Wire bending, performed either manually or using various tools and special equipment, allows products made from this material to be given different configurations. During the bending process, the inner layer of the wire is subjected to compression, and the outer layer is subjected to tension. Wire bending machines, which today are presented in a wide variety of models, are very popular, since bent wire products are actively used to solve various industrial and household problems.

The simplest device for bending wire

To perform bending operations at home without any problems, it is best to choose wire made from soft materials. Simple bending of stiffer wires, if necessary, can be carried out using ordinary plumbing tools:

- pliers (with the help of such a tool, which every home craftsman has, you can form a simple bend in the wire, as well as securely fix its segment for further processing);

- pliers (using this tool, which is one of the types of pliers, you can perform bending of varying degrees of complexity);

- wire cutters or needle nose pliers (using such a tool, the wire can be cut into pieces of the required length).

Simple techniques for manual wire bending

If you need to make a product of complex configuration from wire using the bending method, it is better to first draw it on paper and periodically check the sketch. To form the simplest figures, such a sketch does not need to be used. For example, if you need to create a bent product of a rectangular shape, you can do this as follows:

- The wire at the place of its future bend is clamped in a bench vice.

- The upper (not clamped) part of the wire is bent using ordinary pliers or a hammer.

As a result of this simple procedure, a bend at a right angle is formed on the surface of the wire.

To produce a large number of similar wire parts, templates and homemade devices are used.

Manual bending rules

If you are going to manually bend the wire, you must adhere to a number of recommendations that will allow you to complete this procedure without harm to your own health.

- All bending procedures should be carried out only with gloves made of thick fabric.

- The wire that is being bent must be secured in a vice as securely as possible so that it does not jump out during operation.

- All tools and equipment that you are going to use for work must be in good working order and perform their assigned functions efficiently.

- Heavy tools and equipment that you use when bending should not be placed on the edge of the workbench, so as not to accidentally hit them and drop them on your feet.

- When carrying out all manipulations with the wire bending tool with one hand, the other should be kept as far as possible from the future bend. Pliers or any other tool can break off and injure a hand located close to the bending area.

Wire bending using improvised means is possible only in small quantities, since such a procedure is quite labor-intensive. In addition, this operation can only be used to create products of the simplest configuration.

A specialized wire bending machine allows you to produce various products in large volumes, including those with complex shapes.

Operating principle and types of machines

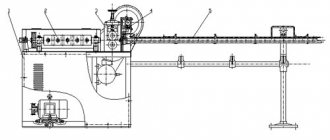

Specialists will help you select wire bending machines. It is noteworthy that the automation system can be installed on any model - bottom console, double console. The first ones are simple and compact. They are designed to perform simple work with a sweep of up to one meter.

Double-cantilever machines are designed to produce parts with complex shapes and longer lengths. In this case, before bending, the material is divided into measured pieces. The deformation process itself is carried out on both sides of the rod towards each other.

An innovative class of equipment – machines with spatially flexible three-dimensional technology. They carry out deformation without welds. The parts are more durable.

Important parameters for choosing equipment are performance, dimensions, and list of functions.

It is also important to consider the reliability of the manufacturer, maintainability of equipment, availability of spare parts, and cost of maintenance. All characteristics must be superimposed on the requirements of a particular enterprise. This is the only way to optimize the budget for workshop equipment. All publications

Working with a wire bending machine

To produce a large number of bent products from wire, various techniques can be used, each of which uses special equipment. The most common and economical method is the coil bending method.

Bending using this technology occurs in several stages.

- The wire, which is wound on coils, is fed to a two-plane roller machine, which aligns it.

- After alignment, the wire is fed to a wire bending machine, on which the product of the required configuration is formed.

- The formed product is cut off, and the entire bending cycle is repeated again.

The use of this technology allows you to fully automate the bending process and thereby achieve high productivity.

Budget wire bending machine

A wire bending machine can also look like a stationary template around which the wire is rolled using movable pressure rollers. Using such devices, bends of even the smallest radius can be formed on the surface of the wire, the value of which is comparable to the outer diameter of the workpiece. At the same time, the configuration of the product formed on such a machine can be quite complex.

The adjustable stops and variable arms of this template allow you to create many combinations of wire bends

A wire bending machine can also operate on the principle of pushing the workpiece through a system of rollers. When using such equipment, the end of the wire is connected to a special wire, which pulls the product through the working parts of the machine. A wire bending machine of this type, due to the features of its design, allows the production of products with even very complex shapes.

