Welding machines are actively used for both industrial and domestic purposes. To perform the work, it is necessary to provide this equipment with electricity. To create a high-quality seam, the alternating current received from the network must be converted into the desired form. For this purpose, you need to use a diode bridge for the welding machine. The master must know why this is necessary and how the rectifier unit works.

Schematic diagram of a welding rectifier Source promkomrostov.ru

Energy conversion during welding machine operation

When connected to the network, the current first flows into a step-down transformer. An alternating electromagnetic field will excite a current in the secondary winding with the parameters required for the welding machine. It will have lower voltage and higher current.

It then passes through a rectifier unit, which will ensure that the current has the same polarity. In this case, significant pulsations will remain. To smooth them out, it will be passed through a capacitor unit. After it, the electricity used directly for arc welding will be largely stable in order to create a high-quality and reliable seam.

Scheme of operation of a diode bridge Source promkomrostov.ru

What is a Schottky diode

The Schottky diode belongs to the family of diodes.

It looks almost the same as its brothers, but there are slight differences. A simple diode looks like this in the diagrams:

diode designation on the diagram

A zener diode is already designated as a diode with a “cap”

Zener diode designation in the diagram

The Schottky diode has two “caps”

Schottky diode designation in the diagram

To make it easier to remember, you can add a head and legs and imagine a little man dancing a lambada)

Various types of welding rectifiers

Depending on the model, various schemes may be used for this purpose. The following types of rectifiers are used:

- Operating on the basis of a transformer.

- Built on the use of transistors that provide rectification and smoothing of the current.

- Diode bridges.

- Using a choke, which is designed to contain sudden surges in current and voltage.

- Based on the use of thyristors.

- Inverter converters, which increase the frequency, bring the current and voltage to the parameters required for operation.

The use of a diode bridge is considered one of the most effective methods of obtaining current with the parameters required for operation.

The following video describes how to assemble a diode bridge:

Definition

In simple terms, a diode bridge is a standard rectifier. It consists of several powerful power diodes connected into a single circuit. On the right is a diagram of a diode bridge. This is his standard scheme, which with experience can be modified to suit your needs. The diodes are attached to the radiators using bolts and nuts. This entire structure is under constant voltage and is designed to perform a simple but important role - to convert alternating current into pulsating current. This process is called straightening, which is why welding bridges are called rectifiers.

By the way, one of the most effective rectifiers is VD 306. It is manufactured by many factories and even the welders themselves make it with their own hands from improvised materials. Factory-made copies allow you to smoothly regulate the current, but at the same time they consume quite a lot of electricity - about 12 kilowatts, and weigh 100 kg. Agree, this is not a very convenient device for amateur welding in the garage. Therefore, it is used in workshops and factories. And at home, they use homemade rectifiers made from diodes or more compact devices. The use of diodes allows you to solve several problems at once:

- The diode bridge stabilizes voltage drops and helps devices with weak technical characteristics start up.

- The quality of the weld becomes better.

- The arc heals easier and faster, even if the device produces a low voltage reading.

- A diode bridge on the welding machine improves arc characteristics. It burns more stable and longer.

Video description

How to assemble a diode bridge

There are also other ways to classify welding equipment. The one that is based on the use of various types of characteristics is often used:

- Rectifiers, which are characterized by steep characteristics, are usually used for manual arc welding. They are also used for working with non-consumable electrodes in a special gas environment. Such a device is capable of creating radio interference, which is suppressed by using appropriate filters.

- Devices with rigid characteristics are used to work with electrodes that melt in carbon dioxide.

- Universal devices can be used for all types of welding work.

These devices must be distinguished by the strength of the current used. Power diodes are designed to operate in cases where it is significant. Industrial level welding machines designed for a three-phase voltage of 380 V can operate with a current of up to 400 A. For single-phase it is 125-180 A.

Operating principle of a welding machine circuit Source ice-people.ru

Application in practice

For example, consider the TELWIN Force 165 inverter device. The input rectifier uses GBPC3508 diode assemblies. The GBPC3508 bridge rectifier can operate with a current of 35 A, reverse voltage - 800 V.

Along with it comes a necessarily smoothing filter made of large capacitors. In addition, there is an electromagnetic compatibility filter that prevents interference from the inverter into the household network.

The output of the inverter uses powerful dual diodes with a common cathode. They have high performance, unlike diodes located at the input of the device.

Thanks to the short recovery time, less than 50 nanoseconds, the devices have time to switch the high-frequency current at the output of the secondary winding.

This device uses dual diodes STTH6003CW, FFH30US30DN or VS-60CPH03, designed for a forward current of 30 amperes for one device (60 amperes for both) and a reverse voltage of 300 volts.

Installed on the radiator. An RC filter is used to protect semiconductors from overload. The control circuit requires a stable power supply without voltage surges.

For this purpose, the device is equipped with zener diodes or a ready-made integrated stabilizer, which provide stable power to the control chips. The result is a compact device that allows high-quality welding of metal.

