Copper wire rod is not the final product. This is a semi-finished product from which such things as contact wires, busbars for electrical distribution panels, wire of all diameters for transformer windings or small inductors and cathodes for electroplating are subsequently made.

Copper rod became the primary form of copper metallurgy because of its versatility as a raw material for further processing. Especially considering that copper is the best material for electrically conductive networks (except for silver). The electrical conductivity of copper is 1.7 times better than that of aluminum and 6 times higher than that of iron.

Characteristics of copper wire

Distinctive features: high electrical and thermal conductivity. Due to its high ductility, copper wire is an indispensable material as a base for electrical devices and wires. Also, copper wire has good flexibility and is resistant to breakage. Not exposed to the external environment, resistant to corrosion.

The technical characteristics of copper wire vary depending on the brand (M1, M2, M3).

Types of copper wire:

— by purpose: general, for low-temperature thermocouples, crushers;

— in shape: square (or rectangular), hexagonal, round cross sections;

- by width or diameter of the section;

— according to the state of the material: hard, semi-hard, soft (as well as all of the above states with increased plasticity);

— in terms of production accuracy: normal, increased;

— by type of cladding: coatings with tin, silver, nickel;

— by brand: M1, M2, M3.

In turn, solid wire, despite its strong structure, does not have high flexibility. Soft copper wire is easy to bend. The MM marking material is the main part for conductive cables and constituent conductors of different sections. Copper wire becomes soft after the annealing operation.

The color of copper wire is golden-red or reddish-pink. The copper surface shines until oxidation (reaction upon contact with air), after which a film of oxides forms and the shine fades.

The surface must be free of cracks, nicks, delaminations, scratches, dents and other defects with a depth greater than the maximum deviation. Drips and stains of technological lubricant, reddened surface are allowed.

The metal products market also offers special types of copper wire:

— MS wire has a special set of properties and is intended for communication lines over the air;

- enameled: MME (soft enameled copper), MTE (hard enameled copper);

— grades of oxygen-free copper wire: MMB (soft) and MTB (hard).

Rolled copper of this type can be produced either from pure copper or clad with coatings of Sn, Ni, Ag. Oxidation resistance, resistance at low or high temperatures (up to 750 ºС), anti-corrosion properties, combines copper and nickel wire. The use of Ni and Ag for cladding allows the production of high-quality products used in: aviation and space defense, electronics, television communications and other fields.

The strength properties of copper-based wire are an order of magnitude higher than those of aluminum.

Basic provisions of GOST

Basic physical properties and quantities in the form of technical parameters, chemical composition, testing methods and geometric dimensions are determined by GOST R-53803-2010. All copper wire rod after 2010 is produced in Russia in accordance with this GOST.

The standard defines the nominal standard sizes of sections adopted today in Russia. This is wire and copper rod with a thickness of 8 to 23 mm. Tolerances for a wire of 8-14 mm can be of the order of 0.4 mm, and for a rod with a cross-section from 15 to 23 mm - 0.6 mm.

Existing standards divide copper wire rod into types, the marking of which indicates the method by which it was manufactured. The methods determine the purity of the metal, on which its price directly depends. Thus, the KMB marking means oxygen-free wire rod. But it also contains subspecies Moo with 99.99% Cu, M1 - 99.9%, M4 - 99.0%, where the numbers indicate the Cu content as a percentage. Moo is a cathode electrolytic grade that is completely devoid of oxygen and has the highest electrical conductivity with the lowest possible resistance. and the cost of a kilogram of such copper is the highest. But the KMor marking informs that this copper wire rod is made from refined waste and copper scrap, that is, this wire rod contains copper of different grades.

Explanation of markings

The “M” in front of the metal purity index simply means “copper.” Two “zeros” (00) – high purity. One zero (0) is just blank. With numbers 1,2,3 – technically clean. The last element of the markings is usually a letter index, indicating the method in which the metal was cast: K - cathode. U – cathode remelted. Oxygen-free copper is designated by the letter B, deoxidized copper by P, and deoxidized copper by introducing phosphorus into the melt will be marked accordingly by the letter F.

In total, about 20 grades of this metal are produced in Russia, intended for use in various industries.

An intermediate position between these grades is occupied by copper rod marked KM.

The GOST adopted in 2010 allows for the production of copper wire rod of other nominal sizes, if such was the customer’s requirement.

