Bibliography

| [1] ISO 630:1995 (ISO 630:1995) | Structural steels. Rolled thick sheets, wide flats, long and shaped profiles (Structural steels - Plates, wide flats, bars, sections and profiles) |

| [2] ISO 1052:1982 (ISO 1052:1982) | Steels for general engineering purposes |

Key words: long products, shaped products, carbon steel, grades, mechanical properties, impact strength, surface, acceptance rules, control methods, marking, packaging

GOST 535-88: Long-rolled and shaped rolled products made of carbon steel of ordinary quality

Home / GOSTs / GOST 535-88: Long and shaped rolled products made of carbon steel of ordinary quality

GOST 535-88: Long-rolled and shaped rolled products made of carbon steel of ordinary quality

GOST 535-88

| Rolled sections and shapes made of carbon steel of ordinary quality |

This standard applies to hot-rolled sections and shaped steel for general and special purposes made from carbon steel of ordinary quality.

1. Basic parameters

1.1. Rolled products are made from steel grades St0, St3kp, St3ps, St3sp, St4kp, St4ps, St4sp, Stbps, St5sp, Stbps, Stbsp in accordance with GOST 380-88.

1.2. The chemical composition of steel must comply with GOST 380-88; at the same time, for steel StZkp, StZps and StZsp, it is allowed to reduce the lower limit of the mass fraction of one of the elements: carbon - up to 0.11% or manganese - up to 0.25% while ensuring the mechanical properties established for the specified steel grades.

1.3. SVP profiles for supporting mine workings in accordance with GOST 18662-83 are made from steel grades Stbps and Stbsp,

1.4. The method of deoxidation, if not specified in the order, is determined by the manufacturer.

1.5. At the request of the consumer, the mass fraction of sulfur in steel of all grades, except for the STO grade, should be no more than 0.040%, phosphorus - no more than 0.030%.

1.6. Depending on the standardized indicators, rental products are divided into categories: 1, 2, 3, 4, 5.

To designate a category, the category number is added to the designation of the steel grade, for example, St3ps1, St3ps5, St5sp2, St4sp3.

The category is indicated in the order. The category, if it is not specified in the order, is determined by the manufacturer.

1.7. Depending on the purpose, long products are divided into groups:

I - for use without surface treatment; II - for cold machining by cutting; Ill-for hot forming;

The group is indicated in the order. The group, if not specified in the order, is determined by the manufacturer.

1.8. In terms of shape, size and maximum deviations, rolled products must meet the requirements:

GOST 2590-71 - for hot-rolled rounds; GOST 2591-71 - for hot-rolled square; GOST 103-76 - for hot-rolled strip; GOST 2879-69 - for hot-rolled hexagonal; GOST 8509-86 - for corner equal-flange; GOST 8510-86 - for unequal corner; GOST 8239-72 - for I-beams; GOST 8240-72 - for channels; GOST 19425-74 - for beams and channels for special purposes; GOST 12492.0-72 - GOST 15492.21 -72 - for profiles of agricultural engineering; GOST 19240-73 - for ground and overhead rails; GOST 18662-83 - for profiles of hot-rolled SVP support for mine workings GOST 5157-83 - for profiles for various purposes; GOST 17152-71 - for blade profiles of earthmoving machines; GOST 21026-75 - for channels with a bent shelf for trolleys; GOST 26020-83 - for I-beams with parallel flange edges;

Examples of symbols are given in the appendix.

Note.

Rolled products are divided into long products and shaped products. Long products are classified as rolled products in which the tangent to any point on the perimeter of the cross section does not intersect this section. Shaped products include rolled products in which the tangent to at least one point of the cross-section perimeter intersects this section. 2. Technical requirements

2.1. Rolled products are manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

2.2. Rolled products are produced in a hot-rolled state. To ensure the required properties, heat treatment can be used.

2.3. At the request of the consumer, the weldability of steel is ensured by complying with the requirements for the chemical composition of steel and the mechanical properties of rolled products.

