Hot rolled sheet

- /

- home

- Rolled metal

- Sheet metal

/

/

GOST 19903-74

Hot-rolled sheets GOST 19903-74

Upon delivery, hot-rolled sheets are divided into:

*sheets;

*rolls.

The standard applies to hot-rolled sheets with a width of 500 mm or more, manufactured in sheets with a thickness of 0.4 mm to 160 mm and rolls with a thickness of 1.2 to 12 mm.

Hot-rolled sheets in the warehouse of the MetalTechService Company are presented in the following assortment, steel grades st3sp/ps, st.09G2S, st.20, st.45, etc.:

| Size, mm | Opening, mm |

| 2 | 1250x2500 |

| 3 | 1250x2500; 1500x3000; 1500x6000 |

| 4 | 1500x3000; 1500x6000 |

| 5,6,7,8,10,12 | 1500x3000; 1500x6000 |

| 14,16 | 1500x3000; 1500x6000 |

| 18,20,22,25 -160 | 1500x3000; 1500x6000 |

To independently calculate the mass of the sheet, use the following information:

Weight of 1 square meter of sheet (based on the specific gravity of 7.85 g/cm3)

| Thickness (mm) | 0,5 | 0,55 | 0,6 | 0,7 | 0,8 | 0,9 | 1,0 |

| Weight kg/m2 | 3,925 | 4,32 | 4,716 | 5,5 | 6,28 | 7,06 | 7,85 |

| Thickness (mm) | 1,2 | 1,4 | 1,5 | 1,7 | 1,8 | 1,9 | 2,0 |

| Weight kg/m2 | 9,42 | 10,99 | 11,77 | 13,34 | 14,13 | 14,91 | 15,7 |

| Thickness (mm) | 2,5 | 3,0 | 3,5 | 4,0 | 5,0 | 6,0 | 7,0 |

| Weight kg/m2 | 19,62 | 23,55 | 27,47 | 31,4 | 39,25 | 47,1 | 54,95 |

| Thickness (mm) | 8,0 | 9,0 | 10 | 12 | 14 | 16 | 18 |

| Weight kg/m2 | 62,8 | 70,65 | 78,5 | 94,2 | 109,9 | 125,6 | 141,3 |

| Thickness (mm) | 20 | 22 | 25 | 30 | 40 | 50 | 60 |

| Weight kg/m2 | 157 | 172,7 | 196,25 | 235,5 | 314 | 392,5 | 471 |

| Category | steel grade |

| 1 | St0, St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St5ps, St5sp, St5Gps |

| 2 | St2kp, St2ps, St2sp, St3kp, St3ps, St3sp, St3ps, St3sp, St5Gps |

| 3 | St3kp, St3ps, St3sp, St3Gps, St3Gsp, St4ps, St4sp |

| 4 | St3ps, St3sp, St3Gps, St3Gsp |

| 5 | St3ps, St3sp, St3Gps, St3Gsp |

| 6 | St3ps, St3sp, St3Gps, St3Gsp |

Hot rolled sheets, GOST 19903-74

This standard applies to hot-rolled sheets with a width of 500 mm or more, manufactured in sheets with a thickness of 0.4 to 160 mm and rolls with a thickness of 1.2 to 12 mm.

The standard fully complies with ST SEV 1969-79 for structural unalloyed rolled products of ordinary quality and low alloy with a thickness of 1.00 to 2.80 mm in sheets and rolls and ST SEV 3901-82 for rolled products with a thickness from 3.00 to 160 mm in sheets .

Rolled sheets are divided into:

a) in terms of rolling accuracy for thicknesses up to 12 mm:

increased accuracy - A; normal accuracy - B;

b) by flatness:

- especially high flatness - PO;

- high flatness - PV;

- improved flatness - PU;

- normal flatness – PN;

c) by the nature of the edge:

- with unedged edge - BUT;

- with edged – O;

d) by size:

- indicating the dimensions of thickness, width and length;

- indicating dimensions by thickness;

- indicating dimensions that are multiples of the width and length of the dimensions specified in the order;

- indicating the measured dimensions.

At the request of the consumer, the thickness difference in rolled products produced in rolls in one cross section should not exceed half the sum of the maximum deviations in thickness.

Maximum deviations in the width of rolled products with cut edges, manufactured in rolls, must not exceed:

+ 5 mm – with a width from 500 to 1000 mm inclusive;

+ 10 mm – for widths over 1000 mm.

Maximum deviations in the width of rolled products with cut edges, manufactured in sheets, should not exceed the standards specified in table. 1.

| Rolled width, mm | Rolled thickness, mm | Maximum deviations for the width of rolled products |

| Up to 800/over 800 | up to 3.9 | +6/+10 |

| Up to 1500/over 1500 | 3.9 to 16 | +10/+15 |

| All widths | 16-60/60-100/100-160 | +25/+50/+75 |

For sheets over 8 m with a thickness of up to 12 mm, maximum deviations in width should not exceed 0.2% of the length.

