Aluminum is perhaps the most common metal in everyday life. In almost every home there are many small objects made of aluminum, this includes various kinds of key rings, gift imitation knives, metal coatings for flash drives, etc. - the list can be continued almost endlessly.

It is quite natural for any man to want to make his small accessories unique. For metal objects, the idea of improvement comes naturally: engraving. To engrave products, you can use a laser engraver. However, this method is not suitable for aluminum.

The melting point of the metal is 600 degrees Celsius. It is difficult to find an engraver for engraving metal with such a melting point, but it is possible. But we have to take into account the oxide film that covers the surface of the metal when it comes into contact with oxygen. And the melting temperature of this film is about 2000 degrees Celsius. This means that the most common method of applying engravings and inscriptions, thermal, is not suitable. It is in such situations that it is worth remembering another method: etching. Note that etching can be both artistic (to create drawings and engravings on the surface of the metal) and technical, with the aim of clearing the metal surface of the oxide film and making the metal suitable for further processing.

Aluminum etching can be done in two ways:

- Electrolytic method.

- Chemical method.

We will analyze each of the methods, as well as their implementation at home, in detail.

Method 1 – cleaning small aluminum products

- To wash things like pots, pans, etc., you first need to wash these things well. Fill the sink with hot water and use dish soap to wash all kitchen utensils. Rinse it in clean water and dry it.

- Now you need to prepare a solution for cleaning aluminum. Take a container and pour a liter of water into it with 2 tablespoons of wine vinegar or citric acid.

- Place the pan on the stove and boil the solution. Once the solution starts to boil, place all the aluminum items you want to clean into the pots. 15 minutes of boiling in the solution will be enough.

- Put on oven mitts and carefully remove the pan from the heat. Drain the solution into the sink.

- Boiled items should be washed with warm water.

- If not everything is completely cleaned, then repeat the boiling again.

Aluminum etching with alkali

Most often, this method uses an aqueous solution of caustic soda (an option with or without additives is possible).

And it is used to clean the surface of an aluminum product from oxide or unnecessary lubricant and obtain a smoother (matte or glossy) surface.

Why is it necessary to clean so thoroughly? To ensure that the finished product (for example, decorative architectural elements, signs) has an ideal surface. This method is also used for deep engraving.

The method of etching aluminum with alkali, on the one hand, is quite inexpensive, but it is very labor-intensive.

Method 2 – cleaning large aluminum items

- Let's say you can't stuff a boat into a pan and boil it. What to do. You need to buy a special acidic solution or aluminum brightener. Such solutions are sold in construction and hardware stores.

- Consider options for protecting exposed skin. Wear goggles and rubber gloves.

- Concentrated solution. Therefore, read the instructions and dilute the solution with water in accordance with it. Typically, 1 part solution contains 10 parts water.

- Apply the solution to the surface to be cleaned. Take a soft bristle brush and soak it in the solution. Using circular motions, begin polishing the aluminum surface. Do this until the metal begins to shine.

- Rinse the solution with water and dry the surface with rags.

Adviсe

Contact our cleaning agency for help.

Precautions

Do not neglect glasses and gloves, otherwise you will regret it later.

Features of aluminum welding

Still, why is aluminum so difficult to weld? There are a number of features of this metal that, to one degree or another, prevent it from being reprocessed using conventional techniques:

- Oxide film. A similar layer is present on many metals, but aluminum oxides have a very high melting point. If under normal conditions such an alloy begins to melt at 560+C (some alloys according to GOST at 660), then the oxides can withstand up to 2000C and only at such a high temperature can they melt;

- Easy oxidation. The metal reacts so actively with air that even drops of molten metal can oxidize and prevent complete mixing of the alloy;

- High thermal conductivity. An excellent property, which when welding implies the use of operating currents 1.5 times higher in comparison with steels;

- High fluidity. A property that makes it difficult to fully control the weld pool and implies the use of special heat removal agents;

- High degree of shrinkage. This leads to the fact that when cooling, the treated area can be significantly deformed;

- Formation of cracks and pores. Metal and its alloys have a number of technological features leading to defects that can be avoided in production conditions and are very difficult to avoid during welding. For example, the hydrogen contained causes the formation of pores, which weakens the seam.

Gas pores in the weld

So we have a metal, the weld of which, when welded, is extremely difficult to give at least the original characteristics of the metal, not to mention improving them. In practice, we find that a weld on aluminum is always worse than the alloy itself.

In addition to the described disadvantages, there are also the peculiarities of certain alloys, which in some cases cannot be processed without proper technical training. However, to be fair, it is worth saying that if you come across an alloy that differs from GOST with high electrical resistance, then its processing will be a little easier.

We recommend! How to weld stainless steel with an inverter yourself

What not to do when cleaning

Aluminum is a fairly soft and pliable material, which is why particularly aggressive cleaning methods should be avoided.

- 1 First of all, you must stop using sharp objects. Do not scrape off blackened or burnt marks with a regular kitchen knife, scraper or wire brush. After this procedure, the surface of the product will be damaged. And if these are dishes, then particles of aluminum will subsequently get into the food during cooking.

- 2 Also, do not attempt to clean aluminum if it is hot. Otherwise, when interacting with water, this material begins to succumb to deformation, and it will be very difficult to restore the product to its original form.

- 3 Powders with abrasive particles can cause both small and quite visible scratches. They will spoil the appearance of an object made of aluminum alloy. For the same reason, you should avoid using sand or sandpaper.

- 4 Also avoid using products that contain acids and alkaline solutions. They have negative effects no less than abrasive preparations. In addition, during a possible chemical reaction, heavy metals and toxins can be released that will cause irreparable harm to the human body.

Lightening the surface of parts

For parts of 1st, 2nd, 3rd accuracy classes, it is advisable to use a sulfuric acid solution (240-260 g/l) at a temperature of

70_80°C. An alkaline solution also gives good results.

(50-60 g/l NaOH), to which 9-10 g/l agar-agar, which plays the role of an inhibitor, is added at a temperature of 60-70 ° C.

The addition of 15 g/l calcium chloride has an inhibitory effect on the dissolution of aluminum in a 1N solution of potassium hydroxide. The combined introduction of it and some organic compounds helps to inhibit the corrosion process of aluminum.

Pickling of cast alloys is carried out in a solution containing 650-700 g/l nitric and 120-140 g/l hydrofluoric acids at room temperature. According to work [4], for better removal of alloying additives (nickel, silicon, titanium) and impurities released during etching, the ratio of nitric and hydrofluoric acids should be selected taking into account the composition of the alloy. So, for the AL2 alloy it should be 3:1, for the AK7 alloy - 10:1, for the D16 alloy - 25:1. Softer processing is achieved when using calcium oxide hydrate (4-6 g/l) at a temperature of 70- 75°C.

The solution for etching parts with spot welding contains 80-100 g/l of phosphoric acid and 4-6 g/l of potassium cuperfluoride. Processing in it is carried out at room temperature.

Lightening of the surface of parts after etching is carried out in the following solutions: for aluminum and its deformable alloys - 300-400 g/l of nitric acid; for casting alloys - 740-760 g/l nitric and 100-120 g/l hydrofluoric acids; for parts with welded seams - 90-100 g/l chromic anhydride and 8-10 g/l sulfuric acid. The temperature in all cases is room temperature.

By etching aluminum parts, they often not only clean the surface of corrosion products, but also give it a certain texture, which will affect further processing (anodizing, deposition of galvanic coatings).

Source

Cleaning agents for aluminum products

How to clean the contamination also depends on what caused the darkening of aluminum. Therefore, to remove plaque, you need to be patient and use several proven methods.

If you need to clean cooking utensils in which food has burnt, it is best to soak the utensil in warm water. After this, washing the product will be much easier. Residues of food will come off on their own when exposed to moisture; all that is required is to wash the pan with a soft sponge and dishwashing detergent.

Among purchased products, it is better to give preference to special products designed for processing glass and porcelain.

Such detergents perform excellent cleaning functions and also add additional shine.

