Universal protractor

To accurately measure various angles, use a universal protractor , which consists of two rulers with disks hinged together. On one disk there are divisions in degrees. When measuring, the product is placed between the rulers so that their edges touch the planes of the product being measured. In this case, the angle is determined by the divisions on the disk.

Rice. Universal protractor

Calipers, calipers and bore gauges

Compasses are used mainly for marking. The legs of the compass must be the same length and thickness, properly sharpened and should not give any clearance when closed. When worn and dull, the legs of the compass are sharpened with a whetstone.

Rice. Measuring instruments: a - compass: b - caliper; c — bore gauge.

Calipers are used for external measurement of parts. The value measured with calipers is determined using a scale bar. Measurement accuracy - up to 0.5 mm. Calipers are hinged and spring.

The hinged caliper is simple in design and convenient to use, but over time, a hinge joint is developed in it, and free movement is obtained. To eliminate free play, the rivet of the hinge head is slightly crimped or riveted.

The ends of the legs lose their original shape as they are used, so they should be periodically filled with whetstone.

A bore gauge to determine the internal dimensions of parts. The values measured by the bore gauge are determined using a scale bar. Measurement accuracy up to 0.5 mm. Bore gauges are spring and hinged.

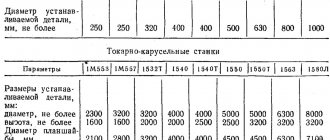

Available varieties

Until a certain point, several types of calipers were available for free sale. Today they can be purchased in three types. Each of them has its own characteristics and methods of implementation. Depending on size, there are eight main groups. It is better to purchase a caliper with a factory passport, which will indicate possible errors and calibration methods. According to the method of determining the size of the decimal part, calipers are divided into:

- with a vernier scale or ШЦ;

- with dial scale or ШЦК;

- with electronic digital scale Shchtsts.

The differences lie not only in the scale used, but also in the presence or absence of certain elements in the design, for example, those in which the main components are present are called universal. There are instruments that can only measure the outer diameter. Their jaws are carbide, so they do not wear out as quickly as regular ones. They are designated ShTC-1. There are also calipers available on the market with a lower error threshold and additional adjustment of the hundredths scale. It is designated ShTs-2.

Calipers

A caliper (Figure a) is a measuring tool that allows you to make three measurements: external, internal and depth with an accuracy of 0.1 mm. This instrument consists of a fixed jaw attached to a scale ruler on which a metric scale is marked, and a movable jaw that moves freely along the ruler. The movable jaw has a cutout with a vernier and a depth measuring rod. Both jaws have pointed ends at the top for internal measurements. There are ten divisions on the vernier at the bottom. The leftmost line is called zero. To determine the size with the caliper jaws apart, you need to count the whole number of millimeters that the leftmost line of the vernier has passed along the ruler (in Figure b this is 11 mm), and then find the vernier line that exactly coincides with any division of the ruler. In the case shown in Figure b, the second line of the vernier (not counting the zero line) coincides with the division on the ruler, therefore, this size will be equal to 11.2 mm.

Rice. Vernier calipers: a - measurement with a caliper; b—vernier reading; 1 - fixed sponge; 2 - pointed end of the sponge; 3 - screw for securing the movable jaw; 4 — scale bar; 5 — vernier; 6 - movable sponge.

Abstract on the topic: Vernier tools. General information

General information about

caliper tools

The most common tools for measuring linear quantities in metal processing include metal measuring rulers, caliper tools, and micrometric instruments.

Metal measuring rulers are used for rough measurements. They are manufactured with upper measurement limits up to 150; 300; 500; 1000 mm. The division value can be 0.5 or 1 mm. Measurement error 0.5 mm.

Vernier tools are used for more accurate measurements.

Vernier instruments are contact means for measuring linear dimensions, the main parts of which are a rod with a scale and a vernier - an auxiliary scale for clarifying the reading (a special device can be used instead of a vernier).

Vernier tools include:

— Calipers;

— Vernier depth gauges;

— Height gauges.

Calipers are used to measure the outer and inner diameters, lengths, thicknesses of parts, etc.

Figure 1 - Types of calipers

Calipers, depending on the method of taking readings, are:

- vernier - equipped with a conventional vernier.

