Brass LO70-1 Brass LMtsA57-3-1 Brass LMtsAZhKS70-7-5-2-2-1 Brass LMtsZh57-1.5-0.75 Brass LMtsKA58-2-1-1 Brass LMtsKNS58-3-1.5-1 ,5-1 Brass LMtsKNSA58-3-1.5-1.5-1 Brass LMtsSKa58-2-2-1-1 Brass LMsh68-0.05 Brass LN65-5 Brass LNKMts49-10-0.3-0.2 Brass LNKoMts49-9-0.2-0.2 Brass LNMts60-9-5 Brass LO60-1 Brass LO62-1 Brass LKS65-1.5-3 Brass LO90-1 Brass LOK59-1-0.3 Brass LOMNA49-0 ,5-10-0.4-0.4 Brass LOMsh70-1-0.04 Brass LOMsh70-1-0.05 Brass LS58-2 Brass LS58-3 Brass LS59-1 Brass LS59-1V Brass LS59-2 Brass LS60 -1 Brass LS63-3 Brass LS64-2 Brass LS74-3 Brass LA85-0.5 Brass L59 Brass L60 Brass L63 Brass L66 Brass L68 Brass L70 Brass L72 Brass L75mk Brass L80 Brass L85 Brass L90 Brass L96 Brass LA77-2 La Tun LA77 -2u Brass LMts58-2 Brass LAZ60-1-1 (LAZH60-1-1L) Brass LAZHMtsS52-2-1-1.5-1 Brass LAMsh77-2-0.04 Brass LAMsh77-2-0.05 Brass LAN59- 3-2 Brass LANKMts 75-2-2.5-0.5-0.5 (alloy 156) Brass LAF94-0.5-0.15 Brass LZhMts59-1-1 Brass LZhS58-1-1 Brass LK62-0 .5 Brass LK75V Brass LKAN80-1-1.9-5.8 Brass LKANMTs75-2-2.5-0.5-0.5 Brass LKBO62-0.2-0.04-0.5

Description

Brass L96 is used : for the production of sheets, strips, pipes, wire; parts for various technical purposes by cold deformation, especially drawing; parts made by forging and embossing; round drawn thin-walled pipes; drawn capillary tubes used in apparatus and instrument making and refrigeration engineering; drawn rectangular pipes intended for the manufacture of waveguides; drawn flat-oval seamless tubes used in automotive and other industries; cold-deformed tubes intended for the manufacture of cellular radiators; wires for electrical parts; medals and badges.

Note

Plain (double) brass. L98 brass is not prone to corrosion cracking; suitable for enameling.

Material L96 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells L96 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, L96 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Standards

| Name | Code | Standards |

| Ribbons | B54 | GOST 15527-2004 |

| Non-ferrous metals, including rare ones, and their alloys | B51 | GOST 28873-90, OST 4.021.009-92 |

| Pipes made of non-ferrous metals and alloys | B64 | GOST 529-78, GOST 2624-77, GOST 2936-75, GOST 11383-75, GOST 20900-75, GOST 617-2006, OST 4G 0.021.400-80, OST 4.021.125-92, OST 4.021.130- 92, TU 48-0808-19-87, TU 48-21-37-79, TU 48-21-477-84, TU 48-21-611-78, TU 48-21-689-80 |

Marking of non-ferrous metals and alloys

- home

- >

- Library

- >

- Metal products: certification, marking, packaging

The market for metal products made from non-ferrous alloys is very wide and diverse, since non-ferrous metals include all metals and alloys, except iron and steels. Differences in the production technology of such alloys and requirements for properties, areas of application of alloys even of the same system can differ significantly, which leads to a variety of marking systems.

Below we discuss the principles of standardization and labeling of alloys based on two main non-ferrous metals - copper and aluminum.

Brass is an alloy based on copper and zinc. Brass products can be produced by casting or forming, and the method of production of the product is taken into account when labeling the appropriate alloy.

Brass is divided into:

- two-component brass (simple), consisting only of copper, zinc and a small amount of impurities,

- multicomponent brasses (special), in addition to copper and zinc, containing additional alloying elements.

Brass with a content of 5 to 20% zinc has a golden color and is called tombac (used in jewelry), with a content of 20–36% Zn is called yellow brass. In practice, brasses with a zinc concentration exceeding 45% are rarely used.

