Application of hot rolled steel strip

Most often, hot-rolled steel strip is used in mechanical engineering and other construction fields. It can be an element of most different metal structures, both assembled by welding and using threaded connections. From metal structures it can be:

- Frame structures;

- Railings, gratings, fences;

- Visors;

- Flooring;

- Awnings;

- Frame structures, etc.

In mechanical engineering, hot-rolled strip is used to produce all kinds of parts for machines and units. It is also a material for the manufacture of other rolled metal products, such as channels and bent steel angles. It has also found application in the manufacture of electric-welded pipes.

Springs, nuts, covers, linings, etc. are produced on the basis of a metal strip. The most important application of steel strip is its use for grounding buildings.

Other areas of application of steel strip:

- Aircraft manufacturing;

- Shipbuilding;

- Architecture;

- Electric power industry;

- Design and instrumentation;

- Bridge construction;

- Furniture industry and forging.

The strip is also used in everyday life: various types of fasteners and kitchen utensils are produced.

Row strips for the production of metal structures

Such strips are produced in a measured length - 6 meters, but there may be exceptions, an unmeasured length - 2.5-6 meters. The size range of such strips of width and thickness is as follows: 60×5, 60×4, 50×5, 50×4, 40×4, 30×4, 20×4, 16×4. They have stripes of the second class of crescent shape and are of ordinary accuracy, that is, class “B”.

Construction stripes

The size range of such strips, relative to width and thickness: 150×8, 120×8, 100×10, 100×8, 1000×6, 80×10, 80×8, 80×6, 60×10, 60×8, 60× 6. According to GOST 103-2006, the marking of this type of rolled metal may contain the following letter designations:

- BC - have the usual sickle shape;

- VSh - have normal accuracy relative to width;

- VT - normal accuracy in product thickness;

- OH - general purpose.

Band

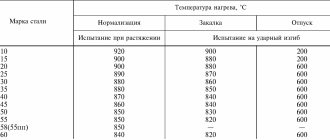

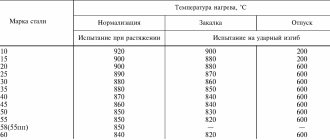

Table 1. Theoretical weight of 1 m of rectangular strip according to GOST 103–76 (thickness 4–18 mm)

| b,mm | Thickness, a, mm | ||||||||||||

| 4 | 4,5* | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 | 18 | |

| 11 | — | 0,387 | 0,432 | — | — | — | — | — | — | — | — | — | — |

| 12 | 0,377 | 0,424 | 0,471 | 0,565 | 0,659 | 0,754 | — | — | — | — | — | — | — |

| 14 | 0,440 | 0,495 | 0,550 | 0,659 | 0,769 | 0,879 | — | — | — | — | — | — | — |

| 16 | 0,502 | 0,565 | 0,628 | 0,754 | 0,879 | 1,005 | 1,130 | 1,256 | — | 1,507 | — | — | — |

| 18 | 0,565 | 0,636 | 0,707 | 0,848 | 0,989 | 1,130 | 1,272 | 1,413 | — | 1,696 | — | — | — |

| 20 | 0,628 | 0,707 | 0,785 | 0,942 | 1,099 | 1,256 | 1,413 | 1,570 | 1,727 | 1,884 | 2,198 | 2,512 | — |

| 22 | 0,691 | 0,777 | 0,864 | 1,036 | 1,209 | 1,382 | 1,554 | 1,727 | 1,900 | 2,072 | 2,418 | 2,763 | 3,109 |

| 25 | 0,785 | 0,883 | 0,981 | 1,178 | 1,374 | 1,570 | 1,766 | 1,963 | 2,159 | 2,355 | 2,748 | 3,140 | 3,533 |

| 28 | 0,879 | 0,989 | 1,099 | 1,319 | 1,539 | 1,758 | 1,978 | 2,198 | 2,418 | 2,638 | 3,077 | 3,517 | 3,956 |

| 30 | 0,942 | 1,060 | 1,178 | 1,413 | 1,649 | 1,884 | 2,120 | 2,355 | 2,591 | 2,826 | 3,297 | 3,768 | 4,239 |