If oxidation has affected the aluminum thoroughly, then more stringent renewal methods will be required. In this case, ordinary table salt mixed with clean water in a 1:1 ratio will help. Rub the resulting mixture onto the damaged product and carefully walk the sponge over the surface.

Cream of tartar works very well with aluminum and can easily remove dark stains. To do this, dissolve 3 tbsp in 5 liters of warm water. l. product and soak the product itself in the resulting solution, leave for 3 hours. After this, all the dirt will come off on its own, the housewife will only have to rinse and wipe the products dry.

Cream of tartar may not always be on hand, so vinegar or citric acid is suitable for these purposes. They should be taken at the rate of 4 tbsp. l. acid per 1 liter of warm water and leave until completely cool. As a precaution, you should use gloves to prevent possible irritation on your hands.

How to lighten aluminum at home - Metalist's Guide

Aluminum pots and pans are still very popular among housewives. The new cookware has a number of obvious advantages - it is very light, quite wear-resistant, and most importantly, it heats up quickly and evenly. If carbon deposits have formed on it, cleaning the dishes is quite easy.

Secrets of cleaning dishes made of this metal

Let's figure out which products can be used for cleaning, and which ones are best kept away from our favorite aluminum pots and pans. Indeed, unfortunately, over time (and especially from improper processing!) the surface tends to become covered with unaesthetic dark spots and loses its shine. First, you need to immediately decide what they don’t like about this metal. So!

You can start washing the dishes by allowing them to cool slightly. After all, the hot soft alloy from which this cookware is made can become quite deformed when it comes into contact with water.

- Forget about using any strong acidic or alkaline cleaners. During the processing of dishes, these products can seriously damage the surface.

- Any cleaning powders, especially abrasive ones, can easily scratch soft metal. Unsightly scratches are also left on dishes by a variety of hard sponges and brushes.

You should not even try to pick at the utensils, trying to clean them of carbon deposits with knives and other sharp objects. Do not rub with sandpaper or sand. After such barbaric treatment, the aluminum frying pan will only be suitable as a flower stand. It is wiser to use only wooden spatulas, which are unable to damage soft metal.

It turns out that it is not so easy to find a suitable remedy. After all, many usual means for washing metal kitchen utensils have to be abandoned due to the increased “capriciousness” of light metal.

How to properly clean aluminum cookware from carbon deposits

The answer to the question directly depends on what exactly needs to be cleaned and how serious the contamination is. It’s one thing to simply wash the pan after a regular rich soup, and quite another if this soup has successfully boiled away, leaving soot on the bottom of the pan.

https://www.youtube.com/watch?v=z_gEnBZJTgk

You can remove carbon deposits in the following ways:

Soaking. To begin with, you can try this simplest, but quite effective method. Moreover, the soaking process can be slightly accelerated if you put the dishes on the fire. In most cases, after heating the water, it is possible to clean the surfaces with a regular sponge and a good dishwashing detergent.

Glass and porcelain cleaners are better for aluminum than metal steel cookware. It has been noticed that glassware products not only cope well with stains, but also help restore shine.

Salt. If the “number” of soaking is not completely successful, and there are still remains of burnt food at the bottom of the pot or frying pan, you can try to remove them using ordinary table salt.

Before you start working with salt, be sure to take care of your hands - wear strong rubber gloves. Otherwise, salt can corrode any small scratch much earlier than the dishes can be put in order.

How to remove dark spots and restore shine

How to clean kitchen appliances that have already lost their shine? Fortunately, there are several methods of varying degrees of labor intensity that allow you to return darkened dishes to their former beauty.

Cream of tartar. This crystalline sediment, formed during wine production, is good for removing dark stains from aluminum cookware.

The container to be cleaned should be filled with hot water, and then 2-4 tablespoons of crystalline powder should be dissolved in it. Let stand for at least an hour (you can put the dishes on the fire and boil the solution for about 10 minutes). Rinse the dishes with clean water and wipe dry.

Stubborn dark stains and minor scratches can be further treated with a thick paste of cream of tartar mixed with water.

Vinegar or citric acid. If it is difficult to obtain cream of tartar, then you can use more affordable means - solutions of vinegar or citric acid.

Cucumber pickle and whey. These acidic liquids also work very well on dark spots.

Soda with silicate glue. These two substances, dissolved in water, can restore devices to almost new condition in just 20-25 minutes. 100 grams of silicate glue (also known as “liquid glass”) and the same amount of soda are diluted in 5 liters of water and brought to a boil. Then the darkened dishes are lowered there. Finish the process with a mandatory thorough rinsing.

If desired, soda ash can be replaced with crushed laundry soap.

We wash spoons, forks and teapots

The problem with spoons and forks made of this material is solved in the same way as problems with large utensils. It is very convenient to “reanimate” them simultaneously with other aluminum cookware. It is enough to put them in a saucepan or frying pan with a cleaning solution, then rinse and wipe dry with a soft towel.

A light kettle, on the bottom of which a thick layer of scale has formed due to hard water, can be easily cleaned with a solution of equal parts vinegar and water. Again, instead of vinegar, you can use citric acid. And those who like experimenting can try using the well-known Coca-Cola.

Material updated 08/03/2017

How to clean aluminum cookware so it looks like new?

Aluminum cookware is still very popular among housewives. This is due to the characteristics of the material.

Such pots and pans are lightweight, heat up quickly, have a long service life and are inexpensive.

However, over time and with intensive use, their appearance does not change for the better: dark spots, burns and other troubles appear. And here housewives have a question: how to clean aluminum cookware?

Aluminum is a delicate and sensitive material. Rough cleaning and washing methods can not only greatly damage the appearance of the dishes, but also make it impossible to further use them. To avoid this, you need to follow a few simple recommendations:

- when there is a sharp change in temperature, aluminum is deformed, so the dishes must cool down before washing;

- powders, abrasive cleaning agents, metal sponges leave scratches, which spoils the appearance of products and also contributes to their faster contamination, since an uneven surface is difficult to wash;

- for cleaning, you need to select special products for aluminum and when using it, be sure to read the instructions, since acids and alkalis can damage the metal, lead to corrosion, staining, etc.;

- if food is burnt, then you cannot use sharp objects (knives, forks, etc.) to remove it, in this case there is a high risk of final damage to the product, and in the end you will simply have to throw away the dishes;

- With constant washing in the dishwasher, aluminum products darken and lose their shine; it is better to clean them by hand.

A quick way to clean aluminum cookware

Aluminum cookware can last for many years if used correctly. But even it is susceptible to darkening, burning, scale formation and grease contamination. Below are methods on how to quickly return aluminum cookware to its original appearance.

The easiest way to clean a pan from burnt food is to fill it with water and detergent and put it on fire.

After 10 minutes, the dirt will soften and can be easily removed with a sponge. It is quite possible to quickly lighten an aluminum pan and get rid of carbon deposits at home using improvised means. You need to take 1 tbsp. l. mustard powder, salt and vinegar, rub the resulting mixture onto the dirty surface and rinse with warm water after 15 minutes.

Rubbing aluminum cookware with 9% vinegar until it shines will help get rid of dark spots. You can simply pour it into the pan and leave it to soften the plaque for 2-3 hours.

Cream of tartar has the same effect. It is dissolved in hot water, poured into a bowl and brought to a boil.

You can effectively and quickly descale an aluminum pan by mixing baking soda with water to a pasty consistency and rubbing the surface with it. After this, you should rinse the dishes with water and ammonia.

Mustard powder will perfectly remove stubborn fat. You just need to pour a little substance onto a sponge, rub and rinse with warm water.

Features of this method

The solutions used contain from four to ten percent sodium. The temperature when etching with alkali is approximately 40-90 degrees Celsius.

If necessary, a moisturizer or special additive is used to obtain a light foamy coating on the workpiece.

The average temperature at the height of the process is sixty degrees. It is at these thermal parameters that high-quality surface cleaning occurs.

The optimal purity of aluminum is 99.5%, and the concentration of caustic soda solution is 10, 15, or 20%.