- dial - which, instead of a vernier, are equipped with a clock-type dial for the convenience and speed of taking readings,

- digital - have a digital liquid crystal display for the highest measurement accuracy and ease of reading results

Vernier depth gauges,

application and design

Vernier depth gauges are used to measure the depth of holes, grooves, and ledges. Structurally, the depth gauge is a frame made of hardened steel, which has a measuring surface, inside which a rod with a hard alloy scale moves (Figure 1). There is also a vernier on the frame, which allows you to measure hundredths of a millimeter. The rod has a recessed scale to prevent wear and tear while moving in the frame.

Figure 1 —

Vernier depth gauges

The measuring surfaces are the ends of the rod and the base. To measure, the rod is lowered all the way into the groove, after which data can be taken from the scale. A variety are tools equipped with microfeeds (see Figure 2).

1 – rod; 2 – microfeed; 3 – clamp; 4 – frame; 5 – vernier; 6 – support

Figure 2 - Vernier depth gauge,

equipped with microfeed

Caliper ,

application and design

Caliper gauges are used for spatial marking and direct measurements of distances from the base surfaces of parts to recesses, protrusions and axes of holes.

1 – rod; 2 – microfeed; 3 – clamps; 4 – frame; 5 – vernier; 6 – base; 7 – holder; 8 – measuring leg; 9 – marking leg

Figure 3 – Height gauges

All of these vernier tools use verniers, which are used to measure fractional divisions of the main scales.

Calipers, their varieties, device

Among vernier tools, calipers are the most widely used.

Calipers can be of a certain type and marked:

ШЦ-I

— a caliper with a double-sided arrangement of jaws intended for measuring external and internal linear dimensions, and also equipped with a ruler for measuring depths;

ShTs-1S is a caliper equipped with a circular scale. Here, the readings of the caliper, corresponding to the position of the jaws, are read using the rod scale and the position of the arrow on the dial scale of the head, coupled by a gear with the rod rack. Unlike vernier readings, this design allows you to read measurement results faster and easier;

ШЦТ-I is a caliper with one-sided jaws made of hard alloys, intended for measuring external linear dimensions and depths under conditions of increased abrasive wear;

ШЦ-II

- a caliper with a double-sided arrangement of jaws intended for measuring external and internal linear dimensions and for marking. ШЦ-II is equipped with a micrometric feed frame. The size of the offset jaws for internal measurements (usually 10 mm) is marked on their side surface and determines the smallest internal dimension that can be checked by this SC. For all internal measurements, the marked jaw size should be added to the scale reading. The movable jaw is equipped with a clamp, often in the form of a screw.

ШЦЦ - Vernier caliper with digital display. This is an electronic caliper

ShTs-

I with a reading accuracy of 0.1 mm

ShTs-I caliper is used to measure the external and internal dimensions and depth of a part (Figure 4).

1 and 9 – fixed measuring jaws; 2 and 8 – movable measuring jaws; 3 - screw; 4 – frame; 5 – bar for measuring depth; 6 – protrusion; 7 – bar with divisions (vernier).

Figure 4 – Vernier caliper ШЦ – 1

Figure 4 shows a simple caliper ShTs-1, which is used to measure parts with an accuracy of 0.1 mm. On the rod, which is a measuring ruler, there are measuring jaws 1 and 9, the other two jaws 2 and 8 are integral with the frame 4, together with which they can move freely along the rod. To secure the frame 4, use a screw 3. The frame 4 has a bar 7, on the bevels of which the divisions that make up the vernier are marked. To measure the depth, a narrow bar 5 is used. The bar 5 is rigidly connected to the frame 4 and moves in the groove of the rod behind the protrusion 6, which has a notch for ease of use.

Vernier is an auxiliary scale with a measurement limit equal to the division value of the main scale. Verniers have different division values, which determine the measurement accuracy of this instrument. The accuracy value (division value) of the measurement is marked on the instrument, for example: 0.1; 0.5; 0.01 mm.

Caliper

ShTs-II with reading accuracy 0.05 mm

Figure 5 —

ShTs-II with a reading accuracy of 0.05 mm

Figure 5 shows a ShTs-II caliper with a reading accuracy of 0.05 mm. The ShTs-II caliper differs from the ShTs-1 in that it has a micrometric (fine) feed device and does not have a depth gauge. ШЦ-II is used for internal and external measurements. Another distinctive feature is the presence of jaws with flat or cylindrical measuring surfaces. The division scale corresponds to 0.05 mm.