| 32 | 1,005 | 1,130 | 1,256 | 1,507 | 1,758 | 2,010 | 2,261 | 2,512 | 2,763 | 3,014 | 3,517 | 4,019 | 4,522 |

| 36 | 1,130 | 1,272 | 1,413 | 1,696 | 1,978 | 2,261 | 2,543 | 2,826 | 3,109 | 3,391 | 3,956 | 4,522 | 5,087 |

| 40 | 1,256 | 1,413 | 1,570 | 1,884 | 2,198 | 2,512 | 2,826 | 3,140 | 3,454 | 3,768 | 4,396 | 5,024 | 5,652 |

| 46 | 1,444 | 1,625 | 1,806 | 2,167 | 2,528 | 2,889 | 3,250 | 3,611 | 3,972 | 4,333 | 5,055 | 5,778 | 6,500 |

| 50 | 1,570 | 1,766 | 1,963 | 2,355 | 2,748 | 3,140 | 3,533 | 3,925 | 4,318 | 4,710 | 5,495 | 6,280 | 7,065 |

| 55 | 1,727 | 1,943 | 2,159 | 2,591 | 3,022 | 3,454 | 3,886 | 4,318 | 4,749 | 5,181 | 6,045 | 6,908 | 7,772 |

| 56** | 1,758 | 1,978 | 2,198 | 2,638 | 3,077 | 3,517 | 3,956 | 4,396 | 4,836 | 5,275 | 6,154 | 7,034 | 7,913 |

| 60 | 1,884 | 2,120 | 2,355 | 2,826 | 3,297 | 3,768 | 4,239 | 4,710 | 5,181 | 5,652 | 6,594 | 7,536 | 8,478 |

| 63 | 1,978 | 2,225 | 2,473 | 2,967 | 3,462 | 3,956 | 4,451 | 4,946 | 5,440 | 5,935 | 6,924 | 7,913 | 8,902 |

| 65 | 2,041 | 2,296 | 2,551 | 3,062 | 3,572 | 4,082 | 4,592 | 5,103 | 5,613 | 6,123 | 7,144 | 8,164 | 9,185 |

| 70 | 2,198 | 2,473 | 2,748 | 3,297 | 3,847 | 4,396 | 4,946 | 5,495 | 6,045 | 6,594 | 7,693 | 8,792 | 9,891 |

| 75 | 2,355 | 2,649 | 2,944 | 3,533 | 4,121 | 4,710 | 5,299 | 5,888 | 6,476 | 7,065 | 8,243 | 9,420 | 10,60 |

| 80 | 2,512 | 2,826 | 3,140 | 3,768 | 4,396 | 5,024 | 5,652 | 6,280 | 6,908 | 7,536 | 8,792 | 10,05 | 11,30 |

| 85 | 2,669 | 3,003 | 3,336 | 4,004 | 4,671 | 5,338 | 6,005 | 6,673 | 7,340 | 8,007 | 9,342 | 10,68 | 12,01 |

| 90 | 2,826 | 3,179 | 3,533 | 4,239 | 4,946 | 5,652 | 6,359 | 7,065 | 7,772 | 8,478 | 9,891 | 11,30 | 12,72 |

| 95 | 2,983 | 3,356 | 3,729 | 4,475 | 5,220 | 5,966 | 6,712 | 7,458 | 8,203 | 8,949 | 10,44 | 11,93 | 13,42 |

| 100 | 3,140 | 3,533 | 3,925 | 4,710 | 5,495 | 6,280 | 7,065 | 7,850 | 8,635 | 9,420 | 10,99 | 12,56 | 14,13 |

| 105 | 3,297 | 3,709 | 4,121 | 4,946 | 5,770 | 6,594 | 7,418 | 8,243 | 9,067 | 9,891 | 11,54 | 13,19 | 14,84 |

| 110 | 3,454 | 3,886 | 4,318 | 5,181 | 6,045 | 6,908 | 7,772 | 8,635 | 9,499 | 10,36 | 12,09 | 13,82 | 15,54 |

| 120 | 3,768 | 4,239 | 4,710 | 5,652 | 6,594 | 7,536 | 8,478 | 9,420 | 10,36 | 11,30 | 13,19 | 15,07 | 16,96 |

