Wire is one of the most popular types of metal products. It can be steel, copper, titanium, aluminum, zinc, nickel and their alloys. There are both bimetallic and polymetallic wires. It is impossible to imagine electrical engineering without wire - but not only that.

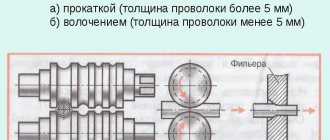

Steel wire is also needed in the production of springs, nails, electrodes, and drills. Although for such purposes it is not even the wire itself that is used, but its semi-finished product - steel wire rod. Let's see how it, and then the wire, is made from solid steel. Actually, wire rod is made in the same way as any other rolled product: the workpiece in the form of a bar (bloom) is heated to a state of “red softness”, and then passed through rollers, which they pull hot metal into wire rod with a cross-section of up to 10 mm. - and then goes to the winding machine, where it is laid in rings.

Responsible Cooling

After this comes the cooling stage of the wire rod. It can be natural (in this case, the wire rod receives the VO marking) and accelerated (UO marking).

Natural cooling produces a softer and more flexible wire rod (and then wire), while accelerated cooling produces a more rigid and elastic one. Industrial fan installations or water flows can speed up the cooling of the wire rod. With the first cooling method, the marking of the wire rod will indicate YO1, and with the second - YO2.

The rapidly cooled wire rod (intended for the production of wire in the future) is cleaned of scale, which should not be more than 18 kilograms per ton on the UO1 wire rod, and no more than 10 kg/t on the UO2 wire rod. Scale is removed either mechanically (then the wire rod is passed through a special descaling machine), or chemically, when the surface of the wire rod is etched with a solution of sulfuric acid with the addition of table salt, trisodium phosphate and other additives.

The chemical method gives a smoother surface, but it is also fraught with the acquisition of the so-called metal. "etching fragility". The mechanical method is safe in this regard, because - but it is less reliable and produces a rough surface.

What will be required for implementation?

The main tasks that need to be solved before launching an enterprise are the search and rental of premises, the purchase of equipment, raw materials, and the selection of qualified personnel.

The production of galvanized wire uses powerful equipment, including 4 main units:

- machines for pre-processing scrap or other raw materials containing metal, melting furnaces, dryers, that is, everything that is needed to prepare the raw materials for the manufacturing process;

- drawing mill, winder;

- device for galvanizing products. This includes an unwinder, a drying machine, instrumentation for control and computing measurements;

- main winder with reels of the required sizes, designed to prepare the wire for sale.

The Chinese line will cost less than analogues from Russia and Ukraine. The price of the equipment will be affected by its power and performance. A production line designed for the production of several types of wire in large volumes will cost at least 20,000,000 rubles. You can purchase a supported version. Its price will be almost half that.

It is also necessary to purchase office equipment and furniture for the administrative staff premises. Before opening an enterprise, you will need to register with the tax authorities and obtain the status of a business entity. You can register as an individual entrepreneur by selecting code from classifier 25.93 “Production of products from wire, chains and springs.”

But, if you plan to sell products among legal entities, then you need to register an LLC.

It is also necessary to obtain permits from Pozhnadzor and Rospotrebnadzor.

To open a small workshop, you can look for and rent an abandoned factory, or a production area in an industrial zone on the outskirts of the city. The amount of rent will be influenced by the condition of the premises, the presence or absence of the need for repairs, transport links and other factors.

For a workshop, it is necessary to rent a minimum of 300 m², and the rented area is divided into separate zones: workshops, warehouses for materials, finished products, premises for administrative personnel.

The total cost of raw materials and equipment to launch the enterprise will be about 15,800,000 rubles. Of them:

- production line – RUB 15,000,000;

- furniture, equipment for administration - 300,000 rubles;

- raw materials – 500,000 rub.

The number of personnel that will need to be hired for the job depends on the number of types of products produced. First of all, it will not be possible to start production without a professional technologist. To ensure stable and timely sales of finished products, it is necessary to form a staff of experienced marketers. Also, the workshop will not be able to work without a manager, foreman, auxiliary workers, production line operators, a storekeeper, and loaders. A company definitely needs an accountant.

You can sell your products wholesale or retail. A high-quality source of information and additional profit is your own website.

You can distribute business cards to hardware stores. Other printed information (flyers, booklets), advertisements in the media will be irrelevant. The most important thing is to gain regular customers and establish stable sales channels for products. To do this, you need to take care of promoting the enterprise with the help of employees. The marketing department will have to try to attract customers (conduct presentation demonstrations of products, develop a system of discounts for loyal, regular customers, etc.).

Advertising expenses will be at least 50,000 rubles.

Nails, bolts and GOST standards

Which method of cleaning wire rod is better? It depends on what they are going to make of it.

For nails, a workpiece with a smooth surface is required, but for the manufacture of fittings, electrodes or bolts, a rough one is also suitable.

In addition, specific defects may form on the surface of the wire rod intended for wire production - burrs or sunsets. Burrs are bulges that will be torn off and “rolled” during further operations (hence the name of another defect - rolls).

The properties of the metal in the wire rod are adversely affected by brewed bubbles - hairs - and “shrinkage cavities”, which occur if the metal was heated too much before rolling and therefore lost some of the carbon that “burned out” during calcination.