Usually, in brasses of simple composition, only the copper content in the alloy is indicated: L96 - brass containing 96% Cu and ~4% Zn (tompak); L63 – brass containing 63% Cu and 37% Zn.

The main alloying elements in multicomponent brasses are: aluminum (A), iron (I), manganese (Mz), arsenic (Msh), tin (O), lead (C), silicon (K), nickel (N), phosphorus ( F), zinc (C) (the symbols of the elements in the brand are indicated in brackets).

Deformable brasses are marked as follows: the letter “L” is placed first, then a series of letters indicating which alloying elements, except zinc, are included in this brass; Further, numbers are indicated through hyphens, the first of which characterizes the average copper content in percentage, and the subsequent ones - each of the alloying elements in the same sequence as in the letter part of the brand.

The order of letters and numbers is determined by the content of the corresponding element: the element that has the most number comes first, and then descending. The zinc content is determined by the difference from 100%.

For example: the brand LAZHMts66-6-3-2 stands for: deformable brass, which contains 66% Cu, 6% Al, 3% Fe and 2% Mn. It contains 100 zinc – (66+6+3+2)=23%. LS59 brass contains 59% Cu, 40% Zn, and about 1% Pb (the number “1” is often not indicated in the brand). LOMsh70-1-0.05 contains 70% Cu, 1% Sn, 0.05% As.

The standard for foundry brasses is GOST 17711–93 “Copper-zinc alloys (brass), foundry. Marks" uses a different marking procedure.

At the beginning of the marking the letters “LC” are placed, then the content of the main component (zinc) as a percentage, then the letters that show the alloying elements and their content as a percentage.

Then the above alloy LS59 according to GOST 17711–93 will be designated as LTs40S. The grade LAZhMts66-6-3-2 corresponds to LTs23A6ZhZMts2. At the end of the marking, the casting method may be indicated, for example “d” - injection molding, then the brand will be designated as LTs40Sd.

This marking system meets some foreign standards and is more convenient to use. It must be taken into account that manufacturing plants of brass and products made from them use markings of both wrought and cast brass in accordance with GOST 17711–93. The main grades of brass according to this standard are given in Appendix G.

Small-sized products made of brass (for example, cutlery, etc.) can be marked with abbreviated brand designations; examples of abbreviated designations are also given in Appendix G.

The term "bronze" includes a large group of copper-based alloys. Historically, the first bronzes were an alloy of copper and tin; bronzes based on such an alloy are called tin. Tin-free bronze, in addition to copper, can contain aluminum, silicon, beryllium, zinc and a number of other elements.

The marking and assortment of produced bronzes is determined by a number of standards: GOST 493–79 “Tin-free foundry bronzes. Brands", GOST 613–79 "Tin bronze foundry. Brands", GOST 5017–74 "Tin bronzes, processed by pressure. Brands", GOST 18175–78 "Tin-free bronze, pressure-processed. Stamps."

The marking system for cast and pressure-processed bronzes is somewhat different.

The marking of all bronzes begins with the letters “Br”, then the symbols of alloying elements and numbers showing their average contents are put down. For tin bronzes, the marking begins with the letters “BrO”. The copper content is defined as 100 – sum (content of alloying elements, %). The symbols for elements in bronze are the same as in brass (see above).

For wrought casting bronzes, numbers showing the average content of alloying elements are indicated with a hyphen at the end of the marking. For cast bronzes, the content of elements is indicated after the letter symbol of the element.

For example, BrOF6.5-0.4 is a deformable tin bronze containing 6.5% tin and 0.4% phosphorus. BrO4Ts4S17 – cast bronze containing 4% tin, 4% zinc, 17% lead.

BrAZH9-4 is a tin-free deformable bronze containing 9% aluminum and 4% iron. BrA10Zh3Mts2 – cast bronze containing 10% aluminum, 3% iron and 2% manganese.

Bronze products may be marked with abbreviated markings (see Appendix 3).

Aluminum

is the basis for the production of a number of industrial alloys and products made from them. Like copper, aluminum alloys can be divided into cast (products are produced by casting) and wrought (products are obtained by pressure processing).

