MAIN TECHNICAL CHARACTERISTICS:

Line for anodizing and electropainting of profiles for architectural applications.

- Power consumption: 45.000 A

When using the appropriate suspension system, it is possible to both anodize and paint some of the aluminum parts. The line for anodizing and painting aluminum profiles is scaled in accordance with the Customer's request.

We provide installation of the following equipment:

- 3 pcs. anode baths at 15,000 Amperes.

- 1 electropainting bath 10,000 Amp.

Declared productivity 700 tons/month.

Production time 24 hours/day for 24 days/month.

Oxide film thickness 15 microns

Oxide film formation time 3 min/micron x 15 microns = 40 min

Number of anode baths 3

Number of downloads per hour 4.5

m2 per hour 450 m2

Aluminum weight 2.7 kg/m2

Annual output in m2 450 m2 x 6912 hours = 3,110,400 m2

Annual capacity in kg 3,110,400 m2 x 2.7 kg/m2 = 8,398,080 kg = 8,398 tons

WATER

Water for first filling: 30 – 35 m3/hour

GAS CLEANING

DESCRIPTION OF OPERATION OF THE GAS WASHING COLUMN

The inlet of the vapors to be treated occurs by suction from the collector, and is located in the lower part of the tower and then they are fed into the vertical channel, where they are immediately washed with a neutralizing solution by jets opposing the ramp. The purified gas then enters the liquid separation zone, which consists of a package of special profile blinds and is then sent to the outlet chimney. The neutralizing solution is contained in a large bath on the foundation, from which it circulates using a submersible centrifugal pump made of isostatic polypropylene, stabilized in ultraviolet rays, without a single metal part in contact with the pumped liquid through the spray supply line. For maintenance, inspection windows are provided for loading and unloading of the filling substance, a bottom valve and an overflow valve connected to the wastewater sent to the wastewater treatment plant.

Basic bath equipped with level controls for the following positions:

- Max. level: with a closed solenoid valve connected to the hydraulic system.

- avg. level: solenoid valve open.

- min. level: blocking the submersible pump to avoid running dry.

- solenoid valve for adding neutralizing solution.

All phases are controlled from the main electrical panel, mounted on the tower or near a pH meter (with a measuring probe). All these phases are monitored by a main control panel mounted on the tower (or close to it) and a pH meter (with measuring probes).

The treatment plant is designed for a minimum efficiency of 95%. In accordance with European emission standards.

- NaOH < 1 mg/ms

- H2SO4 < 1 mg/ms

GAS:

For anodizing line: 1.600.000 kcal/hour consumption: 70 m3/hour approximate value

COMPRESSED AIR

Consumption: 500 l/hour

pressure: 7-8 bar quality: dehydrated and oil free

INSTALLED ELECTRICAL POWER APPROX: 1880 kW

ELECTRICAL POWER USED APPROX: 1500 kW

LIGHT LEVEL:

Bath line: 250 LUX approx. Loading/unloading area: 200 LUX approx.

FLOOR LOAD:

Floor load: bath area: 3.5 tons/m2

Floor load: equipment area: 1.5 tons/m2

Floor load: loading/unloading area: 3.5 tons/m2

EQUIPMENT FOR PROFILE SUSPENSION:

- Aluminum wire

- Hexagon stands

- Double comb stand

- Stands with single comb

- Polypropylene pliers

- Polypropylene clamps

PERSONNEL REQUIRED FOR AUTOMATIC LINES

Shift calculation:

- 6 operators in loading area

- 4 operators in the unloading area

- 1 operator on the computer

- 1 operator for basket movements

- 1 chemical technologist

We actively use new opportunities

The products of the MiSSP plant have become even better. All aluminum parts of equipment that are assembled in factory workshops are subject to a mandatory anodizing procedure. To ensure maximum quality and service life of the plant's main products, it is especially important that blow molds also undergo an anodizing process. Customers have already appreciated the advantages of the appearance of MiSSP equipment, and the new level of reliability of components is confirmed by the results of specially performed studies.