Pros and cons of using a diode bridge

In some devices, instead of using a diode bridge for a welding machine, a transformer is included in the design. The latter method provides lower quality work. A circuit with a diode bridge allows you to take advantage of the following advantages:

- With its help, the electric arc becomes more stable.

- Current rectification contributes to more economical energy consumption during operation.

- Relatively high efficiency.

- The rectifier not only converts current, but also stabilizes voltage. It allows the welding machine to operate reliably even in cases where the power grid is unstable.

- The amount of spatter is reduced during welding.

- Compared to using a transformer when using a diode bridge, the device has less weight and more compact dimensions.

- Carrying out welding work ensures higher reliability of the connection.

Welding rectifier disassembled Source ice-people.ru

However, the use of diode bridges also has the following disadvantages:

- The parameters of energy coming from the electrical network play an important role. The use of diode bridges puts forward certain stability requirements.

- Higher quality of work is associated with a small loss of power.

- Higher risk of short circuit.

- The use of this method causes an increase in the cost of equipment.

The use of diode bridges for rectification ensures higher welding quality.

The master must constantly monitor the performance of the device Source radioelementy.ru

Main characteristics

The main parameters that people pay attention to when choosing rectifiers for welding machines are:

- maximum permissible constant reverse voltage;

- maximum average forward current for the period;

- operating switching frequency;

- constant forward voltage at maximum forward current;

- maximum permissible case temperature.

The amplitude of the household network is about 310 V, so you need to use diodes with a reverse voltage of 400 V or higher. Direct current is strictly related to the power of the device, and attention is also paid to it. The operating frequency shows in which rectifier the semiconductor can be used, used in the network or output block of the inverter.

How to get the current needed for work

The power supply for the welding machine must meet the requirements of the specific model. There are 2 options:

- Single-phase voltage 220 V. It is often used to operate household welding devices. It provides a less uniform current compared to three-phase.

- Three-phase voltage 380 V. This option is often used when carrying out industrial welding. It is available for domestic purposes, provided that the owner can provide this opportunity. Such devices operate more stably and efficiently.

The frequency in both cases is 50 Hz.

The current regulator for welding is described in the video below.

Schottky diode in RF circuits

Schottky diodes also have fast switching speed. This means we can use them in high frequency (RF) circuits.

So, let's take a frequency generator and set the sine frequency to 60 Hz

Let's take a 1N4007 diode and a 1N5817 Schottky diode. Let's connect them using a simple half-wave rectifier circuit

and we will take evidence from them

As you can see, both of them do an excellent job of rectifying the signal at a frequency of 60 Hz.

But what happens if we increase the frequency to 300 kHz?

Wow! The Schottky diode more or less copes with its task, which cannot be said about a simple 1N4007 diode. A simple diode cannot cope with its task of not allowing reverse current to pass through, so we see a negative surge on the oscillogram

From this we can conclude: Schottky diodes are recommended for use in RF circuits.

Video description

CURRENT regulator for welding machine.

A voltage is supplied from the network, which varies according to a sinusoid. It cyclically becomes positive and negative. Entering the primary shell of the transformer, constant changes in current create an alternating electromagnetic field, which excites periodic fluctuations in voltage and current in the secondary winding. The difference is that at the transformer output the power consumption is reduced.

Then the current passes through the diode bridge. Since the input voltage varies according to a sinusoid, positive and negative pulses are received at the input, which alternate with each other. After passing through the diode bridge in the welding machine, the former remain unchanged, and instead of the latter, positive ones pass through, having the same amplitude. Thus, a strongly pulsating voltage of the same sign appears at the output.

In order to smooth out the pulsation, a capacitor unit is used for further processing. Its output produces a constant voltage with a high level of stability.

Diagram and view of a diode bridge consisting of 4 diodes Source radioelementy.ru

Welding Application

Any transformer DC welding machine or inverter contains power diodes. They are designed to rectify alternating current. To increase the efficiency, the diodes are connected in a bridge circuit, in which case both half-cycles fall on the load.

In a transformer welding machine, rectifier diodes are installed at the output of the secondary winding. Welding equipment has a step-down transformer; accordingly, the no-load voltage is significantly lower than the input voltage, so high-power and low-frequency devices are required here. B200 rectifier diodes (maximum current 200A) are suitable for this.

The welding inverter requires two rectifiers. One is located at the input of the power source. It converts alternating current 220 volts 50 Hz into direct current, which is further converted into alternating current of high frequency (40-80 kHz).

With a device power of 5 kW, the rectifier diodes should have a reverse voltage of 600-1000 V and an average forward current of 25-35 A at a frequency of 50 Hz.

The second rectifier is located after the high-frequency transformer. Here the requirements are different. The maximum forward current must be at least 200 A at a frequency of 80 kHz, and the reverse voltage must exceed the open circuit voltage (60-70 V).

In any case, diodes from the powerful category are used, with a platform for mounting a radiator, since without heat removal the device will quickly burn out.