There is also a list of chemical elements that are strictly regulated by GOST according to their maximum values in the composition of copper for industry. These are bismuth, arsenic, sulfur, antimony, lead, tellurium, selenium, silver, iron and oxygen. Their share in the total mass of a copper ingot or wire rod should not exceed values from 0.001 to 0.005%. The most harmful to the quality of copper is the content of bismuth and lead in it, since these substances make copper brittle with even slight heating. Therefore, the mass percentage of these elements should not exceed 0.001%. The presence of sulfur and oxygen in copper improves its ability to be cut, but sulfur at the same time impairs the ductility of this metal.

The content of substances such as phosphorus, cobalt, silicon, nickel, manganese, chromium, tin, zinc and aluminum is not regulated by GOST.

There may be dents, scratches, gouges and scratches on the surface of the drawn wire, but if their dimensions do not exceed 0.2 mm, the material is suitable for production. An exception is made only for high-precision technologies.

Product requirements

But in some cases additional requirements are put forward:

For finished products, twisting and unwinding tests are provided.

- Wire with a cross-section of 16 mm or more must withstand 3 cycles of twisting and unwinding. With a cross section from 13 to 16 mm – 5 cycles. And with a cross section from 8 to 13 - 10.

- The elongation of the wire rod at break must be at least 35%.

- The value of temporary resistance in megapascals must be expressed as a number of at least 160.

Additional tests may be carried out at the request of the client. So, these may be tests for hydrogen embrittlement for grades KMB and for helix elongation - such a test may be required for grades KM and KMor.

Although quite standard and even high-quality copper can fall into the “copper scrap” category. This can happen when:

- The percentage of metal oxidation in the coil exceeded the weight measurement method of 0.01.

- The presence of mechanical defects in the form of tears, notches and dents, if cleaning could not eliminate these defects.

- Exceeding the shelf life of the coil of wire rod for more than 3 months (after the expiration of this period, a comprehensive check of all parameters of the coil is required, and if at least one of them does not comply, even refined copper with a purity of 99.99% can be considered scrap). Therefore, the production of high-purity cathode electrolytic copper grades is always done for a specific customer and in the case of only 100% prepayment, with a warning about the possible consequences of failure to pick up the ordered wire rod on time.

Wire M1

M1 brand wire is considered the highest quality and most expensive. The purity of the copper alloy used for its production is 99.9%. Composition: Cu – 99.9%, impurities (such as Pb, Fe, Ni, S, As, Sb, Bi, Sn) – not higher than 0.1%. According to physical characteristics, there are: hard (M1T), soft (M1M). Other types of M1 wire: oxygen deoxidized (M1P), oxygen-free (M1B), phosphorus deoxidized (M1F), cathode (M1K).

Wire M1 differs from other rolled products (M2, M3) by increased performance characteristics, due to the minimum content of impurities in the material. It has good thermal and electrical conductivity. Bends well while maintaining strength properties. Nice appearance.

This wire is most often used in such areas as aircraft and shipbuilding, and electric power. They produce cords, cables, thermocouples, wires, and high-tech cryogenic equipment.

Manufacturers

Manufacturers of wire rod strictly monitor the quality of their products, so they are produced in accordance with GOST standards. Currently, a large number of brands of this rolled metal are known.

There are many popular wire rod manufacturers:

- Liepajas Metalurgs – Latvia;

- TECRUBE – Azerbaijan;

- "Absolute" - Russia;

- Alkor Trading Company – Russia;

- "Amurstal" - Russia;

- "Areal" - Russia;

- "Balcom" - Russia;

- Belarusian Ministry of Health;

- VISMA - Belarus;

- "Danko" - Ukraine;

- Dnepropetrovsk MZ;

- "Dneprospetsstal" - Ukraine.

This list of companies that are engaged in the production and sale of wire rod from copper, steel, and aluminum cannot be called complete; there are many more of them in Russia and the CIS countries.

Wire M2

It is primary copper, which has a high content of the base metal and a minimal amount of impurities. M2 wire is made from copper alloy having a technical purity of no less than 99.7%, and impurities of no more than 0.3%, respectively (the same elements as in the M1 grade). The percentage of oxygen is not more than 0.08.

According to the production method, copper wire M2 is: M2b (oxygen-free), M2f (deoxidized with phosphorus), M2k (cathode), M2r (deoxidized with oxygen). According to physical parameters, they are divided into: hard (M2T) and soft (M2M) rolled copper.

Related Posts via Categories

- Copper wire against late blight - reliable disease prevention

- Copper wire - from electrical appliances to jewelry

- Weight of steel, copper and aluminum wire - tables and calculation formulas

- Copper sheet is a popular rolled product with special properties.

- Copper grades - production features and main properties!

- Welding wire for semi-automatic machines - choosing the right working tool

- Stainless steel welding wire – for corrosion-resistant seams

- How to choose and how much tying wire to use for tying reinforcement?