The line installed at the factory has a total heater power of 33.5 kW, and its overall dimensions are 12x2.5x2.1 meters. All operations are performed in galvanic and rinsing baths made of plastic from the world's best manufacturers - ROCHLING and SIMONA. Equally important, in order to maximally comply with environmental protection requirements, the MiSSP plant purchased and installed a galvanic waste treatment line.

Having modern and high-performance galvanic equipment, the MiSSP plant offers enterprises and entrepreneurs in the region a new service - it accepts orders for anodizing. Fair, low prices and high quality of all work performed are guaranteed!

INSTALLATION DESCRIPTION

DEGREASING BATH + ETCHING BATH

- Bathtub made of rolled steel sheets of thickness. 3 mm

- External steel supports, plate 150×12

- Insulation with mineral wool, density 80 kg/m3, lined with steel sheet thickness. 1.2 mm with double acid-resistant painting

11 WASHING BATHS

- Bathtub made of rolled steel sheets of thickness. 3 mm

- External steel supports, 150×12 plate with double acid-resistant paint

NEUTRALIZATION BATH

- Bathtub made of rolled steel sheets of thickness. 3 mm

- External steel supports, 150×12 plate with double anti-acid paint

ANODIZING BATHS

- Bathtub made of rolled steel sheets of thickness. 3 mm

- External steel supports, 150×12 plate with double anti-acid paint

ELECTRIC PAINT BATH

- Bath made of rolled steel sheets 3 mm thick

- External steel supports, 150×12 plate with double anti-acid paint

BATH GILDING

- Stainless steel bath sheet AISI316, thickness 3 mm.

- External steel supports, plate 150×12

- Insulation with mineral wool, density 80 kg/m3, lined with steel sheet thickness. 1.2 mm with double anti-acid painting

COLD FIXING BATH

- Stainless steel bath sheet AISI316, thickness 3 mm.

- External steel supports, plate 150×12

- Insulation with mineral wool, density 80 kg/m3, lined with steel sheet thickness. 1.2 mm with double anti-acid painting

HOT FIXING BATH + HOT WASHING BATH

- Stainless steel bath sheet AISI316, thickness 3 mm.

- External steel supports, plate 150×12

- Insulation with mineral wool, density 80 kg/m3, lined with steel sheet thickness. 1.2 mm with double anti-acid painting

ACCESSORIES FOR 1st DEGREASING BATH AND PICKING BATH

- 1 stainless steel steam heating coil AISI 304, complete with brackets, automatic temperature control valve

- 1 bracket for temperature sensor

- 1 bath stirrer consisting of perforated stainless steel. pipes Ø 42.2, with supporting brackets and air inlet valve.

- 1 PVC pipe Ø 40 and fittings for water supply.

ACCESSORIES FOR 11 RINSE BATHS

- 1 bath stirrer, consisting of a Ø 40 perforated PVC pipe fixed to the bottom of the bath with corresponding brackets and an air inlet valve.

- 1 x PVC top pass-through damper

- 1 PVC outlet pipe Ø 90 for overflow

- 1 PVC relief valve Ø 50

- 1 PVC pipe Ø 40 and fittings for water inlet

- PVC cladding thick. 1.8 mm

ACCESSORIES FOR 1st NEUTRALIZATION BATH

- 1 PVC discharge pipe Ø 90 for overflow

- 1 relief valve UNI 2277 Ø 40 made of PVC

- 1 PVC pipe Ø 40 and fittings for water inlet

- PVC cladding thick. 1.8 mm

ACCESSORIES FOR 3 ANODIZING BATHS

- Double electrical fittings with aluminum rods on opposing inputs

- Rectangular extruded aluminum electrodes

- 1 bath stirrer consisting of 2 PVC pipes Ø 40

- 1 PVC coupling complete with liner, clamps, flange PN 10 Ø 4'' for acid inlet.

