Anyone who searches for and sells non-ferrous metal sometimes has doubts about the type of scrap and, accordingly, its true value upon delivery.

Copper is a non-ferrous metal, and brass is an alloy that is typically 70% copper, so it often resembles it.

A mistake can be quite costly. For copper at collection points they give 285-300 rubles, for brass - about 150 . There are many ways to find out what kind of metal we see - copper or brass, and we will tell you how to distinguish them from each other in this article.

A LITTLE ABOUT COPPER

At its core, copper is a compound of crystals of silver, calcium, gold, lead and nickel. This combination is fundamental in acquiring certain properties.

Physical properties of copper:

- High softness index;

- High level of plasticity;

- Good ductility;

- High electrical and thermal conductivity.

Chemical properties of copper

- Low oxidation rates when used under standard conditions;

- Possibility of reacting with halogens, selenium and sulfur;

- Nitrogen, hydrogen and carbon do not react when they come into contact with copper;

- It dissolves in nitric acid concentrate, while dilute sulfuric and hydrochloric acids do not lead to a reaction.

Applications of copper

- Electrical engineering. Low resistivity allows the use of copper in the manufacture of power and other types of cables, wires and conductors of various directions. It must be taken into account that the presence of additional impurities can significantly reduce the electrical conductivity of the metal;

- Devices related to heat exchange. Copper's good thermal conductivity makes it suitable for cooling radiators, air conditioning and heating systems, computer systems and heat pipes;

- Pipe production. High levels of mechanical strength and ease of processing make copper a popular material in the production of seamless round pipes;

- Making dishes. Copper is most often used as a material for making decorative dishes and food storage containers;

- Decorations. The beautiful shade of copper and environmental friendliness make it an attractive material for the production of costume jewelry;

- Construction. Due to its high anti-corrosion properties, copper is successfully used as the main roofing material for residential buildings;

- As a ligature binder when working with other metals;

- Medicine. In medicine, copper is used as a component of some ointments and drops;

- Pyrotechnic devices.

Benefits of Copper

- High anti-corrosion properties;

- Aesthetically attractive appearance;

- High thermal conductivity;

- Good indicators of flexibility and ductility while maintaining strength;

- Low level resistance.

Flaws

High price. The main (conditional) disadvantage of copper can be considered the rather high cost of the material.

Aluminum

The characteristic properties of pure aluminum are its low specific gravity, low melting point, high thermal and electrical conductivity, high ductility, very high latent heat of fusion and a durable, although very thin, oxide film covering the surface of the metal and protecting it from the penetration of oxygen inside.

Low density makes aluminum the basis of lightweight structural materials; Great plasticity makes it possible to apply all types of pressure treatment to aluminum and obtain from it sheets, rods, wire, pipes, the thinnest foil, deep-drawn stamped parts, etc.

Good electrical conductivity ensures the widespread use of aluminum in electrical engineering. Since the density of aluminum is 3.3 times lower than that of copper, and the resistivity is only 1.7 times higher than that of copper, then aluminum per unit mass has twice the conductivity of copper.

A durable oxide film quickly covers a fresh cut of metal even at room temperature, providing aluminum with high resistance to corrosion in atmospheric conditions.

Sulfur dioxide, hydrogen sulfide, ammonia and other gases found in the air of industrial areas do not have a noticeable effect on the corrosion rate of aluminum. The effect of water vapor on aluminum is also insignificant. In contact with most metals and alloys that are noble in the electrochemical potential range, aluminum serves as an anode and, therefore, its corrosion in electrolytes will progress.

To avoid the formation of galvanic couples in a humid atmosphere, the junction of aluminum with other metals is sealed by varnishing or other means.

Long-term tests of aluminum wires have shown that they are not inferior to copper wires in terms of resistance to corrosion.

