Propane reducer nut size

The parameters of nuts for gas cylinders are determined by GOST 949-73 standards.

The nominal thread diameter of the nuts is 27 (mm), the height of the nuts is 24 (mm).

The main dimensions of hexagonal brass nuts with a thread diameter of 27 (mm) with removable fittings, which are used to connect reducers to gas cylinders, in accordance with the manufacturers’ working documentation and the provisions of GOST 949-73 (Steel cylinders of small and medium volume for gases on P Additionally:

Maximum permissible deviations in dimensions, deviations in shape and location of surfaces of nuts for gas cylinders must comply with the provisions of GOST 1759.1.

The thread of the nuts for connecting reducers to gas cylinders must comply with GOST 24705 standards.

Technical requirements for the production of nuts must comply with GOST 1759.0.

Important: the material used for nuts with removable fittings for gas cylinders is brass, usually LTs40MtsZZh or LTs16K4 alloys in accordance with GOST 17711-93 (Copper-zinc (brass) casting alloys. Grades).

Detailed data on the main dimensions of hex nuts for gas cylinders are presented in the tables below.

| General view General characteristics of nuts for gas cylinders | d Nominal thread diameter in (mm) |

| Parameter Parameter of fitting |

Caution: The above data are official figures from manufacturers, but please note that the information is for reference only and is not guaranteed to be completely accurate.

Comments. Have questions? We will answer everything.

Source

Guide to unscrewing the valve

An additional supply of tightness is never superfluous, but when replacing shut-off valves on a gas cylinder, the strength of its fastening can become a big problem. The difficulty lies in fixing the cylinder body so that it does not rotate when the valve is unscrewed with a key.

It is with this problem in mind that further step-by-step actions for replacing shut-off valves will be considered. There are many ways to secure the body of a gas cylinder; let’s look at some of them.

Method 1: Attaching the limit bar

You will need the following tools and materials: a pipe wrench, two bolts at least 20 mm long with two nuts and a metal corner profile at least a meter long. Instead of a corner, you can use any other product in which you don’t mind drilling two small holes.

Next, you need to measure the distance between the two nearest holes on the cylinder shoe and drill the corresponding holes from one edge of the metal profile. After this, screw the iron bar to the cylinder body using bolts and lay it on its side. This design will not allow the cylinder to rotate.

Then you need to place your foot on the metal profile, and using your hand, using a key, carefully unscrew the valve.

Step-by-step photo instructions for the process are presented below.

Method 2: welding the cylinder to a metal base

This method is quite dangerous and should only be used by a professional welder with extreme caution. The shoe is grabbed in two places so that after unscrewing the valve, you can easily tear the cylinder off the base.

After welding the body, the fittings are carefully unscrewed using a pipe wrench. Then the internal thread of the cylinder should be cleaned of any remaining sealant.

Methods for fixing a gas cylinder are not limited to the described options. Many alternative methods can be used to secure it. Liquid water condensation sometimes accumulates at the bottom of the container, so after removing the valve, be sure to turn the container over so that water can flow out of it.

Propane reducer

Propane is the most widely used natural hydrocarbon gas by mankind. It is used in everyday life, construction, industrial production and transport as an inexpensive and easy-to-use fuel.

Propane is used to cook food and heat rooms; propane is used for welding, heating industrial installations and as fuel for land and small water transport.

Propane is also convenient because it can easily be used where there are no gas pipelines.

For this purpose, most countries of the world have created wide networks for refilling and delivering gas cylinders. The gas in the cylinder is in a liquefied state; it evaporates in the upper part of the cylinder and flows to the consuming devices through the valve. The gas pressure in the cylinder is much higher than the operating pressure of the consumer devices.

To reduce pressure (or pressure) and maintain it at a constant level, a simple but effective mechanical device is used - a propane reducer or adapter.

How many M3 propane is in 1 5, 12, 27, 50 liter cylinder?

We have made special calculations that conditionally transform propane-butane into a gaseous state. Under standard conditions (100 kPa, 288 K), 0.526 m³ of propane or 0.392 m³ of butane is formed from 1 kg of liquefied gas. Taking into account the percentage of the mixture (60% prop.), the volume of combustible gas is calculated using the formula M*(0.526*0.6+0.392*0.4). How many cubic meters are in a propane tank can be seen in the table below. The last line shows the number of liters of propane-butane mixture (in the liquid phase).