- Copper and its main alloys

- Application of flux-cored wire for semi-automatic machines

Electrical copper wire

Manufacturing is carried out in accordance with GOST 434-78, from grade M1 or higher. It is characterized by a rectangular cross-section, with a thickness from 0.5 to 12.5 mm, a width from 2 to 35 mm. This copper wire can be purchased in the following grades: PMM (soft), PMT (hard). Produced in coils. Electrical round copper wire is used to make: cords, cables, wires, motor windings, etc.

At 20 ºС, the product has an electrical resistance: not exceeding 0.01724 Ohm•mm2 for MM brand products; 0.01780 Ohm•mm2 – for MT (Ø up to 2.44 mm inclusive); 0.01770 Ohm•mm2 – for MT (Ø above 2.44 mm).

For a product of the MM brand, the relative elongation is:

— Ø from 1.80 to 5.00 mm (inclusive) – 30%;

— Ø more than 5.00 mm – not less than 35%.

Tips for choosing

Typically, factories and large industrial enterprises buy wire rod from non-ferrous types of metal. For construction or installation, a steel type of wire is purchased. When purchasing, you need to know that the product must be sold in skeins. The skeins usually include 1 or 2 cores. It is also worth knowing that with a two-core skein, there must be 2 labels on the product.

From these designations we can conclude that the product has normal strength and a diameter of 5 mm. The product was produced using accelerated cooling. This product fully complies with GOST.

In addition to studying information from the manufacturer, you need to conduct a visual inspection of the cores. The product should not have scale, cracks, or burrs. A defective product is one that has voids, bubbles and lack of carbon

And also you should not ignore the general color of the wire rod. If the color is uniform, then you can be sure that the wire will be strong and flexible along its entire length

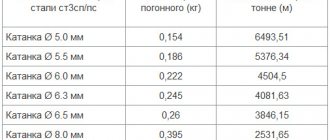

For various jobs in which wire rod can be used, there are specific requirements for its properties. When buying wire rod, you must evaluate the length and size of its cross-section; the cost of wire rod per 1000 kg directly depends on these characteristics. The cost of a product is also influenced by the material from which it is made.

Copper wire is considered the most expensive, aluminum wire is 2 times cheaper, steel wire is the most inexpensive, the cost of which does not exceed 30 rubles. for 1000 g. If desired, the consumer will be able to buy a coil of wire rod, which contains from 160 to 500 kg. And also in small retail trade you can find skeins with lower weight.

For more information about the production of wire rod, see the video below.

Copper Welding Wire

These rolled copper products are widely in demand these days in various fields. Based on the name, copper welding wire is used when performing gas welding work. Depending on the nature of the work performed, one or another grade of metal or alloy is used. When welding thin sheet metal, welding wire is indispensable.

For example, for automatic welding of copper structures, or submerged arc welding, in environments with inert gases, pure copper wire is used. Welding electrodes are produced from rolled products of this type, which are used to weld cast iron and copper.

In microelectronics, such products are used as connections in semiconductors. Also, copper welding wires with large cross-sectional areas are used in modern annealing and processing technologies when working with silicon crystals.

Brief description of properties

Properties of the material that allow it to be used in many industries:

- Plasticity combined with high strength. This combination of physical properties allows the use of a wide range of mechanical influences for processing, followed by a long service life.

- Low electrical resistance. Only silver is superior to copper in this parameter.

- Low resistance coefficient with increasing metal temperature. At least within the temperature range from 20 to 100⁰С.

Copper wire production

The main copper alloys for making wire are M1, M2, and sometimes M3. GOST 859-2001 determines the chemical composition. The process of selection, sample preparation and analysis of the chemical composition of non-ferrous metals and alloys is carried out in accordance with GOST 24231-80.

Drawing is the most common method of producing wire. The technology of this process involves pulling the workpiece through holes of the required diameter (cold deformation). So, for example, they produce copper wire with a diameter of 2 mm.

Copper has absorbed high plastic properties and can be cold deformed without problems. When producing copper electrical wire, it is important to be able to obtain a constant diameter with the absence of cavities and other possible defects. This non-ferrous rolled product is produced using special installations called drawing mills.

The main working part is the die of the machine; it is made from tool steel, which has increased strength properties. Drawing eyes, which are one or more holes located in the dies. The wire diameter depends on the working diameter of the hole.

The first step in the production of copper wire is to form a thick piece of wire rod. If it is necessary to obtain thin wire, the workpiece is gradually passed through drawing eyes, the diameters of which decrease. This technology makes it possible to produce wire with a diameter of 0.2 mm with the highest precision.