2.4. Standardized rental indicators by category are given in table. 1.

Table 1

| Category | Chem. compound | Temporary resistance | Yield strength | Relative extension | Cold bending | Impact strength | Steel grades | |||||||||||

| at t in °C | After mechanical aging | |||||||||||||||||

| +20 | -20 | |||||||||||||||||

| 1 2 3 4 5 | — + + + + | + + + + + | — + + + + | — + + + + | + + + + + | — — + — — | — — — + + | — — — + | St.0; St3kp; St3ps; Art. 3sp; St.4kp; St.4ps; St.4sp; St.5ps; St.5sp; St.6ps; St.6sp; St.3kp; St.3ps; Art. 3sp; St.4kp; St.4ps; Art.4sp;Art.5ps; St.5sp; St.3ps; Art. 3sp; St.4ps; St.4sp; St3ps; Art. 3sp; St3ps; Art. 3sp; | |||||||||

Notes

- The “+” sign means that the indicator is normalized.

- For steel grades St0, St3ps and St3sp, the yield strength and bending are not standardized.

- Category 2 rolled products from steel grades St3ps, St3sp, St4ps and St4sp are produced with a thickness of less than 5 mm.

2.5. The mechanical properties of rolled products under tension, as well as bending test conditions, must comply with the standards given in table. 2.

table 2

| steel grade | Tensile strength, N/mm2 (kgf/mm2) for thicknesses, mm | Yield strength, N/mm2 (kgf/mm2), for thicknesses, mm | Relative elongation,%, for thicknesses, mm | Bending until the sides are parallel (a is the thickness of the sample, d is the diameter of the mandrel) for thicknesses, mm | ||||||||

| to 10 | St.10 | to 10 | St. 10 to 20 | over 20 to 40 | over 40 to 100 | over 100 | up to 20 | over 20 to 40 | St.40 | |||

| no less | up to 20 | St.20 | ||||||||||

| St0 St3kp St3ps St3sp St4kp St4ps St4sp St5ps St5sp St6ps St6sp | Not less than 300(31) 360-460 (37-47) 370-480 (38-49) 380-490| 370-480 (39-50)| (38-49) 400-510 (41-52) 410-530 (42-54) 490-630 (50-64) 490-630 (50-64) Not less than 590 (60) | — 235 (24) 245 (25) 245 (25) 255 (26) 265 (27) 285 (29) 285 (29) 315 (32) | — 235 (24) 245 (25) 245 (25) 255 (26) 265 (27) 285 (29) 285 (29) 315 (32) | — 225 (23) 235 (24) 235 (24) 245 (25) 255 (26) 275 (28) 275 (28) 305 (31) | — 215 (22) 225 (23) 225 (23) 235 (24) 245 (25) 265 (27) 265 (27) 295 (30) | — 185 (20) 205 (21) 205 (21) 225 (23) 235 (24) 256 (26) 255 (26) 295 (30) | 18 27 26 26 25 24 20 20 15 | 18 26 25 25 24 23 19 19 14 | 15 24 23 23 22 21 17 17 12 | — d=ad=ad=ad=2a d=2a d=3a d=3a — | — d=ad=ad=ad=2a d=2a d=3a d=3a — | |

Notes:

- For shaped rolled products with a thickness of over 20 mm, the value of the yield strength is allowed to be 10 N/mm2 (1 kgf/mm2) lower than the specified value.

- It is allowed to reduce the relative elongation for shaped rolled products of all thicknesses by 1% (abs.).

2.6. The impact strength of long and shaped rolled products of categories 3, 4, 5 from steel grades St3ps, St3sp, as well as categories 3 from steel grades St4ps, St4sp must correspond to that given in table. 3.

Table 3

| steel grade | Rolled thickness, mm | Sample type according to GOST 9454-78 | Impact strength KCU, J/cm2 (kgcm/cm2), not less | ||

| at temperature, C° | after mechanical aging | ||||

| +20 | -20 | ||||

| St3ps,St3sp | 5-9 10-25 26-40 | 3 1 1 | 108(11) 98(10) 88(9) | 49(5) 29(3) — | 49(5) 29(3) — |

| St4ps,St4sp | 5-9 10-25 26-40 | 3 1 1 | 98(10) 88(9) 69(7) | — — — | — — — |

Notes:

- The "-" sign means that the test is not carried out.