When leveling the wire, a wire bending machine is also used, which in this case is used for straightening. The working parts of such equipment can be straight frames or two-plane straight blocks. At the same time, rotating straightening frames are more efficient, which is why they are used in cases where leveling the surface of the wire needs to be done as smoothly and efficiently as possible.

Advantages of using CNC wire bending machines

Wire bending machines of this group are controlled by an operator from a computer. This makes it possible to rotate the bending arms within three-dimensional space in different sequences. The use of this class of equipment significantly increases the productivity of enterprises. To change or set bending parameters, you only need to enter the information into the program. Other advantages of CNC technology include:

- high speed of completing assigned tasks;

- extreme ease of maintenance;

- safety for workers;

- impeccable bending accuracy;

- versatility of use (the equipment is adjusted to the diameter of the wire and the material of its manufacture);

- uninterrupted operation around the clock.

Types of professional equipment

The simplest type of professional equipment used to bend wires are machines with one console. Meanwhile, such devices can only produce products of simple geometric shapes, the development length of which does not exceed 1000 mm.

More complex products with a development length of over 1000 mm make it possible to create double-cantilever equipment, in which the workpiece is deformed simultaneously from both ends. This machine can produce products with many complex curves.

The most complex wire products allow the creation of 3D machines on which bending can be performed simultaneously in three dimensions. The machines of this category are endowed with such unique functions by a rotary bending console, all movements of which are controlled by an electronic automated system. Despite all the advantages of processing using such equipment, it is quite expensive, so these machines are used in exceptional cases.

Types of Wire Bending Machines

Depending on the technology, there are several types of wire machines:

- manufacturing parts from coils;

- bending from a metal rod;

- rolling bending;

- bending by pushing;

- CNC machines.

Machines for producing coiled wire

The specified type of unit is used for mass production. Such wire bending machines have high productivity and efficiency compared to others.

The wire manufacturing process goes through several stages:

- take the unwinder;

- a coil of wire is fixed in it;

- the wire is affected by two mechanisms at once, one of which is planar, the other is roller;

- the wire becomes a straight rod;

- a straight wire rod is placed in the bending section of the apparatus;

- the output is a part that has the desired shape;

- the finished product is cut with special mechanical scissors.

Such a bending machine is capable of producing only a certain type of finished product. This is due to the presence of devices in it that are pre-configured for the production of parts having a certain shape.

The units produce simple-shaped parts and do not offer a wide variety of them. The number of bending operations on such machines is limited to five.

Devices that bend wire from a metal rod

This device is considered more technologically advanced than the previous one. The machine carries out additional processing of the finished product, which is not done by a unit from a coil.

The device allows you to do stamping and carving on wire products.

This type of machine has two main disadvantages:

- has low productivity;

- requires the installation of an auxiliary workpiece feeding device, which has a complex design.

Roll bending devices

Devices of this type are designed for the production of round-shaped parts. The wire is fed on the machine onto a shaft with a predetermined radius. Feeding is carried out using guide rollers. A rotational movement of the shaft is created, resulting in the wire bending around the finger several times.

The device allows you to adjust the spring pitch and bending angle of the part. This is ensured by the position of the rolling rollers in relation to the shaft.

This manual bending machine produces only one type of product. To change the type and shape of the manufactured product, a preliminary replacement of bending devices will be required. It will be necessary to carry out commissioning work.

Units operating by pushing method

The pushing method is used for wire that needs to be shaped into a complex geometric shape.

The pushing procedure is based on the forward movement of the metal material through the roll forming device. The given shape of the part is given by rolling rollers. Instead of a machine's roll forming device, a spring-coiling device can be used.

The equipment on which wire bending is possible in this way is complex and requires special knowledge.

Numerically controlled devices

Progress in machine tool construction has made it possible to introduce CNC units, with the help of which wire bending has become possible.

The machines produce 2D-shaped parts and 3D-shaped products. The machines are controlled by an industrial computer. Thanks to the computer, it is possible to rotate the bending consoles in three-dimensional space in any sequence.

CNC units have high labor productivity. If you need to change the shape and type of products, you just need to change the production program on the computer.

Processing methods

If we talk about bending wire on a large scale (in production or a specialized plant), then various methods are used to plastically deform it.

One of the most common and economical is the bay processing method.

In this case, wire rings are wound onto coils, and then they are fed to two-plane roller machines that straighten the wire.