Thus, during the reaction, aluminum dissolves in sodium hydroxide, releasing hydrogen. As a result, a composite aluminate is formed, and it exists only in an alkali solution.

How to clean aluminum pans: 7 home remedies

Caring for aluminum utensils is a complex process. Many housewives cannot imagine how to clean burnt aluminum cookware well without hard sponges, metal scrapers and abrasive powder. But all this must be avoided, because if you overdo it with cleaning, you can damage the protective layer of the dishes, and then they will become hazardous to health.

It is also better not to use detergents based on alkali and chlorine - they lead to darkening and deterioration of the material. The following methods will help you clean an aluminum pan from soot, grease, scale and burnt food without the use of chemicals and keep it in excellent condition for a long time.

Food products

Dark spots can be removed using natural acid products. Bunches of sorrel should be laid out on the bottom of an aluminum pan, filled with water and simmered for 30 minutes over low heat, covered with a lid. Curdled milk, kefir and cucumber pickle have a similar effect. By leaving this mass in the pan overnight, you can renew it without much effort.

You can rub half an apple on the burnt surface, let the acid work, then wash with a sponge and liquid soap. To clean the pan from burnt food, you need to cook 2-3 cut onions in it for half an hour. You should first peel the onion, otherwise the metal may darken.

Lemon acid

With its help you can easily get rid of carbon deposits on aluminum utensils. You can clean the inside of the pan in a simple way: dilute 2 tbsp. l. citric acid in 1.2 liters of water and boil for 15-25 minutes in a dirty container. These same simple methods will also help in the fight against scale on aluminum products. You need to dissolve 15 g of citric acid in 1 liter of water, bring to a boil, remove the lid and keep the pan on the fire for 5-10 minutes. When the solution has cooled slightly, add 2 tbsp. l. detergent and boil again, then remove any remaining scale with a soft cloth.

Vinegar

To remove stubborn dirt, just pour 1.5 liters of water and 1.5 cups of vinegar into the dishes, bring to a boil, then rinse and wipe thoroughly. You can simply leave this mixture in a cleanable container overnight. In the morning, all that remains is to rinse the pan with a sponge with detergent and 1 tbsp. l. ammonia.

The pan can be cleaned from carbon deposits on the outside in this way: mix 2 tbsp. l. coarse salt and 1 tsp. water, rub the mixture onto the surface with a sponge. To clean the inside of a burnt pan, you need to mix 900 ml of water with 2 tbsp. l. salt and boil for 20 minutes. The simplest method for removing burnt food is to fill a wet pan with salt, let it sit for 2-3 hours and remove the dirt with a sponge. This way you can get rid of burnt jam without scratching the dishes with a hard brush.

Cutting edges for welding

Aluminum, along with high thermal conductivity, also has a high latent heat of fusion - 96 cal/g (for iron 64 cal/g, for copper 49 cal/g). Consequently, to form a reliable connection between the molten metal of the welding wire and the base metal, it is necessary to directly influence the welding arc on the entire area of contact of the liquid and solid phases of the weld pool. When welding with a non-consumable electrode, a pool of liquid metal is formed only directly in the arc combustion zone and mainly due to the melting of the base metal (the share of filler material in a single-pass weld does not exceed 30%); the reinforcement has a smooth transition to the base metal (Fig. 1, a). When welding with a consumable electrode (Fig. 1, b), the arc is much more concentrated and deeply recessed into the base metal, the size of the weld pool is increased due to the deposited metal (the share of which in the weld is 50% or more) and as a result, the peripheral part of the pool is not directly exposed , arc exposure; there is a risk of non-fusion formation.

Rice. 1. Sections of the weld pool during welding: a - with a non-consumable (tungsten) electrode; b - consumable electrode at currents of more than 500 - 550 A.

Therefore, it is necessary that the shape of the cutting of the edges allows those places where lack of fusion may occur to be re-melted with an arc when applying subsequent beads. Thus, the correct preparation of edges for welding determines the high quality of the welded joint and the manufacturability of its implementation. In all cases, preference should be given to double-sided welding.

If double-sided welding is impossible or impractical, then special attention should be paid to preventing and eliminating defects in the root of the weld.

Top 5 household chemicals

In addition to traditional methods for cleaning aluminum cookware, there are household chemical products suitable for this metal. Old stains of any type can be easily removed using the following means:

- Products from Solclean. The products do not contain aggressive components and are designed for soft metals. The composition includes white clay, corundum and oleic acid, which effectively dissolve fat and burnt particles.

- Cleaning product "Sanitary". An oxaline-based liquid that easily removes stubborn stains from aluminum pans. Blackness, grease and burnt food will dissolve after the first use.

- Shumanit of the Israeli brand "Bagi".

- "Aries Cleaner" from Amway.

- "Mr. Cheester" from .

The last three products are especially effective in cleaning aluminum frying pans and pots from carbon deposits, even old ones. The simplicity of the method lies in the fact that you just need to lubricate the inner and outer surfaces of the dishes with the substance, let it sit for 10 minutes and rinse with a sponge under water.

These household chemicals must be used with caution:

- You need to rub the dishes with gloves to avoid damaging the skin;

- due to the strong smell, it is better to cover the dishes being processed with a bag and open the window;

- Avoid frequent cleaning of aluminum pans with this method.

If you follow all the recommendations for caring for aluminum products, they will last a long time.

Which method, in your opinion, is the most effective? Share in the comments, read all the reviews.

Lightening aluminum at home

Questions about how and how to clean aluminum are relevant for many.

Aluminum products are distinguished by their lightness, convenience and beautiful shine, but as a result of use they quickly darken, become covered with plaque or oxide, which spoils the aesthetic appearance and interferes with the full use of the item. To restore the shine and purity of aluminum, use folk remedies and special household chemicals, follow the recommendations for care and use.

Aluminum is used to make dishes, automobile parts, furniture elements, etc. It is resistant to rust, but is susceptible to carbon deposits, limescale, darkening and oxidation

Cleaning features, general recommendations

Heating of aluminum cookware occurs evenly and does not require much time. After some time, carbon deposits begin to appear on aluminum cookware and traces of oxide become noticeable. Most often, they try to clean aluminum using dishwashing detergent, but it can only remove external dirt and grease.

Dishes made from this material should only be washed cold, since they can easily be damaged when hot. If a hot metal is immersed in cold water, it will become deformed, and therefore you should try to avoid such a failure.

You should not try to clean burnt food immediately using iron sponges and other objects. To make the task easier, you just need to pour warm water and wait about half an hour. During this time, the food will get wet and can be removed using a regular dishwashing sponge.

It is not recommended to wash aluminum cookware in the dishwasher, since the dishwasher uses hot water during the washing process, which can damage the material. To avoid deformation, it is recommended to wash aluminum cookware by hand with warm water.

You should not use strong acids in the process, as they will not be able to restore the shine of the dishes, and may harm them. It is also not recommended to clean it with metal sponges, which leave scratches on the dishes.

Catalog

Basic properties and features of welding

Aluminum alloys are used in welded structures for various purposes. Their main advantages as structural materials are low density, high specific strength, and high corrosion resistance. Pure aluminum, due to its low strength, is used for the manufacture of structures in some cases in the chemical, food and electrical industries. High-purity aluminum is used in new technology industries, including the production of semiconductors. Semi-finished aluminum alloys are mainly used as structural materials. In terms of the ratio of strength and fluidity to density, high-strength aluminum alloys are significantly superior to cast iron, low-carbon and low-alloy steels, pure titanium and are inferior only to high-alloy steels of increased strength and titanium alloys.

Aluminum alloys are divided into casting and wrought according to the solubility limit of elements in solid solution. In welded structures, semi-finished products (sheets, profiles, pipes, etc.) from wrought alloys are mainly used. The concentration of alloying elements of deformable alloys is less than the solubility limit, and when heated, these alloys can be transferred to a single-phase state, which ensures their high deformability.