In the manufacture of wire, to obtain a high-quality surface without defects, lubricants are used to protect and reduce the degree of friction between the workpieces and steel matrices. The blanks and dies are constantly cooled with special mixtures, water or air, because Elevated temperatures lead to deterioration in the quality of finished products. For example, in this way, round copper electrical wire is produced, which is subject to increased demands.

Drawing is a highly productive process, waste-free production, regardless of the diameter of the resulting product.

The wire is then further processed to give it the required properties. For example, when annealed it becomes soft. Electrical copper wires are subjected to tinning and other processing methods.

Finished products are delivered to the warehouse or sent to the buyer. Delivery in coils is carried out for copper wire with a diameter of less than 1 mm, and for larger diameters, the rolled products are twisted into coils. You can buy copper wire according to the following parameters: Ø from 0.2 to 0.8 mm - in coils weighing up to 100 kg; Ø 0.8 - 1 mm - in coils weighing up to 25 kg.

General information about copper

Copper. The name in the periodic table of elements is Cuprum (Cu). Serial number – 29. Group I or secondary subgroup in the table, in its 4th period. The name comes from the name of the island of Cyprus, from where it was exported to the ancient city-states of the Mediterranean for use in everyday life, on the farm and in war.

In the metallic phase it is a pink-red substance, soft and malleable when heated to 700-800⁰C. Melts at a temperature of 1084.5⁰ C. Can be processed by pressure both cold and hot, as well as all types of soldering and casting into any shape, as well as cutting. After melting, when the melt temperature reaches 2,560⁰С, the liquid metal begins to boil.

The chemical composition of impurities and the method of obtaining the metal also affects such properties of copper as thermal conductivity, specific heat, resistivity and associated electrical conductivity, elasticity, hardness and tensile strength.

Copper grades

The classification of copper in Russia is adopted according to GOST 895-2001 and R-53 803-2010 “Copper. Stamps."

When cathode grades of copper are used in electrically conductive networks or in high-precision equipment, they are often divided into subtypes MooK (cathode) and MooB (oxygen-free), having a purity of 99.99 (the percentage of impurities of foreign substances is 0.001).

The emphasis on oxygen-free copper is not in vain: oxygen in the metal is not only an undesirable oxidizing agent, but also significantly reduces the ductility and strength of the metal. No less harmful is the presence of hydrogen molecules in the atmosphere, which, with significant heat treatment of copper (and not necessarily its melt), diffusely penetrates deep into the metal into its upper boundary layer and reduces copper oxide to pure metal and water. Molecular water, when heated repeatedly, is capable of producing local high pressure in the crystal lattice, which can form breaks, porosity and microcracks in the monolith.

These phenomena are especially harmful if high-temperature soldering or welding of copper surfaces is done, since the strength of the joints is reduced.

Hydrogen disease

However, “hydrogen disease” is typical only for high-temperature welding and soldering. With “soft” soldering, below 400⁰С, the phenomenon of hydrogen embrittlement can be neglected; hydrogen atoms below 400 degrees do not diffuse deeply into the metal - and the more the soldering temperature drops below 400⁰С, the less the influence of this metal reducer from oxides.

To prevent oxidation or the influence of hydrogen, the metal is melted

- In a vacuum.

- In an atmosphere of inert gases (argon).

- Under a layer of charcoal.

Although the most common way to prevent “hydrogen disease” is to introduce into the metal during melting an additive that binds oxygen and does not affect the physical parameters of the metal after casting or broaching. Phosphorus is used as an additive.

The quality criteria used in Russia and the EU countries are almost the same. The difference often lies in the requirements for controlling the quantity and quality of permissible or specially introduced impurities. Thus, Russian M1F and Cu-DHP, although they are analogues, have different impurities. In practice, this is expressed in the fact that in Russia the control of impurities is stricter, and the chemical composition of the metal is more stable in its physical characteristics. In M1F, it is under no circumstances allowed to use scrap during smelting, especially from refined copper fragments. This is the norm in Cu-DHP.

Because of this, conflicts often arise regarding the price of these metals with different degrees of purity - moreover, the price of purer Russian M1F is underestimated at auction when purchasing it from us. And, on the contrary, in reverse transactions it is overestimated for us - which indicates the influence of factors that have nothing to do with the quality or complexity of production.

Strength can be characterized by three states of the same grade: at a tensile strength of 210 MPa, copper is “soft”, at 250 MPa it is semi-hard, and at 280 MPa it is hard. Accordingly, M (foreign analogue of R 220), PT (R 250) and T (R – 280). Although, in addition to T, there are also more durable (solid) states of copper. Copper can even be quenched as a way to increase hardness - to do this, it is heated to 600⁰C and slowly cooled.