England, 1568: The Company of Mineral and Battery Works creates the world's first metal wire machine.

Another 350 years passed, and at the beginning of the twentieth century, also a representative of England, Harry Brierley, received stainless steel. It took four and a half centuries of inventions and discoveries for stainless steel products to come into use. Today, stainless steel wire is used in everyday life and in production, in medicine and electrical engineering.

What types of stainless wire do manufacturers produce?

Depending on the purpose and characteristics, stainless wire is classified into one of the following categories:

- The knitting machine is designed to perform packaging work, produce masonry mesh, ropes and chain-link mesh, and connect reinforcement when reinforcing concrete structures.

- The welding machine is used to perform semi-automatic or automatic welding.

- Cold-fretted material is used in the manufacture of mesh for fences and enclosures, electrical wires, and automobile parts.

- Spring is used for the manufacture of springs, pins, hooks and other products for which elasticity is important.

To prevent the mesh from acquiring this appearance, it is made of stainless wire

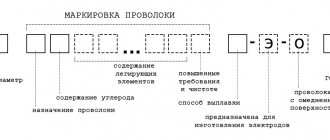

Labeling, packaging and storage

Stainless steel wire is produced in accordance with GOST 18143-72 from anti-corrosion, heat-resistant alloy steel with a cross-section from 0.2 to 7.5 mm. The marking of the wire determines its chemical composition, production technology and type of metal surface treatment. The numbers indicate the percentage of elements that determine the basic properties of the product. As an example, stainless steel wire 12Х18Н10Т:

- 12 – carbon content not more than 0.12%;

- X18 – chromium 18%;

- H10 – nickel 10%;

- T – titanium about 1%.

The presence of other elements, the content of which does not exceed 1%, is not indicated in the labeling. In the designation of cold-rolled stainless steel wire, the last one is indicated by the letter “X”. Oxidized stainless steel wire has a tarnished color and is marked with the letter “T”. Basically, this type of marking is applied to wire produced by heat treatment (hot rolled). Light-colored stainless steel wire without tarnish or oxides is designated “TS”. The letter “P” is added to the marking of a high-strength product. The plasticity class is indicated by the corresponding numbers: 1 – first, 2 – second.

Stainless steel wire requires careful handling during transportation and storage. Depending on the diameter, it is packaged in skeins or wound on reels and protected from mechanical damage with film or paper. Transportation is carried out mainly in covered vehicles. Stainless steel wire is stored in closed heated warehouses.

How is stainless steel made?

Stainless steel wire can be produced in two ways:

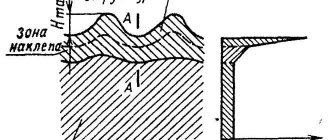

- Cold drawing. When using it, a steel workpiece is pulled through a special tool (die), in which a tapering hole (die) is made. The resulting wire is characterized by high surface cleanliness and accuracy of geometric dimensions, but is characterized by uneven properties from the periphery to the center of the cross section.

- Hot broaching. When using this method, the steel billet is pulled through a die at a temperature of 550–800 °C. Its main distinguishing feature is the uniformity of properties over the entire cross-sectional area.

Welding wire marking

The wire is produced by cold rolling and hot working. It has two types of accuracy - normal and increased. In the latter case, the letter P is placed in parentheses after the marking.

Stainless steel wire has two main markings - domestic and foreign.

Russian markings are alphanumeric - 10Х17Н13М2Т. The following order of letters and numbers indicates its internal structure and chemical composition. The numbers determine the percentage composition of a particular element, and the letter indicates the element itself. The abbreviation presented above is deciphered as follows:

- 0.1% carbon;

- chromium - 17%;

- nickel - 13%

- manganese - 2%

- The letter T means that the wire is produced by heat treatment.

The European standard is quite complex and does not have a single standard marking. Each steel manufacturer patents its composition.

Where is stainless steel used?

Stainless steel wire has a wide range of applications:

- One of the most important areas is welding of high-alloy steels in mechanical engineering (including for the manufacture of equipment for oil production and refining). For this purpose, cold-drawn wire of grades 12x18N10T, Sv-01x19N9, Sv-06x15N60M15 and others are used.

- In the food industry, the material is in demand due to its chemical inertness and hygiene. This makes contact with dishes and food safe.

- One of the useful characteristics of stainless wire is its resistance to chemically aggressive substances. This property allows it to be used in electrical engineering.

- Stainless steel wire is used in the manufacture of furniture as some structural elements. What is important here is its corrosion resistance, long service life and attractive appearance.

- The material is in demand in the manufacture of medical equipment. In particular, high-precision surgical instruments.

- Another area of application for stainless steel is the production of springs for the automotive industry.

From us you can buy stainless wire at manufacturer prices in the required quantity.

Quality requirements

Highly alloyed stainless wire contains from 0.01 to 0.24% carbon and more than 30% alloying elements. The basis is iron. The surface must be smooth without holes, nicks, delamination, cracks and clean - without film, scale and other contaminants. The surface of the wire may contain scratches, individual dents, local rippling, and scratches, including drawn ones. The presence of defects is allowed, the depth of which does not exceed the maximum deviation in accordance with the diameter of the section.

Quality control of stainless wire is carried out in several comprehensive ways, which include:

- Accurate control in accordance with GOST of the diameter of the rod and curl.

- Testing of finished products for deformation and rupture.

- Measuring the level of electrical resistance.