Most of the elements that make up aluminum alloys have limited solubility, which changes with temperature. This gives the alloys the ability to be strengthened by heat treatment. In this regard, deformable alloys are divided into alloys that are not strengthened by heat treatment with a concentration of alloying elements below the solubility limit at 20 0C) and alloys that are strengthened by heat treatment (with a concentration of alloying elements above this limit). Deformable alloys that cannot be strengthened by heat treatment include technical aluminum AD1, AD, aluminum-manganium alloy AMts (Al + 1.3% Mg) and the group of alloys of the A1-Mg system: AMg1, AMg2, AMg3 and AMg6. In welded joints, these alloys are capable of maintaining up to 95% of the strength of the base metal with high ductility and high corrosion resistance.

Thermally hardenable wrought aluminum alloys can be divided into several groups.

1. Duralumins are alloys based on the A1-Cu-Mg system: D1, D16, D19, VAD1, VD17, M40, D18.

2. Aviali - alloys based on the A1-Mg-Si and A1-Cu-Mg-Si system AB, AD31, AD33, AD35, AK6, AK6-1, AK8.

3. Alloys based on the A1-Cu-Mg-Fe-Ni system: AK2, AK4, AK4-1.23 (Al-Cu-Mn-Li-Cd)

4. Alloys based on the A1-Cu-Mn system: D20, D21 and VAD

5. Alloys based on the Al-Zn-Mg-Cu system B93, B95, B96, B94.

6. Alloys based on the Al-Mg-Zn system: V92, V92Ts, ACM.

Of the listed alloys, those that can be welded include: AD, AD1, AMts, AMg, AMg3, AMg5V, AMg6, AB, AD31, ADZZ, AD35, M40, D20, VAD1, V92Ts.

For welding work, wire made of aluminum and aluminum alloys is used according to GSST 7871-75;

In the weld pool, aluminum alloys interact with gases and slags. The metallurgical features of welding aluminum and its alloys are determined by their interaction with environmental gases, the intensity of evaporation of alloying elements, as well as the characteristics of crystallization under the conditions of the welding process.

At 1000 0C, the oxidation reaction of aluminum can occur at pO2 = 44.06 * 10-46 MPa. The resulting aluminum oxide covers the surface of the parts with a denser and more durable film. At 20 0C, aluminum oxidation processes proceed according to a parabolic law. An important characteristic of the aluminum oxide film is its ability to adsorb gases, especially water vapor. The latter is retained by the oxide film until the melting temperature of the metal.

The coefficient of thermal expansion of the oxide film is almost 3 times less than the expansion coefficient of aluminum, therefore, when the metal is heated, cracks form in it. If aluminum contains alloying additives, the composition of the oxide film can change significantly. The resulting complex oxide film in most cases is more friable, hygroscopic and has worse protective properties.

The oxide film on the surface of aluminum and its alloys complicates the welding process. Having a high melting point (2050 0C), the oxide film does not melt during the welding process and covers the metal with a durable shell, making it difficult to form a common pool. Due to the high adsorption capacity for gases and water vapor, the oxide film is a source of gases dissolving in the metal and an indirect cause of the occurrence of various types of discontinuities in it. Particles of the oxide film that get into the bath, as well as some of the films from the surface of the base metal that are not destroyed during the welding process, can form oxide inclusions in the seams, reducing the properties of the joints and their performance.

To carry out welding, measures must be taken to destroy and remove the film and protect the metal from re-oxidation. For this purpose, special welding fluxes are used or welding is carried out in an atmosphere of inert protective gases. Due to the high chemical strength of the Al2O3 compound, the reduction of aluminum from the oxide under welding conditions is practically impossible. It is also impossible to bind Al2O3 into strong compounds with a strong acid or base. Therefore, the action of fluxes for welding aluminum is based on the processes of dissolving and washing off the dispersed oxide film with molten flux. Under conditions of electric arc welding in interstate shielding gases, the removal of the oxide film occurs as a result of electrical processes occurring at the cathode (cathode sputtering). Under these conditions, there is a need to increase the quality requirements for pre-treatment of parts before welding in order to obtain a thin and uniform film over the entire surface of the welded edges. To prevent additional oxidation and clogging of the bath with oxides, it is necessary to use a high-purity protective gas.

Hydrogen, unlike other gases, has the ability to dissolve in aluminum and, under certain conditions, form pores in the weld metal. The solubility of hydrogen in aluminum changes at different temperatures. The concentration of hydrogen dissolved in a metal [H] depends on the pressure of molecular hydrogen that is in equilibrium with it.

Under real conditions, the partial pressure of molecular hydrogen in the gas phase of the arc is negligible. Therefore, the main source of hydrogen dissolving in the weld pool is the reaction between the moisture contained in the oxide film and the metal. As a result of this reaction, the concentration of atomic hydrogen in the surface layer of the atmosphere in contact with the metal may correspond to the high pressure of molecular hydrogen in equilibrium with the metal. Therefore, in the presence of water vapor in the bath area, the concentration of hydrogen dissolved in the metal may be much higher than the equilibrium one. When cooled, dissolved hydrogen tends to separate from the metal due to a decrease in solubility. Bubbles of released hydrogen, not having time to float up from the bath, remain in the seam, forming pores. Therefore, the main measure to combat porosity when welding aluminum is to reduce the concentration of hydrogen dissolved in it to a limit below 0.69–0.7 cm3/100 g of metal. The main source of hydrogen dissolving in the weld metal during argon-arc welding is moisture adsorbed by the metal surface and included in the oxide film in the form of hydrated oxides. Its quantity is determined by the condition of the metal surface and depends on its treatment before welding.

Prevention of porosity when welding aluminum can be facilitated by reducing the specific surface area of the filler wire by increasing its diameter and reducing the share of filler metal in the formation of the weld. Rational treatment of the surface of the wire and base metal is used to reduce the thickness of the oxide film and the amount of moisture present in it. Magnesium increases the solubility of hydrogen in aluminum, so the increased tendency to porosity when welding aluminum-magnesium alloys is explained by a different mechanism of pore formation. On the surface of alloys containing magnesium, there is an oxide film consisting of Al2O3 and MgO oxides. Such a film has a greater thickness, lower density due to defects in its structure, and a greater moisture reserve than a film made from Al2O3. During the welding process, when the base and filler metals are melted, part of the moisture contained in the internal defects of the film does not have time to react. The film particles entering the bath contain residual moisture, which decomposes with the release of hydrogen. The hydrogen formed in film defects transforms into a molecular form and is then released in the liquid metal of the bath in the form of bubbles, bypassing the dissolution stage. With this mechanism of pore formation, as measures to reduce porosity, in addition to the usual ones associated with the use of rational surface treatment of the wire and base metal, as well as reducing the specific surface of the wire involved in the formation of the weld, tightening the regimes becomes an effective measure to combat porosity. However, with more stringent conditions, there is a danger of increasing hydrogen pressure in discontinuities, which makes it difficult to perform multi-layer welds and welding.

The crystalline structure of the weld metal determines its mechanical properties. Pure aluminum, when crystallized, has the ability to form a coarse, coarse-crystalline structure in the weld metal. When welding aluminum alloys, the crystal structure and mechanical properties of the weld metal can vary depending on the composition of the alloy, the filler metal used, welding methods and modes. All welding methods are characterized by high cooling rates and directed heat removal. During crystallization under these conditions, dendritic liquation often develops, which leads to the appearance of eutectic in the metal structure. Eutectic reduces the ductility and strength of the metal. In this regard, crystallization cracks may occur in the seams during the crystallization process. Improving the crystalline structure of weld metal when welding aluminum and some of its alloys can be achieved by modification during the welding process. Therefore, special wires with added modifiers are increasingly used as a filler metal in welding. The introduction of these elements in small quantities makes it possible to improve the crystalline structure of the weld metal and reduce their tendency to crack. Stirring the metal of the weld pool during the welding process using an external magnetic field also reduces the tendency of the weld metal to crack.

When choosing a filler metal, one should also take into account the possibility of various chemical compounds appearing in the weld metal structure. When welding aluminum alloys containing magnesium using filler wire containing silicon, needle-shaped Mg2Si precipitates appear in the weld metal and especially in the fusion zone, reducing the plastic properties of the welded joints. Insignificant additions of sodium, which can enter the weld metal through fluxes, adversely affect the properties of compounds made of alloys of the Al-Mg system.