- Determination of the impact strength of rolled products of round cross-section is carried out starting from a diameter of 12 mm, square, starting from the square side of 11 mm, shaped - from thicknesses from which samples of types 1 and 3 can be cut according to GOST 9454-78.

- When testing rolled products for impact strength, it is allowed to reduce the value of impact strength on one sample by 30%, while the average value must not be lower than the standards indicated in the table.

2.7. Delamination is not allowed at the ends of rolled rods (rods).

2.8. For group I, individual rolled out bubbles, dirt, ripples, imprints, and marks are allowed on the surface of long products without cleaning, without removing the profile dimensions beyond the minus deviation. Other types of defects must be removed by gentle stripping or cutting, which does not take the profile size beyond the limits of minus deviation.

2.9. For group II, defects are allowed without cleaning, the depth of which does not exceed: minus maximum deviation for rods with a size of at least 100 mm; sums of maximum deviations - for bars measuring 100 mm or more. The depth of defects is calculated from the nominal size.

2.10. For group III, individual rolled bubbles, dirt, rippling, imprints, and marks are allowed on the surface of long products without cleaning without cleaning, which do not take the profile dimensions beyond the limits of minus deviation.

Other types of defects must be removed by gentle stripping or cutting, the depth of which should not exceed:

- sums of maximum deviations of diameter or thickness for rods measuring 40 mm or less;

- 5% of diameter or thickness - for rods with sizes over 40 to 140 mm;

- 8% of diameter or thickness - for bars larger than 140 mm.

The depth of stripping or cutting is calculated from the minimum size of the rolled product.

In a cross-section of rolled products (diameter or thickness) of more than 140 mm, no more than two strippings of maximum depth are allowed, which should not be located on the same axis.

2.11. The depth of occurrence, cleaning or cutting out defects on the surface of rolled products that do not have standardized maximum deviations should not exceed 10% of the thickness of the profile element being cleaned.

2.12. Defects are removed by flat sanding or cutting with a width of at least five times the depth.

2.13. The rental must be trimmed. When cutting rolled products in a cold state, waviness and chips are allowed on the cut surface (end), which do not take the length of the profile beyond the nominal size and maximum deviations along the length. When producing shaped rolled products, the cutting angle should not extend the length of the rolled product beyond its nominal size and maximum deviations along the length. Burrs should not exceed 0.5 mm for shaped steel thicknesses up to 10 mm and 0.1 for thicknesses over 10 mm. When cutting long products with a diameter (thickness) of up to 80 mm, the length of the crumpled end should not exceed the diameter of the profile being cut. The bevel of the cut is not controlled. When cutting long products with a diameter (thickness) of more than 80 mm, the cut angle should not exceed 5 mm, and the size of burrs should not exceed 2 mm. When cutting long rolled products with scissors in a hot state, knife imprints up to 0.25 times the diameter (thickness) of the rolled product are allowed. Rolled products with a diameter (thickness, width) up to 40 mm of unmeasured length may be manufactured with uncut ends.

2.14. Marking and packaging - in accordance with GOST 7566-81 with additions. Rods with a diameter (square side) of over 80 mm are subject to piece-by-piece hot stamping. The mark is applied to the end of the rod and contains the steel grade or its symbol indicating the decoding in the quality document, the heat number or its symbol indicating the decoding in the quality document.

2.15. Marking of rolled products is carried out with indelible paint in the colors specified in GOST 380-71.

3. Acceptance

3.1. Rentals are accepted in batches. The batch must consist of rolled products of the same size and one melting ladle. For rolled steel grade St0, the number of changes is c. batches are not limited.

3.1.1 In a batch consisting of rolled products of category I, the presence of several heats is allowed, and the batch must consist of rolled products of the same size and one grade of steel. The weight of the batch is no more than the wagon norm.

3.1.2. The batch must be accompanied by a quality document in accordance with GOST 7566-81 with the additions: rental categories; surface quality groups; if there are several heats in a batch, the number of heats in the batch.

3.2. To check the quality of rolled products by chemical composition and mechanical properties, the following is taken from the batch: for chemical analysis, one sample from the melting ladle; for tensile and bending tests - one rod, coil or strip; for impact strength testing - two rods, coils or strips.

