal turning tools, and what are they?

Today, metal turning tools are widely used in the production and manufacture of various parts and mechanisms when processing bodies of rotation. At the same time, the variety of technical solutions in the field of turning cutting tools is enormous. There are several groups:

- neutral, right or left (determine the cutting direction);

- according to material - from quick cutter or hard alloy;

- solid or composite, consisting of several elements.

The above classification demonstrates only a small part of the differences in design. And although they all differ from each other in functional purpose, they also have some common features.

How to choose the right turning cutting tool

Turning cutting tools can machine virtually any type of surface. Depending on the holder used, it is possible to produce a part either cylindrical or with a shaped surface. When choosing a tool for metalworking, you should pay attention to many factors that determine their quality. Thus, reliable equipment cannot be cheap. If you choose between price and quality, it is better to bet on the latter aspect, but of course you have to pay for quality. But it should be understood that a good cutting unit will last much longer and will save money overall.

Particular attention should be paid to the material of the cutting part. Currently, the vast majority prefer to choose products made from hard alloys, which, along with wear resistance, allow you to work with almost any metal.

An important detail is the cutting edges. They must be durable, since durability during processing of the part depends on this. With rapid wear of the cutting edge, it is necessary to change equipment more often, and this leads to an increase in the cost of processing and, accordingly, the cost of the product.

Depending on the metal being processed, one or another type of carbide is selected from which the cutting part of the metal turning tool is made, and cutting modes. High speed steel is only suitable for low speed work and soft materials. But products made of hard alloy, mineral ceramics or cubic boron nitride have a high level of wear resistance and allow you to work with a high level of productivity.

Turning tool accessories, service life

If you decide to purchase a turning tool, then you should think in advance about what additional equipment you need. The fact is that due to high operating speeds, even the most expensive equipment will not be able to work efficiently if the equipment lags behind, so it is necessary to acquire a holder. They help keep it in a fixed position, which has a positive effect on work results. If you need to make a precise cut, you must be sure that the turning cutting tool will not slip - this will help ensure the holder. It is attached directly to the machine. Many holders have several holes at once, which will allow you to change attachments directly during operation, which will significantly speed up the process. You can also select holders with adjustable locking, allowing you to vary the supported turning tool within a given range. This again will allow you to save on equipment by buying one product instead of one.

Types of equipment used

Metal turning is carried out on screw-cutting lathes, automatic machines or turning machining centers. Most lathes are horizontal equipment.

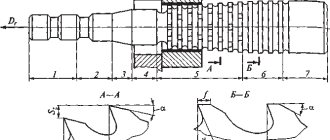

Main components of a manual lathe:

- The bed is the supporting part of the equipment on which all its other elements are located.

- The headstock, which houses the electric motor and drive system that drives the spindle.

- Spindle - supports and rotates the workpiece, which is secured in the collet chuck.

- A tailstock that secures the opposite end of the workpiece (sometimes this includes a rest - a device that supports long workpieces whose rigidity is reduced).

- A support is a reciprocating moving platform on which the working head with a tool is fixed.

Lathes can be controlled by a computer, in which case they are called computer numerical control lathes. All operations performed on such units are automated and controlled by a built-in computer.

Where can I buy metal turning tools?

The best prices for goods and we guarantee their quality. If you are going to buy a turning cutting tool, then you should pay attention to the following factors:

- price;

- reputation of the manufacturer;

- quality;

- range.

On our website you can purchase turning tools from the most famous manufacturers. We guarantee a high level of product reliability. Another convenient advantage is the fact that we deliver to the consumer’s warehouse. We offer a wide selection of turning cutting tools with an optimal price-quality ratio.

Choosing cutters for a lathe

Let us briefly list the main types of cutters, depending on the purpose, that may be needed for the work:

- Scoring - used for face processing, cutting ledges at different angles relative to the axis of the workpiece.

- Go-through cutters are the most commonly used types of cutters; they are used to grind a workpiece to the required diameter. They can be used for turning external chamfers; they are divided into straight, bent and thrust.

- Cutting - used for cutting off part of a workpiece or boring grooves.

- Boring – used for boring holes.

- Chamfering – for preparing internal and external chamfers.

- Threaded - for cutting external threads.

- Shaped – for turning parts of complex shapes.

Please note that over time the cutters become dull and require periodic sharpening. It is not recommended to sharpen brazed cutters, as you may lose the cutting layer. The need for sharpening can be determined by overheating, grinding and burrs on the workpieces being processed.

Types and Types of Tools

A lathe is a universal tool for carrying out work using tools:

- cutter (cutters are the main type of tool in turning);

- drilling (drills, countersinks, countersinks, reamers);

- thread-cutting (taps for internal threads, dies for external threads).

Numerous capabilities of turning equipment make it possible to solve the problems of cleanliness and accuracy of processing, so, using sequential operations using various types and designs of tools, you can achieve high performance in all the necessary parameters of cleanliness and accuracy of machined surfaces.