Sandblasting

is an effective method of combating corrosion, stains and paint using an abrasive. Can be used both for individual parts and for prefabricated metal structures: cars, fixed trusses, stairs.

The final result depends on the choice of materials and the quality of the work. Therefore, he carefully selects abrasive materials and the degree of surface cleansing.

We carry out sandblasting of any complexity

Unlike chemical or laser cleaning, sand cleaning of metal parts allows you to manually control the pressure applied. Depending on the goals, the degree of purification can be:

Easy.

Performed with quartz sand. Removes burnt marks, molding residues, dirt, and grease deposits from metal. Provides good surface preparation for painting or galvanizing. Cleans parts from rust without reducing the thickness of the material.

Superficial.

Performed with plastic abrasive. Used for finishing. Gives the metal a grainy texture, removes traces of rust, scale, and paintwork from the top layers. Provides high-quality adhesion.

Deep.

High grade sand is used. Relief defects are smoothed out, even a dense corrosion layer is removed, and surfaces are cleaned to a shine. However, the final thickness of the material is significantly reduced.

Craftsmen manually clean

surfaces.

The abrasive pressure power is adjustable from 5 bar (delicate cleaning) to 7 bar (complete removal of dirt and rust). Not only quartz sand is used, but also copper slag.

Unlike quartz, cooper slag has greater hardness and dynamic strength of particles. Forms a slight dust cloud. Used in open sandblasting.

For gentle surface cleaning, a low-hardness plastic abrasive is used. Excellent for non-aggressive cleaning of soft metals (aluminium, duralumin) from minor contaminants.

Consumption of quartz sand

To calculate the average consumption, the general ratio is correct: per 1 sq.m - 30 kg of abrasive*.

If you use less powerful devices with an air flow rate of 200 l/min, approximately 0.25 kg/min of sand will be consumed.

In high-power compressors with an air flow rate of about 10 cubic meters/min, the cost of quartz sand will be up to 12 kg.

*We provide approximate figures and are for reference only. Specific indicators depend on various factors: the power of the sandblasting unit, the volume of work, the degree of surface contamination, the characteristics of quartz sand and some others. The RosQuarts company offers to buy quartz sand for cleaning metal structures at the best prices with delivery to the site anywhere in Russia and the CIS countries.

Price list for metal sandblasting service

| Type of work | Price (per m2) | |

| Sandblasting of metal structures | from 550 rub. | Order |

| Sandblasting of metal structures against corrosion | from 550 rub. | Order |

| Sandblasting cleaning of metal structures from paint (not powder) | from 600 rub. | Order |

| Sandblasting of ferrous sheet metal | from 500 rub. | Order |

| Sandblasting of ferrous sheet metal from corrosion (rust) | from 500 rub. | Order |

| Sandblasting cleaning of sheet metal from paint (not powder) | from 550 rub. | Order |

| Sandblasting metal grating | from 600 rub. | Order |

| Sandblasting metal grating from corrosion (rust) | from 600 rub. | Order |

| Sandblasting of forged products on both sides more details | from 1000 rub. | Order |

| Sandblasting stainless steel sheets | from 600 rub. | Order |

| Sandblasting of stainless steel sheets after rolling | from 600 rub. | Order |

| Sandblasting of ferrous sheet metal from scale | from 700 rub. | Order |

| Sandblasting of metal grating painted with powder paint | from 1000 rub. | Order |

| Removing paintwork | from 700 rub. | Order |

Airless painting

An important component of the safety of any surface is the correct protective coating. Protection applied using the airless method is the most reliable and durable protection. Thanks to this method, foreign substances in the supplied mixture, condensate and oil are eliminated, material consumption is reduced, and the most uniform layers of paint, varnish, primer, fire protection, zinc-containing stainless compounds are applied, and visual defects in the form of overlapping layers are completely eradicated. It is worth noting that when applying such compositions, special skills are required from painters, as well as professional, expensive equipment. In addition, painting or protection work can be carried out in particularly dangerous and difficult conditions, requiring painters to have skills and qualifications in the field of industrial mountaineering. Our company has been working in the field of anti-corrosion protection, sandblasting, airless painting for more than 7 years, and during this time we have completed a huge number of complex projects in the field of oil production, civil engineering, utilities, as well as at strategic sites in many regions of our country and abroad.

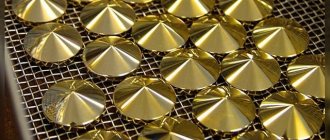

Examples of processed products

Types of abrasives

The first devices worked only on sand, but soon other materials began to be used for metal processing.

