What wire is used to tie reinforcement cages?

Knitting wire with diameters of 0.8, 1, 1.2, 1.4, 1.6, 1.8, 2 mm is used to connect reinforcing bars into flat and three-dimensional frames; the weight of 1 linear meter is in the range of 0.004-0.025 kg.

When carrying out reinforcing work, wire is used after annealing, which increases the ductility of the metal product. Depending on the method of heat treatment, products with a light or black surface are distinguished.

- Bright annealing. It is carried out in an environment of inert gases without the presence of oxygen. The surface of such products is clean, not contaminated with scale.

- Black annealing. Occurs in air, so there are oxides on the surface. Such wire gets very dirty on your hands, but its technical parameters do not differ from the properties of rolled products after bright annealing.

Wire without heat treatment has low ductility and breaks easily when knitting, so when using it, a large amount of waste is formed.

For use in aggressive environments, zinc-coated rolled steel is used. There are products with coating classes Ts1 and Ts2. The weight of 1 m of knitting wire with and without coating is assumed to be the same. To increase the service life of metal products, in addition to the zinc layer, polymer coatings of different colors are applied.

How much does a coil of tying wire weigh?

To determine the weight of a long-rolled coil, you need to know the footage and diameter of the wire. The mass of 1 m of a product is determined by its diameter in one of the following ways: using online calculators, using a table or using a formula. By multiplying the weight of 1 m of metal products by the number of meters, the total weight of the coil is obtained.

What does wire consumption depend on?

The consumption rate of tying wire per 1 ton of reinforcement ranges from 5 to 20 kg, and it takes from 20 to 50 cm to complete 1 knot. These indicators are influenced by such parameters as:

- Type of reinforcing structure.

- Diameter of fittings.

- The spacing of longitudinal and transverse elements.

- The diameter of the wire.

- Knitting tool.

- View of the connection node.

These parameters are individual for each design, and accordingly, the calculation of material consumption per ton is different for each.

Table of weights of binding wire of various diameters

| Diameter, mm | Weight 1 m, kg | Diameter, mm | Weight 1 m, kg | Diameter, mm | Weight 1 m, kg |

| 0,6 | 0,0022 | 2,0 | 0,0247 | 4,0 | 0,0986 |

| 0,8 | 0,00395 | 2,2 | 0,030 | 4,5 | 0,1249 |

| 1,0 | 0,00617 | 2,5 | 0,039 | 5,0 | 0,1541 |

| 1,2 | 0,00888 | 2,8 | 0,048 | 5,5 | 0,1865 |

| 1,4 | 0,0121 | 3,0 | 0,0555 | 6,0 | 0,222 |

| 1,6 | 0,0153 | 3,2 | 0,0631 | 6,3 | 0,2447 |

| 1,8 | 0,02 | 3,5 | 0,0755 | 7,0 | 0,3021 |

To determine the mass of 1 meter of long products, you can use the formula M = ρ*π*(d2/4) , in which:

- ρ – steel density, 7500 kg/m3;

- π – 3,14;

- d – diameter, m.

The standards indicate the minimum coil weight for binding wire of different diameters. So, for products with diameters of 0.6-1 mm without coating it is 5 kg, 1.1-2 mm - 8 kg, 2.2-3.6 mm - 12 kg, 4-6 mm - 30 kg. The maximum weight of the coil, determined by the standards, is 1500 kg. However, in each individual case, the mass of coils, coils and reels can be set by the customer. There is only one rolled section in one skein, and no more than three in a bay.

In addition to carrying out reinforcement work, long products made from low-carbon steels are used for the manufacture of masonry and plaster mesh, cages and enclosures for animals, tying goods, insulating heating mains, and in the construction of fences.

Technical characteristics of wire VR-1

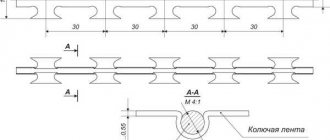

Metal products are produced from wire rod by cold drawing on specially shaped rolls. They provide the formation of corrugations necessary to improve the adhesion of the wire to the concrete.

A periodic profile is formed by dents diametrically located on the surface. Their depth is 0.15-0.25 mm, pitch is 2-3 mm. The starting material for the manufacture of VR-1 wire is low-carbon steel. Strength type – normal and increased. Standard diameters are 3.0, 4.0, 5.0 mm, but products with intermediate diameters of 2.5-4.8 mm can be manufactured according to specifications.

Weight of wire VR-1 according to GOST 6727-80

| Diameter, mm | Options | Steel grade used | Meter weight, kg | Meters per ton |

| 3 | Skeins | 1-3sp/ps | 0,052 | 19230 |

| 4 | Skeins | 1-3sp/ps | 0,092 | 10870 |

| 5 | Skeins | 1-3sp/ps/kp | 0,144 | 6944 |

Rolled products are sold in coils of 500-1500 kg or in smaller weights - 20-100 kg. The skeins may contain a bandage that divides them into 3-5 smaller elements. Russian manufacturers do not produce VR-1 wire in rods, since this is an energy- and labor-intensive process. In addition, regulatory documents require the production of VR-1 wire in coils. But at the request of the customer, manufacturers or trading companies unwind the coils and straighten them into rods 2-4 m long. The straightened products are connected into bundles weighing 0.1-0.5 tons.