- 1 PVC coupling complete with liner, clamps, flange PN 10 Ø 4'' for acid outlet, complete with filters.

- 1 perforated PVC pipe Ø 110 complete with brackets for cooling sulfuric acid.

- 4 flanges PN 10 DN 100 made of PVC

- 2 valves for PN 10 DN 100 PVC bushings

- 1 PVC pipe Ø 40 water inlet

- 1 PVC pipe Ø 40 acid inlet

- 1 pneumatic cylinder containing:

- 2 electrical contacts with aluminum rods and water cooling.

- 1 5-way valve

- 2 valves to regulate air flow

- 1 solenoid valve for automatic control

Specifications:

Double effect cylinder:

- internal diameter: 200 + 200 mm.

- Force 12 atm: 7,000 kg.

- Compressed air: 10 atm.

- PVC cladding thick. 1.8 mm

ACCESSORIES FOR 1ST ELECTRIC PAINTING BATH

- Double electrical fittings with aluminum rods on opposing inputs

- Tubular cathodes made of stainless steel AISI304

- 1 bath stirrer consisting of 2 PVC pipes Ø 40

- 1 PVC coupling complete with liner, clamps, flange PN 10 Ø 4'' for acid inlet.

- 1 PVC coupling complete with liner, clamps, flange PN 10 Ø 4'' for acid outlet, complete with filters.

- 1 perforated PVC pipe Ø 110 complete with brackets for cooling sulfuric acid.

- 4 flanges PN 10 DN 100 made of PVC

- 2 valves for i PN 10 DN 100 PVC bushings

- 1 PVC pipe Ø 40 for water inlet

- 1 PVC pipe Ø 40 for acid inlet

- 1 pneumatic cylinder containing:

- 2 electrical contacts with aluminum rods and water cooling.

- 1 5-way valve

- 2 valves to regulate air flow

- 1 solenoid valve for automatic control

Specifications:

Double effect cylinder:

- internal diameter: 200 + 200 mm.

- Force 12 atm: 7,000 kg.

- Compressed air: 10 atm.

- PVC cladding thick. 1.8 mm

ACCESSORIES FOR 1ST GILDING BATH

- 1 stainless steel steam heating coil AISI 304

- 1 3-way motorized valve

- 1 bracket for temperature sensor

- 1 set bath stirrer

- 1 valve and drain tray for water inlet

ACCESSORIES FOR 1st COLD FIXING BATH

- 1 stainless steel steam heating coil AISI 304, complete with brackets, automatic valve and thermostat.

- 1 bracket for temperature sensor

- 1 bath stirrer consisting of stainless steel perforated pipe Ø 42.2, with corresponding brackets and air inlet valve.

- 1 PVC pipe Ø 40 and fittings for water inlet

ACCESSORIES FOR 1st HOT FIXING BATH + 1 HOT RINSE

- 1 stainless steel steam heating coil AISI 304, complete with brackets, automatic valve and thermostat.

- 1 bracket for temperature sensor

- 1 bath stirrer consisting of stainless steel perforated pipe Ø 42.2, with corresponding brackets and air inlet valve.

- 1 PVC pipe Ø 40 and fittings for water inlet

Specifics and purpose of the process

At its core, the anodizing process is similar to galvanic processing of steel. The main difference is that with the galvanic method, compositions based on zinc or chromium act as a protective coating. When anodizing steel, no auxiliary compounds are used, and the protective film is formed directly from the material of the surface being treated.

The oxide film of natural origin, which is formed during the operation of parts, does not differ in the thickness and durability of the coating. When anodizing, the layer formation process can be adjusted. As a result, the oxidized area does not collapse, but becomes stronger.

The technological process has its own requirements: the metal being processed must have only one oxide and have high adhesion to the surface.