The properties of welded joints also depend on the processes occurring in the heat-affected zones. When welding pure aluminum and alloys that are not hardened by heat treatment, grain growth and some softening caused by the removal of cold hardening are observed in the heat-affected zone. Grain growth and softening of cold-worked metal during welding varies depending on the welding method, modes and degree of previous cold-working of the alloy. The weldability of Al-Mg alloys is complicated by their increased sensitivity to heat and their tendency to form porosity and swelling in areas of the base metal immediately adjacent to the weld. The ability of these alloys to form porosity in heat-affected zones is associated with the presence of molecular hydrogen in the ingots. After processing such ingots (pressing or rolling), discontinuities form in the metal in the form of channels or collectors in which hydrogen is under high pressure. To check the quality of the metal intended for welding, it is recommended to conduct a special test.

When welding alloys that are hardened by heat treatment, changes occur in the areas near the weld that worsen the properties of the metal being welded. Measuring hardness and studying the structure of the metal in the thermally affected zone of alloys of this group makes it possible to detect areas of metal in it with varying degrees of decomposition of the solid solution and coagulation of the hardener. However, the most dangerous change that sharply worsens the properties of the metal and promotes the formation of cracks is the melting of grain boundaries. The appearance of liquid layers between grains reduces the mechanical properties of the metal in a heated state and contributes to the formation of crystallization cracks.

Regardless of the welding method and the initial state of the metal, a zone of melting of grain boundaries is observed in the immediate vicinity of the weld. The width of this zone varies depending on the welding method and modes. The widest zone appears in gas welding and the narrower zone in welding methods with severe thermal effects. The distribution of the eutectic in this zone varies depending on the initial state of the alloy. In welded joints obtained by welding a hardened alloy, the eutectic is located in the form of a continuous layer around the grains, while in joints made of annealed metal, discontinuities appear in the occurrence of the eutectic. Subsequent heat treatment fails to restore the properties of the metal in the area adjacent to the seam, which leads to a large change in the strength of the joints and makes these joints unreliable in operation.

Alloys D20, VAD1, M40 and others have better weldability. Self-hardening alloys of the ternary system A1—Mg—Zn are especially promising. When welding these alloys, it is possible to obtain joints with a strength of 80-90% of the strength of the base metal in a hardened and aged state. Aluminum and its alloys are characterized by high thermal and electrical conductivity, which necessitates the use of high currents and powerful machines for electric resistance welding, especially when spot welding these materials. To increase the efficiency of heating and melting, it is advisable to weld these metals at short current pulse durations or at high speeds during fusion welding.

Welded structures made of aluminum and its alloys are prone to warping, which is explained by the relatively high coefficient of thermal expansion. Reducing deformations in structures can be achieved through the use of technological measures (selection of an appropriate welding method, selection of optimal modes, heating, etc.).

Welding technology

Preparation for welding

When preparing parts made of aluminum alloys for welding, the welded edges are profiled and surface contaminants and oxides are removed. Degreasing and removal of surface contaminants is carried out using organic solvents or by treatment in special alkaline baths.

White spirit, technical acetone, and RS-1 and RS-2 solvents are used as solvents for degreasing parts made of aluminum alloys. Degreasing of aluminum alloys can be carried out in an aqueous solution of the following composition: 40-50 g/l technical trisodium phosphate (Na3PO4 * 12H2O), 40-50 g/l soda ash (Na2CO3), 25-30 g/l liquid glass (Na2SiO3). Bath temperature 60-70 0C, treatment time 4-5 minutes. Removing the surface oxide film is the most critical operation in the preparation of parts. In this case, the old oxide film obtained as a result of long-term storage and containing a significant amount of adsorbed moisture is mainly removed.

The oxide film can be removed using metal wire brushes with a diameter of 0.1-0.2 mm with a pile length of at least 30 mm or by scraping. After cleaning, the edges are again degreased with a solvent. The duration of storage of parts before welding after cleaning is 2-3 hours. On a larger scale of production, the surfaces of parts are etched. Etching in alkaline baths using the following technology is widely used:

1) degreasing in a solvent;

2) etching in a bath of an aqueous solution of 45-50 g/l NaOH; bath temperature 60-70 0C; etching time 1-2 minutes for unclad materials; if it is necessary to remove technological cladding (for example, on AMg6 alloy), the etching time is selected at the rate of 0.01 mm per 2.5-3 minutes;

3) rinsing in running hot water (60-80 0C), then in cold water;

4) clarification in a 30% aqueous solution of HNO3 at 20 0C for 1-2 minutes or in a 15% aqueous solution of HNO3 at 60 0C for 2 minutes;

5) rinsing in cold running water, then in hot water (60-70 0C);

6) drying with hot air (80-90 0C).

When welding parts made of aluminum alloys containing high concentrations of magnesium (for example, AMg6 alloy), the edges of the parts and especially their end surfaces must be cleaned with a scraper before welding. The same baths are used to process electrode wire made of aluminum alloys. In many cases, electrochemical polishing is recommended for processing filler wire after pickling, especially for alloys containing magnesium. A solution of the following composition is used as an electrolyte: 700 ml of orthophosphoric acid, 300 ml of sulfuric acid, chromium oxide. During the wire polishing process, the electrolyte temperature is maintained at 95-100 0C. When the electrolyte overheats above 100 0C, the surface is etched, and when the temperature drops below 90 0C, the polishing process stops. The quality of wire preparation is controlled by surfacing process beads with subsequent assessment of the porosity of the weld metal by weighing.

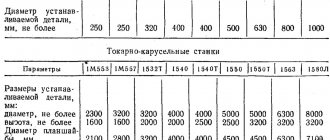

Before contact welding (spot and seam), in some cases the overlap surfaces are additionally cleaned with rotating metal brushes. When joining sheets with a thickness of more than 2.5-3 mm, the clad layer is removed by deep etching to prevent the formation of lack of penetration. Before butt contact welding, the ends of the parts are subjected to mechanical processing by cutting, for example, on metal-cutting machines.

The surfaces of parts welded by resistance spot or seam welding are controlled by external inspection or by measuring at 20 0C the electrical resistance of witness samples or the parts themselves. If the surfaces are in satisfactory condition, the electrical resistance should not exceed 120 μOhm. A more objective idea of the properties of surfaces is given by the resistance of parts during the welding process, which can be assessed by the rate of increase in voltage removed from the electrodes at the initial stage of the welding process, for example, 0.01-0.02 s after turning on the current.

Connection types

The main types of joints used in welding parts made of aluminum alloys are regulated by GOST 14806-69. When fusion welding aluminum alloys, the most rational type of joints are butt joints, which can be made using any welding method. To eliminate oxide inclusions in the weld metal, linings with rationally shaped grooves or cutting edges on the back side of the seam are used, which in some cases ensures removal of oxide inclusions from the joint into the forming groove or groove.

The use of fluxes in argon-arc welding, applied to the end surfaces before welding in the form of a dispersed suspension of fluorides in alcohol, also helps to reduce the number of oxide inclusions in the weld metal. When cutting edges, their opening angle must be limited in order to reduce the volume of deposited metal in the joint, and, consequently, the likelihood of defect formation. The specific selection of structural elements of the prepared edges of the parts being welded, their sizes and the sizes of the seams made for the main types of joints must be made in accordance with GOST 14806-69.

Spot and seam resistance welding is characterized by lap joints, the dimensions of which are established by GSST 15878-70. In this case, the ratio of the thicknesses of the welded parts, as a rule, does not exceed 1: 2. For flash butt welding, butt joints are used. The shape of the parts must ensure their reliable fastening in the clamps of the machine and the current supply near the joint. The cross-sectional areas of the parts in the connection area should be approximately the same. When welding aluminum and its alloys, several welding methods are used.