Main product parameters

The wire used for tying reinforcement for concrete can be supplied to the customer in coils or wound on spools. In this case, the weight of such a skein or reel is specified by the requirements of the regulatory document. Thus, the standard states that the minimum weight of a skein or reel in which wire with a diameter of 1.1–2 mm is supplied should be:

- 2 kg (if the product has a zinc coating);

- 8 kg (without zinc coating).

High-quality wire has standardized rigidity and can withstand a greater number of bends

The consumer, by prior agreement with the manufacturer, can order skeins whose weight will be 0.5–1.5 tons. Only one piece of the product can be wound onto skeins of binding wire for reinforcement, regardless of their weight. Unlike skeins, spools can contain up to 3 such sections.

The shipping documents for a batch of binding wire for reinforcement indicate only the weight, and the length can only be determined approximately. The standard does not stipulate this parameter, and determining the length of the product in a coil or on a reel is also made more difficult by the fact that even the regulatory document states that the diameter of the wire supplied to the customer may differ from the nominal one downwards.

An example of an accompanying invoice for a batch of binding wire

Tolerances for maximum deviations in the diameter of a binding wire with a cross-sectional size of 1.1–2 mm, depending on the manufacturing accuracy, are in the range of 0.05–0.12 mm. In order to determine how many meters of a product there are in a coil, you must first find out what specific gravity it has (in other words, how much 1 linear meter of wire of a certain diameter weighs). A quick and accurate method for determining this parameter is to divide the mass of a pre-weighed piece of product by its length. To find out how many meters of knitting wire for reinforcement are in a skein, it is enough to divide the total weight of the skein by the resulting value.

Permissible deviations of wire diameter according to GOST

The second method for determining the total length of wire in a coil is purely calculational and allows you to calculate fairly approximate parameters. Knowing the nominal diameter of the wire in a coil, which may differ from the actual value of its cross-section in a larger direction, the weight of one meter of the product is determined by the formula. Taking into account these errors, the calculated weight of one meter of binding wire for reinforcement will be less than its actual value. This means that the actual length of the product in the skein will be greater than that obtained when performing calculations.

The error between the actual and calculated values will be even greater if the coil contains zinc-coated wire. In such cases, the increase in error is due to the fact that the density of zinc, which coats the surface of the wire, is less than that of steel (the density of steel is 7850 kg/m3, while the density of zinc is 7133 kg/m3). To accurately determine the length of galvanized wire in a coil, complex calculations are required taking into account the thickness of the protective layer, which can also vary along the entire length of the product. This is why such calculations will always produce values with varying degrees of accuracy.

Minimum weight of a piece of wire on a reel

In practice, to determine the weight of one linear meter of both coated and not coated with a protective layer of zinc binding wire for reinforcement, the same formula is used M = qx S xh, where:

- M – weight of one linear meter of wire, measured in kg;

- q is the density of the metal from which the wire is made;

- S is the cross-sectional area of the wire, measured in m2;

- h – product length.

The cross-sectional area of the wire, which is a circle of a certain diameter (d), is calculated by the formula S = 3.14 x d2/4.

As an example, let's calculate the length of a coil of knitting wire weighing 8 kg and having a diameter of 1.1 mm.

- Cross-sectional area: S=3.14 x 0.00112/4 = 0.00000095 m2.

- Weight of one linear meter of the product: M=7850 x 0.00000095 x 1 = 0.00745 kg.

- Length of wire in a coil: L=8/0.00745 = 1073 m.

Types of wire

The most widely used wire is steel. It is classified according to its scope and characteristic features:

- general purpose wire, material – low carbon steel (nail production),

- stainless steel wire, material – heat-resistant, corrosion-resistant alloy, hardware production;

- galvanized wire, material – galvanized steel, production of springs, cables, electrodes, etc., resistant to environmental influences, variety – rope wire for harsh operating conditions, spring – with high elasticity and strength,

- the reinforcing wire has a special surface shape that promotes stronger adhesion to concrete,

- knitting wire, material – low-carbon steel, feature – high ductility, produced by passing through a drawing machine.

How to write off wire?

How can I write it off? Answer: If the product will be used (in your case, tying wire) as a material for packaging, then it must be transferred from account 41 “Goods” to account 10 “Materials”. When transferring goods to materials, you will need an order from the manager.

Interesting materials:

How to register for a clinic using compulsory medical insurance? How to power a sconce from an outlet? How to pay for kindergarten through mobile Sberbank online? How to pay for school meals through Sberbank Online? How to fill out the Avon return form? How to fill a soul stone through the console? How to fill out a payment order 2022? How to fill the Great Soul Stone? How to refill HP Deskjet 2620 printer cartridge? How to refuel in GTA?

Requirements for wire mesh VR-1 according to GOST 23279-85

According to GOST 23279-85, welded flat mesh is sold in bags or rolls weighing no more than three tons. The roll is tied with knitting wire in three places, the package in four. The tags accompanying the rolls or bags contain information about the manufacturer, date of manufacture, weight in tons and batch number. There must be at least two such tags. They are located on different sides of the package or roll.

Products can only be stored in dry rooms with normal temperatures. Bags and rolls are stored horizontally on pallets. Packages can be stacked in stacks, the height of which does not exceed 2 m, rolls - no more than three pieces in height.