Design and types

The design of the device is quite simple, but its manufacture requires high dimensional accuracy and careful processing of the valve seat.

Propane reducer device

The propane reducer consists of the following components and parts:

- Sealed housing made of metal or impact-resistant plastic.

- Inlet pipe equipped with a union nut.

- Strainer and volumetric filter element.

- Working pipe equipped with a threaded nipple.

- High and low pressure chambers separated by an elastic membrane.

- Valve, its seat with seal and stem.

- Return or reducing spring.

- Adjustment screw.

- Setting spring.

- Pressure gauge.

Propane reducers come in two-stage and single-stage types. In a single-stage adapter, the pressure is reduced from input to operating pressure in one step. The two-stage has an additional high-pressure chamber and another valve. reduction occurs in two stages. This design is effective if the inlet pressure is very high, and is used in special cases. Single-stage balloon adapters are the most widely used due to their simplicity of design and ease of operation.

On the body of the device, its parameters must be stamped or indelibly painted, including the date of manufacture, maximum pressures, type of gas and performance. Propane adapters, like propane tanks, are painted red.

Features of equipment selection

Several recommendations for choosing gas equipment:

- Plate. If you are using an old unit, before connecting it is necessary to check that the fastenings and burners are not damaged and are working.

- Gas reducer. The main part when connecting bottled gas. It regulates the propane pressure at the outlet and lowers it to the required level. Must be equipped with threaded connections with brass nuts. For a cylinder with a valve, model RDSG 1-1.2 is used, for a container with a valve RDSG 2-1.2 is suitable.

p, blockquote 16,0,0,0,0 –>

- Hose for connecting the plate and cylinder. Purchased at specialized sales points, it must be intended specifically for gas. Its length must exceed the distance between the connected equipment by 150 cm, since it is prohibited to use it in a tense state.

p, blockquote 17,0,0,0,0 –>

Important! Do not use old hoses, as the integrity of their internal surface may be damaged.

Operating principle of the gearbox

Propane enters the high-pressure chamber through the supply pipe. It presses on the membrane, compresses the spring and opens the valve. Gas enters the low pressure chamber and presses on the membrane on the other side.

As soon as this pressure, together with the force of the compressed spring, becomes equal to the specified operating value, the valve closes and the gas supply to the chamber stops. A specified reduced pressure is created in the working pipe. As gas is consumed from the working chamber, the gas pressure at the inlet again compresses the spring and opens the valve, and a new portion of gas enters the working chamber. The cycle repeats. In a two-stage propane reducer, the working chamber of the first stage is the high-pressure chamber of the second stage.

How to choose a propane reducer model

When choosing a propane adapter, you need to study its characteristics, stamped on the body or applied with indelible paint. Critical to your choice will be:

- Working temperature.

- Maximum inlet pressure, kg/cm3.

- Working pressure, kg/cm3.

- Maximum gas consumption, m 3 /hour.

- Connection method.

Propane reducer and its parts

Thus, the operating temperature of most models lies in the range of -15+45˚С. This is enough for reliable operation of the device in a temperate climate zone. The maximum pressure at the inlet is usually 25 kg/cm 3, which will allow operation from a cylinder. The operating pressure must be no less than that required by the technical specifications for the consumer device. For most of them it does not exceed 3 kg/cm 3 . Using a propane adapter with a maximum flow rate less than the total of the consumer devices will lead to their unstable operation, combustion failure and the creation of a fire hazard.

The method of connecting the inlet pipe is usually common to all and is determined by the outlet connection of a standard gas cylinder. It is a ½" threaded union nut with a left-hand thread.

With the output, working pipe, the situation is a little more complicated. Some propane adapters, especially household ones designed to connect gas stoves or heaters, are equipped with a single option - a 6.3 mm nipple outlet. Such gearboxes will cost less.