Gas welding

When welding aluminum alloys, it is recommended to use a flame of a gas mixture O2: C22

| Metal thickness, mm | 0,5-0,8 | 1,0 | 1,2 | 1,5…2,0 | 3,0…4,0 |

| Acetylene flame power, l/h | 50 | 75 | 75…100 | 150…300 | 300…500 |

To protect the metal from oxidation and remove oxides from the edges of the parts being welded, special fluxes are used. The most common flux is AF-4A with the following composition: 28% NaС1, 50% KS1, 14% ZiСl, 8% NaF. When welding, flux is introduced either with a filler rod, or is pre-applied to the edges in the form of a paste diluted in water. It is impossible to store flux for a long time (more than 8-10 hours) in a diluted state. Welding wire made of aluminum or its alloys is used as a filler metal. The diameter of the filler wire depends on the thickness of the metal being welded.

Manual electric arc welding of aluminum and its alloys can be carried out with a carbon or coated metal electrode. Carbon electrode welding is used for welding defective castings, welding aluminum tires, and sometimes for welding thin material along flanges. In this case, filler material is used in the form of rods coated with flux. Carbon arc welding is carried out using direct current of direct polarity. Carbon or graphite rods of different diameters can be used as electrodes. Welding modes for butt joints made of aluminum are given in Table 1.

Table 1. Modes for welding butt joints made of aluminum with carbon and graphite electrodes

| Metal thickness, mm | Current, A | Diameter, mm | ||

| filler rod | carbon electrode | graphite electrode | ||

| 2-5 | 120-250 | 4-6 | 12,5 | 10,0 |

| 5-10 | 250-400 | 5-6 | 15 | 12,5 |

| 10-15 | 400-500 | 6-8 | 18 | 15 |

More often, arc welding is used with coated metal electrodes, the rods of which are made from welding wire (GOST 7871-75) coated with a mixture of chloride and fluoride salts. A solution of sodium chloride in water or a solution of dextrin is used as a binder, and an aqueous solution of carboxylmethylcellulose (CMC) is also proposed. The thickness of the coating layer depending on the diameter of the electrode rod is given in Table 2.

Table 2. Coating thickness depending on the diameter of the electrode rod, mm

| Electrode rod diameter | Coating thickness per side | Electrode rod diameter | Coating thickness per side |

| 3,0 | 0,25-0,3 | 5,0 | 0,5-0,75 |

| 4,0 | 0,3-0,5 | 6 or more | 0,75-1,6 |

OZA-1 electrodes with a rod made of SvA1 wire are used for welding aluminum, and OZA-2 electrodes with a rod made of SvAK5 wire are used for welding defective castings

Welding is carried out using direct current of reverse polarity.

Automatic arc welding using a flux layer

This type of welding is performed with a consumable electrode and is used for butt joints of metal with a thickness of 4 mm and above. The arc is powered by direct current of reverse polarity.

To join aluminum, an automatic arc welding process using a consumable electrode under a layer of flux is used. For this purpose, fluxes with reduced electrical conductivity are used. For example, the composition of ceramic flux DA-64 is as follows: 30-44% cryolite, 48-38% potassium chloride, 19-15% sodium chloride, 3-3.5% quartz sand. The flux is mixed with an aqueous solution of carboxylmethylcellulose (14-10% of the charge weight), rubbed through a sieve and calcined at 280-320 0C for 6 hours. Welding is often carried out with a split electrode. In structures operating in corrosive environments, flux residues must be carefully removed after welding.

Gas shielded arc welding is widely used for welding aluminum and its alloys. Argon with a purity of at least 99.9% (according to GOST 10157-73, grades: highest, first and second) or a mixture of argon and helium is used as a shielding gas. When welding with a consumable electrode, argon with the addition of up to 5% O2 is sometimes used.

The main advantage of the gas tungsten arc welding process is the high stability of the arc. Thanks to this, the process is used when welding thin sheets. The arc is powered by alternating current from sources with falling external characteristics. Welding is carried out manually or automatically. For manual welding, tungsten electrodes and filler wire are used, depending on the thickness of the metal being welded:

| Thickness of welded metal, mm | Up to 2 | St.2 to 5 | St.5 |

| Filler wire diameter, mm | 1,0-1,5 | 1,5-3,0 | 3,0-4,0 |

Automatic welding is carried out without feeding or with feeding filler wire. When manually welding thin sheets with a non-consumable electrode without an additive (along the flange) or with an additive in one pass, the torch is moved with a forward angle. The angle of inclination of the torch to the flat surface of the part is about 600. The filler wire is fed at the smallest possible angle to the flat surface of the part.

In mechanized or automatic welding with a non-consumable electrode, the torch is positioned at right angles to the surface of the part, and the filler wire is fed so that the end of the wire rests on the edge of the weld pool; the feed speed varies from 4-6 to 30-40 m/h depending on the thickness of the material.

Pulsed arc tungsten electrode welding is also used for welding aluminum alloys. In this case, it is possible to weld aluminum alloys with a thickness of 0.2 mm or more. There are specialized power sources for pulsed arc welding of aluminum alloys using alternating current. Expansion of technological capabilities when welding metal of large thicknesses is achieved through the use of the method of submerged arc welding with a tungsten electrode. The method allows you to weld material up to 20 mm thick in one pass. In this case, special tungsten electrodes with yttrium and tantalum additives and welding torches with improved protection of the welding zone are used.

Aluminum alloys are subjected to three-phase arc welding with tungsten electrodes. The ability to regulate heat input during three-phase arc welding allows it to be used for metal of different thicknesses. With three-phase welding, metal with a thickness of over 30 mm is successfully welded in one pass.

Consumable electrode welding in shielding gas is used for material with a thickness of more than 3 mm. To power the arc when welding with a consumable electrode, direct current sources with a rigid external current-voltage characteristic are used. Welding is carried out using a current of reverse polarity, which ensures reliable destruction of the oxide film due to cathode sputtering and normal formation of seams. Welding can be performed semi-automatically or automatically on backing plates with a forming groove. The advantage of the consumable electrode welding process is high productivity, which increases with increasing metal thickness.

Semi-automatic consumable electrode welding is possible in various spatial positions and allows you to replace the less advanced process of welding aluminum alloys with coated electrodes; In this case, semi-automatic machines with a pull-type feed mechanism are recommended. Pulse-arc welding with a consumable electrode expands the possibility of welding aluminum alloys in various spatial positions. At the same time, the formation of seams is improved, the residence time of the metal of the weld pool in the molten state is regulated, and hence the occurrence of metallurgical reactions.

In plasma welding (compressed arc), the energy concentration in the heating spot is high, which makes this type of welding promising for joining aluminum alloys. The advantage of plasma welding is high speed, a significant reduction in the heat-affected zone, process stability, due to which there is no need to control and maintain a constant arc length, which makes manual welding easier. During plasma welding, due to deep penetration, the share of the base metal in the formation of the seam sharply increases. However, it is necessary to ensure the accuracy of assembling parts for welding and guiding the torch along the joint. For aluminum alloys, it is necessary to use plasma welding with an alternating current arc supply.

Using a low-current compressed arc (microplasma), it is possible to weld aluminum alloys with a thickness of 0.2-1.5 mm at a current of 10-100 A. When microplasma welding, argon with a purity of at least 99.98% is used; Helium with a purity of 99.95% is used as a shielding gas. Helium, protecting the weld pool from the atmosphere, impedes the development of the ionization front in the radial direction, and additionally compresses the arc, making it spatially stable. Welding torches are designed for the use of lanthanum tungsten electrodes with a diameter of 0.8-1.5 mm.

Basic recommendations for MIG welding of aluminum

Before starting to work with aluminum for the first time, the welder must become familiar with the characteristics of the material and its welding technology. Pure aluminum conducts electricity four times better than steel, so the process of welding it has its own technological features. Aluminum's ability to conduct heat (about 2.2 W/cm K) is also significantly higher than that of steel (about 0.6 W/cm K). For example, commonly used aluminum alloys such as AlMg4.5Mn or AlMg5 have a thermal conductivity of 1.2 to 1.3 W/cm K, which is also higher than the thermal conductivity of steel. Due to the high thermal conductivity, it is very difficult to perform high-performance welding due to insufficient penetration depth. Crystallization of the weld pool occurs very quickly and, therefore, incomplete release of gases is possible, leading to the formation of pores in the weld. To avoid this, it is necessary to increase the welding current, preheat the part, and use helium or its mixture with argon as a shielding gas. At the initial section of the welded joint, some fragility of the seam is also possible due to insufficient penetration due to “not heating” the part. Technically, this problem is solved by using a functional 4-stroke mode implemented in welding machines. In the first welding stroke, you can set a welding current pulse of greater strength than the main welding current, which will speed up the heating of the parts being welded.

