Offers straight cutting machines to buy at competitive prices. This is the main type of equipment when working with wire; it is actively used in the production of masonry and reinforcing mesh, in the production of fences and various wire products. These specialized machines were created to quickly, efficiently and safely for people on the construction site to straighten wire and cut it into pieces of specified length.

This section of the catalog presents straightening machines for wire and reinforcement and cutting (cutting) machines that can solve the main production problems faced by manufacturers of wire products.

Industrial methods

In production, specialized straight cutting machines are used to straighten almost all types of metal wire. The process is based on two main methods:

- straightening by rolling through a system of 5-6 pairs of rollers, which are located sequentially in different planes so that each subsequent pair is perpendicular to the neighboring one;

- straightening by drawing through several specially made dies.

As a rule, such machines must have a special device for automatically unwinding wire from coils or coils.

To work with elastic types of wire and alloy steel rod, the production technology involves heating and tempering the steel structure of the workpiece using gas burners or high-frequency inductive heaters.

How an industrial straightening and cutting machine works can be seen in the video:

Design of straightening and cutting machines for wire and fittings

The design of the correct machines is thought out in such a way that during operation the complete safety of the operator standing near the equipment is ensured. In addition, it is designed to ensure ease of operation, reconfiguration and maintenance, minimal operating errors and wear resistance.

The structure of the machine includes: unwinder, straightening cylinder, broaching and cutting devices, bed, receiving line, electrical control unit, etc.

Straightening of the wire is carried out by the dies of the straightening-cutting machine, secured with adjusting screws. The position of the dies can be adjusted to achieve the best results.

The lower and upper drawing rollers have several grooves of different diameters (for different thicknesses of the drawn wire). To switch the rollers into reverse motion mode (used for adjustment), there is a separate button on the control panel. The clamping force between the upper and lower feed rollers can be changed using the adjustment knob.

The receiving ruler is used as a device that determines the required specified length of the straightened wire rod, its cutting and automatic unloading of the rods onto the receiving brackets. Length adjustment is carried out by adjusting the position of the stop plate on the receiving ruler.

The principle of operation of the wire machine is as follows: the operator manually pulls the end of the wire from the unwinder to the feed rollers of the machine, then, thanks to the lever-eccentric mechanism, the rollers are clamped, and the wire enters the correct drum. Thanks to the dies installed on a very quickly rotating frame, the wire is straightened in all planes. In addition, the rotation of the frame eliminates marks from rollers and other tools. After straightening is completed, the wire enters the rear feed rollers and is pulled further onto the receiving line. Having reached the thrust plate, the rod presses on it, which sets the cutting device in motion. The finished rod falls into the receiver. Then the process is repeated again.

Drawing (diagram) of a straightening machine

- Machine bed

- Straightening cylinder

- Pulling mechanism

- Cutting mechanism

- Receiving line

How to straighten wire without a machine

Unfortunately, at home, making a good roller machine capable of straightening wire with a diameter of over 2 mm is quite expensive and labor-intensive. Moreover, if the need for a straight wire rod is one-time.

An example of one of these devices can be seen in the photo.

Therefore, in order to straighten the metal wire from the coil, it is worth using the most common method of force stretching, for this you must be guided by the following sequence:

- First you need to firmly fix one end of the wire in something massive and solid. To do this, you can wrap its end around the base of a power line pole or a strong tree with a trunk diameter of at least 25 centimeters.

- Next, we manually unwind the coil on the ground and, if possible, stretch it as much as possible.

- At the second end of the unwound wire we make a loop and secure it in a device capable of pulling it with force, that is, moving it a certain distance.

- The straightening process itself consists of slowly stretching the metal wire with great force until it becomes shaped like an ideal string. To secure the straight shape, you can leave it in this tense state for some short time, from about 5 to 30 minutes.

A fairly wide range of devices can be used as a tensioning device, depending on the diameter of the metal wire. So, for a wire 2-3 mm in diameter, a steel scrap with the effort of two strong men or the use of a manual mechanical winch may be enough. But straightening wire for a diameter of 5 mm or more will require much significant effort and for this you will need to use either the towbar of a personal car, or the dynamic force of a tractor or truck.

It is worth keeping in mind that straightening a wire with a diameter of more than 5 mm, made of alloy steel, will require not just tension to the shape of the string, but stretching until the wire breaks. As a rule, the rupture occurs at the attachment point on one of the ends, and for safety reasons you should not be near the stretched wire.

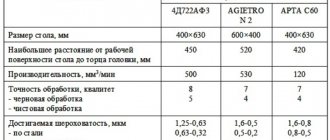

Machine Specifications

When analyzing proposals for ready-made equipment, special attention should be paid to its technical parameters. They directly depend on the initial characteristics of the material being processed. To do this, you need to familiarize yourself with the technical documentation and read reviews from owners.

The determining criterion for selection is the type of straightening machine, which must correspond to the above-described classifiers. Then the maximum and minimum diameter of the workpiece being processed is taken into account. To ensure normal operation and convenience of personnel, the overall dimensions should make it possible to install the complex on a specific site of the production facility.

Main technical characteristics of the straightening machine for steel rods:

- maximum and minimum diameter of the workpiece;

- feed speed, m/sec;

- length of cut rods, m;

- cutting accuracy, mm;

- overall dimensions and weight.

The speed of changeover for processing rods of other diameters is also taken into account. Additionally, it is recommended to purchase a set of shafts for alignment.