- Determination of the composition of the chemical elements of the steel used in the section.

Areas of application of stainless steel wire

Steel threads are used not only as consumables for welding equipment. They are used for the following purposes:

- production of springs, nets, filters and other structures;

- weaving of steel ropes and cables;

- manufacturing of high-precision medical devices;

- as reinforcing elements during construction work;

- creation of parts and components for household appliances.

Simple in design, stainless steel wire is an integral part of equipment, materials and mechanisms. The use of low-quality products has a negative impact on the service life.

Summing up

Welding wire for stainless steel comes in different sizes, characteristics, parameters, which, however, does not change its composition.

This composition should be similar to the one with which you are going to interact, which in turn will affect the final result of the welding work. When working with corrosion-resistant steel, do not neglect its refractoriness.

We will be glad if you tell us in the comments about your experience in welding work on corrosion-resistant steel using stainless filler wire and a semi-automatic welding machine.

Your experience can help many novice masters and more. We wish you success in your work!

Advantages and types

Stainless steel wire from ORINNOX is a popular material used in various industries and fields. This is due to its advantages:

- Resistance to corrosion processes arising due to exposure to moisture.

- Long service life.

- Elasticity and flexibility, heat resistance.

- Easy to use.

- High strength values with a small cross-section.

- Versatility - used in many areas.

- Affordable price.

According to the type of processing, stainless steel wire can be oxidized, copper-plated and light-colored (without oxidation). The use of additional coatings improves the physical characteristics of the product. The presence of an oxidized film allows the threads to conduct current with less resistance, which is why such blanks are used in the electrical industry.

Stamps

The blanks are made from corrosion-resistant steel grades 12Х13, 20Х13, 30Х13, 08Х18Н10, 12Х18Н10Т, 10Х17Н13М2Т and other high-alloy steels.

All of these materials are based on iron (Fe), carbon (C) and chromium (Cr). Some steels contain alloying elements, such as tungsten (W), molybdenum (Mo), which improve their properties. The amount of one or another component depends on the brand.

The chemical composition of these corrosion-resistant steels is given in the GOST 5632-72 standard.

Acceptance rules

Reception of products is carried out in batches, which should contain products of only one type and assortment. Based on the results, a report is drawn up containing the following information:

- name of the enterprise and its trademark;

- product labeling;

- batch number;

- summary results of the conducted admission tests;

- number of skeins or reels;

- total product weight.

The diameter and surface condition are checked for each unit of production . Physical properties and corrosion resistance should be tested on 5 percent of products.

If non-compliance with the requirements of the standard is detected even for a single indicator, extended control should be carried out on 10% of the samples that did not participate in the first stage of control. If inconsistencies are found in them, the batch will have to be checked completely.

Sales of products on the domestic market

Sales of stainless steel products are carried out directly by manufacturing enterprises and companies involved in rolling metal products. The sales features of such companies can be found in detail on various metal sales websites. A striking example of a large stainless steel seller is. It offers a wide range of stainless steel wire of various grades and sizes.

Stainless steel wire has a matte surface without traces of oxide stains on it. The maximum diameter will be 6 millimeters, the minimum is 0.3 millimeters. The AISI 321 model is considered the most used; the Russian analogue is steel 08Х18Н10Т, and 12Х18Н10Т is also close to it. This variety is characterized by heat resistance, high alloying, and meets industrial conditions in accordance with GOST 18143 −72.

According to the production method, the wire is divided into heat-treated and cold-drawn steel. Products made from cold-drawn stainless steel have a typical diameter in the range from 0.51 mm to 1.01 mm. For heat-treated products, the diameter will range from 0.3 to 6 mm.

Classification

Modern stainless wire is made not just from steel with a minimal level of corrosion. It is also always a high-level alloyed material that is resistant to strong heat. The universal long structure is easy to recognize - it looks like a thread or string. Mostly stainless steel wire has a circular cross-section. It is used in a variety of areas, therefore it is represented by a number of modifications.

Knitting wire is very popular. It is used to fix reinforcement - and it is not surprising that this material should not rust during normal use for as long as possible. The basic requirements are stated in GOST 3282-74. Experts have long noted that the thicker the reinforcement, the larger the cross-section of the wire used should be. It must be positioned as evenly as possible, because otherwise the loads will be distributed incorrectly.

But welding wire can also be stainless. This material is valuable because the finished weld also has excellent anti-corrosion properties. Basically, special steel fibers are used for fully or partially automated welding processes. It is useful both for working in an inert gas atmosphere and for welding powdered metal.

Cold-worked wire deserves special attention. It is needed to:

- make brushes for manual cleaning and various cleaning machines;

- produce metal fiber (one of the types of reinforcement for concrete);

- make cables and ropes;

- get simple springs;

- make parts for cars and trucks;

- form fences and other enclosing structures.

Stainless steel spring wire is made from steel with a high content of carbon additives. It is used when it is necessary to make particularly complex and important springs. The cross-section of the metal thread can be in the shape of a circle, oval or rectangle - depending on what is needed in a particular case. The fiber diameter ranges from 0.3 to 5 mm. If alloy steel is used, the largest diameter increases to 8 mm.

It is customary to distinguish the following types:

- hot rolled products;

- cold rolled products;

- light metal (free of oxides);

- oxidized products;

- copper-plated wire;

- products of normal and increased accuracy;

- wire of ductility categories 1 and 2.