Recently, more and more facing materials are used for decorative and everyday purposes. For example, this category includes corrugated steel sheet (the internal base consists of the use of various types of metal in it).

Over the past decade, steel sheets with a metal surface have become quite common in our daily lives. Using their unique characteristics, for example, an anti-slip element, corrugated sheets can be found in vehicles, on escalators, in the manufacture of technical mechanisms for food products, in the construction industry, in the furniture industry (as decorative elements), etc.

Manufacturing of metal sheet

If a person is interested in purchasing products of this type, then on the global web he can find a large number of photos of corrugated sheets. In addition, the World Wide Web is ready to provide all the information that exists today. In particular, it is easy to find out that this metal product is a special type of sheet metal, the creation process of which is done in a unique way.

After the final production of the metal sheet, you can see that one side looks like an ordinary flat surface, and the other undergoes the art of applying corrugations - a special convexity that looks unusual and extremely attractive.

The production of corrugated sheets of this type occurs through the use of hot rolling, which assumes that a heated sheet of metal passes through special rolls of a rolling mill.

Through this unique process, the metal product, when subjected to such a powerful transformation in the molten state, turns into a material called corrugated sheet.

Different texture - different name

The functional surface of a metal sheet is characterized by the fact that each pattern made on the metal is made of a pair of elements connected to each other.

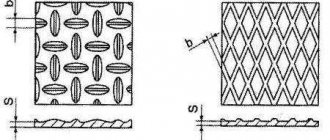

In general, the decorative patterns that form the basis of the second part of the sheet are a separate riffle. It is precisely because of the different textures that metal products are divided into the following names:

- lentils - one riffle;

- duet – two riffles;

- quintet – five riffles.

The patterns that are located on the surface of the corrugated sheet are placed at different angles in relation to each other. Thanks to this effect, the riffle can look like a diamond or an oval.

Bottom line

Having become thoroughly familiar with this building material, you can safely choose it as a variety of coatings, because it, combining a good price, long service life, strength and endurance, is one of the best materials that exist on this planet.

Corrugated sheet is rightfully considered the best of metal sheets, and therefore is widely used in various factories, military equipment, gardening and the most common architecture. Providing safety and long service life, it does not force its users to worry about durability and wear resistance. An ideal choice for construction.

Weight of metal sheet

Since metal (which can be of different types) is used to make such a material, the weight of the corrugated sheet can vary from ultra light to very heavy.

The weight of metal sheets of this direction is calculated as kilograms per square meter. For example, if you order a corrugated sheet with a thickness of 2.5 mm (with a diamond coating), then its weight will be 21 kg/m².

If a corrugated sheet with a thickness of 5 mm is required, then its weight will be 41.8 kg/m². When ordering a corrugated sheet with a thickness of 12 mm, its weight will be 99.3 kg/m².

TECHNICAL REQUIREMENTS

2.1. Sheets and rolls are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

Changed edition. Change No. 4 .

2.2. Sheets and rolls are made from carbon steel of ordinary quality, grades St0, St1, St2 and St3 (boiling, calm and semi-quiet) with a chemical composition in accordance with GOST 380.

By agreement between the manufacturer and the consumer, it is allowed to produce rolled sheets without rationing the content of chromium, nickel, and copper.

Changed edition. Change No. 4 .

2.3. At the request of the consumer, it is possible to produce sheets from steel of other grades.

Changed edition. Change No. 1, 3 .

2.4. Sheets rolled on sheet rolling mills are cut on four sides.

Changed edition. Change No. 1 .

2.5. Sheets and coils rolled on a continuous rolling mill may be supplied with rolled longitudinal edges.

The notches on the edges should not extend the sheet beyond the nominal dimensions in width.

Changed edition. Change No. 1 .

2.6. The surface of the sheets should be free of rolled and ingot films, indentations, scale shells, rolled bubbles, cracks and dirt. There should be no delamination on the edges of the sheets.

2.7. Ripples, scale, rust, prints, and individual films are allowed on the surface of the sheets, the depth of which does not exceed the maximum deviations in thickness.

Advantages of stainless steel corrugated sheet

Very often we come across corrugated sheets made of stainless steel. Such products can be found anywhere, as they have a number of advantages that distinguish them from ordinary metal sheets. This may include:

- immunity to persistent environmental influences;

- preservation of appearance and technical characteristics when using chemical elements;

- long service life;

- immunity to oxidative processes;

- good strength properties;

- good anti-corrosion properties.

Stainless steel corrugated sheets are often used in the preparation of special anti-slip coatings, which are often installed inside residential buildings.

Thanks to its patterned surface, this product is considered safe to use and a person can safely walk on it without fear for their health.

The metal product made of stainless steel lends itself very well to various types of processing, due to which it has excellent strength characteristics.

Application of corrugated sheet metal with lentil pattern

Metal corrugated lentil sheets are widely used in organizing internal space in factories and factories. It is laid as a floor covering both in workshop areas, and it is also used to make steps of staircases, flights, and transitions. The presence of a textured pattern increases the adhesion of the soles to the surface. This reduces the likelihood of slipping when moving. Increased occupational safety and health.

Often, a sheet with a corrugated (patterned) lentil can be found outside of production areas. It is laid as a flooring in front of the entrances:

- to public assignments;

- shopping and entertainment centers;

- in front of the entrances of residential buildings.

Another way to use this rolled metal is the construction of ramps. Increased traction between wheels and metal makes it easier for people with disabilities who use wheelchairs to climb and descend inclined surfaces.

Lentil corrugated steel sheet is an absolutely fire-resistant material. Therefore, this product is used not only as a floor covering. It is also used as wall material. Rolled metal is mounted on walls in rooms that are at risk of fire.

Interesting decor

Modern decorated sheets are very popular these days. They skillfully incorporate exquisite exterior finishes, high strength and good corrosion resistance. Decorated sheets are used during:

- creating unique solutions for the interior;

- finishing work to decorate the facade of premises, buildings or elevators;

- development of products containing an advertising component (this includes outdoor banners, supermarket windows, etc.).

In addition, corrugated decor is used to decorate various handicrafts (for example, these can be lighting devices, furniture products, household appliances, outdoor sculptures, etc.).

Due to their appearance, these corrugated sheets give structures an unusual look.

Where and how it is used

Corrugated sheets are used in almost all areas of construction, and not only. They are used to decorate floors, ceilings, roofs, stairs, interiors and trunks of cars, and the most daring architects even cover the outer walls of houses with them (not a bad look for a Hi-tech house).

In addition, corrugated sheets are often laid in front of supermarket doors and on steps, because it does not allow shoes to slip (due to the convexities), which ensures complete safety for people walking on it.

Often, for safety reasons, this material is also chosen for finishing premises in various industries, where it plays its main role very well.

Also, corrugated steel sheets are often used for the construction of various fences or doors. Believe me, it is much harder to break open a steel door than a wooden one, which is another advantage of this material.

This product is often used to create various bodies and vessels, which provides workers with all the convenience to complete their tasks.

Purchase

Each construction market sets its own prices. Therefore, the price of corrugated sheets is different everywhere. Before placing an order (especially a large one), you should carefully study the market in order to understand, based on in-depth analysis, where it is more profitable to buy the required product. Depending on the size and thickness of the product, one sheet can cost a person from 2,000 to 20,000 rubles.