Video:

Afterwards, the material is processed on bending equipment (the required shape is created), at the end the wire is cut, and the entire work cycle is repeated again.

IMPORTANT TO KNOW: Tapping a pipe

Moreover, all work is fully automated, which allows you to save time and money and use the device to create a simple curved structure with a development length of about 1000 mm.

For rolling wire with your own hands, there are special devices that consist of fixed templates of certain radii of curvature (the radius can be one or several).

The material is rolled around the created template using pressure rollers.

Basically, this technology is used to create bent products that have a small bending radius (about the same as the diameter of the wire).

The method of pushing the wire is reminiscent of the way 3-roll equipment works on a profile bending and spring-coiling machine.

The material is pushed into the device using a special wire, then it is pressed against various rollers, which makes it possible to change the bending parameters and make transitions to different radii.

This device allows you to bend various structures that have a complex configuration and large bending radii on the development - from 1000 mm or more.

Video:

You can straighten the wire using straightening equipment or a special device. This equipment includes units consisting of rotating leveling frames or two-plane leveling blocks.

In this case, rotating frames are preferable, as they allow the material to be aligned more smoothly.

Homemade manual machine for artistic wire bending

In order to bend wires to create metal patterns on fences, stair railings, and for decorating facades, special factory-made equipment is used.

However, it is also possible to independently manufacture such a device.

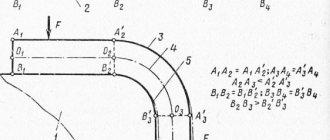

Rice. 1

Rice. 2

Brief manufacturing steps:

- Make a frame (2) measuring 150x80 mm from a steel plate 30 mm thick.

- A through hole is drilled at the end of the frame (visible in Fig. 1) for the adjusting bolt, blind holes (2) and (3) for fixing the rollers, (4) and (5) for fixing the frame to the corner. The holes are threaded with M8 threads.

- An unequal angle 60x40 mm with a shelf thickness of 5 mm and a length of 200 mm is screwed to the table.

- For the groove in Fig. 1, a steel block 90 mm long is made. A blind hole with a thread (1) for the adjusting bolt, a through hole (2) for fixing the rotation angle adjustment knob, a hole (3) 10 mm deep with an M8 thread for a roller with a corrugated surface are drilled in the block.

- The assembled frame (2) with guide rollers (3), two handles (5) and (6), and a roller with a grooved surface are screwed to the corner.

Homemade and industrial methods of wire bending

It is difficult to say where products made from wire, which is a metal thread or a thin rod, have not been used today. Wire bending made it possible to give products any desired shape. Both using hand tools and mechanical influences on special equipment.

From a physical point of view, the process of bending wire consists of simultaneous compression of the inner and stretching of the outer layers of the metal of the wire. The process can also be accompanied by a longitudinal displacement of these layers if twisting occurs. This technology for working with metal wire is widely used in many industries and in jewelry.

Methods for bending metal wire

There are several main ways to give metal wire the required shape of the finished product, so we can highlight:

- manual method of bending wire using special tools and simple devices. It is used for wire with a diameter of up to 3 mm in the manufacture of simple products in utility production or households. As a rule, it does not require virtually any financial investment or special knowledge;

- manual method of making jewelry from wire up to 2 mm in diameter. Requires special tools and devices, as well as certain knowledge and skills for working with precious metals;

- bending wire from a coil, which is based on a special device called an unwinder;

- bending wire from a metal rod;

- bending using wire rolling method;

- bending metal wire using the pushing method.

Wire bending machines

Mechanical machines for the mass production of parts and finished products from metal wire are widely used in industrial production. Depending on the technology used to shape the finished product, there are:

- A wire bending machine that produces parts directly from a coil. It is the most productive and economical option for mass production of wire products. This happens due to the fact that the coil of wire is installed in a special device - an unwinder, from which the metal thread enters the correct block. There it is exposed to a roller or plane mechanism, as a result of which the output takes the form of an even and straight rod. After this, the wire enters the bending unit of the machine, where, with the help of mechanical devices, it is given the required shape of the finished product. At the end of the process, the finished part is cut with mechanical scissors. Typically, such a wire bending machine can produce one type of finished product, which is determined by pre-installed mechanical devices and limited by the ability to manipulate the feed mechanism. Therefore, the shapes of products produced on such machines are not very complex in configuration, since the number of bending operations is limited to five.