By agreement with the consumer, maximum deviations in the width of rolled products with cut edges, manufactured in sheets, should not exceed:

+ 5 mm – for widths up to 1000 mm inclusive;

+ 10 mm – for steel widths over 1000 mm.

Maximum deviations in the width of sheet metal, rolled sheet-by-sheet and manufactured with an unedged edge, should not exceed by more than 50 mm the maximum deviations in width specified in Table 1.

By agreement between the consumer and the manufacturer, other maximum deviations are allowed to ensure that the consumer receives sheets with the dimensions specified in the order.

Maximum deviations in the width of rolled products rolled on continuous mills and manufactured with uncut edges must not exceed:

+ 20 mm – for widths up to 1000 mm;

+ 30 mm – for widths over 1000 mm.

Maximum deviations along the length of rolled sheets must not exceed the standards specified in Table 2.

| Rolled length, mm | Rolled thickness, mm | Maximum deviation along the length of rolled products, mm |

| Up to 1500 / Over 1500 | up to 3.9 | +10/+15 |

| Up to 2000 / Over 2000 up to 6000 | 3.9 to 16 | +10/+25/+35 |

| Up to 3000 / St 3000 to 6000 | 16 to 60 | +15/+25/+40 |

| All lengths | 60 to 100 >100 >160 | +50/+75 |

Maximum deviations along the length of rolled products rolled on continuous mills and cut into sheets must not exceed the standards specified in Table 3.

| Rolled length, mm | Rolled thickness, mm | Maximum deviation, mm |

| Up to 1500 / Over 1500 | up to 3.9 | +15/+20 |

| Up to 4000 / Over 4000 | 3,9 | +20/+25 |

Deviations from flatness per 1 m length of rolled products manufactured in sheets should not exceed the following standards:

a) Particularly high flatness

- Sheet thickness 0.4-1.4 mm – 8 mm.

- Sheet thickness is 1.5-3.9 mm. – 8 mm.

- Sheet thickness 4 mm or more – 5 mm.

b) High flatness

- Sheet thickness 0.4-1.4 mm – 10 mm.

- Sheet thickness is 1.5-3.9 mm. – 10 mm.

- The thickness of sheets 4 mm and more is 8 mm.

c) Improved flatness

- Sheet thickness 0.4-1.4 mm – 15 mm.

- Sheet thickness is 1.5-3.9 mm. – 12 mm.

- Sheet thickness 4 mm or more – 10 mm.

d) Normal flatness

- Sheet thickness 0.4-1.4 mm – 20 mm.

- Sheet thickness is 1.5-3.9 mm. – 15 mm.

- The thickness of sheets 4 mm and more is 12 mm.

Rolled sheets with particularly high flatness are produced by agreement between the consumer and the manufacturer.

When producing rolled products in sheets and rolls with uncut edges, tears and other defects (if they are present on the edges) should not exceed half of the maximum deviations in width and lead the sheets beyond the nominal size along the width specified in the order. Rolled products produced in rolls should not have twisted and crumpled ends. Curved edges at an angle of no more than 90 degrees are allowed in some places.

The telescopicity of rolled products produced in rolls should not exceed the following standards:

— for rolled products up to 2.5 mm thick and up to 800 mm wide – 50 mm.

— for rolled products up to 2.5 mm thick and over 800 mm wide – 100 mm.

- for rolled products with a thickness of over 2.5 mm and a width of up to 800 mm - 35 mm.

— for rolled products with a thickness over 2.5 mm and a width over 800 mm – 70 mm.

According to the agreement between the manufacturer and the consumer, the telescopicity of rolled products in rolls up to 2.5 mm thick, width St. 800 mm should not exceed 70 mm. The excess of one internal or one external turn above the surface of the roll end is not telescopic. A loose fit between the two outer turns of the roll is allowed.

The thickness of rolled products is measured:

- on sheets - at a distance of at least 100 mm from the ends and at least 40 mm from the edges;

- on rolls - at a distance of at least 40 mm from the edges and at least 2 m from the end of the roll.

The width of rolled products produced in rolls is measured at a distance of at least 2 m from the end of the roll. Partial width ends should not exceed the width of the roll. At the request of the consumer, ends of partial width must be trimmed.

Rolled products may consist of no more than two pieces (separate or connected by a weld). The length ratio of the roll should not be less than 1:5. In agreement with the consumer, rolls with a large number of pieces or welds are produced.

The internal diameter of the roll must be no less than 650 mm and no more than 1000 mm. The maximum weight of each roll should not exceed 20 tons. By agreement between the consumer and the manufacturer, rolls of other weights are allowed.

back to list

Sheet metal

This type of metal products includes metal sheets intended for the manufacture of welded pipes and structures, bent profiles, ship hulls, chemical and heat exchange equipment, car bodies, aircraft and carriages, electrical cabinet housings, electronic machines, refrigerators and many other products. Metal sheet provides optimal solutions to structural problems while minimizing metal costs.

Sheet steel is divided into:

Production method:

- hot rolled;

- cold rolled.