A universal outlet is also a threaded connection; you can attach both a union nut and an adapter to a 6.3 or 9 mm fitting. If you are going to connect several devices to the gearbox at the same time, then you need to choose the option with a threaded outlet, to which you will screw the manifold-distributor. For safety reasons, each collector outlet must be equipped with a separate valve that shuts off the pipe.

What's happened?

Car owners understand that the process of tightening the nuts on a wheel is quite complicated in itself. It is much easier to unscrew them using a tool. It is precisely in order to cope with such a problem that different types of wheel wrenches are provided, which help solve a task that requires great strength and skill.

Balloon rotary wrench

It is especially difficult to do this if the nuts have begun to become covered with a layer of corrosion, which connects them “tightly” with the studs. This problem is encountered due to the threaded connection, where moisture or other liquid can leak.

The fact is that there is a small gap inside the bolt where a layer of rust can form. After this, the nut will not give in easily if you try to remove it by hand. Another problem that a car owner may face is the destruction of studs during such operations.

After this, you will have to comprehensively solve the problem. If we talk about those who most often face this need, then we cannot fail to mention trucks - here corrosion forms at a higher rate.

To solve this problem, car owners purchase wheel cylinder rotary keys. With such a tool, the whole process is much faster and easier, and the risk of breaking the studs becomes minimal. Not long ago, a specific type of such wrenches appeared - impact wrenches, which help solve more complex problems.

Now they are used even in passenger cars. If we talk about the traditional type of tool, then the gearbox key is a plate with side parts (notches), as well as internal perforations. At the same time, it is manufactured to the dimensions of specific valve areas.

Different types of gear wrenches are used for different areas. Most often they can be seen when working on a car, if it is necessary to unscrew the nuts from the wheel. Moreover, all keys have a similar function - they are aimed at connecting and removing parts where great effort is required.

Planetary gear wrench

Sequence of installation and use

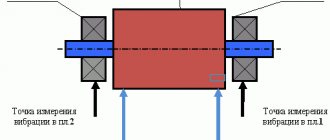

There are simple rules for installing and using the gearbox, but they must be followed strictly. Propane is a fire hazard and explosive under certain conditions. The lives and health of people, as well as material values, are at stake.

Before installation, it is necessary to inspect the reducer, cylinder and valve for mechanical damage, gas odor and extraneous sounds.

Propane reducer installation sequence

First, the propane adapter with the adjusting screw fully screwed is connected to the cylinder, then the consumer is connected to the reducer.

Next, the valve on the cylinder is partially opened. If there is no gas leakage through the connections and the gearbox housing, then the valve opens completely and the operating pressure is set using the adjusting screw, gradually releasing it.

Upon completion of work, disassembly is carried out. The cylinder valve is closed, then the consumer device is disconnected. The remaining propane from the hoses and the working chamber is released into the atmosphere. And finally, if necessary, the propane reducer is disconnected from the cylinder.

Mandatory Precautions

Before replacing the gas cylinder valve, precautions must be taken. Work must be carried out in such a way as to protect people from potential hazards and keep the equipment in working condition.

The following precautions are used when preparing to replace a gas valve:

- The remaining contents of the cylinder can only be vented in an open space. An exception can be made only for nitrogen, air and argon.

- The work area should be well ventilated, although it is advisable to carry out work outside.

- There should only be one closed gas cylinder within the workplace.

- The flywheel must be unscrewed slowly to prevent electrification.

- You can begin replacing the valve only after the pressure in the cylinder and outside has been completely equalized.

When screwing the valve into the cylinder, fum tape or special lubricants are used, which provide increased tightness and strength of the connection. When replacing a faucet, such seals greatly complicate the process of dismantling it. To solve this problem, you can heat the valve with a hairdryer.

You can heat the shut-off valves only after bleeding the gas from the cylinder and closing the tap. In this case, the procedure is safe and will not lead to unpredictable situations.

An alternative to a hairdryer is to wrap a cloth around the valve and then pour boiling water over it. With this heating method, any suitable plug should be screwed onto the outlet fitting to prevent water from entering there.

After taking all precautions and warming up the shut-off valves, you can begin to unscrew the valve, which can be a difficult task at home.

If, in addition to replacing the cylinder shut-off device, you also need to replace the valve installed on the gas pipeline, we advise you to study the procedure and rules for performing this work.

