Nichrome wire is a popular material that has already taken its place as a “traditional” one among many similar products. It is obtained thanks to an alloy of nickel and chromium.

If you are also looking for such an option, then simply enter nichrome wire to buy into your search query and then look through all the proposed products.

Examples of using nichrome wire for heating elements

Nichrome alloys are the main materials for the manufacture of heating elements. Nichrome wire or tape is necessarily used in such types of equipment as:

- kitchen appliances - stoves, ovens, food warmers, dishwashers, etc.;

- household appliances - irons, hair dryers, electric kettles, washing machines, boilers, etc.;

- laboratory equipment - autoclaves, drying ovens, rheostats;

- industrial units – roasting and drying furnaces;

- various electrical products.

For those who are interested in how to determine nichrome wire at home from the point of view of procuring recyclable materials, we can advise disassembling any heaters. They all contain nichrome.

True, you will not be able to divide it by grade, and scrap producers set reasonable prices depending on the nickel content in it. In this regard, industrial consumers of nichrome are in an advantageous position, as they can sort failed heating elements by alloy grade. The price difference between them can be large.

Examples of where you can get nichrome alloy

There are several ways to get nichrome. Each of them differs in the ease of obtaining and the quality of the material, but it is worth considering all possible options.

Ordering material

Nichrome, kanthal, nickel, and wire of some other alloys are sold in wholesale stores. The assortment provided by wholesalers is very large; you can order wire of any desired alloy of any cross-section and thickness. Relevant information about available stores can be found by calling the city's information service, or using an Internet search.

Even if the customer lives in a remote locality where the supplier’s organization is not located, you can request delivery, choosing the most convenient of the proposed options.

The caveat is that you will have to pay a considerable amount for delivery, and intermediaries send orders in large quantities and are unlikely to agree to supply a couple of meters of material.

Shopping in stores

Probably the most adequate option of all possible for those who require high-quality wire of a certain cross-section, especially when only a few meters of material are required.

Purchasing also has its options:

Pricing policy, features of receiving compounds based on nickel and chromium

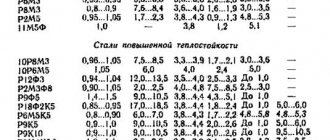

Nichrome is accepted by almost every scrap metal delivery point that handles non-ferrous raw materials. The cost of scrap is determined by the nickel content, which makes the X20N80 grade more valuable in the secondary metal market. According to GOST 10994-74, the percentage of Ni for the X15N60 compound is set in the range of 55 – 61%. For grade Х20Н80 nickel content: 73 – 78%.

Nichrome rod X20N80 8 mm thick

Therefore, before handing over nichrome, like any other nickel-containing alloy, you must make sure that the collection point is equipped with the appropriate equipment. Typically these are spectral analyzers that determine the exact percentage of nickel in a compound. This approach will ensure maximum efficiency in the sale of high-temperature alloy scrap; the profit received will clearly correspond to the content of the base metal.

The second factor that determines the price, regardless of the brand, is the thickness of the wire. The limit parameter is 3 mm, nichrome waste that does not overcome it is cheaper by an average of 20 rubles per kg.

Peculiarities

First of all, it should be noted that the high popularity of the heating cable is due to its impressive efficiency. It converts almost all electrical energy into heat, allowing you to minimize losses and achieve optimal consumption of available resources.

If we single out situations for which underfloor heating is considered the best solution, then their list will look like this:

- use of cold coatings (optionally, ceramic tiles);

- high level of humidity in rooms (most often these are bathrooms);

- inability to connect to central heating (relevant for dressing rooms and hallways, as well as insulated loggias and balconies);

- the need to heat suburban real estate.

Another remarkable feature of floors equipped with a heating cable is the ability to install them under a variety of types of coverings. It’s enough just to get acquainted with the principle of operation and arrangement of such heating systems, as well as with their main varieties.

Factors affecting the cost of scrap

Why does the price of nichrome vary significantly between different receivers? What does it depend on? Is it possible to get maximum benefit by studying the market and preparing your existing nichrome waste accordingly?

Nickel included in the alloy is an expensive raw material. In its pure form, it is present only in meteorites .

In deposits (you can count the open ones on one hand), nickel is presented in the form of ore with many impurities.

Recycling nichrome is economically beneficial. The higher the nickel content in the sample, the higher the acceptance cost. For each interest, on average, from 3 to 5 rubles .

An increase or decrease in the price of nickel on the stock exchange responds, albeit not instantly, to the assessment of secondary nichrome.

Demand for raw materials in a specific region. The more enterprises that consume nichrome scrap, the higher the purchase cost. In large industrial cities, the price per kilogram of alloy is higher (up to three times) than in the outback.

The type of nichrome being handed over also affects the cost.

We highlight the following types of nichrome scrap:

- wire;

- ribbon;

- rod;

- scrap of unknown origin at first glance.

At points where assessment is carried out for each type separately, new wire with a thickness of 3 mm .

Let's move on to the numbers:

| Type of secondary raw materials | Maximum price for 1 kg, rub. | National average price for 1 kg, rub. |

| Nichrome wire Х20Н80 (new) from 3mm | 800 | 360 |

| Nichrome tape Х20Н80 (new) | 800 | 360 |

| Nichrome rod Х20Н80 | 700 | 300 |

| Scrap | 600 | 280 |

The table shows approximate scrap prices per 1 kilogram for the most expensive brand of nichrome. For the X15N60 , prices are 20% lower.

The price of nichrome scrap per 1 kg in small points is lower than the cost indicated in the table, by approximately 20-25%.

Admission conditions and restrictions

When choosing a point for delivery of nichrome raw materials, you should pay attention to some information about the conditions for receiving a particular point.

The seller must pay attention to the following points:

- The maximum declared value refers to an alloy in which the nickel content approaches 80% , and scrap in its pure form (without dirt or chemical residues).

- Is there a limit on the weight of the batch (some have a minimum weight, for example, 500 kg). They will, of course, accept less, but the price will be reduced.

- What method is used to check the nickel content in raw materials (instrumentation).

What material is best for coils?

A novice vaper should start by making coils

from kanthal.

This is the most affordable and unpretentious material

for making

coils

. As a last resort - stainless steel. But it is worth remembering that the use of stainless steel requires maintaining low resistance when operating the mod.

Interesting materials:

Blanching - what is it in cooking? More or less what is this? A homeless person has settled in the building, where should I contact? Who is the husband's brother to the wife? Who is my husband's brother? Who is my sister's husband's brother? Who is my sister's husband's brother? Who is my sister's brother to my husband? Who is the wife's brother to her husband? Who is my wife's brother?

Progressive alloy in everyday life and industry, as a potential source of scrap

The service life of the alloy is set regardless of the brand and is at least 4000 hours. This is a low value, suggesting about six months with continuous use and about five years with a temporary workload of 10%. Naturally, in practice, the service life is determined by the homogeneity of the alloy, the thickness of the spiral and specific operating conditions. The relatively short service life of the material ensures regular replenishment of secondary nichrome volumes from parts of household heating appliances and industrial equipment.

Heat-resistant production equipment is not the only source of this alloy waste. The household use of heat-resistant compounds is quite wide:

- spirals of electric heating devices;