The use of a large number of different aluminum-based alloys has led to a variety of marking systems.

Most grades of cast aluminum alloys are defined in the GOST 1583–93 standard “Cast aluminum alloys. Technical conditions".

The most common cast aluminum alloy is called silumin. These are alloys of the aluminum-silicon system with a small amount of other elements (manganese, zinc) and they are separated into a separate group as having the highest casting properties. Such alloys are marked with the letters “AL” from the words “aluminum casting” and a number indicating the serial number of the alloy from AL2 to AL12. The properties of the alloy depend on the composition and method of producing the casting; we can roughly assume that as the number increases, the complex of indicators of the alloy properties (strength and ductility) increases.

In general, aluminum-based casting alloys are marked with two letters. The second letter indicates the element from which the alloy is derived. For example, “AK” is the aluminum-silicon system, “AM” is aluminum-copper, “AMg” is aluminum-magnesium, etc. Then comes a number indicating the content of the element. If the alloy is alloyed, indicate the letter designations of the elements and their content.

For example, AK12M2 is an alloy of the aluminum-silicon system, with a silicon content of 12% (on average) and copper 2%. AMg4K is an aluminum-magnesium system containing 4% magnesium and 1% silicon.

At the end of the brand there may be a letter characterizing the characteristics of this alloy: “h” - pure; “pch” – increased purity; “och” – special purity; “l” – casting alloys; “s” – selective. The symbols for casting methods are the same as for brass (Appendix G).

If the cast aluminum alloy is thermally hardened, a heat treatment designation is placed at the end of the mark (GOST 1583-93):

- T1 – artificial aging without pre-hardening;

- T2 – annealing;

- T4 – hardening;

- T5 – hardening and short-term incomplete artificial aging;

- T6 – hardening and complete artificial aging;

- T7 – hardening and stabilizing tempering;

- T8 – hardening and tempering.

The symbol "T3" is used for other alloys.

To obtain deformable aluminum alloys, various alloying systems are used - Al–Mn (AMts alloys), Al–Mg (AMg alloys), duralumins, etc. In some cases, their marking system has developed spontaneously in the likeness of copper alloys, taking into account the peculiarities of production or area of application alloy Currently, various systems of symbols for aluminum wrought alloys are being replaced with a unified digital marking system. Alloy markings, incl. digital, defined in GOST 4784–74 “Aluminium and deformable aluminum alloys. Stamps."

The first digit indicates the alloy base, aluminum alloys are marked “1”, the second digit indicates the alloy system:

More common are the alloys of the Al–Mg system, which have a better set of physical and mechanical properties compared to alloys of the Al–Mn system. The alloys are not strengthened by heat treatment, and the marking consists of letters indicating the type of alloy and numbers indicating the percentage content of the main element - magnesium from AMg2 to AMg7 (GOST 4784–74). Digital marking of alloys AMts - 1400, AMg - 15XX, where XX are two digits that indicate the magnesium content in tenths of a percent (1520 - on average 2% Mg).

Duralumin is the most common deformable aluminum alloy, combining a high level of properties with low density (dur - “hard” in French).

Duralumin itself is designated as D1...D16, the set of property indicators increases with increasing alloy number. According to GOST 4784, all these alloys are marked from 1110 to 1160, for example, D1 - 1110, AK4 (forging) - 1140, etc. Taking into account the composition and production method, high-strength aluminum alloys are designated differently: B95 (high-strength) - 1950, AB (avial) - 1340, etc.

European standards EN 1982: 99 “Copper and copper alloys. Ingots and casting" casting copper bronzes are designated as ССХХХК. Here the symbols “SS” are “copper casting”, the symbols “ХХХ” are the alloy number. For example, the alloy according to the DIN standard CuSn3Zn8Pb5 (bronze BrO3Ts8S5, the composition is visible from the marking) according to EN is designated as CC490K, the less alloyed alloy CuSn12 (BrO12) is CC483K.

Wrought copper alloys according to EN are designated CWXXXA, CWXXXC (from copper wrought, wrought copper). XXX is the alloy number, which depends on the alloying. For example, pure copper grade M1 (GOST 495) corresponds to CW004A, Cu-Zn alloy (0.5%) CW119C.

In the USA, copper and copper-based alloys are defined by ASTM and UNS standards.