To check the quality, the wire rod is subjected to tests, the main one of which is the elasticity test. A quality wire rod can easily withstand a 180-degree bend around a pin that has the same diameter as the wire rod being tested. You can learn more about the requirements for such rolled metal products in GOST 30136–95.

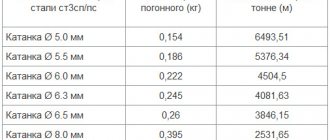

In this GOST, wire rod diameters of 5, 5.5, 6, 6.3, 6.5, 7, 8 and 9 mm are defined as standard and mandatory for all manufacturers. At the request of the customer, metallurgical enterprises can produce wire rod with a cross-section larger than 9 mm, but such orders are quite rare.

Due to technological features, the production of wire rod with a diameter of 8 mm is the cheapest - it is in greatest demand. Adds 8 mm “caliber”. and ease of calculation:

- one meter of wire rod with a diameter of 8 mm. has a mass of about 400 g (395 g to be precise),

— in a ton of such wire rod there will be 2531 meters (that is, 2.5 kilometers “with a small margin”).

These are very convenient numbers - they are easy to remember, you don’t need to look into special tables.

Financial calculations

Start-up capital

| Type of expenses | Amount, rubles |

| Paperwork | 5 000 |

| Renting premises | 100 000 |

| Production Line | 15 000 000 |

| Raw materials | 500 000 |

| Furniture, office equipment | 300 000 |

| 50 000 | |

| Total | 15 955 000 |

Monthly expenses

| Type of expenses | Amount, rubles |

| Rent | 100 000 |

| Taxes | 30 000 |

| Communal payments | 50 000 |

| Staff salaries | 500 000 |

| Raw materials for production | 200 000 |

| Fare | 20 000 |

| Total | 900 000 |

How much can you earn?

The price of the wire varies depending on the thickness of the product and its shape. For example, a wire with a diameter of 0.8 mm in a 110 m reel will cost the buyer approximately 250 rubles. Using the equipment, the enterprise can produce up to 8 tons of products every month.

As for the specific amount of net profit, in the first few months it will barely cover operating expenses. However, after six months, the initial investments will gradually begin to pay off, and the net profit minus monthly costs will range from 450,000 - 500,000 rubles. The most important thing is to find regular customers and eliminate the presence of finished products for a long time in the warehouses of the production workshop, ensuring the fastest possible sale of products.

Payback period

The payback period for the investment will be approximately 24-36 months.

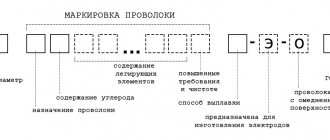

Delivery and labeling

The finished wire rod is wound into coils weighing at least 160 kg. Typically, each coil is a continuous piece, which is marked according to the requirements of GOST 7566. A marking is attached to each coil, which indicates the manufacturer, wire rod diameter, grade and grade of steel, and heat number. However, it is allowed to wind two sections of wire rod into one coil - but only if one section does not exceed 10% of the mass of the coil. In this case, the manufacturer must guarantee the weldability of the products and put two marking labels - one for each segment.

According to the technical conditions TU 14-15-254-91, wire rod according to TU is manufactured in 4 classes:

class VK - high-quality wire rod;

class VD - wire rod with high deformation;

class KK-quality wire rod;

class PD - structural wire rod.

Wire rod in business and production

Wire rod is considered a semi-finished product, but is quite widely used on its own. Steel wire rod serves as a means of fastening when transporting large-sized cargo by rail. It is also used to fasten load-bearing structural elements and reinforce reinforced concrete (the cheapest 8-mm wire rod is very suitable for this). Products with a thickness of 6.5 mm are used to strengthen brickwork, install lightning rods and make cables used in the construction of cable-stayed bridges. However, the main purpose of wire rod is still the role of an intermediate semi-finished product in the production of nails, welding electrodes, winding springs - and, of course, the production of wire.

Application areas of aluminum wire

Long aluminum thread has found wide application in various spheres of human activity.

Application of aluminum wire

Round wire is used as a welding material for manual, arc, argon and automatic welding. The aluminum seam protects the item from corrosion and thermal deformation. With minimal weight, metal ensures structural strength. These types of work are typical for construction, shipbuilding, mechanical engineering and aircraft construction.

Long aluminum cord is a universal fastening material. It is used in the manufacture of furniture. Springs, mesh, fittings, rivets, decorative parts made of aluminum - this is not the entire list of useful items made of rolled aluminum.

Food industry: cheese and sausage production.

Wire is closely related to the electrical industry. These are antennas, different types of cables and wires for laying power lines, electrodes, communications. Hardware, drills, springs, and electrodes are made from wire.

Metal thread is indispensable in the production of parts for chemical industry equipment and high-tech devices.

Aluminum is used in a very large number of different industries

Aluminum tape is used in various sectors of the modern national economy: for welding, electrical wiring, construction of structures that come into contact with a humid environment.

Wire is used to make decorative items, souvenirs, and jewelry, which can be separate items or part of the interior. Wire weaving is a modern form of creativity.

Long material has found application in landscape design, in the manufacture of gazebos, benches, and fences.

Aluminum wire has unique technical characteristics. It is a multifunctional metal that helps implement innovative projects in science and technology.