The caliper has a double-sided arrangement of jaws intended for measuring external and internal linear dimensions and for marking. ШЦ-II is equipped with a micrometric feed frame.

The ShTs-2 caliper (Figure 5) consists of a rod 1 with jaws 7 and 8. Markings are marked on the rod. Frame 4 with jaws 6 and 9 can move along rod 1. A vernier 5 is screwed to the frame. For rough measurements, frame 4 is moved along rod 1 and, after securing with screw 10, a count is taken. For accurate measurements, use the micrometric feed of the frame, consisting of screw 2, nut, slider 12 and screw 11. Having clamped screw 11 of the slider, rotate the nut 3 and feed the frame 4 until the jaws 6 and 7 or 8 and 9 fit snugly to the part being measured, after which the Countdown.

Jaws 6 and 7 are used for external and internal measurements. When measuring internal dimensions, the thickness of the jaws, which is marked on them, is added to the readings obtained. Jaws 8 and 9 are used for marking and external measurements.

Measurements with calipers, reading the results of readings

Rules for handling vernier calipers

1 Before starting work, wipe the caliper with a clean cloth to remove grease and dust. Do not clean the tool with sandpaper or a knife.

2 Do not place the tool on heating devices.

3 Only clean parts without burrs, burrs or scratches can be measured. Hands should also be clean and dry.

4 The jaws of the caliper have sharp points, so be careful when measuring.

5 Do not allow the caliper jaws to become distorted. Secure their position with a clamping screw.

6 When reading the measurement scales, hold the caliper directly in front of your eyes.

Taking measurements using a caliper

The ShTs-I caliper, being a high-precision measuring instrument, allows you to determine the internal and external - linear - dimensions of parts, the depths of protrusions and holes. Measurements are carried out with an accuracy of 0.1 mm.

External and internal dimensions are measured using wide lower and auxiliary pointed jaws, respectively. By the way, pointed jaws are also used for marking parts. The depth of the holes and the size of the protrusions are determined using a depth gauge, which is an element of a caliper.

The measurement process with a vernier, pointer or digital caliper is exactly the same, the only difference is in the presentation of the data by the device. It is for this reason that we will consider working with a vernier caliper using the example of a vernier caliper, and comments explaining the work with other types of devices will be given along the way.

Preparing for the measurement process

Before proceeding directly to measurements, the caliper should be cleaned of grease and dust (paying special attention to the working surfaces) and checked for accuracy.

It is not difficult to check for accuracy with a vernier instrument - just align the main (wide) jaws of the instrument located below. In this case, the zero marks of two scales must coincide - the movable vernier scale and the fixed scale of the working - millimeter - surface. At the same time, the nineteenth line of the millimeter scale should align with the tenth line on the vernier. If both conditions are met, the tool is suitable for use.

In order to check the dial and digital calipers, it is also necessary to align the jaws of the device. The arrow on the dial of the pointer instrument should point to the zero mark. The display of the electronic caliper should show the number “0”.

Measuring the external dimensions of parts

using a caliper

External and internal dimensions are measured using wide lower and auxiliary pointed jaws, respectively. By the way, pointed jaws are also used for marking parts. The depth of the holes and the size of the protrusions are determined using a depth gauge, which is an element of a caliper.

In order to measure the external size of a part, it is necessary to firmly clamp it between the main – lower – jaws (Figure 6). The caliper should be held in the right hand (four fingers wrap around the bar, the thumb rests on the frame).

Figure 6 - Measuring the diameter of the outer part of the part

The frame is moved with the thumb and, upon reaching the correct distance between the jaws in contact with the surface being measured, it is fixed using a clamp with the thumb and index finger of the right hand.

Before reading the result, you need to make sure that the jaws are in the correct position: there are no distortions, and when moving the part between them, the normal force is maintained (the part passes between the measuring surfaces, easily contacting them).

Measuring internal dimensions and depth

The internal dimensions of the part are measured using the pointed jaws of a caliper. To do this, it is enough to bring them into a closed state and place them in the part being measured. (

Figure 7). After this, the auxiliary sponges are separated.

Figure 7

—

Measuring the diameter of the hole

Before determining the result, check that the same conditions are met as when reading readings when measuring external dimensions.

Determining hole depth

To determine the hole depth

It is enough to place a depth gauge located at the end of the caliper (Figure 8).