Which group an abrasive belongs to depends on its origin:

- Natural materials

- special sands for sandblasting. During the development of the technology, natural material (especially sea and desert sand) was highly valued due to the lack of analogues. Currently, safety requirements impose restrictions on the use of natural abrasives. - Plant materials

are agricultural by-products, such as processed seeds, husks, and shells. Abrasives of plant origin act on the working area gently and delicately. - Industrial materials

- metal, non-metal and waste from the metallurgical industry. The most common metal abrasive is shot. Long-lasting shot and granulate are produced from almost any type of metal; only the size of the fraction varies. Non-metallic abrasive, characterized by durability and excellent cleaning results, is an industrial product. This is, for example, glass grain. Materials from the third subgroup are products from waste slag. It has average characteristics.

Sandblasting is necessary for the safe operation of pipelines in industry and utilities. Sandblasting machines appeared in Russia relatively recently, but have already proven their effectiveness and ease of use. How much will the sandblasting service cost? This depends on the degree of contamination and the size of the pipe.

Advantages of sandblasting

Sandblasting metal structures is an effective way to protect parts from rust. Increases the adhesive properties of paint and varnish coatings. Advantages:

Advantages

- Abrasive blast cleaning devices are compact and practical. A mobile sand cleaning unit allows you to process even hard-to-reach surfaces.

- The price of the service is lower than alternative mechanical or chemical cleaning. Due to the low price of materials for working equipment.

- Exposure to sand does not affect the durability of the product, preserving the original structure of the material.

- The constant development of cleaning technology and the search for new abrasive materials makes the sandblasting system a leader among metalworking services.

- Cleaning with abrasive materials is a universal way to combat a range of problems on any surface. Suitable for metals with different properties.

Reviews

Sandblasting

- an effective method of combating corrosion, dirt and paint using an abrasive. Can be used both for individual parts and for prefabricated metal structures: cars, fixed trusses, stairs.

The final result depends on the choice of materials and the quality of the work. Therefore, he carefully selects abrasive materials and the degree of surface cleansing.

Benefits of our metal sandblasting services

performs metal sandblasting in Moscow, Lyubertsy and the Moscow region. We use quartz, cooper-slag, plastic abrasives and modern equipment: high-strength nozzles, remote control, mobile equipment. This gives us a number of advantages:

- Manual work guarantees careful impact on the local area while completely preserving the rest of the surface.

- Selection of the optimal sand fraction from 0.5 to 1.5 ensures guaranteed quality for any type of work.

- Thanks to prompt work, the client receives the finished product in a short time.

- Sand cleaning is carried out in accordance with the requirements for preparing metal materials for painting GOST 9.402-2004.

- A system of discounts for regular customers provides favorable payment terms for large volumes of work.

has been working in the metalworking industry since 2007. We are one of the leaders in the Russian market for the production and processing of metal. We always provide high quality services - when you choose us, you don’t have to worry about the results.

You can find out detailed information about prices for sandblasting by contacting the manager by phone +7

or

by leaving a request on the company's website

.

The sandblasting shop is located at Moscow region, Lyubertsy district, pos. Tomilino, st. Gogol, 39/1.

Recommendations for high-quality abrasive blasting cleaning

The main document that regulates the rules for sandblasting is the technological map. Such a document is drawn up for each object to be processed, it indicates all the features of this object, and it is used to select both material and equipment for sandblasting.

Sandblasting a wooden surface

As an example, consider the flow chart for cleaning the facade of a building.

- The task that sandblasting the facade of a building solves is to remove traces of contamination from the given object. To do this, it is necessary to use a dry abrasive mixture and equipment that will ensure its supply under high pressure.

- The working material should be dry sand, sifted through a sieve with mesh sizes of 1–1.2 mm.

- Air under pressure created by the compressor unit is supplied to the sandblasting unit, where it is mixed with the abrasive material located in its tank.

- Air mixed with abrasive material is supplied under pressure to the nozzle of the device and supplied to the surface being treated.

- To prevent damage to the facade being processed, the working pressure of the abrasive mixture supplied from the device nozzle should not exceed 4 atm.

- If sandblasting is carried out on the facades of buildings up to three floors high, it is necessary to ensure that the pressure generated by the compressor does not exceed 3 atm.

- Under the influence of the abrasive material, the diameter of the hole in the nozzle of the device increases, through which the material is supplied to the surface being treated. It is acceptable that after 1.5–2 hours of operation of the sandblasting unit, the diameter of this hole will increase by half its nominal size.

- When performing sandblasting, it is necessary to monitor its performance and the consumption of working material, which may change due to an increase in the diameter of the feed hole in the nozzle. If these parameters change significantly, the installation nozzle must be replaced immediately.

- After the treatment of the building facade is completed, it is necessary to remove the remaining sand and dust from the treated surface, for which air supplied under high pressure is used.