3.2.1. When rolling melts to various thicknesses (diameters, square sides), rods for mechanical testing are selected from the minimum and maximum thickness of the rolled product.

3.3. If unsatisfactory test results are obtained for at least one indicator, a repeat test is carried out in accordance with GOST 7566-81.

3.4. To control the surface quality and dimensions of rolled products, 10% of rods, coils or strips are selected from a batch, but not less than 5 pieces.

3.5. Chemical analysis of finished rolled products and bending testing may not be carried out; the established standards are ensured by the manufacturing technology

4. Control methods

4.1. Sampling methods for determining the chemical composition of steel - according to GOST 7565-81.

4.2. Chemical analysis - according to GOST 22536.0-87; GOST 22536.1-77; GOST 22536.2-87; GOST 22536.3-77; GOST 22536.4-77; GOST 22536.5-87; GOST 22536.6-77; GOST 22536.7-77; GOST 22536.8-87; GOST 22536.9-77; GOST 22536.10-77; GOST 22536.11-87; GOST 22536.13-77; GOST 17745-72; GOST 18895-81 or other methods approved in accordance with the established procedure and ensuring the necessary accuracy of analysis. In case of disagreement between the manufacturer and the consumer, the assessment is carried out using standard methods.

4.3. Sampling methods for mechanical and technological tests - according to GOST 7564-73 (option 1).

4.4. The tensile test is carried out according to GOST 1497-84 on samples of five times the length, one sample from the rod.

4.5. The bending test is carried out according to GOST 14019-80 using one sample from the rod.

4.6. The impact strength test is carried out according to GOST 9454-78 on two samples of types 1 or 3 from the rod for each temperature.

4.7. Determination of the susceptibility to mechanical aging is carried out according to GOST 7268-82 on two samples from the rod.

4.8. Control of mechanical properties is carried out for the minimum and maximum thicknesses (diameter, square side) of rolled products of one heat: for thicknesses up to 10 mm, St. 10 to 20 mm, St. 20 to 40 mm, St. 40 to 100 mm. When monitoring mechanical properties, it is allowed to use statistical and non-destructive testing methods in accordance with the regulatory and technical documentation on methods for testing metal products. When the manufacturer uses statistical control methods in accordance with the regulatory and technical documentation, the control of mechanical properties provided for by this standard may not be performed. The manufacturer ensures that the manufactured products comply with the requirements of this standard. In arbitration cases and during periodic quality checks, the control methods provided for in this standard are applied.

4.9. The quality of the surface is checked by inspection without the use of magnifying devices. Delamination of rolled products is controlled by inspection of the ends of the rolled products.

4.10. The geometric dimensions and shape of the profile are checked using measuring instruments in accordance with GOST 162-80, GOST 166-80, GOST 427-75, GOST 882-75, GOST 3749-77, GOST 5378-66, GOST 6507-78, GOST 7502-80 or tools certified according to GOST 8.326-78 and GOST 2216-84.

4.11. To determine the mass of I-beams with parallel flange edges, a sample of at least 300 mm in length is cut from each selected rod.

4.12. The mass of profiles is checked on samples 1 m long. For I-beams with parallel flange edges, a sample length of less than 1 m, but not less than 300 mm, is allowed.

5. Transportation and storage

5.1. Transportation and storage - according to GOST 7566-81.

Appendix Required

Examples of rental symbols

Rental symbol scheme

X1.. X1_1 X2 GOST X3 . . . ———— X4 X5 X6 GOST 535-88

X1 - type of rolled product (circle, square, hexagon, strip, angle, I-beam and others; X1_1 - Size of rolled product or profile number; X2 - Accuracy of rolled product - A, B, C (GOST 2590-71, GOST 2591-71, GOST 8509 -86 and others); X3 - Number of the standard for the assortment (GOST 2590-71, GOST 2591-71, GOST 8509-86 and others); X4 - Group by purpose - I, II, III (according to GOST 535-88); X5 - Rolled category - 1,2,3,4,5 (according to GOST 535-88); X6 - Steel grade according to GOST 535-88 (St3kp, St3ps and others);