| 125 | 3,925 | 4,416 | 4,906 | 5,888 | 6,869 | 7,850 | 8,831 | 9,813 | 10,79 | 11,78 | 13,74 | 15,70 | 17,66 |

| 130 | 4,082 | 4,592 | 5,103 | 6,123 | 7,144 | 8,164 | 9,185 | 10,21 | 11,23 | 12,25 | 14,29 | 16,33 | 18,37 |

| 140 | 4,396 | 4,946 | 5,495 | 6,594 | 7,693 | 8,792 | 9,891 | 10,99 | 12,09 | 13,19 | 15,39 | 17,58 | 19,78 |

| 150 | 4,710 | 5,299 | 5,888 | 7,065 | 8,243 | 9,420 | 10,60 | 11,78 | 12,95 | 14,13 | 16,49 | 18,84 | 21,20 |

| 160 | 5,024 | 5,652 | 6,280 | 7,536 | 8,792 | 10,05 | 11,30 | 12,56 | 13,82 | 15,07 | 17,58 | 20,10 | 22,61 |

| 170 | 5,338 | 6,005 | 6,673 | 8,007 | 9,342 | 10,68 | 12,01 | 13,35 | 14,68 | 16,01 | 18,68 | 21,35 | 24,02 |

| 180 | 5,652 | 6,359 | 7,065 | 8,478 | 9,891 | 11,30 | 12,72 | 14,13 | 15,54 | 16,96 | 19,78 | 22,61 | 25,43 |

| 190 | 5,966 | 6,712 | 7,458 | 8,949 | 10,44 | 11,93 | 13,42 | 14,92 | 16,41 | 17,90 | 20,88 | 23,86 | 26,85 |

| 200 | 6,280 | 7,065 | 7,850 | 9,420 | 10,99 | 12,56 | 14,13 | 15,70 | 17,27 | 18,84 | 21,98 | 25,12 | 28,26 |

Continuation of Table 1. Theoretical weight of 1 m of rectangular strip according to GOST 103–76 (thickness 20–60 mm)

| b, mm | Thickness, a, mm | |||||||||||

| 20 | 22 | 25 | 28 | 30 | 32 | 36 | 40 | 45 | 50 | 56 | 60 | |

| 11 | — | — | — | — | — | — | — | — | — | — | — | — |

| 12 | — | — | — | — | — | — | — | — | — | — | — | — |

| 14 | — | — | — | — | — | — | — | — | — | — | — | — |

| 16 | — | — | — | — | — | — | — | — | — | — | — | — |

| 18 | — | — | — | — | — | — | — | — | — | — | — | — |

| 20 | — | — | — | — | — | — | — | — | — | — | — | — |

| 22 | — | — | — | — | — | — | — | — | — | — | — | — |

| 25 | 3,925 | — | — | — | — | — | — | — | — | — | — | — |

| 28 | 4,396 | 4,836 | — | — | — | — | — | — | — | — | — | — |

| 30 | 4,710 | 5,181 | — | — | — | — | — | — | — | — | — | — |

| 32 | 5,024 | 5,526 | 6,280 | — | — | — | — | — | — | — | — | — |

| 36 | 5,652 | 6,217 | 7,065 | — | — | — | — | — | — | — | — | — |

| 40 | 6,280 | 6,908 | 7,850 | 8,792 | 9,420 | 10,05 | 11,30 | — | — | — | — | — |

| 46 | 7,222 | 7,944 | 9,028 | 10,11 | 10,83 | 11,56 | 13,00 | — | — | — | — | — |

| 50 | 7,850 | 8,635 | 9,813 | 10,99 | 11,78 | 12,56 | 14,13 | 15,70 | — | — | — | — |

| 55 | 8,635 | 9,499 | 10,79 | 12,09 | 12,95 | 13,82 | 15,54 | 17,27 | — | — | — | — |

| 56* | 8,792 | 9,671 | 10,99 | 12,31 | 13,19 | 14,07 | 15,83 | — | — | — | — | — |

| 60 | 9,420 | 10,36 | 11,78 | 13,19 | 14,13 | 15,07 | 16,96 | 18,84 | 21,20 | — | — | — |

| 63 | 9,891 | 10,88 | 12,36 | 13,85 | 14,84 | 15,83 | 17,80 | 19,78 | 22,25 | 24,73 | — | — |