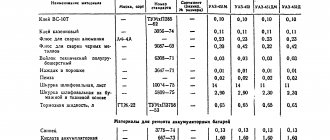

Table 1. Main characteristics of conductor materials

Density, kg/m 3 10 3

Electrical resistivity at 20 °C, Ohm×m 10 –6

Average temperature coefficient of resistance from 0 to 100 °C, 1/deg

Wires, cables, tires, conductors of squirrel-cage rotors, housings and bearing shields of small electrical machines

Cadmium bronze - contacts, phosphor bronze - springs

A LITTLE ABOUT BRASS

Brass is an alloy of copper and zinc. The percentage of zinc can vary from 5 to 45%. In some cases, the percentage of zinc content may slightly exceed 45%. The zinc in brass is intended to improve the quality of the metal, while significantly reducing its cost compared to the original material - copper.

Brass is divided into two main groups in its composition:

- Two-component. They consist of two components - copper and zinc. Moreover, the latter is the main binding component and usually makes up from 30 to 50%. Two-component brass containing up to 97 percent copper is called red. Their second name is “tompak”. Brass with a copper percentage not exceeding 35 is called yellow;

- Multicomponent. Alloys containing several alloy additives. The most commonly used amplifiers are manganese, tin, nickel, lead and silicon.

The marking of a brass alloy directly depends on the type and percentage of components. Thus, two-component brass is marked with alphabetic and numerical designations, where L denotes the material, and subsequent numbers indicate the percentage of copper content. Multi-component alloys have more complex markings, but the essence remains the same as simple brass.

Basic properties of brass

- Ease of processing under pressure;

- Good anti-corrosion resistance;

- High temperatures, aggressive environments, and exposure to sulfur dioxide increase the risk of corrosion;

- When temperatures drop, ductility increases, but strength does not decrease;

- When exposed to temperatures from 200 to 600 degrees, fragility increases significantly;

- Good anti-friction qualities;

- Good ability to weld with other metals.

Application areas of brass alloy

- Manufacturing of bushings and other transition parts;

- Production of components for motor units;

- Plumbing equipment and accessories;

- Decoration elements of various directions;

- Shipbuilding;

- Army needs.

Advantages of brass

When comparing brass with copper, there are common properties and characteristics:

- Ease of processing and polishing;

- Aesthetic appearance;

- Loyalty of tombak when welding with other metals;

- High anti-friction properties.

And yet: how to distinguish copper from brass ? There are many indicators by which you can see how copper differs from brass, such as the difference in temperature, color, hardness, etc...

Application

Deformable brass

Red brass

(French tombac, from Malay tambaga

- copper) - Double brasses containing up to 20% Zn are called tompak (brasses containing 14-20% Zn are called semi-tompak) (https://metallicheckiy-portal.ru/marki_metallov/lat). It has high ductility, anti-corrosion and anti-friction properties, and welds well with steel. It is used for the manufacture of bimetal "steel-brass". Due to its golden color, tombak is used for the manufacture of artistic products, insignia and accessories.

| Double wrought brasses | |

| Brand | Application area |

| L96, L90 | Parts of machines, thermal and chemical equipment, coils, bellows, etc. |

| L85 | Parts of machines, thermal and chemical equipment, coils, bellows, etc. |

| L80 | Parts of machines, thermal and chemical equipment, coils, bellows, etc. |

| L70 | Sleeves for chemical equipment, individual stamped products |

| L68 | Most stamped products |

| L63 | Nuts, bolts, car parts, condenser pipes |

| L60 | Thick-walled pipes, nuts, machine parts. |

| Multi-component wrought brasses | |

| Brand | Application area |

| LA77-2 | Marine condenser pipes |

| LAZ60-1-1 | Details of sea vessels. |

| LAN59-3-2 | Parts of chemical equipment, electrical machines, marine vessels |

| LZhMa59-1-1 | Bearing shells, aircraft and marine parts |

| LN65-5 | Gauge and condenser tubes |

| LMts58- 2 | Nuts, bolts, fittings, machine parts, Soviet small change coin of the 1958 model, in denomination 1-5 kopecks. |