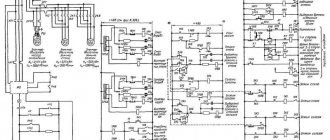

Purpose of the cylinder propane reducer BPO 5-2

The BPO 5-2 propane reducer is used to reduce and stabilize the pressure of household gas supplied from standard cylinders to consumers such as welding torches and cutters, heaters and a large number of other types of consumers.

Design and principle of operation of the propane reducer BPO 5-2

This propane reducer is built according to a single-chamber design; at the inlet it has a pipe with a threaded union nut for connection to the cylinder. The body is cast from aluminum alloy, the body cover is made of polyamide.

A special feature of the propane reducer is its small size and weight, which makes the BPO 5-2 convenient for transportation and storage.

Technical characteristics of propane reducer BPO 5-2

The propane reducer is produced by the oldest manufacturer of gas equipment in the country -:

Technical characteristics of gearboxes

- Weight 0.34 kg.

- Length × width × height 135 × 105 × 96mm.

- Operating temperature -15+45˚С.

- Maximum inlet pressure 25 kg/cm3.

- Working pressure 3 kg/cm3.

- Maximum gas consumption, 5 m 3 /hour.

- Connection method W 21.8-14 threads per 1″ LH.

- Working connection M16x1.5 LH.

Complete set of propane gas reducer BPO 5-2

Package Included:

- Propane reducer assembly.

- Technical certificate.

- Nipple for sleeve 6.3 or 9 mm.

- Package.

Safety precautions when working with propane reducer BPO 5-2

Propane is a source of increased danger. In order to consciously follow safety requirements, you need to understand exactly what threats the gas itself and the devices that use it pose:

Safety precautions when working with propane reducer BPO 5-2

- First of all, propane is flammable. Improper handling can cause a serious threat to the life and health of people, as well as material values.

- You can't breathe propane. A person dies in a propane atmosphere. If small amounts are inhaled, it causes poisoning, causing headaches and vomiting.

- Propane is explosive under certain conditions; when a certain concentration of propane in the air is reached, a volumetric explosion occurs. An explosion also occurs when the temperature in the cylinder rises sharply.

- When propane quickly leaks from a cylinder into the atmosphere, a strong drop in temperature occurs, which can lead to severe and deep frostbite.

Rules for working with a propane cylinder

To avoid these unpleasant consequences, the following rules must be observed when working with propane:

- Do not handle propane near open flames or high heat.

- Do not bring other flammable substances into the work area.

- Do not use materials that are chemically incompatible with propane, such as nitrates and perchlorates, near propane.

- Do not use gas equipment and fittings that have visible mechanical damage and signs of gas leakage.

Operating rules for propane reducer BPO 5-2

The operating rules contain, first of all, requirements for strict compliance with the safety measures listed above.

Each time before starting operation, it is necessary to inspect the propane reducer, connecting fittings, and supply hoses for mechanical damage and visible and audible signs of leakage. If such signs are detected, it is unacceptable to begin operation; damaged equipment must be repaired or replaced.

Rules for operating a propane reducer

If the pressure gauge needle does not move or, on the contrary, jumps at a constant gas flow rate, it is faulty and must be replaced.

It is also necessary to carefully monitor the timing of the scheduled verification of the pressure gauge of the propane reducer for compliance with the passport technical requirements. Such verification must be carried out by a special certified organization at least once every five years.

In addition, it is necessary to follow the procedure for connecting the propane reducer to the cylinder and to consuming devices. At least once a month you need to check the condition of the filter and clean it if necessary.

Gas cylinder volume

It is difficult to find an industry or household that does not use various gases. At production sites, gases are used for cutting and welding metals. In this article we will look at one of the characteristics of a gas cylinder - volume.

Gas cylinder volume

In everyday life it is used for cooking and heating homes.

To store and transport gases, containers made of metal or composite are used.

Gas cylinder device

A container for storing and transporting technical gas is a cylinder of a certain shape and volume, which has a hole in the upper part for installing a valve.