Hot-rolled round steel with a diameter of 30 mm of normal rolling accuracy (B) according to GOST 2590-71. grade St5ps, category 1, group II: 30-V GOST 2590-71 Circle———— St5ps1-II GOST 535-88

Hot-rolled equal-flange corner products, size 50x50x3 mm, high rolling accuracy (A) according to GOST 8509-72, grade StZsp, category 3 group I: 50x50x3-A GOST 8509-86 Angle———— St3ps3-I GOST 535-88

Hot-rolled products, I-beam number 30 according to GOST 8239-72. grade StZps, category 4, group I: 30-GOST 8239-72 I-beam———— St3ps4-I GOST 535-88

T-rail according to GOST 19240-73 steel grade St5sp, category I group I: GOST 19240-73 T-rail ———— St5ps1-I GOST 535-88

I-beam with parallel flange edges, number 40B according to GOST 26020-83, steel grade StZsp, category 5, group I: 40B GOST 26020-83 I-beam———— St3ps5-I GOST 535-88

CONTROL METHODS

4.1. Sampling methods for determining the chemical composition of steel are in accordance with GOST 7565.

4.2. Chemical analysis - according to GOST 22536.0 - GOST 22536.11; GOST 27809; GOST 17745; GOST 18895 or other methods approved in accordance with the established procedure and ensuring the necessary accuracy of analysis.

In case of disagreement between the manufacturer and the consumer, the assessment is carried out using standard methods.

4.3. Sampling methods for mechanical and technological tests are in accordance with GOST 7564 (option 1).

4.4. The tensile test is carried out according to GOST 1497 on samples of five times the length, one sample from a rod, coil, strip or rod.

4.5. The bending test is carried out according to GOST 14019 using one sample from a rod, coil, strip or rod.

4.4; 4.5. (Changed edition, Amendment No. 1).

4.6. The impact bending test is carried out according to GOST 9454 on two samples from a rod, coil, strip or rod for each temperature.

For rolled products with a thickness of 10 mm or more, type 1 samples are used; from 5.0 to 9.9 mm - type 3 samples; from 3.0 to 4.9 mm - samples with a width equal to the thickness of the rolled product, the height of the sample and the depth of the concentrator must correspond to those established for sample type 3.

For rolled products with a nominal thickness of 5 and 10 mm or manufactured with a deviation of minus tolerance, impact strength is determined on samples with a thickness equal to the thickness of the rolled product.

(Changed edition, Amendment No. 2).

4.7. Determination of the susceptibility to mechanical aging is carried out according to GOST 7268 on two samples from a rod, coil, strip or rod. The thickness of the samples must correspond to the thickness adopted in clause 4.6.

4.8. Control of mechanical properties is carried out for the minimum and maximum thicknesses (diameter, square side) of rolled products of one heat: for thicknesses up to 10 mm, St. 10 to 20 mm, St. 20 to 40 mm, St. 40 to 100 mm.

When monitoring mechanical properties, it is allowed to use statistical and non-destructive testing methods, but normative and technical documentation on methods for testing metal products.

When the manufacturer uses statistical and non-destructive testing methods in accordance with the regulatory and technical documentation, the control of mechanical properties provided for by this standard may not be performed. The manufacturer ensures that the manufactured products comply with the requirements of this standard. In arbitration cases and during periodic quality checks, the control methods provided for in this standard are applied.

4.9. The quality of the surface is checked by inspection without the use of magnifying devices.

Delamination of rolled products is controlled by inspection of the ends and edges of rolled products.

4.10. The geometric dimensions and shape of the profile are checked using measuring instruments in accordance with GOST 162, GOST 166, GOST 427, TU 2-034-225, GOST 3749, GOST 5378, GOST 6507, GOST 7502 or tools certified in accordance with GOST 8.326 * and GOST 2216.

* PR 50.2.009-94 applies on the territory of the Russian Federation.

4.11. The weight of I-beams with parallel flange edges is controlled by weighing one sample with a length of at least 1 m with a weight of 1 m of profiles of no more than 20 kg, on a sample with a length of at least 0.3 and with a weight of 1 m of more than 20 kg.