ASTM standards for all copper alloys begin with the letter “B.” The marking of the alloy itself begins with the letter “C” (copper) and is written as CХХХХХ, where ХХХХХ is a five-digit digital number. Alloys with a number less than 80000 are processed by pressure, more than 80000 are cast. The marking C1ХХХХ corresponds to copper of varying degrees of purity, the rest - to alloys. For example, grade C11000 ASTM B133 corresponds to grade M1.

Pressure-processed copper alloys in Japanese standards have the same markings, only four numbers. If the numbers in the markings of US and Japanese alloys coincide, then the alloys have a similar chemical composition.

For example, double brass according to ASTM B36, B111, etc. is designated as C2X000, where X increases with increasing zinc content - from 1 to 8. L70 brass corresponds to the C26000 grade. Tin brass is marked C4ХХХХ – LO90–1 corresponds to C41000.

Bronze S51100 corresponds in composition to bronze BrOF4–0.25. Casting brass LTs23A6Zh3Mts corresponds to S86200.

In the USA, cast aluminum alloys are defined by ASTM standards (ASTM B 85, B 26, B 108) and the Aluminum Association (AA). AA marking is the most common and is used as an international marking.

According to the standards of the Aluminum Association, cast aluminum alloys are grouped into series and have a three-digit designation depending on the alloying system - XXX.

The first number shows the alloying system:

The designation XXX.0 is used for all castings (i.e. cast alloys). For example, alloy 356.0 according to AA corresponds to alloy AK7 (AL9) according to GOST 1583 (aluminum-silicon 7% Si). According to ASTM B26 it is designated SG70A.

In Japan, cast aluminum alloys according to the JIS H5202 standard are designated as follows: AC NX (AC - cast aluminum, N - series number according to the alloying system, X - letters corresponding to a specific alloy alloying system).

Example. Alloy AC 4 D corresponds to AK5Mch according to GOST (aluminum - silicon 5% - copper 1%). In the USA this alloy is designated as 305.

In most foreign standards, wrought aluminum alloys have a digital marking system.

In the USA, according to ANSI H35.2, wrought aluminum alloys are designated by the letters “AAХХХХ”, where “AA” indicates that the alloy is a wrought aluminum alloy, “ХХХХ” is a four-digit digital marking.

According to the standards of the Aluminum Association, wrought alloys have a four-digit designation depending on the alloying system - XXXX.

The first number shows the alloying system:

The second digit shows the serial number of the alloy modification relative to the base alloy, in the base alloy the second digit is “0”, the last two digits are the alloy number and its purity.

For example, grade 2022 is a base aluminum-copper alloy (4.5% Cu), it approximately corresponds to alloy 1230 according to GOST (alloy 1230 additionally contains 0.05% Mg).

Japan uses the same designation system for wrought aluminum alloys as the United States.

According to EN, aluminum casting alloys are divided into series from 1ХХХ to 8ХХХ, where ХХХ is the serial number in the series, with an additional letter “A” or “B” at the end. Series 1ХХХ corresponds to unalloyed aluminum, for example 1080A, Al–Cu – 2XXX, Al–Mn – 3XXX, Al–Si – 4XXX, Al–Mg – 5XXX, Al–Mg–Si – 6XXX, Al–Zn – 7XXX, other systems 8ХХХ . Consequently, this system largely coincides with the Aluminum Association markings.

Wrought aluminum alloys according to EN 573 are designated as AW–AlXXX, where XXX is the type and content of alloying elements. For example, the AW–AlZn5.5MgCu alloy corresponds to Aluminum Association grade 7475.

Thus, converting an alloy from one marking to another is quite difficult, and if there is no appropriate documentation, it is not possible. Therefore, manufacturers of alloys and rolled products for foreign supplies must indicate by what standard the corresponding metal products are produced and rarely determine the corresponding analogue according to GOST. To correctly translate one alloy grade into another, it is necessary to use special reference publications - translators of alloy grades.