How to choose

The most popular type of factory-made diode bridge is VD306. It is convenient in that it is equipped with the ability to perform smooth adjustments. It should be taken into account that during operation it consumes 12 kW of electricity. The weight of this device reaches 100 kg. This device is most convenient to use for industrial welding.

You can make a diode bridge with your own hands. It is made from power diodes. There can be from two to five of them in the scheme. A self-made diode bridge will cost less, but to create it, a specialist must have a professional understanding of the equipment.

A welding machine designed for three-phase voltage 380 V has the best performance characteristics. However, there is not always an appropriate power supply network available at the place of work. For example, if you need to carry out welding on a summer cottage, it is unlikely that you will be able to provide it with energy.

Such devices are heavier than those that use a single-phase network. The weight of the latter is in the range of 30-80 kg.

For reliable operation of a diode bridge, it is necessary that the voltage and current values used for which it is designed exceed the actual ones by 1.5-2 times. The maximum reverse voltage of the diodes used should be twice as high as that provided by the transformer. Powerful diodes for a welding machine are necessary for trouble-free operation.

Description of the operation of the diode bridge Source radioelementy.ru

Schottky diode reverse voltage

So, as you remember, a diode allows electric current to pass in only one direction, and in the other direction it blocks the passage of electric current to some critical value, called diode reverse voltage .

This value can be found in the datasheet

diode reverse voltage

It is different for each brand of diode

If this value is exceeded, a breakdown will occur and the diode will fail.

Safety instructions for use

Many types of welding diodes cannot work fully if there is excessive dust. Therefore, they need to be blown out before use. One of the most convenient means for this is using a household hair dryer. With its help, you can not only eliminate dust, but also remove moisture, which affects the electrical characteristics of the equipment. This purge must be carried out at least once a quarter.

Diode bridge for a welding machine Source prosvarku.info

If the welding machine has not been used for a year, it must be warmed up before use. To do this, the device is given the opportunity to work a little in all available modes. The time during which this preparation is carried out must be at least two hours.

During operation, the welding machine consumes a large amount of energy. It is important to ensure that it does not overheat. If its temperature exceeds the permissible level, you need to take a break from work.

It is necessary to check the presence of insulation on all conductive parts. If it is broken, it must be restored. The terminal connections must be secure. During operation, the welding machine must be grounded. If it overheats, one of the following may be the cause:

- There is a short circuit in the transformer winding.

- The cooling fan is not working at full speed.

- The core insulation is broken.

- Due to a malfunction in the secondary circuit of the transformer, the operating voltage is reduced.

If any malfunctions are found, they must be corrected before you start using the welding machine.

Repair of a welding rectifier Source kedrweld.ru

What types of devices are used in welding equipment?

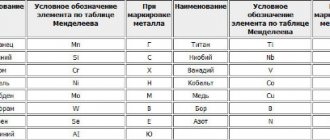

The segment of elements for process equipment - welding power diodes is presented in a variety of options that have unique characteristics and fundamental values for performing the action. Below we provide a detailed specification of diodes for welding equipment.

| Name | Purpose |

| LEDs | A special semiconductor that forms conditional optical radiation in the circuit during the passage of an effective electric current. |

| Rectifier | Internally, these components do not have any resistance (internal view). The amount of resistance will depend directly on the voltage supplied to the diode. |

| IR diode | Used for equipment in the technological part of welding, which provides for remote control of the operation of welding equipment. |

| Photodiodes | The basic principle of operation and direct operation of the component is to convert the light flux into an electrical type. |

| Zener diode | This option is used for a constant source of current supply. The main functional purpose is threshold, that is, achieving a certain voltage value for the device. There is a subcategory of stabistors, which are designed for low powers and voltages. |

| Varicaps (capacitive diode complexes) | The principle of operation of a diode for a welding inverter is similar to a capacitor device. The principle of the effective part of the work lies in the reverse voltage variant, at which the barrier component of the capacitive characteristics changes. |

| Schottky diodes | These types of diodes are characterized by a low voltage drop and a very high speed, which do not accumulate and do not absorb the main characteristics of drives. In the structural part, such diodes have the form of plates, which are covered with a special high-resistivity epitaxial molding film. The main material and component is a silicon base. Schottky diode components are typically used in switching circuits. |

| Thyristors | Two types and technological states are used - open or closed. For the closed method, low conductivity is acceptable, while for the open method, a high category of semiconductor conductivity is acceptable. The functional significance of the diode bridge of a welding inverter lies in the dynamic mode of constant transition from one state to another, moreover, under the influence of the main signal. |

| Immistors | They have a parallel connection option, which uses two thyristors. This option is used for devices with a variable voltage source. |

The main criterion for all types of diode designs is the current value. According to the system described above, there is a division into the following types of diodes, regardless of the name:

- Low power, with an indicator of up to 3 * 102 ma;

- Average power parameter – 3*102 ma – 10A;

- The maximum value is from 10 Amperes.