- A wire bending machine for bending wire from a metal rod is a more technologically advanced method, which has a number of advantages compared to working from a coil. This is especially necessary when the finished product requires additional processing. This can be threading or stamping, which can only be done until the finished product is shaped. The disadvantages of such a machine are its need for an additional complex mechanism for feeding workpieces and relatively low overall productivity.

- The wire bending machine for bending wire using the rolling method is mainly used for the production of various round-shaped parts and various types of round springs. For example, such a machine for bending wire by rolling works due to the fact that the wire is fed through guide rollers onto a shaft of a given radius, where, due to its rotational movement, it bends around the finger a given number of times. In this case, the wire is twisted along a given radius, which has a bending finger and rolling rollers. Due to the position of the rolling rollers relative to the central shaft, the bending angle or spring pitch can be set and adjusted. A wire bending machine by rolling, like other similar mechanical devices, is capable of producing only one type of product per operation. To change the range of products, both the replacement of bending devices and commissioning work are required.

- Wire bending machine for bending metal wire using the pushing method. For certain wire parts, during their manufacture, it is necessary to give them complex shapes of certain geometric shapes, such as variable radii, irregular arcs, spiral appearance, and the like. It is not very effective to do this by running in, and sometimes it is even technologically impossible. Hence, the only possible way is to use the wire pushing method. The principle of operation is the forward movement of metal wire through a three-roll roll forming unit or a special spring-coiling device, in which the shape of the finished product is given due to the position of the rolling rollers. As a result, you can obtain any given curvature or a smooth change in the size of the radius. The main difference between rolling and other bending methods is that the equipment is more complex, requiring special knowledge during setup and maintenance.

- Straightening machines are used as an additional device in technological lines for the production of various metal wire mesh for straightening the wire and giving it a certain shape. Two technologies are used here: straightening using the rotation method using a frame and straightening using a two-plane straightening block. The two-plane block does not straighten very perfectly, but it does not twist the wire. But the rotating straightening frame has a more complex design, but many machine tool manufacturers still prefer it to the classic straightening block design.

CNC machines

The development of machine tool construction has made it possible to produce wire bending machines with one or two bending consoles. They can produce finished products not only in flat 2D shapes, but also in spatial 3D models. The transfer of control of production processes to an industrial computer made it possible for a CNC machine to rotate bending consoles in three-dimensional space in any given sequence.

Wire bending with CNC machines not only allows for higher productivity, but also allows for the production of products of different shapes just by changing the production program.

Do-it-yourself wire bending devices

Metal wire, or rather, various products made from it, is widely used in any household.

Bending wire with your own hands using hand tools allows you to produce a fairly large number of household products, such as:

- clamps,

- brackets,

- hangers, etc.

But for this we have to use the softest and most flexible types of wire, so that we can easily bend the metal into the shape we need.

So, for working with wire up to 3 mm in diameter, round nose pliers, pliers and a bench vice are suitable, and you can cut the wire with wire cutters or side cutters. This set is quite enough to give the metal wire the desired shape and its subsequent processing.

Working with large diameter wire has certain difficulties. But if it is also rigid, then to bend it manually you will need to use special bending devices.

Of course, you can buy a ready-made bending device, but it’s quite possible to make the tool yourself. How to make a device for bending wire with your own hands from available parts can be seen in the photo.

How to bend wire into a ring evenly

In order to bend the wire into a ring and make it the correct shape, you must use either a pre-made wooden blank of the required diameter, or use a piece of metal pipe of a suitable diameter. We wind at least two turns onto the template and make marks, while not forgetting to allow for the thickness of the cut. Next, cut the wire and weld an even ring.

If anyone knows other ways to make complex shapes from wire, you can share them in the comments block.

Search for records using a filter: Select BendingProtectionForgingCuttingWeldingDrilling Select RebarSquareCircleSheetStripWirePipeAngleChannel/Beam Select AluminumBrassCopperStainless SteelTitaniumCast Iron

wikimetall.ru

Simple DIY wire bending devices

To perform bending in single or small-scale versions, sets are used, consisting of two steel plates, axles, rollers and a bushing with a central channel of 6 mm. The number and location of axes can be changed.

Operating principle of the bending device:

- The bottom plate is secured in a vice.

- The top one is turned to a certain angle. If it is necessary to make precise shapes, a protractor is built into the device.

- Due to the protruding axes and the support sleeve, the product bends at the desired angle.

Using such a bending device, you can work with unalloyed and stainless wire with a diameter of 3-4 mm, welding rods, fittings with a smooth surface of class AI of small diameter.