| 65 | 10,21 | 11,23 | 12,76 | 14,29 | 15,31 | 16,33 | 18,37 | 20,41 | 22,96 | 25,51 | — | — |

| 70 | 10,99 | 12,09 | 13,74 | 15,39 | 16,49 | 17,58 | 19,78 | 21,98 | 24,73 | — | — | — |

| 75 | 11,78 | 12,95 | 14,72 | 16,49 | 17,66 | 18,84 | 21,20 | 23,55 | 26,49 | — | — | — |

| 80 | 12,56 | 13,82 | 15,70 | 17,58 | 18,84 | 20,10 | 22,61 | 25,12 | 28,26 | 31,40 | 35,17 | — |

| 85 | 13,35 | 14,68 | 16,68 | 18,68 | 20,02 | 21,35 | 24,02 | 26,69 | 30,03 | 33,36 | 37,37 | 40,04 |

| 90 | 14,13 | 15,54 | 17,66 | 19,78 | 21,20 | 22,61 | 25,43 | 28,26 | 31,79 | 35,33 | 39,56 | 42,39 |

| 95 | 14,92 | 16,41 | 18,64 | 20,88 | 22,37 | 23,86 | 26,85 | 29,83 | 33,56 | 37,29 | 41,76 | 44,75 |

| 100 | 15,70 | 17,27 | 19,63 | 21,98 | 23,55 | 25,12 | 28,26 | 31,40 | 35,33 | 39,25 | 43,96 | 47,10 |

| 105 | 16,49 | 18,13 | 20,61 | 23,08 | 24,73 | 26,38 | 29,67 | 32,97 | 37,09 | 41,21 | 46,16 | 49,46 |

| 110 | 17,27 | 19,00 | 21,59 | 24,18 | 25,91 | 27,63 | 31,09 | 34,54 | 38,86 | 43,18 | 48,36 | 51,81 |

| 120 | 18,84 | 20,72 | 23,55 | 26,38 | 28,26 | 30,14 | 33,91 | 37,68 | 42,39 | 47,10 | 52,75 | 56,52 |

| 125 | 19,63 | 21,59 | 24,53 | 27,48 | 29,44 | 31,40 | 35,33 | 39,25 | 44,16 | 49,06 | 54,95 | 58,88 |

| 130 | 20,41 | 22,45 | 25,51 | 28,57 | 30,62 | 32,66 | 36,74 | 40,82 | 45,92 | 51,03 | 57,15 | 61,23 |

| 140 | 21,98 | 24,18 | 27,48 | 30,77 | 32,97 | 35,17 | 39,56 | 43,96 | 49,46 | 54,95 | 61,54 | 65,94 |

| 150 | 23,55 | 25,91 | 29,44 | 32,97 | 35,33 | 37,68 | 42,39 | 47,10 | 52,99 | 58,88 | 65,94 | 70,65 |

| 160 | 25,12 | 27,63 | 31,40 | 35,17 | 37,68 | 40,19 | 45,22 | 50,24 | 56,52 | 62,80 | 70,34 | 75,36 |

| 170 | 26,69 | 29,36 | 33,36 | 37,37 | 40,04 | 42,70 | 48,04 | 53,38 | 60,05 | 66,73 | 74,73 | 80,07 |

| 180 | 28,26 | 31,09 | 35,33 | 39,56 | 42,39 | 45,22 | 50,87 | 56,52 | 63,59 | 70,65 | 79,13 | 84,78 |

| 190 | 29,83 | 32,81 | 37,29 | 41,76 | 44,75 | 47,73 | 53,69 | 59,66 | 67,12 | 74,58 | 83,52 | 89,49 |

| 200 | 31,40 | 34,54 | 39,25 | 43,96 | 47,10 | 50,24 | 56,52 | 62,80 | 70,65 | 78,50 | 87,92 | 94,20 |

* - strips of this thickness are manufactured at the request of the consumer.

** - strips of this width are manufactured according to customer requirements. Also, at the request of the consumer, strips are made in the following sizes: 8x17, 12x27, 13x22, 13x25, 15x25, 17x25, 17x30, 19x25, 19x28, 19x34, 23x27, 23x36, 24x32, 24x39, 26x36, 26x44 , 27x34, 32x39, 28x17, 34x24 mm .