- ← Section 4.3

- Section 5 →

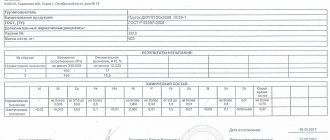

Chemical composition

| Standard | P | Fe | Cu | Zn | Sb | Pb | Bi |

| GOST 617-2006 | ≤0.01 | ≤0.1 | 95-97 | Remainder | ≤0.005 | ≤0.03 | ≤0.002 |

Cu is the base. According to GOST 15527-2004, GOST 617-2006, the sum of other elements must be ≤ 0.20%. In brass, a mass fraction of nickel of up to 0.30% is allowed due to the mass fraction of copper, which is not taken into account in the sum of other impurities. For antimagnetic brass, the mass fraction of iron should not exceed 0.030%.

Sale of rolled metal wholesale and retail

| Application: | deforms very well in a cold state, especially by drawing; not prone to corrosion cracking; suitable for forging, embossing, enameling |

Mechanical properties at T=20 °C of material L96

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| soft alloy | 220-260 | 45-55 | ||||||

| hard alloy | 420-480 | 1-3 |

| Material hardness L96, soft alloy | HB 10 -1 = 50 - 60 MPa |

| Material hardness L96, hard alloy | HB 10 -1 = 130 - 145 MPa |

Physical properties of material L96

| T | E 10- 5 | a 106 | l | r | C | R 109 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 1.14 | 17 | 245 | 8850 | 389 | 43 |

Foundry and technological properties of material L96

| Melting point, °C: | 1070 |

| Hot processing temperature, °C: | 700 — 850 |

| Annealing temperature, °C: | 450-600 |

Chemical composition in % of material L96

| Fe | P | Cu | Pb | Zn | Sb | Bi | Impurities |

| up to 0.1 | up to 0.1 | 95 — 97 | up to 0.03 | 2.8 — 5 | up to 0.005 | up to 0.002 | only 0.2 |

Note: Zn is the base; percentage of Zn is given approximately

Mechanical properties:

| sв | — Short-term strength limit, [MPa] |

| sT | — Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | — Elongation at break, [%] |

| y | — Relative narrowing, [%] |

| KCU | — Impact strength, [kJ/m2] |

| HB | — Brinell hardness, [MPa] |

Physical properties:

| T | — Temperature at which these properties were obtained, [Deg] |

| E | — Modulus of elasticity of the first kind, [MPa] |

| a | — Coefficient of thermal (linear) expansion (range 20° - T), [1/degree] |

| l | — Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | — Material density, [kg/m3] |

| C | — Specific heat capacity of the material (range 20° — T), [J/(kg deg)] |

| R | — Electrical resistivity, [Ohm m] |

Magnetic properties:

| Hc | — Coercive force (no more), [A/m] |

| Umax | — Magnetic permeability (no more), [MGn/m] |

| P1.0/50 | — Specific losses (no more) at magnetic induction 1.0 T and frequency 50 Hz, [W/kg] |

| B100 | — Magnetic induction Tl (not less) in magnetic fields at a magnetic field strength of 100, [A/m] |

Weldability:

| no limits | — welding is performed without heating and without subsequent heat treatment |

| limited weldability | — welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | — to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding |

Mechanical characteristics

| Section, mm | σB, MPa | d5, % | d10 | HV, MPa |

| Round radiator tubes in delivery condition according to GOST 529-78 (samples, diameter indicated in cross-section) | ||||

| 10 | 470.4-568.4 | — | — | — |

| 10 | 392-588 | — | — | — |

| Drawn seamless flat-oval tubes in delivery condition in accordance with GOST 2936-75 | ||||

| 340-590 | — | — | — | |

| Drawn capillary tubes as delivered according to GOST 2624-77 (samples) | ||||

| — | ≥200 | ≥40 | ≥35 | — |

| — | ≥250 | ≥5 | ≥4 | — |

| Cold-deformed and pressed pipes as delivered in accordance with GOST 617-2006 (the outer diameter is indicated in the cross-section, values for pipes of increased ductility and strength are given in brackets) | ||||

| ≤360 | ≥200 (210) | ≥38 | ≥35 (40) | ≤55 |

| ≤360 | ≥240 (270) | ≥10 | ≥8 (8) | — |

| ≤200 | ≥190 | ≥32 | ≥30 | ≤80 |

| 200 | ≥180 | ≥32 | ≥30 | — |

| ≤360 | ≥280 (310) | — | — | 90-135 |