The delivery set of gas tanks includes:

- valve;

- prefabricated body consisting of a shell, upper and lower bottom. For the manufacture of vessels, high-quality steel or composite materials are used;

- shoe - a support designed to allow the container to be installed in a vertical position;

- protective cap is a cylinder design element that protects the valve from damage during transportation and operation.

Gas cylinder device

Sometimes a gearbox may be included in the package. This is what is called a pressure regulating device.

Gas leaves the cylinder through the valve. This device consists of a body made of metal, a valve, and a control steering wheel. The body is made in the form of a tee. One part is designed to install it in a container. The other one is for securing the control valve stem and the side one is for installing the plug.

The valve includes a stem and a valve. It is the valve that controls the movement of gas through the valve. The rod serves to transmit torque from the control wheel to the valve.

Internal contents of the gas cylinder

In fact, the cylinder resembles an ordinary lighter. Inside the container there is gas in two states of aggregation. In the lower part of the volume there is liquid, in the upper part there is gas.

In order to know what gas is in the cylinders, they are painted in different colors and marked with the name of the technical gas. For example, oxygen cylinders are painted blue and labeled “OXYGEN.”

Painted in different colors and marked with the name of the technical gas

Metal and composite gas cylinders

On the territory of our country there are several GOSTs regulating technical conditions for gas containers. In particular, GOST 949-73 regulates standards for steel vessels with a volume of 0.4 to 50 liters and operating at pressures from 9.8 to 19.6 MPa.

Metal cylinders are rightfully considered the optimal solution to the problem of storing and transporting technical gases. For the production of cylinders, low-carbon or alloy steel alloys are used. Cylinders are produced with a volume from 5 to 50 liters and a weight from 4 to 22 kg. Containers with a volume of 50 liters must be installed outdoors in a metal box specially made for this purpose. Containers with a smaller volume can be installed indoors, for example, in a garage or repair shop.

In addition to cylinders made of steel, products made of composites are used for storing and transporting gas.

They have the following advantages:

- Light weight, the difference between cylinders of the same volume can reach 70%.

- Increased resistance to shock loads. Explosion proof, even when exposed to open flame.

- The design of the composite cylinder is made in such a way that gas leakage is practically impossible.

- The polymer materials used in the manufacture of the cylinder eliminate the occurrence of corrosion and the formation of sparks.

- Composite vessels have an interesting appearance.

For the manufacture of cylinders of this type, fiberglass and epoxy resins are used.

It should be noted that over time the vessel may change its color, but this does not affect its performance properties.

To ensure the safe operation of polymer vessels, the following measures have been taken:

- Installing an overpressure relief valve.

- Installation of a melting insert.

As the temperature rises, the gas begins to increase in volume and, as a result, its excess is formed. They create excess pressure on the vessel. A safety valve is designed to eliminate excess pressure. It opens when a certain pressure level is reached.

Under the influence of elevated temperature, the pressure inside the vessel also increases, in this case the fuse-link is triggered. The insert will melt and form a hole through which excess gas escapes. But, after the fuse link has tripped, the container must be disposed of.

Containers of different volumes, made of composite materials, are designed to operate at temperatures from -40 to +60 degrees.

Design, volume and marking of gas vessels

The design, volume and marking of gas vessels are regulated by GOST 15860-84 (steel cylinders), GOST R 55559-2013 (composite vessels).

Specifications

The technical parameters of the vessel for storing and transporting certain volumes of gas are indicated in the technical passport. In particular, it should reflect the following data:

Technical characteristics of gas cylinders

- Serial number assigned to the vessel at the manufacturer;

- Actual volume in liters;

- The actual mass of the empty vessel in kilograms;

- Working and test pressure in atmospheres;

- Date of release and next re-examination;

- Code - the mark of the manufacturer or certified laboratory where the recertification was performed.

The amount of gas in a household cylinder is 50, 27, 12, 5 liters

There are certain relationships between the volume of a cylinder and its weight. So, 21.2 kg of gas can be stored in a 50-liter cylinder, and 2 kg of gas in a five-liter vessel.

The amount of gas in a household cylinder is 50, 27, 12, 5 liters

Rules for the safe use of gas cylinders

When operating compressed gas containers, certain safety rules must be observed.

Moving a gas cylinder

In particular, the following must not be allowed:

- Gas leaks through joints and threaded connections and the formation of an explosive mixture with air.