The video describes in detail the design and operating principle of the straightening machine:

How to straighten a wire with your own hands

If the wire rolled into coils can be considered conditionally smooth, then in order for it to become straight, we just need to get rid of the large radius curvature.

But how to straighten the wire in the form of crumpled remains and poorly stored waste? They represent not only turns, but various zigzags located in different directions from the axis. In this case, straightening the wire with the right approach to the state of an ideal straight rod is quite achievable. There are several most effective ways to align the wire. Depending on the choice, they will have slightly different quality results.

So, from simple to complex:

- You can remove creases from the wire by securing both ends in your hands and starting to forcefully roll it through a pipe or door handle.

Straightening the wire works well if its straightened sections are placed on a flat surface of the workbench. Cover it with a wooden block and start rolling it over her so that she can move freely. Just a few such rollings give quite good results.- To straighten soft copper wire, you need to secure it at one end at a height. To the other hang a not very heavy load, such that it cannot tear it. By rotating the load clockwise and back several revolutions around its axis, you can achieve an ideal result.

- Straightening the wire will follow a similar method. If one end is secured in a vice, and the other is clamped in the chuck of a screwdriver or electric drill. The straightening process will occur from slow rotation and at the same time holding the wire under strong tension. Just a few turns will be enough for complete straightening.

- Also, a screwdriver or electric drill will be needed to straighten small pieces of wire up to 30 centimeters. To do this, make a spinning hole in a wooden block with a diameter slightly larger than the wire one and pass one end of the rod through it. We fix this end in the chuck and begin to slowly rotate, pulling the wire through the hole.

- To align a wire of not very large diameter, you can make a fairly simple and cheap device with your own hands.

For this we need a massive wooden board measuring 500 x 120 x 50 mm. We hammer 5-7 nails with a diameter of 3-5 mm into it in a straight line with an indentation to the diameter of the wire. The distance between the nails directly depends on the diameter of the wire and its elasticity. The higher these indicators, the larger the gaps between the metal rods. The process of straightening the wire will consist of simply pulling it between the nails along the marking line. For clarity, a schematic photo will help you.

If you know your original way to straighten the wire with your own hands, then please share it with us in the comments block.

Advantages of buying a straightening machine in

- We have been supplying straightening and cutting machines for more than 10 years; we have long-term experience working with manufacturers, which allows us to guarantee the quality of the supplied machines.

- In addition to delivery, our company installs and commissions equipment for our customers free of charge. We provide a full range of services: setting up straightening cutting machines, supplying spare parts (dies, straightening and feeding rollers, knives, etc.), warranty and post-warranty repairs, personnel training, consultation on operation and maintenance issues.

- We can offer wire cutting machines in different price ranges and required productivity.

- When purchasing a machine, we provide all the necessary information: passport of the straightening machine, diagrams, drawings, operating instructions in Russian.

If you find it difficult to decide which model of straightening machine will best suit your requirements, contact our managers by phone or email listed on the website, or through the Online Consultant window. Our specialists will try to choose the best option for you, and will also familiarize you with the terms of payment, delivery and subsequent service.

Basic bending methods

If it is necessary to perform a small amount of work, then hand tools are used to bend the wire. For bending soft metal materials or when the wire diameter does not exceed 3 mm, pliers or round nose pliers are used. These tools allow you to securely clamp a part of the product in one tool, and use another to bend the wire to the desired angle.

In this way, you can bend the material using a carpenter's vice. In this case, the wire is fixed in a vertical position, and the change in direction is also carried out using pliers or any other clamping device or mechanism.

If it is necessary to make a rounded bend, then for this purpose any rod of suitable diameter is used, which is also clamped in a vice. A rounded bend will need to be made when making springs from elastic wire yourself.

To do this, it is enough to clamp a rod or pipe of a suitable diameter in a vice, fix the end of the wire on one side, and use pliers to wind the wire the required number of turns.

If the wire has to be bent too often, then the most correct solution would be to purchase special devices or machines.

Tools for bending this material are a design in which the wire is clamped and bent using human muscle power. Machine tools usually use electric drives, and for the manufacture of complex products such machines are equipped with electronic controls.

Rules for work

Wire bending is not a complicated process, but to work effectively with this material you must adhere to the following rules:

- For work, you must use gloves made of thick fabric.

- Use only working tools and automatic machines.

- If a vice is used to perform this operation, then before starting the process, you must make sure that the workpiece is securely fixed.

- Before bending, the workpiece should be leveled.

Following these recommendations will help prevent scraps and injuries in the event of a sudden release of material from the holding device. You should also take care of the wiring and proper grounding when using machines that run on electricity.

Equipment use

If the volume of work is large enough, then equipment equipped with an electric motor will allow you to perform a large number of operations. The use of machines will significantly increase labor productivity, but at the initial stage it will be necessary to make some efforts to study the process of operation of a wire bending machine.

The most economical machine for bending wire is considered to be coil equipment, in which the material is supplied from bulk coils.

The process of bending wire on such equipment is carried out in the following order:

- The wire from the coil is fed to a roller mechanism, which aligns the material.

- The straightened wire enters the bending mechanism.

- At the next stage, bending and separation of the wire products occurs.

- After cutting the finished product, the process is repeated.

To make wire bending work as comfortable as possible, CNC machines are used.

Despite the significant cost of such equipment, the return on investment in a business occurs within a few months. Machines equipped with a microprocessor allow not only to fully automate the process, but also to carry out welding work on curved products.