| LMtsA57-3-1 | Details of sea and river vessels |

| LO90-1 | Condenser pipes of heating equipment |

| LO70-1 | Condenser pipes of heating equipment |

| LO62-1 | Condenser pipes of heating equipment |

| LO60-1 | Condenser pipes of heating equipment |

| LS63-3 | Watch parts, bushings |

| LS74-3 | Watch parts, bushings |

| LS64-2 | Printing matrices |

| LS60-1 | Nuts, bolts, gears, bushings |

| LS59-1 | Nuts, bolts, gears, bushings |

| LZhS58-1-1 | Parts made by cutting |

| LK80-3 | Corrosion-resistant machine parts |

| LMsh68-0.05 | Condenser pipes |

| LANKMts75- 2- 2.5- 0.5- 0.5 | Springs, pressure tubes |

Foundry brasses

- Corrosion resistant

- usually with good anti-friction properties

- good mechanical and technological properties

- good fluidity

- low tendency to segregate

| Foundry brasses | |

| Brand | Application area |

| LTs16K4 | Reinforcement parts |

| LTs23A6ZhZMts2 | Solid worm screws, compression screw nuts |

| LCZOAZ | Corrosion-resistant parts |

| LTs40S | Cast fittings, bushings, cages, bearings |

| LTs40MtsZZH | Critical parts operating at temperatures up to 300 |

| LTs25S2 | Car hydraulic system fittings |

Jewelry alloys

| Jewelry alloys | ||

| Type of processing | Color | Alloy name |

| casting | yellow | Brass granules M67/33 |

| casting | green | Brass granules M60/40 |

| casting | gold | Brass granules M75/25 |

| casting | yellow | Brass granules M90 |

DIFFERENCE IN COPPER AND BRASS IN MELTING TEMPERATURE

The main difference between copper and brass in terms of temperature is that copper melts at a temperature of 1082 degrees, while most brass alloys melt at 880-1000 C. It is worth considering that the melting point of both materials is an indicator the differences can be considered conditional, due to the fact that the melting temperature of brass changes (increases and decreases) depending on the additives included in the alloy. It is almost impossible to achieve such conditions at home. In this regard, to carry out identification using high temperature, the heating method with a gas burner can be used. When the 600C mark is reached, a pale ashy coating of zinc oxide will appear on the surface of the brass alloy.

How do alloying additives affect

An alloying is an additive to an alloy that changes its composition and, as a result, gives it some new properties, or increases or decreases existing properties. To reduce the loss of metal from the surface of the melt, aluminum is added to it; the resulting oxide film plays a protective role. To increase strength and improve anti-corrosion properties, magnesium is added to the alloy, separately or together with aluminum and iron. Moreover, additives have practically no effect on the density of the metal.

The addition of nickel to the melt eliminates the manifestation of negative aspects in terms of oxidative processes. It is possible to improve the ductility, malleability of the alloy and the conditions for its cutting by introducing an additive such as lead into the brass composition. Silicon in combination with lead improves sliding to such an extent that an alloy alloyed with this additive can be used on equal terms with tin bronze. At the same time, silicon added without other additives specifically increases the hardness and strength of brass. If the metal is planned to be used on a ship, tin is added to it, which makes it resistant to salt water.

DIFFERENCE OF COPPER AND BRASS IN SPECIFIC GRAVITY AND DENSITY

The brass alloy has a lower density compared to copper, and therefore the specific gravity will be less than that of copper. Determining which is heavier: copper or brass, if we are talking about a small volume, without using scales will be quite problematic.

Determining the type of material using a scale

- Determine density. This characteristic has fixed values and corresponds to 8.96 g/cm3 for copper and 8.73 g/cm3 for brass;

- Selection of necessary equipment. Such equipment will be: spring scales, tape measure, calculator and a cylindrical container with water;

- Determination of mass by weighing;

- Mass is converted to gram unit of measurement;

- Calculation of volume in cubic centimeters. For samples of the correct shape, it is necessary to measure the length, width and height, and multiply the values. For objects of irregular shape, the calculation is carried out by immersion in liquid and calculating the displaced volume;

- Calculation of density based on the data obtained. For this action, mass and volume are converted into the required dimensions and divided among themselves.