- Thermal effects on containers, which can lead to an increase in gas volume and pressure inside the container.

- Impact-type mechanical influences that can damage the walls of the container.

Technical characteristics of propane reducer BPO 5-3

The propane reducer BPO 5-3 is produced by Krass. While maintaining the operating principles common to a propane reducer, it compares favorably with the budget BPO 5-2:

- Weight 0.67 kg.

- Length × Width × Height 164 × 108 × 136mm.

- Operating temperature -15+45˚С.

- Maximum inlet pressure 25 kg/cm3.

- Working pressure, 4 kg/cm3.

- Maximum gas flow 5 m 3 /hour.

- Connection method W 21.8-14 threads per 1″ LH.

- Working output M16x1.5 LH.

Technical characteristics of propane reducer BPO 5-3

The propane reducer BPO 5-3 produced by Krass is deservedly considered not an amateur, but a professional device.

It should be noted that under the name BPO 5-3 Ridius produces its own propane reducer and is a subsidiary of the Vyritsa Metal Products Plant, however, the characteristics and case materials used by Ridius do not allow their products to be classified as professional.

Purpose of the cylinder propane reducer BPO 5-3

The BPO 5-3 propane reducer is used to reduce, stabilize and control the pressure of domestic gas supplied from standard cylinders to consumers such as welding torches and cutters, heaters and a large number of other types of consumers.

Complete set of propane gas reducer BPO 5-3

- assembled device;

- nipple for connecting hoses with a diameter of 6.3 or 9 mm;

- screw;

- product data sheet;

- packing box.

Complete set of propane gas reducer BPO 5-3

Advantages of the BPO 5-3 cylinder propane reducer

- precise setting of working pressure

- laser printing of parameters on the body

- ergonomic adjustment handwheel

- Manufacturer's barcode on the body simplifies accounting, logistics and order completion for the seller

Design and principle of operation of the propane reducer BPO 5-3

The propane adapter is made according to a single-chamber design, but is distinguished by a larger membrane area, a larger rod stroke and a larger flywheel size. All these design advantages allow you to more accurately set and regulate operating pressure.

The body of the propane reducer is made entirely of brass, which increases strength, reliability and extends service life

Operating rules for propane reducer BPO 5-3

The operating rules for a propane reducer do not differ from the rules for BPO 5-2

Safety precautions when working with propane reducer BPO 5-3

Safety measures also coincide with those for BPO 5-2, however, due to the higher operating pressure, it is necessary to carefully ensure that the permissible parameters are not exceeded - consumers.

Source

| p Thread pitch in (mm) | S Wrench nut size in (mm) |

| Value Parameter value | |

| Nominal thread diameter (d) | M27 |

| Thread pitch (p) | 3 (mm) |

| Wrench nut size (S) | 46 (mm) |

| Circumcircle diameter (e) | 50.9 (mm) |

| Nut height (m) | 24 (mm) |

| Thread direction | L.H. |

| Nut weight | 0.220 (kg) |

| Value Parameter value | |

| Connection length (l) | 26 (mm) |

| Outer diameter (d1) | 9 (mm) |

| Internal diameter (d2) | 6 (mm) |

| Weight of fitting | 0.115 (kg) |

Screwing in new shut-off valves

Before tightening the valve, all connected parts must be degreased to prevent clogging of the locking mechanism. To do this, you can use a cloth with regular detergent or moistened with white alcohol. After this, rinse the surfaces with plain water and allow them to dry.

A new valve is never screwed to a cylinder with bare threads. It is imperative to use a sealant: special thread compound or fluoroplastic fum tape. They are applied to the lower fitting and only after that the valve is tightened.

The thickness of the gas fum tape is greater than sanitary tape and is 0.1 - 0.25 mm, and its reel should be yellow. The tape is wound with tension in 3-4 layers. It is better to twist it once again when it breaks than to make the seal loose.

It is advisable to tighten the valve with a torque wrench. Steel shut-off valves are screwed with a maximum force of 480 Nm, and brass valves - 250 Nm. After clamping the valve, you can proceed to subsequent steps to test the tightness of the resulting connection.