Figure 8

—

Measuring the depth of the hole

After this, you need to start moving the main jaws apart until the depth gauge hits the surface. Once this has happened, the device can be read. The dimensions of the protrusions are determined in the same way. Do not allow the caliper jaws to become distorted. Secure their position with a clamping screw.

(Please note: not every caliper comes with a depth gauge!)

Reading readings.

Determining the readings of a vernier caliper

To determine the readings of a vernier caliper, it should be held directly in front of your eyes (the “sideways” position is strictly prohibited - it will lead to additional errors).

When measuring a part, do not allow the jaws of the caliper to become skewed. Their position must be fixed with a locking screw.

Figure 9 -

Determining the readings of a vernier caliper

It does not matter what parameter was measured - external, internal size or depth - the size is read using the same algorithm.

The surface of the vernier scale has a slight bevel, designed to better align it with the main scale - it is by the relative position of these two graduations that the size of the part is determined.

First of all, the number of whole millimeters is determined, corresponding to the value of the division of the main scale, located on the left side of the zero mark of the vernier and closest to it.

Then the number of fractions of a millimeter is determined. A stroke is found on the vernier scale that coincides with one of the marks on the main scale (see Figure 9). If there are several such strokes, take the value closest to the vernier zero - it is this value that displays the number of tenths of mm.

By adding the whole part and tenths, you get the full size of the part or the depth of the hole.

Determination of dial and digital caliper readings

Figure 10 -

Determining readings from dial and digital calipers

Reading readings from a dial gauge is quite easy.

The “whole” value is determined by the main scale of the device, while the number of tenths or hundredths is indicated by the arrow of a graduated dial. The readings are then added up. Working with a digital caliper is even easier - the readings are displayed in a user-friendly format on the device display (see Figure 10).

Reading the measurement results (C) is shown in Figure 7. To obtain the measurement result (C), the readings of the rod scale (A) and the vernier scale (B) are summed up, so the measurement result is C = A + B.

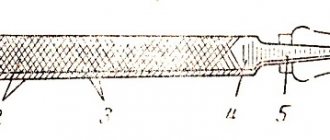

Vernier depth gauge

A depth gauge can be used to measure the depth of grooves on shafts, holes, etc. When measuring, the reference planes of the depth gauge are placed on the plane of the product from which the measurement is made. It is necessary to ensure that the support jaws of the depth gauge are free of potholes and rust. Periodically, the support jaws must be ground in using a test plate. During the grinding process, the movable ruler should be at zero. Measurement with a depth gauge is carried out in the same way as with a caliper.

Rice. Measurement with a depth gauge

Operating principle of the electronic version

In fact, an electronic caliper does not have anything supernatural in the principle of its operation. The calculation is carried out in the same manner as in the mechanical version, only it is automated due to the electronic vernier scale. There is a capacitive sensor inside the module. It does not react to the displacement of the movable bar or scale. So that it can take readings, a small discharge from the capacitors is applied to it. There are two of them in the scheme. Inside the main bar there is an element that accumulates static electricity and transfers it to the sensor.

Vernier gauge

A caliper is a connection between a caliper and a depth gauge.

A caliper gauge measures the thickness of gear teeth to determine their wear and size. Knowing the height of the gear tooth from the drawing (counting from the initial circle), set its size on the vertical scale of the vernier gauge; After this, the jaws of the caliper are placed on the tooth and the thickness of the tooth is measured using a horizontal caliper. The measurement accuracy of the caliper is up to 0.02 mm.

Rice. Vernier gauge

Technical condition and verification of calipers

One of the most important requirements for ensuring the accuracy of a tool is its cleanliness. A magnetized layer of metal filings, preservative lubricant, dirt - all this can significantly distort the measurement result. The result is also affected by tool wear, deformation, and settings violations. To avoid this, it is necessary to have the caliper checked annually at a specialized service center with repairs and adjustments. The simplest check for the correctness of the readings is the coincidence of the zero strokes when the jaws are completely closed.

Shtikhmas telescopic

Using a telescopic gauge, internal dimensions are measured in the range from 12 to 150 mm. The movable measuring rod of the gauge enters the stationary part of the body, from which it is pressed outward by a spring. There is a locking rod inside the housing that can be used to clamp the measuring rod in any position. To measure a hole, you need to release the measuring rod, insert the pin into the hole and, having given it the correct position, clamp the fixing rod, and then carefully remove the pin from the hole. After this, use a caliper or micrometer to measure the length of the measuring rod along with the fixed part.