(Changed edition, Amendment No. 1, 3).

4.12. (Deleted, Amendment No. 1).

RENTAL CHARACTERISTICS INSTALLED BY AGREEMENT OF THE CONSUMER WITH THE MANUFACTURER IN THE NTD

1. Rolled products with a normalized mass fraction of nitrogen in electric steel.

2. Rolled products with a lower hourly fraction of manganese, reduced against the norms of the table. 1 per manganese equivalent equal to:

BM = 0.3 (Cr%) + 0.5 (Ni%) + 0.7 (Ci%),

where Cr, Ni, Cu is the residual actual mass fraction of chromium, nickel, copper in steel, not exceeding the standards specified in Table 1.

3. Rolled products calibrated from steel grades 08, 55 and 60 in a cold-worked or heat-treated state with control of mechanical properties.

4. Rolled products with normalized impact strength on type I samples at a temperature of minus 40°C.

5. Rolled products with normalized impact strength on type II samples at a temperature of plus 20°C and sub-zero temperatures.

6. Rolled without control of relative contraction.

7. Rolled products calibrated and with a special surface finish with normalized hardness in a normalized and tempered state and hardened with a tempering state.

8. Long-rolled products with standardized hardness in a normalized state.

9. Rolled products with standardized hardness within specified limits.

10. Rolled products without hardness control.

11. Rolled products with a standardized austenite grain size.

12. Rolled products with standardized purity for non-metallic inclusions.

13. Rolled products with standardized purity based on hair fibers identified on the surface of finished parts by the magnetic method or etching.

14. Rental of small-tonnage lots.

APPENDIX 6

Recommended

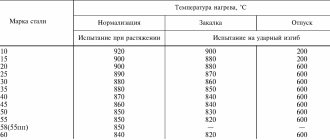

Heat treatment modes for workpieces to control the mechanical properties given in Tables 3 and 4

Table 10

Recommended minimum shutter speeds:

- when normalizing or hardening - 30 minutes; when tempering 200°C - 2 hours;

- when tempering 600°C - 1 hour.

- The cooling medium during quenching is water.

APPENDIX 7

Recommended

Heat treatment modes for workpieces to control the mechanical properties given in Table 8

Table 11

APPENDIX 8

Mandatory

SAMPLE SELECTION SCHEME FOR DETERMINING HARDNESS AFTER HARDENING

h3 style=”text-align: right;”>APPENDIX 9

Recommended

Modes of thermal treatment of samples to determine hardness after hardening, given in table. 8a

Table 12

Notes:

- Holding time during hardening (after reaching the hardening temperature) 20 min.

- Oil temperature (65±10)°C.

APPENDICES 8, 9 (Introduced additionally, Amendment No. 1).

SCHEME 1 RENTAL SYMBOL

In the design documentation it is allowed to provide examples of symbols in accordance with Scheme 2.

Examples of symbols

Long-rolled products, round, normal rolling hardness (B), curvature class II, unmeasured length (ND), diameter 100 mm according to GOST 2590-88, made of grade 30 steel, surface quality group 2GP, with mechanical properties according to Table 3 (M1), with hardness according to clause 2.1.10 (TV1), with impact strength control according to Table 4 (KUV), with deburring (US), with hot upset test (65), without heat treatment:

Circle V-11-ND-100 GOST 2590-88/30-2GP-M1-TV1-KUV-UZ-66 GOST 1050-88

Long-rolled products, square, increased rolling accuracy (B), class I in curvature, cut length (MD), with a square side of 25 mm according to GOST 2591-88, made of steel grade 35, with surface quality of group 1GP, with mechanical properties according to the table .8 (M3), with hardness according to table 7 (TB2), with macrostructure (KMS) normalized in points according to table 6, with decarburization according to clause 2.2.14 (1C), heat treated (HT):

Square B-1-MD-25 GOST 2591-88/35-1GP-M3-TV2-KMS-1S-TO GOST 1050-88

Rolled strip, normal rolling accuracy (B), sickle shape class 2, deviation from flatness class 2, multiple measured length (CD), thickness 36 mm, width 90 mm according to GOST 103-76, from steel grade 45, with surface quality group 3GP , with mechanical properties according to Table 3 (M1), with hardness item 2.1.10 (TV1), with normalized hardenability (HR), without heat treatment:

Strip V-2-2-KD-36x90 GOST 103-76/45-3GP-M1-TV1-PR GOST 1050-88

Hot-rolled profile for oblique washers, cut-to-length (MD), with dimensions 2ВхНхй = 32×5.8×4 mm according to GOST 5157-83, made of steel grade 35, with surface quality group 3GP, with mechanical properties according to Table 3 (M1 ), with hardness according to clause 2.1.10 (TV1), without heat treatment:

Profile for oblique washers MD-32x5.8x4 GOST5157-83/35-3GP-M1-TV1

Calibrated rolled products, round, with a tolerance range according to L11, cut length (MD), with a diameter of 10 mm according to GOST 7417-75, made of grade 45 steel, with surface quality of group B according to GOST 1051-73, with mechanical properties according to Table 5 ( M2), with hardness according to clause 2.3.8 (TV3), with decarburization according to clause 2.3.11 (2C), cold-worked (NG):

Circle M1-MD-10 GOST 7417-75/45-V-M2-TV3-2S-NGGOST 1050-88

Calibrated rolled products, square, with a tolerance field of L1, a multiple of the measured length (CD), with a square side of 15 mm in accordance with GOST 8559-75, from steel grade 20, with surface quality of group B in accordance with GOST 1051-73, with mechanical properties according to table. 8 (M3), with hardness according to table. 7 (TV2), ensuring weldability (GS), cold-worked (NG):

Square M1-KD-15 GOST 8559-75/20-B-M3-TV2-GS-NGGOST 1050-88

Calibrated rolled products, hexagonal, with a tolerance range of h12, of unmeasured length (ND), with an inscribed circle diameter of 8 mm according to GOST 8560-78, made of grade 45 steel, with surface quality of group B according to GOST 1051-73, with mechanical properties according to Table 3 (M1), with hardness according to table. 8a (TV4), heat treated (TO):

Hexagon M2-ND-8 GOST 8560-78/45-V-M1-TV4-TO GOST 1050-88

Rolled products with special surface finishing, round, with tolerance range L11, of unmeasured length (ND), with a diameter of 8 mm, with surface quality of group B according to GOST 14955-77, made of grade 20 steel, with mechanical properties according to Table 5 (M2), with hardness according to table 7 (TV3) cold-worked (NG):

Circle M1-ND-8 GOST 14955- 77/20-V-M2-TV3-NG GOST 1050- 88

Examples of symbols that can be given in design documentation:

Rolled products with special surface finishing, round, with tolerance range L11, unmeasured length (ND), diameter 8 mm, surface quality group B according to GOST 14955-77, made of grade 20 steel, with mechanical properties according to Table 5 (M2), with hardness according to table 7 (TV3), cold-worked (NG):

(Changed edition, Amendment No. 1).

APPENDIX 2

Mandatory

Types of tensile strength

Tensile strength is one of the main mechanical parameters of steel, as well as any other structural material.

This value is used in strength calculations of parts and structures; based on it, it is decided whether a given material is applicable in a particular area or whether a more durable one needs to be selected.

The following types of tensile strength are distinguished:

- compression - determines the ability of a material to resist the pressure of an external force;

- bending - affects the flexibility of parts;

- torsion - shows how suitable the material is for loaded drive shafts that transmit torque;

- stretching

Types of material strength tests

The scientific name for the parameter used in standards and other official documents is tensile strength.

Marking of steels according to Russian standards

Marking steel according to Russian standards makes it possible to determine the composition of the metal and, in part, whether it belongs to a certain type.

If the presence of carbon in steel is more than 1%, its amount is not indicated in the marking. The steel grade includes letter designations of alloying additives indicating their quantity in tenths and hundredths of a percent, but if the component content is less than 1.5%, then only the letter designation is present in the marking.

Read also: The simplest do-it-yourself switching power supply circuit

In addition to the chemical composition, the marking contains symbols characterizing the purpose of the steel and the degree of its quality.