Materials and welding wire

The range of aluminum alloys today is very wide. Regarding aluminum welding wire, the general requirement is to use it in a timely manner. Storage time when the package is opened should be kept to a minimum, since rapid oxidation of the surface leads to deterioration in the quality of the wire. The influence of high air humidity is especially harmful. The edges and area near the weld seam of the parts being welded must be thoroughly cleaned of contamination. This should be done immediately before welding. In a very short time, the aluminum is coated with a layer of aluminum oxide (Al2O3).

Shielding gases for welding

Aluminum and aluminum alloys must be welded under protective inert gases. Argon is mainly used for this. But it is preferable to use a gas mixture of argon and helium. The higher thermal conductivity of helium determines a correspondingly higher temperature of the weld pool, which turns out to be an advantage when welding metal sheets of large thickness. The use of a mixture of protective gases promotes more complete gas release and a reduction in the number of pores.

Special recommendations for MIG welding

Welders

Standard MIG/MAG machines are very suitable for welding aluminum

Cleaning aluminum cookware

The main disadvantage of aluminum is its softness. It is very easy to damage and also leave scratches on it. Even with frequent washing with a melamine sponge, the surface will soon begin to become matte, as a large number of micro-scratches will remain on it.

- To restore shine, you need to use borax, ammonia and GOI paste. The latter needs to thoroughly rub the aluminum, and then, using a rag soaked in solvent, thoroughly rub the cutlery.

- Aluminum cookware can be cleaned with such products as soap, ammonia, table vinegar and table salt.

- Soot, oxide and other contaminants that accumulate on aluminum cookware can be easily removed using soft foam sponges or polymer bristles, microfiber or cotton cloths, and rags. It is necessary to ensure that they do not contain rougher and harder materials that can leave scratches.

- A good aluminum cleaner is a special product designed for cleaning glass or porcelain. They do an excellent job, gently removing dirt and adding shine to the dishes.

Choice of product

The disadvantages of aluminum include the softness of the metal and its instability to abrasive influences. If you plan to keep your pans shiny for longer, avoid using wire wool, brushes, abrasive sponges, or sandpaper.

Even the use of a melamine sponge, which can rid the metal of the oxidation film, will affect the appearance of the utensils - the shiny surface will become dull due to numerous micro-scratches.

Polishing with GOI paste will help return it to ideal condition - rub a rag soaked in a solvent with a piece of hard paste, and then polish the metal surface to a mirror shine.

When choosing how to clean aluminum, you should pay attention to substances that are almost always at hand for any housewife. These include:

- laundry soap;

- baking soda;

- salt;

- table vinegar;

- lemon juice or citric acid;

- dairy products;

- cream of tartar;

- office glue;

- oxalic acid, etc.

When cleaning aluminum utensils from blackness, stains and carbon film, use brushes with semi-rigid polymer bristles, foam sponges, cotton or microfiber napkins, and rags.

If advice on how to clean a burnt pot or frying pan at home does not help you cope with the task, you can try using special products for cleaning porcelain and glass. Or resort to such means as “Chister”, “Bagi Shumanit”, “Oven Cleaner”, etc. Use special equipment according to the manufacturer's instructions.

New aluminum utensils shine attractively, but after some time of regular use they become dull and become covered with unsightly stains. Usually, housewives use the same usual composition for washing aluminum dishes as for pots and pans made of other materials, primarily stainless steel.

But this is the wrong approach. Conventional dishwashing detergents can clean the aluminum surface of ordinary contaminants, but they will not save you from oxidation and will not be able to completely protect you from the gradual formation of plaque, which, under regular exposure to high temperatures, turns into carbon deposits over time.

Remove carbon deposits

Cleaning oxides and carbon deposits is also quite simple. This will require funds and products that many people have in their homes. Moreover, such cleaning does not take much time and does not require serious effort.

- Aluminum is clarified using brine from cucumbers, fermented milk products such as milk and kefir. It is necessary to pour the available product into the dishes that need to be cleaned for half a day. Most often they leave it overnight so that you can simply wash the dishes in the morning. If you need to clean some objects from carbon deposits, they can be placed at the bottom of the container that was filled. Cleansing occurs thanks to the acids found in these products.

- A sour apple will help clear carbon deposits and remove oxidation. The fruit needs to be cut in half and rubbed onto the desired surface until shiny. The acid will corrode all dirt, and therefore, after rinsing with water, the item will shine.

- Contaminants can be removed using a saline solution. You need to take salt and water in equal proportions, and the first ingredient should be completely dissolved. Using a sponge, you need to apply the solution to the item that requires cleaning, leave it in this state for a while, and then rinse thoroughly with water.

Aluminum resistance welding

The next way to get a high-quality seam when working with aluminum is aluminum spot welding. It runs at a high current density of 15 thousand Amperes per square centimeter. Under such conditions, the metal melts in thousandths of a second and freezes almost instantly. This allows you to avoid internal defects and preserve the basic properties of the repaired product.

Aluminum spot welding

Resistance welding allows you to work with products up to 7 mm thick. Among the disadvantages, it is worth noting the possibility of welding a part and an electrode. To avoid this, special gaskets are used that remove heat from the electrode. Their thickness can vary between 0.2 – 0.5 mm. In modern welding machines for welding aluminum, technologies for accelerating the pulsed action of current are used to improve the quality of work. The welding time is reduced, while the welding currents increase.

We recommend! Direct and indirect plasma welding

Remove corrosion and oxide

Cleaning aluminum objects - a flask, dishes, coins - is quite simple if you know the easiest methods to do it. It is recommended to use traditional methods rather than standard dishwashing detergents, which will not cope with heavy stains.

Cream of tartar

You can remove blackness from aluminum using cream of tartar. Cleaning aluminum from oxide and corrosion with this product is quite simple: you just need to pour hot water into a bowl, dissolve the stone in it and add a small amount of citric acid. You need to bring the resulting solution to a boil, let it cool and wipe all the walls with a soft cloth.

Cream of tartar can be diluted with water to form a paste that can be rubbed onto dishes like a cleaning powder. This will help restore the shine to the material.

Table vinegar

Using 9% table vinegar, aluminum can be easily cleaned. This method is usually used for coins, but will actually clean more than just coins. If we are talking about dishes, then you just need to pour the solution into it and bring to a boil. Then let it cool and wash the item. If you need to clean other things, they should be boiled in this solution and then washed.

Soap solution

A soap solution helps get rid of light stains, but will not help restore the original appearance. You need to dissolve a small amount of soap shavings in water, and then thoroughly wash the aluminum object with the solution. To add shine, mix ammonia and borax in a ratio of 1:3 and rub the surface, and then rinse thoroughly with water.

Baking soda

Baking soda can easily remove stains of any complexity. To do this, you need to make a paste out of it by adding a small amount of water, and then just gently rub it for a couple of minutes, depending on the complexity of the contamination. After this, the remaining natural powder is easily washed off with clean water.

Glue and soda

You can clean aluminum from oxidation using a homemade product. You will need to take 100 grams of baking soda and office glue for 10 liters of hot water. All this must be mixed and the required items immersed in this solution. You need to keep the item in such a product for at least three hours, and then clean it well with a sponge.

Cleaning aluminum from oxides: 20 best folk and chemical remedies

In every home you can find products that are made of durable aluminum. Most often, frying pans, saucepans, fittings, sinks and window frames are made from this metal. Over time, the aluminum surface oxidizes, and therefore every person should know all the features of cleaning aluminum from oxides.