By thickness.

- From 0.5 to 3.9 mm - thin sheet;

- From 4 to 160 mm - thick sheet.

By type of delivery:

- sheets;

- rolls.

Hot rolled sheet steel

Hot-rolled sheet of ordinary quality

- Plate steel (thickness 4-160mm)

Manufactured according to GOST 14637-89 PDF.

The assortment must comply with GOST 19903-74 PDF.

Chemical composition

steel must comply with GOST 380 PDF.

By type of product, rolled products are manufactured:

- in sheets from 4 to 160mm;

- in rolls from 4 to 12mm.

According to standardized characteristics, it is divided into 6 categories: 1-5 in the hot-rolled state, 6th in the hardened state.

According to rolling accuracy:

- A - increased accuracy;

- B - normal accuracy.

By flatness:

- PO - especially high flatness;

- PV - high flatness;

- PN - normal flatness.

By the nature of the edge:

- BUT - with unedged edge;

- O - with trimmed edge.

- Thin sheet steel (thickness 0.5-3.9mm)

Manufactured according to GOST 16523-89 PDF.

The assortment must comply with GOST 19903-74 PDF.

The chemical composition of steel must comply with GOST 380 PDF.

By type of product it is divided into:

- sheets (with cut edge);

- rolls (with unedged and trimmed edges);

According to standardized characteristics, there are 5 categories.

According to the minimum value of tensile strength (B) for strength groups: OK300V, etc. , where OK - ordinary quality; 300 - corresponds to the lower limit of tensile strength).

According to the quality of surface finishing into groups:

- III - enhanced finishing;

- IY - regular finish.

Low alloy hot-rolled sheet.

Rolled sheets of low-alloy steel are manufactured in accordance with GOST 19281-89 PDF with a thickness of 4-60 mm.

Depending on the type of metal product and thickness, low-alloy hot-rolled sheets are made from steel grades: I09G2, 09G2S, 09G2S-12, 17G1S, 17G1SU, 10HSND.

The chemical composition must comply with GOST 19281-89 PDF.

Rolled sheet and low-alloy steel are produced in the following strength classes: 265, 295, 315, 325, 345, 355, 375, 390, and 440.

The surface, requirements for the edges and ends of this sheet metal must comply with GOST 14637-89 PDF.

This type of product is used for welded, riveted or bolted structures in products, mainly without additional heat treatment.

High-quality hot-rolled structural sheet.

- Plate steel.

Manufactured according to GOST 1577-93 PDF with a thickness of 4-160 mm.

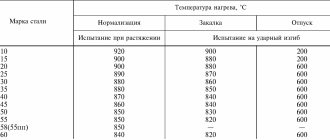

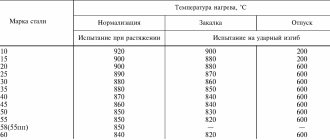

Depending on the type of metal product and thickness, high-quality hot-rolled structural sheets are made from steel grades:

sheet thickness 4-160mm: St08(kp,ps); St10(kp, ps), St15(kp, ps), St20(kp, ps), St25, St30, St35, St40, St45 (high-quality carbon structural steel).

sheet thickness 4-80 mm: St50, St55, St60 (high-quality carbon structural steel); 65, 70, 60G, 65G, 70G (spring carbon and alloy steel), 15G, 20G, 30G, 40G, 50G, 10G2, 35G2, 20Х, 30Х, 38ХА, 40Х, 45Х (structural alloy steel).

The chemical composition must correspond to:

- high-quality structural carbon steel - GOST 1050-88 PDF;

- alloyed structural steel - GOST 4543-71 PDF;

- carbon and alloy spring steel - GOST 14959 PDF.

Depending on the standardized characteristics, rolled products are produced in three categories:

- 1 - by chemical composition;

- 2 - by chemical composition and hardness;

- 3 - in terms of chemical composition, mechanical properties and hardness - for sheets up to 80 mm thick and strips.

Sheet metal up to 80mm thick is produced:

- without heat treatment;

- heat-treated -T (annealed, normalized, highly tempered).

- Thin sheet steel

Manufactured according to GOST 16523-89 PDF with a thickness of up to 3.9 mm inclusive.

The assortment must comply with GOST 19903-74 PDF.

Rolled products are made from steel grades: 08(kp,ps), 10(kp,ps), 15(kp,ps), St20(kp,ps), St25, St30, St35, St40, St45.

The chemical composition of steel must comply with GOST 1050-88 PDF.

By type of product it is divided into:

- sheets (with cut edge);

- rolls (with unedged and trimmed edges).

According to standardized characteristics, there are 6 categories.

According to the minimum value of tensile strength (B) for strength groups: K260V, etc. , where K is qualitative; 260 - corresponds to the lower limit of tensile strength)

According to the quality of surface finishing into groups:

- III - high finish;

- IY - regular finish.

Rolled products are produced by heat treatment, with an etched and unetched surface.

Buy from METALLSERVICE

home

>

GOSTS AND TU

> Hot rolled sheet