The assortment for hot-rolled strip is regulated by GOST 103–76. This standard applies to general purpose hot-rolled steel strip and steel strip for nuts with a width of 11 to 200 mm and a thickness of 4 to 60 mm.

According to rolling accuracy, strips are divided into:

- increased accuracy - B;

- ordinary accuracy - V.

The range and maximum dimensional deviations are given in Table 2. The cross-section, thickness, width and weight of 1 m of strip must correspond to those indicated in Figure 1 and Table 1

.

Table 2. Maximum deviations for the thickness and width of general-purpose strips and strips for hot stamping of nuts

| Strip thickness, mm | By strip thickness, mm | Strip width, mm | By strip width, mm | ||

| Rolling precision | Rolling precision | ||||

| B | IN | B | IN | ||

| From 4 to 6 incl. | +0,2/–0,3 | +0,3/–0,5 | 70; 75 | +0,3/–1,3 | +0,3/–1,4 |

| From 6 to 16 incl. | +0,2/–0,4 | +0,2/–0,5 | 80; 85 | +0,5/–1,4 | +0,7/–1,6 |

| From 16 to 26 incl. | +0,2/–0,6 | +0,2/–0,8 | 90; 95 | +0,6/–1,6 | +0,9/–1,8 |

| From. 25 to 32 incl. | +0,2/–0,7 | +0,2/–1,2 | 100; 105 | +0,7/–1,8 | +1/–2,0 |

| 36; 40 | +0,2/–1,0 | +0,2/–1,6 | 110 | +0,8/–2,0 | +1/–2,2 |

| 45; 50 | +0,2/–1,5 | 0,3/–2,0 | 120; 125 | +0,9/–2,2 | +1,1/–2,4 |

| From 50 to 60 | +0,2/– 1,8 | +0,3/–2,4 | From 130 to 150 | +1/–4,4 | +1,2/–2,8 |

| From 11 to 60 | +0,3/–0,9 | +0,5/–1,0 | From 150 to 180 | +1,2/–2,5 | +1,4/–3,2 |

| 63, 65 | +0,3/–1,1 | +0,5/–1,3 | From 180 to 200 | +1,4/–2,8 | +1,7/–4,0 |

Table 3. Limit deviations in the thickness and width of strips for cold stamping of nuts

| Strip thickness, mm | Maximum deviations in strip thickness, mm | Strip width, mm | Maximum deviations in strip width, mm |

| 5 | ±0,2 | From 11 to 36 | ±0,4 |

| From 6 to 12 | ±0,3 | ||

| 14; 16 | +0,3/–0,4 | ||

| 18 | ±0,4 |

Maximum deviations in the length of strips for general purpose and strips for hot stamping of nuts. Depending on the steel grade, strips are produced in the following length ranges:

- from 3 to 10 m from carbon steel of ordinary quality, low-alloy and phosphorous;

- from 2 to 6 m from high-quality carbon and alloy steel.

Depending on the purpose, the strips are made:

- measured length;

- multiple measured length;

- measured length with a remainder of no more than 15% of the batch weight;

- multiple measured length with a remainder of no more than 15% of the batch weight;

- of unmeasured length.

Maximum deviations along the length of strips for cold stamping of nuts. The remainder is considered to be strips of at least 2 m in length made of ordinary quality carbon steel, low-alloy and phosphorous steel and at least 1 m in length from high-quality carbon and alloy steel.

The standard regulates the maximum deviations along the length of strips of measured or multiple measured lengths. They must not exceed:

- + 30 mm for strips up to 4 m long;

- + 50 mm for strips from 4 to 6 m long;

- + 70 mm for strips over 6 m long;

- + 200 mm for strips obtained from strip mills.

By agreement between the manufacturer and the consumer, strips up to 20x30 in size are produced in rolls.

The crescent shape of the strip should not exceed:

- 0.2% of length – for strips of class 1;

- 0.5% of length – for class 2 strips.

By agreement between the manufacturer and the consumer, it is allowed to produce strips with a crescent shape of up to 0.8% of any measured length.

The thickness, strip width, and crescent shape are measured at a distance of at least 500 mm from the end of the strip and at least 3 m from the end of the roll.