TRANSPORTATION AND STORAGE

5.1. Transportation and storage - in accordance with GOST 7566 with the following addition.

5.1.1. Products are transported by all types of transport in accordance with the rules for the transportation of goods in force for this type of transport. By rail, transportation is carried out depending on the weight and overall dimensions in covered or open cars. The weight of the cargo package should not exceed 10,000 kg for mechanized loading in open vehicles, and 1,250 kg in covered vehicles. Packaging, means and methods for forming packages - in accordance with GOST 7566.

When sending two or more packages, the dimensions of which make it possible to arrange a transport package with overall dimensions in accordance with GOST 24597, the packages must be formed into transport packages. Fastening means - according to GOST 21650.

(Changed edition, Amendment No. 1).

ANNEX 1

Mandatory

Alloying additives in alloys

These are substances deliberately added to the melt to improve the properties of the alloy and bring its parameters to the required ones. Some of them are added in large quantities (more than a percent), others in very small quantities. I most often use the following alloying additives:

- Chromium. Used to increase hardenability and hardness. Share – 0.8-0.2%.

- Bor. Improves cold brittleness and radiation resistance. Share – 0.003%.

- Titanium. Added to improve the structure of Cr-Mn alloys. Share – 0.1%.

- Molybdenum. Increases strength characteristics and corrosion resistance, reduces fragility. Share – 0.15-0.45%.

- Vanadium. Improves strength parameters and elasticity. Share – 0.1-0.3%.

- Nickel. Promotes an increase in strength characteristics and hardenability, but at the same time leads to an increase in fragility. This effect is compensated by the simultaneous addition of molybdenum.

Metallurgists also use more complex combinations of alloying additives, achieving unique combinations of physical and mechanical properties of steel. The cost of such grades is several times (or even tens of times) higher than the cost of conventional low-carbon steels. They are used for particularly critical structures and assemblies.

How is strength testing performed?

Strength tests for tensile strength are carried out on special test benches. One end of the test sample is fixedly fixed in them, and a drive mount, electromechanical or hydraulic, is attached to the other. This drive creates a smoothly increasing force that acts to break the sample, or to bend or twist it.

The electronic control system records the tensile force and relative elongation, and other types of deformation of the sample.

ACCEPTANCE

3.1. Rentals are accepted in batches. The batch should consist of rolled products of the same size and one melt - a ladle.

For rolled steel grade St0, the number of heats in a batch is not limited.

3.1.1. In a batch consisting of rolled products of categories 1 and 2, the presence of several heats is allowed, and the batch must consist of rolled products of the same size and one grade of steel. The weight of the batch is no more than the wagon norm.

3.1.2. The batch must be accompanied by a quality document in accordance with GOST 7566 with the additions:

rental categories;

surface quality groups;

if there are several heats in a batch - the number of heats in the batch;

instructions on ensuring weldability - “st”.

By agreement between the manufacturer and the consumer, it is allowed in the quality document not to indicate the results of all tests performed, but to indicate: “The product complies with GOST 535.”

3.2. To check the quality of rolled products using chemical chemicals; The following are selected from the batch based on composition and mechanical properties:

for chemical analysis - one sample from the melt - ladle;

for tensile and bending tests - one rod, coil of strip or rod.

for impact strength testing - two rods, a coil of strip or rod.

3.2.1. When rolling melts to various thicknesses (diameters, square sides), rods, coils, strips or rods for mechanical testing are selected from the minimum and maximum thickness of the rolled material.

3.1.1, 3.1.2, 3.2, 3.2.1. (Changed edition, Amendment No. 1)

3.2.2. To control the mass of I-beams with parallel flange edges, one rod is selected from the rolled stock of each standard size of one heat.

(Introduced additionally, Amendment No. 1).

3.3. If unsatisfactory test results are obtained for at least one indicator, a repeat test is carried out in accordance with GOST 7566.

3.4. To control the surface quality and dimensions of rolled products, 10% of rods, coils or strips are selected from a batch, but not less than 5 pieces.

3.5. Chemical analysis of finished rolled products and bending testing may not be performed; the established standards are ensured by the manufacturing technology.