At the same time, the protective layer must have a porous structure for unhindered contact of the working mixture with pure metal, accelerating the process of film formation. Although most metals meet the above requirements, aluminum, tantalum, steel and titanium respond best to anodization. There are two types of oxide films, which differ in structure and purpose:

- Porous. Its properties have been described above. This layer is obtained by oxidation in an acidic electrolyte environment. This structure is an excellent basis for applying paints and varnishes.

- Barrier. It is an independent protective coating, preventing contact of steel with external negative factors. Obtained in neutral solutions.

Anodized surfaces are used not only as a protective layer. Modern designers actively use oxidized aluminum as an interior finishing element. It is possible to change the shade of the protective layer: from pearl to golden, depending on the materials used and the voltage level.

Warm anodizing

An alternative method for obtaining a shiny layer is warm anodizing, which can be done in a home workshop. The method has the following features:

- At home, it is impossible to accurately maintain the set temperature and other conditions during the electrolytic reaction.

- The anodized coating turns out to be porous, which is good if you plan to paint the product.

- The layer is not strong enough, it can be destroyed during operation under the influence of external agents (for example, sea water), it is easy to scratch, and it has low resistance to abrasion.

The work is performed at room temperature (on average 15-20°C, but not more than 40°C). The stages of work repeat the factory technology. The part is fixed on a suspension, degreased (for example, in nitric acid), washed in distilled water and lowered into an oxidation solution.

Anodizing an aluminum part at home Source ytimg.com

General issues.

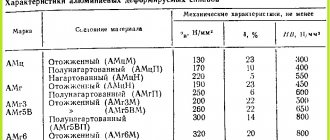

The modern metallurgical industry produces a huge number of different aluminum alloys. All of them can be divided into deformable and casting. The choice of a specific alloy in the manufacture of parts is usually justified by its physical and mechanical properties and price.

The designer is usually interested in:

• Properties of the alloy, ensuring the easiest processing of the source material by the selected method. It is obvious, for example, that some types of aluminum are easy to cast, others are sharpened, and others are well extruded to produce a profile. • Properties of finished products made from a particular alloy. For example, the D16T alloy is hard, which is important for body parts, while technically pure aluminum is very soft and ductile. • The cost of the alloy and its availability.

Unfortunately, few people pay attention to its ability to be plated when selecting an alloy during part design. Meanwhile, inattention in this matter often leads to the fact that already manufactured parts simply cannot be coated and all the work goes down the drain. How to choose the right aluminum for electroplating and what subtleties of the process should be taken into account when designing parts? To begin with, you should consider the nomenclature and structural features of aluminum alloys (the nomenclature is presented in detail in GOST 4784-97).

Wrought alloys can be divided into high-strength, medium-strength and low-strength.

•

High-strength wrought aluminum alloys include duralumin (D), containing copper, manganese, magnesium, silicon, and iron as alloying additives. A typical example is the D16 alloy. The main alloy in it is copper, which forms intermetallic compounds with aluminum. In addition, the class of high-strength alloys includes type B alloys containing zinc, copper, magnesium and manganese - for example, B95, as well as highly alloyed magnesium.

• Medium strength alloys

(medium alloyed magnalium, avial) contain magnesium and silicon.

•

Non-hardening aluminum alloys (AMg or AMts) contain magnesium, manganese, or both of these elements together.

•

Among

the casting alloys,

AK and AL (silumin) should be highlighted. The main feature of their composition is the large percentage of silicon in the alloy, up to 14%.

Aluminum blanks made from alloys that are not highly corrosion resistant are protected with a surface layer - plating, usually pure aluminum. Sometimes this may be a layer of another material, for example, paintwork. The cladding layer may vary in thickness. A thinner layer, which presents less difficulty in coating, is designated by the letter B, a thicker layer by the letter A.