Features of the material

Aluminum is a metal whose surface is painted silver with a slight white tint. This material has certain features that you should familiarize yourself with in advance. These include the following:

- High level of density. Products made from this metal are very durable and are not subject to mechanical damage.

- Good thermal conductivity. This figure is almost the same as that of silver, gold or copper.

- Protection from corrosive plaque. Aluminum structures never rust, but instead of rust, oxide may appear on their surface.

How to clean at home

There are several effective means that will help you clean the aluminum surface from the formed oxide at home.

Soda

To eliminate oxidation that has appeared on the aluminum surface, you can use baking soda. The main advantage of this product is its accessibility, since soda powder is available in almost every home.

Before you begin removing oxides, you need to prepare a solution. To do this, add 150 grams of soda to 300-400 milliliters of water. The mixture is stirred until a thick paste forms. Treat the damaged surface with the prepared mixture and wash it off with water.

Coca Cola

Many people believe that carbonated drinks can only be used as a drink, but this is not true. Housewives use them to remove rust and oxidation from metal surfaces.

Among the most effective drinks is Coca-Cola, which will help restore an aluminum product. To remove oxides, the damaged coating is placed in a container with effervescent liquid and left for 40-60 minutes.

If there is a lot of oxidation, the procedure is extended to 2-3 hours.

Sorrel

Some people use only oxalic acid, but even fresh sorrel leaves will help remove oxides. First, you need to place a bunch of sorrel leaves in a small saucepan and fill them with cold water. Then the container is placed on a gas stove and boiled for half an hour. When the liquid boils, the aluminum product is soaked in it.

The procedure lasts an hour and a half, after which the soaked surface is rinsed and wiped dry.

Apple

Fresh apples contain trace elements that help remove oxidized stains from any metal surface. Using this method is very simple. It is enough to cut one apple into two equal parts, and then rub it on the oxidized mark. After 40-50 minutes, the treated coating is washed with soapy water and dried. If the stains remain, the procedure is carried out again.

Sour milk, kefir, brine

These products contain natural acids that effectively fight oxidation. Brine, sour milk and kefir do not have to be mixed, and therefore these products can be used separately. They are poured into a small pan, after which an aluminum part is placed in it. It soaks for about three hours. This is enough to eliminate even old oxides.

Soda and glue

Sometimes serious oxidation appears on the metal, which is difficult to eliminate. In this case, it is better to use a product made from glue and soda. To create it, pour four liters of water into a pan, after which 80 grams of soda and 2-3 tablespoons of adhesive liquid are added to it. The prepared solution is boiled for forty minutes, and then the aluminum part is wiped with the created liquid.

Ketchup

Regular ketchup made from tomatoes will help remove minor oxidized traces. This is an unusual method that housewives do not use very often. The main advantage of this method is that after its use the aluminum surface will begin to shine.

To remove dirt, apply a thin layer of ketchup to the surface and leave it there for 10-15 minutes. After this, it is washed off with running water, and the part is wiped with a dry towel.

Onion

Oxidation that appears on a metal surface can be eliminated using an ordinary onion. To do this, pour water into a saucepan and add a few onion heads. Then the mixture is boiled for 40-50 minutes, after which the part is soaked in the boiled onion liquid. You can also not boil the onions, but simply cut them and wipe the contaminated surface with them.

Garage Recipes

There are several garage recipes that will help you make anti-oxidation products.

Boiling soda

Ordinary boiled water will help remove new traces of oxide. The liquid must be boiled in a small saucepan in advance.

Then the boiling water is poured into a basin in which all parts that need cleaning will be soaked. The soaking time lasts about 3-4 hours. Then all products are washed and wiped from any remaining water.

If the oxides have not disappeared, you will have to use other, more effective means.

Borax

A dense oxidized film can be removed using a special pharmaceutical borax. To restore an aluminum product, perform the following steps:

- add 10-15 grams of borax to a glass of water;

- stir 3-4 drops of ammonia into the mixture;

- treat the metal coating with the prepared liquid;

- after forty minutes, the remaining composition is washed off from the surface.

Sodium hydroxide

You can remove a layer of stubborn dirt with caustic soda. The advantages of this procedure include the fact that it is easy to carry out at home. The product in an amount of 150-200 grams is added to 7-8 liters of water and mixed thoroughly. It is necessary to use heated water, the temperature of which is 60-80 degrees. The part should be washed with the prepared sodium solution.

Household chemicals

The most effective way to clean aluminum cookware is to use household chemicals. The most commonly used drug is “Mole,” which is used to combat blockages in drain pipes. A few spoons of powder are added to half a liter of water. Oxidized parts are placed in the created solution for two minutes, and then cleaned with a brush and soapy water.

Anodizing as a method of protection

When using this technique, you will have to add purified water mixed with sulfuric acid to a plastic container. A special power source is then connected to the electrolyte bath and to the workpiece. Electricity will be passed through the electrolytic solution. The procedure lasts 35-45 minutes, after which the product is washed to remove loose dirt.

Rules for caring for aluminum cookware

There are several recommendations that will help you properly care for aluminum cookware:

- Products must be washed after each use;

- The dishes should be stored in rooms with an average level of air humidity;

- When washing, do not use abrasive products.

Conclusion

Over time, products made from aluminum begin to oxidize and become covered with dark spots. To get rid of them, you will have to familiarize yourself with common effective methods for cleaning aluminum coatings.

Recommendations and care tips

Before using aluminum cookware for the first time, it is recommended to calcine it thoroughly. To do this, it is recommended to pour a small amount of sunflower oil and a tablespoon of salt into the bottom of the pan, and then keep it on the fire for a while, stirring the salt. After completing the procedure, it is recommended to wait for the dishes to cool, after which they should be washed thoroughly.

It is not recommended to use abrasive products when washing, as they can remove the protective layer, which will subsequently cause the dishes to darken. If the dishes previously contained dairy products, eggs or dough, then you must first wash the dishes with cold water, and only then use hot water.

If you boil clean water or potato broth in an aluminum container, it may darken. In order for the dishes to acquire shine, you need to add a small amount of ammonia to it each time you rinse. It is also not recommended to store such types of products as pickles and mushrooms in dishes made of this material. And you can’t ferment cabbage in it either.

It is necessary to protect dishes made from this material from mechanical damage, since aluminum bends and breaks easily. This point especially applies to lids. If you follow these few care rules, products made from this material will delight you with cleanliness and shine for a long time.

Problems of using arc technologies

They are associated with some restrictions on the use of an electric arc and the characteristics of aluminum. Among them are:

- low productivity when welding thick metal;

- high requirements for the preparation of base and filler materials

- increased defectiveness of welds. Formation of hot cracks and oxide film inclusions.

- the characteristics of the weld are inferior in strength to the base metal.

- the complexity of manufacturing volumetric structures, where welding is expected in various spatial positions

We recommend! Direct and reverse polarity when welding with an inverter machine

If any of these points cause certain inconvenience or insufficient quality of the weld, it is possible to use other technologies, which we will discuss below.

Further processes occurring during etching with alkali

During this process, the amount of caustic soda gradually becomes less. And thus the speed of the process itself decreases, but the viscosity increases.

Provided that no sodium hydroxide was added to the container at all, the reaction can slow down very much. But eventually the brownish or clear aluminum etching solution turns white.

And from this moment on, the speed of the process increases.

As a result of the reaction, aluminum oxide hydrate precipitates, which looks like a suspension. Caustic soda is also released, which is also necessary for the etching process to continue.

Results with the method under consideration

It has been experimentally established that a solution of caustic soda, when used intensively during the etching process, begins to “absorb” aluminum. And this happens until the amount of caustic soda decreases to one-fourth of the original volume. And after this, the process will continue with free caustic soda, fluctuating in its quantity. And this, in turn, depends on temperature, frequency of use and intensity of stops (pauses).

In this case, the hydrate will slowly settle into sediment or form crystals at the bottom and/or sides of the container. The resulting hydrate will be quite dense and will not be easy to remove. Sometimes it tries to settle right on the surface of the heating coils.