Rice. Shtikhmas telescopic: 1 - fixed part; 2 — release spring; 3 - measuring rod; 4 — body; 5 — fixing rod.

Micrometer

The micrometer is used for external measurement of parts with an accuracy of 0.01 mm. The most common micrometers are the following sizes: 0-25; 25—50; 50-75; 75-100 mm. The device of a micrometer is shown in the figure.

Rice. Micrometer: a - section of a micrometer; b - determination of size; 1 - bracket; 2 — heel locking screw; 3 - heel; 4 — screw with micrometric thread; 5 - drum; 6 - ratchet; 7 — sleeve with divisions up to 0.5 mm; 8 — clamping ring.

The micrometer bracket on the left side has a hardened and ground heel, secured with a locking screw. On the right side of the bracket there is a sleeve with a fixed scale; a steel sleeve with a micrometric thread, the pitch of which is 0.5 mm, is fixed in the sleeve. A micrometer screw is screwed into the sleeve, at the outer end of which there is a drum with a scale having 50 divisions located around the circumference and a ratchet.

To measure, the part is placed between the screw and the heel, after which the drum is turned by the ratchet and the screw is pulled out until it comes into contact with the part being measured. To determine the size, you need to count the number of millimeters on the surface of the sleeve, including the half-millimeter division passed, and then see which division on the edge of the drum coincides with the axial line made on the sleeve. This division will correspond to the number of hundredths of a millimeter that needs to be added to the previous data. At the micrometer position shown in Figure b, the size is set to 20.05 mm.

Tips for taking measurements

Before you start taking measurements, you need to thoroughly inspect the caliper itself and make sure it is in good working order. First of all, the jaws are brought back to their initial position. In this case, it is worth assessing at what division the zero line is located; if on the vernier scale it coincides with the starting value, then everything is fine. The surface of the sponges is visually inspected. There should be no notches on them, and there should be no space between them; they should fit well. It is in this case that it will be possible to talk about minimal error and ideally accurate results in relation to the part being produced. It is advisable that the part being measured is firmly secured in a vice. This will prevent it from shifting during the process, which could affect the numbers. It must be placed between the working jaws and the first ones brought together. For metals and plastics, force must be applied to ensure that the jaws fit snugly. If the measurement is carried out on wood or other soft material, then excessive force will only cause harm.

Advice! To make it easier to move the vernier scale, the design provides a special wheel. The caliper must be held by the ruler with the flat of your palm, and the wheel must be moved with your thumb. After measuring, do not forget to secure the result with a bolt from above. An example of reading readings can be seen in the video

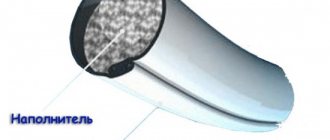

Shtikhmas micrometric (bore gauge)

A micrometric gauge is a tool for measuring the internal dimensions of products with an accuracy of 0.01 mm. In terms of its structure, the micrometric shtihmas is similar to a micrometer. The stichmas consists of a sleeve that has a tip with a spherical measuring surface at one end, and a micrometric screw with the same surface at the other. Dimensions are determined in the same way as with a micrometer. To increase the measurement limits, the micrometer gauge has a set of replaceable measuring rods, which allows you to measure sizes up to 250 mm.

Rice. Micrometric shtihmas: 1 and 5 - spherical measuring surfaces; 2 - sleeve; 3 - locking screw; 4 - drum.

Indicator

The indicator is used to measure deviations in product dimensions. Indicators are used to check the vertical and horizontal planes of individual parts, as well as the runout, ovality and taper of shafts and cylinders. The measurement accuracy of the indicator is up to 0.01 mm.

The indicator consists of a housing, inside of which there is a mechanism consisting of several gears, a rack, stops and a dial with an arrow. The dial has 100 divisions, each of which corresponds to 0.01 mm. When the measuring pin moves by 0.01 mm, the arrow moves around the circle by one scale division, and when the pin moves by 1 mm, it makes one revolution. The measuring pin moves back under the action of a spring.

Rice. Indicator: a - indicator section; b - universal stand for mounting the indicator; 1 - measuring pin; 2 - worm wheel; 3 and 5 — teeth; 4 - rod; 6 and 9 — springs; 7 — carriage; 8 — carriage guide.