Now let’s look at what galvanic operations aluminum can, in principle, be used for. Essentially, there are two main options here:

• Anodizing (oxidation)

• Application of metal coating (nickel plating, tinning, silver plating, copper plating, chrome plating, etc.).

Anodizing aluminum is used to protect against corrosion, increase microhardness, improve appearance, primer for painting, electrical insulation, etc.

Nickel plating creates a highly decorative shiny layer that is stable in alkalis at any concentration and temperature (pure aluminum dissolves easily in alkalis).

Tin plating (tin plating) ensures solderability and the ability to safely pair aluminum with copper parts.

Silver and copper plating improves electrical conductivity and reduces contact resistance in electrical contacts.

Let us highlight the general features of aluminum that can affect both the quality of anodization and the quality of metallization:

• The more alloying components in an alloy, the worse its coating. Significant difficulties are created by the presence of silicon in the alloy. For high-silicon alloys, electroplating is practically impossible.

• AL alloys (silumins) are very difficult to coat and cannot be properly recoated, i.e. When designing, it is necessary to include a certain percentage of irrevocable defects from galvanization.

• Plating is a problem for electroplating. The greatest difficulty cladding presents for metallization - almost always the coating on it will peel off, sometimes not immediately, but after long-term storage or during soldering. Thin technological cladding (denoted B) is usually removed during routine preparation of the aluminum surface, thick (A) - not Always. In addition, the cladding layer is not uniform in thickness. It can also be damaged and removed during the manufacture of parts. As a result, a situation may arise where part of the part is free from plating, and part is not. During the removal of a thick cladding layer during etching, the clean surface can be severely damaged. Unfortunately, it is not always possible to visually determine where the cladding has already been removed and where it has not. It is therefore advisable to manufacture parts from unclad aluminum for electroplating, or to first remove the outer layer mechanically by 2.5-3% of the thickness of the workpiece or more.

• Do not coat aluminum parts tightly coupled with parts made of other metals (steel, brass, copper, etc.). In this case, non-aluminum parts will be damaged. Such parts must be separated before coating. It is also undesirable to coat parts consisting of several aluminum alloys at the same time.

• The presence of a large number of blind (especially threaded) holes is undesirable. Because Since all galvanic operations take place in solutions, these solutions easily flow into blind holes and are very reluctant to leave them upon completion of the processes. Often, electrolyte residues can remain in the holes of an apparently completely dry part and leak out after a certain time (sometimes after packaging), forming drips and causing severe damage to both the coating and the part itself.

Process of processing various types of metal

Anodizing steel is carried out taking into account the properties and characteristics of the metal. For other connections these conditions may not be acceptable. Let us consider the features of processing individual metals and alloys based on them.

Anodizing of copper and its alloys

This metal is very difficult to oxidize. The electrochemical method is considered optimal, as a result of which a color change occurs. Phosphate or oxalate solutions are used as a working mixture.

The process has high technological requirements, so it is extremely rare in practice.

Titanium anodizing

The procedure is considered mandatory, since the oxide film not only increases the strength of the workpiece, protecting it from mechanical damage, but also changes color in a wide range depending on the voltage level during the operating cycle.

Almost any acid is suitable for processing titanium.

Silver anodizing

For anodic oxidation of silver, experts recommend using liver sulfur - it can impart blue or purple shades without changing the properties of the silver surface.

The operating cycle duration is 30 minutes. After obtaining the desired color, the product is removed from the container and washed first with warm and then with cold water.

Aluminum anodizing

Aluminum anodization has become the most widespread.

Many methods have been developed for applying the oxide film, including color coating. The decorative purpose of oxidation is especially popular. The coating technology is not very complex. If desired, aluminum oxidation can be carried out at home - it will not require large expenses.

Anodizing is a universal technology that can be used both as preparatory work before painting and as independent protection of the metal surface. In addition, processed elements can be given additional visual effects.

Have you tried performing anodic oxidation at home? Did you manage to achieve the desired quality? Share your experience in the comments block.