The results obtained are compared with standard indicators and become determining what kind of material the sample is.

HOW TO DISTINGUISH COPPER FROM BRASS BY COLOR

- If patina forms on the metal, it must be cleaned using non-aggressive household chemicals or by polishing;

- The object is placed in a source of bright white light, which can be a fluorescent lamp;

- As an analytical sample to facilitate the determination of copper and brass by color, you can use a polished copper 50-kopeck coin from 1997-2006. Copper with no impurities has a reddish-brown tint;

- Brass has a more yellow tint compared to copper. It is worth considering that there are brass samples with a high content of zinc impurities. This alloy will have a light gold or gray tint.

It is worth considering that this method of distinguishing copper from brass may not always be authentic. So, for example, an alloy containing up to 85% copper component can be distinguished from pure metal only by a barely noticeable yellowish tint, while the main color will be similar to the color scheme of copper.

Heat treatment

Temperature 600-650 °C is critical for zinc. The metal oxidizes when heated this way. This is a real way to visually distinguish bronze from brass in a burner flame:

- Bronze. The alloy will simply heat up. Its color and mechanical properties will remain unchanged. Attempting to bend a bronze specimen may result in its destruction.

- Brass. Oxidation of zinc causes an ashy coating on the surface of the joint. Additionally, after heat treatment at 600 °C, brass becomes ductile, and the alloy sample does not break when bent.

All that remains is to find a powerful burner. Here a gas stove or a lighter flame will not be enough.

Video - Melting bronze and brass:

HOW TO DISTINGUISH COPPER FROM BRASS BY SOUND

It is advisable to apply this criterion to sufficiently large samples of copper and brass. Otherwise, the need to use auxiliary equipment cannot be avoided. When using sound perception, you need to know that a dull sound is characteristic of a low density, and a voiced sound is characteristic of a higher one:

- Copper samples, which are softer and have lower density, reproduce duller, low-quality sounds;

- Brass, unlike copper, produces a high, ringing sound with a tendency to increase.

DIFFERENCE IN HARDNESS

For this method of comparing copper and brass , suitable objects are suitable for bending and making dents:

- Copper, as a purer material, has greater ductility and the ability to deform without violating its integrity;

- Brass, which is an alloy of copper and reinforcing additives, has low ductility and higher strength and brittleness compared to copper, and therefore, if you try to deform, it will have greater resistance and may burst.

DIFFERENCE BETWEEN COPPER AND BRASS BY SHAVINGS

For such a comparison, you need to have a metal cutting machine or a drill with a large diameter attachment:

- Copper. It is distinguished by a florid shape, a long spiral without notches and good ductility (Figure 1);

- Brass. As a hard and brittle material, it produces crumbly, needle-like chips without a clear coil (Figure 2).

Figure 1. Copper shavings

Figure 2. Brass shavings

PRICE DIFFERENCE BETWEEN BRASS AND COPPER

The cost of pure metal is much more expensive than the alloy. Thus, the main differences between copper and brass can be displayed in the table:

| Copper | Brass |

| Plastic, soft | Solid |

| Reddish brown-pink shade | Golden tone |

| Lower sound on impact | Alt |

| Heavy | Easier |

| The shavings are twisted into a spiral | Needle shavings |

By drilling

The simplest method. This method is carried out using a drill or milling equipment. The cut part of the product will allow you to determine the type of metal:

- when drilling copper, long solid chips will come from the point of impact, which will twist into a spiral;

- Brass begins to crumble under the influence of cutting tools, so needle-like particles become waste.

This method is only suitable for determining the alloy of products that will not be used in the future. Typically, drilling is used for scrap metal with subsequent delivery of products to the secondary market.