Figure b shows a universal stand for attaching an indicator, with which parts are measured in different positions.

To measure cylinder wear, the indicator is mounted on a special device - a passimeter.

Rice. Indicator with passimeter for measuring cylinder wear: 1 and 2 - rods; 3 - movable tip; 4 — swinging lever; 5 - fixed rod; 6 — calibrated rings; 7 — set of fixed rods; 8 — key for disassembling and assembling the device head.

The measuring part (head) of the device consists of a movable tip and a fixed rod. The movement of the movable tip is transmitted by the swing arm and rods to the indicator measuring pin, which in turn acts on the mechanism and the pointer. The indicator kit includes a set of fixed rods and calibrated rings that allow you to measure cylinders of different diameters. Before measurement, a stationary rod is installed in the head of the device (sometimes calibrated rings are placed under the collar of the stationary rod). To select the rod and ring, the cylinder is first measured (approximately) with a caliper or ruler.

Feeler gauge and thread gauge

The feeler gauge is a calibrated steel plate or a set of plates of varying thickness. Each plate indicates its thickness in millimeters. Feeler gauges are used to measure gaps between two parts. When measuring large gaps, several plates are used together. When taking measurements, do not allow sharp bends of the probe and large forces. It is necessary to ensure that there is no dirt or metal dust on the probes, which interferes with the accuracy of the measurement.

Rice. Measuring tools: a - a set of flat probes; b - thread gauge.

The thread gauge is used to check and determine the number of threads per 1 inch or thread pitch (in millimeters) on bolts, nuts and other parts. It is a set of steel dies (threaded templates) with a tooth profile corresponding to the profile of a standard inch or metric thread. The number of threads per inch or thread pitch is marked on each comb. A mark of 55° is knocked out on the body of the inch thread gauge, and 60° of the metric thread gauge. To check the threads on a bolt or nut, it is necessary to successively apply thread gauge dies until a comb is found whose teeth exactly match the threads of the part without clearance. The size of this comb will correspond to the thread being measured.

Is the electronic version good?

If you are just starting to master the process of measuring with a caliper, then the digital option can help out. Its advantage is also the high speed of measurements. The bottom line is that after the jaws are brought together on the part, the final number is instantly displayed on the digital display. There is no need to look closely at the vernier scale. As a rule, such devices come with a full set of capabilities, which includes double-sided jaws, as well as a depth gauge. The presence of a display practically does not increase the final weight. The module is no heavier than the additional scale that is present on the standard version. Advanced versions of this type of caliper have additional input/output ports, as well as a built-in converter. You can transfer the received values to an external drive or PC in a few touches.

The electronic part of the caliper requires power. Most often, this role is played by a CR2032 battery. Although consumption is minimal and one charge lasts for a long time, an unpleasant incident may happen and the device will run out at the wrong time when measurements need to be taken. Another disadvantage is that microcircuits and electronic sensors do not tolerate vibrations and shocks. This means that the accuracy of the caliper may increase if not handled carefully. The contacts of the electrical part are subject to oxidation due to moisture, which easily damages the electronic caliper. In some cases, the converter may not operate correctly, which can have far-reaching consequences in the production process. A conventional mechanical device lacks all these nuances.

Templates

The radius template is used to measure radii of products. The template is a thin steel plate with convex or concave curves. On the surface of each template are stamped numbers that determine the size of the radius of curvature in millimeters.

A template for checking the sharpening angle of twist drills with a diameter of up to 50 mm is made in the form of a steel plate with a cutout with an angle of 116-118°. A millimeter scale is applied to the edge of the cutout (Figure a), which is used to check the length of the cutting edges of the drill.

Rice. Templates for checking the sharpening angle of twist drills: a - simple; b - universal.

Using a universal template (Figure b), you can check, in addition to the sharpening angle of the drill, also the thread (metric 60° and inch 55°).

Test plate

The test plate is a cast iron plate with a precisely machined surface and edges. It is widely used for marking and inspection work. The surface of the plate should not have burrs, marks or rusty spots. The plate is installed strictly horizontally in level. To check, the product or slab is coated with a thin layer of paint, then the product is placed on the slab and moved along it. The paint imprint determines the accuracy of the product's processing. At the end of the work, the surface of the stove is wiped, greased with oil and covered with a wooden lid.

Rice. Test plate